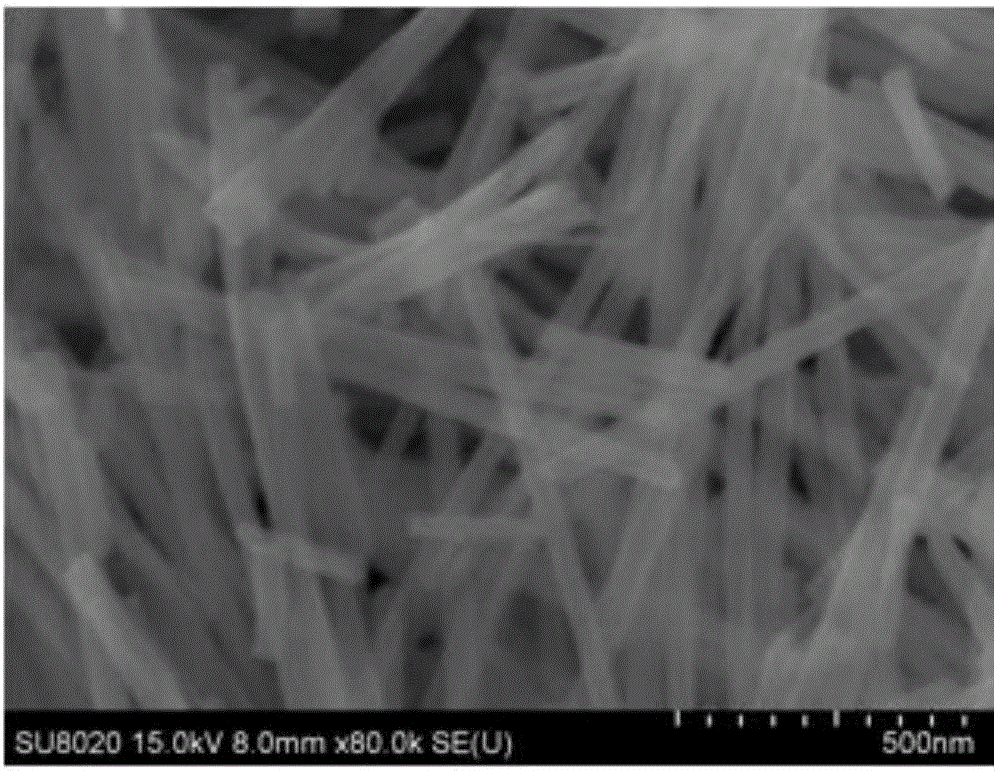

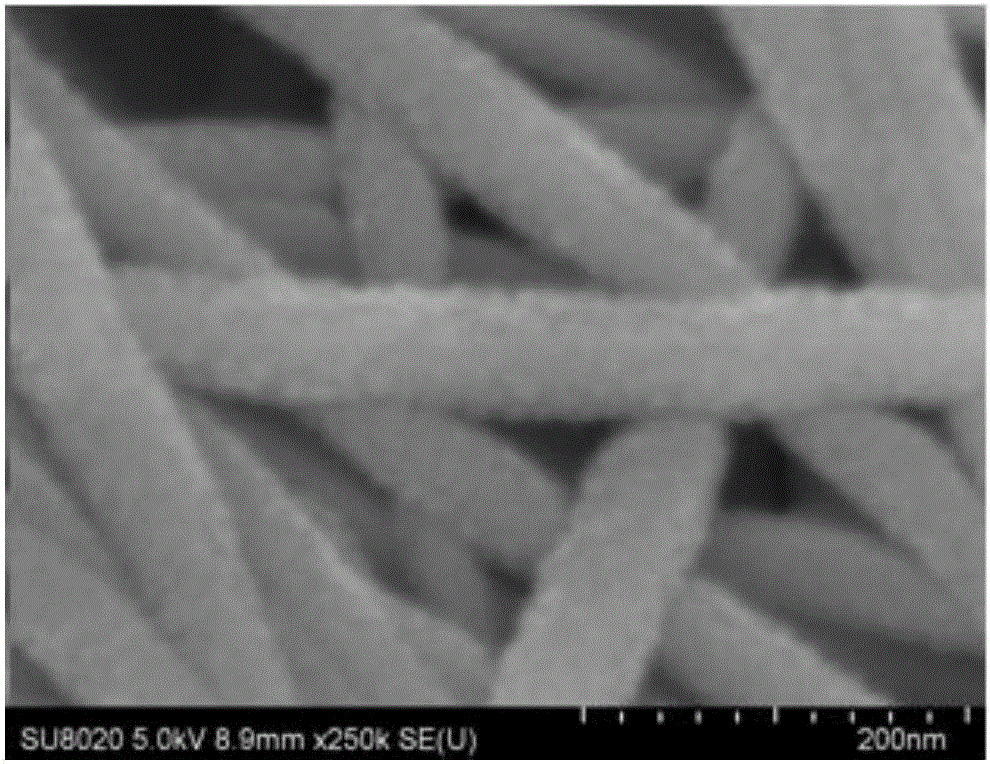

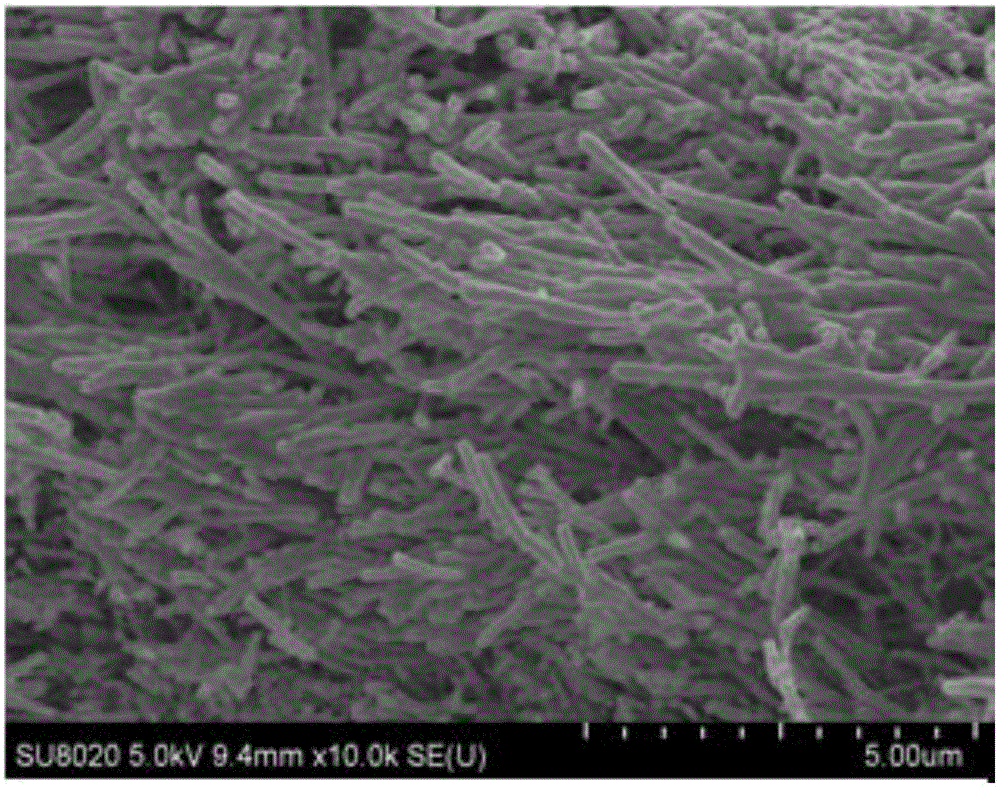

TiN/TiO2 three-dimensional nanowire array with core shell structure and preparation method thereof

A core-shell structure, three-dimensional nanotechnology, applied in the field of nanostructures, achieves good electrical conductivity, is conducive to large-scale industrial production, and has the effects of controllable purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A TiN / TiO with a core-shell structure 2 The preparation method of the three-dimensional nanowire array, the specific steps are as follows:

[0026] (1) Place the titanium mesh in a beaker containing acetone for ultrasonic cleaning for 10 minutes, then put it into a beaker containing ethanol for ultrasonic cleaning for 10 minutes, take it out and put it in a beaker containing deionized water for ultrasonic cleaning for 10 minutes, and finally take out Put it on the filter paper to dry naturally;

[0027] (2) Put the pretreated titanium mesh into a reaction kettle with 1 mol / L NaOH solution, react in an oven at 220°C for 15 hours, take out the titanium mesh and soak it in 0.1 mol / L dilute hydrochloric acid for a period of time to make sodium The ions and hydrogen ions are fully ion exchanged, and then the titanium mesh is taken out, rinsed with deionized water, and dried naturally after rinsing;

[0028] In this step, the titanium mesh reacts with the NaOH solution to f...

Embodiment 2

[0033] A TiN / TiO with a core-shell structure 2 The preparation method of the three-dimensional nanowire array, the specific steps are as follows:

[0034] (1) Place the titanium mesh in a beaker containing acetone for ultrasonic cleaning for 10 minutes, then put it into a beaker containing ethanol for ultrasonic cleaning for 10 minutes, take it out and put it in a beaker containing deionized water for ultrasonic cleaning for 10 minutes, and finally take out Put it on the filter paper to dry naturally;

[0035] (2) Put the pretreated titanium mesh into a reaction kettle with 1 mol / L NaOH solution, react in an oven at 220°C for 15 hours, take out the titanium mesh and soak it in 0.1 mol / L dilute hydrochloric acid for a period of time to make sodium The ions and hydrogen ions are fully ion exchanged, and then the titanium mesh is taken out, rinsed with deionized water, and dried naturally after rinsing;

[0036] In this step, the titanium mesh reacts with the NaOH solution to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com