Method for preparing nano twin crystal boron carbide powder

A technology of boron carbide powder and nano-twins, which is applied in the direction of chemical instruments and methods, nanotechnology, carbon compounds, etc., can solve the problems of low efficiency of nanometer and micron boron carbide powder, difficult removal of magnesium element, high cost, etc., and achieve the goal of preparing powder The effect of high body purity, uniform particle distribution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Weigh 100g of boric acid, put 46.1g of sucrose into a beaker, add 400ml of deionized water and stir to obtain a colorless and transparent solution.

[0043] The above colorless and transparent solution was placed on a flat heating platform, heated at 120°C and continuously stirred until the solution was evaporated to dryness to obtain a block product, which was ground into a powder.

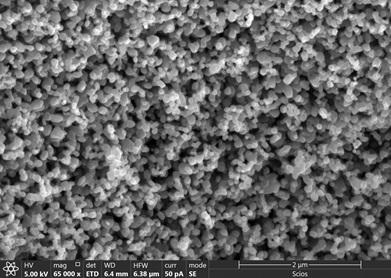

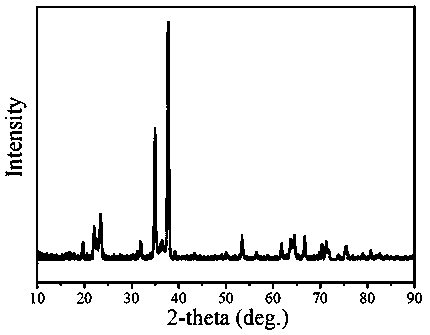

[0044]Put the above-mentioned ground powder in a graphite crucible, put the graphite crucible in a tube furnace, first evacuate to a vacuum degree lower than 1e-2Pa, and heat it to 1500°C at a rate of 5°C / min. Keep it warm for 30 minutes, and obtain nano-twinned boron carbide powder after cooling. Such as figure 1 SEM image of the prepared nano-twinned boron carbide powder. It can be seen from the figure that the particle size distribution of the prepared boron carbide powder is uniform, and the average particle size is about 100nm. figure 2 The X-ray diffraction pattern of the prepare...

Embodiment 2

[0046] Weigh 205.8g of boric acid, put 100g of glucose into a beaker, add deionized water, mix and stir until the powder is completely dissolved, and a colorless and transparent solution is obtained.

[0047] Put the above aqueous solution on a flat heating platform and set the temperature at 150°C, stir continuously, heat and evaporate to dryness to obtain a block product, and grind the block product into a powder.

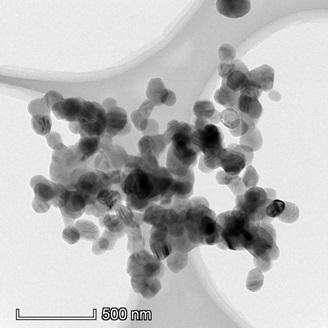

[0048] Put the above-mentioned ground powder in a graphite crucible, put the graphite crucible in a tube furnace, vacuumize to 1e-2Pa, turn on the heating system, raise the temperature to 1700°C at a rate of 10°C / min, and keep it warm for 10min. After cooling, nano-twinned boron carbide powder is obtained. Such as Figure 5 Shown is the scanning electron microscope picture of the prepared nano-twinned boron carbide powder. Figure 6 It is a transmission electron microscope bright field image of nano-twinned boron carbide powder.

Embodiment 3

[0050] Weigh 100 g of boric acid and 38 ml of glycerin into a beaker, add deionized water and stir to mix evenly to obtain a colorless transparent solution.

[0051] Put the above solution on a flat heating platform and set the temperature at 300°C, stir and heat until the solution is evaporated to dryness to obtain a block product, and then grind the block product into powder.

[0052] Put the above ground powder into a graphite crucible, heat the graphite crucible to 1450° C. in a tube furnace, hold the temperature for 120 minutes, and obtain nano-twinned boron carbide powder after cooling. Such as Figure 7 SEM image of the prepared nano-twinned boron carbide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com