Preparation method of visible light catalyst barium-indium-oxygen

A catalyst and visible light technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low product purity and miscellaneous preparation cycles, and achieve simple process steps and low production costs. , the effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

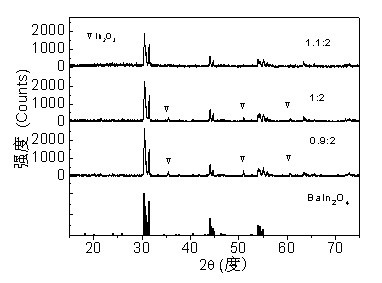

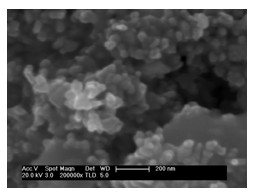

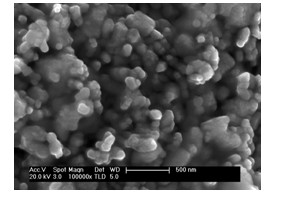

[0035] A kind of visible light catalyst barium indium oxide BaIn 2 o 4 A preparation method comprising the steps of:

[0036] (1) Preparation of precursors by co-precipitation method

[0037] Weigh barium nitrate and indium nitrate in different molar ratios (0.9:2; 1:2; 1.1:2 respectively) and dissolve them in 250mL of water, wherein the molar concentrations of barium nitrate are 0.072mol / L and 0.080mol respectively / L and 0.088mol / L, the molar concentration of indium nitrate is 0.16mol / L;

[0038] Weigh sodium carbonate and sodium hydroxide of appropriate quality and dissolve them in 600mL of water, wherein the molar concentrations of sodium carbonate and sodium hydroxide are 0.08mol / L and 0.33mol / L respectively;

[0039] Slowly drop the aqueous solution of barium nitrate and indium nitrate into the aqueous solution of sodium carbonate and sodium hydroxide, and react for 40-60 minutes under the stirring of the booster electric mixer, then stop the mixer and let the solutio...

Embodiment 2

[0046] A kind of visible light catalyst barium indium oxide, namely BaIn 2 o4 A preparation method comprising the steps of:

[0047] (1) Preparation of precursors by co-precipitation method

[0048] Weigh barium nitrate and indium nitrate with a molar ratio of 1.1:2, and dissolve them in 250mL of water, wherein the molar concentrations of barium nitrate and indium nitrate are 0.088mol / L and 0.16mol / L, respectively;

[0049] Weigh sodium carbonate and sodium hydroxide of appropriate quality and dissolve them in 600mL of water, wherein the molar concentrations of sodium carbonate and sodium hydroxide are 0.08mol / L and 0.33mol / L respectively;

[0050] Slowly drop the aqueous solution of barium nitrate and indium nitrate into the aqueous solution of sodium carbonate and sodium hydroxide, and react for 40-60 minutes under the stirring of the booster electric mixer, then stop the mixer and let the solution stand for sedimentation, after about 30 minutes, Pour off the supernatant i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com