Low-aluminum-content and high-aging-resistance hot-rolling thin steel plate for cold formation and manufacturing method thereof

A technology of hot-rolled thin steel plate and aluminum content, which is applied in the direction of temperature control, etc., can solve the problems of poor product purity and poor anti-effectiveness, and achieve the effect of good edge quality, high timeliness, and easy purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

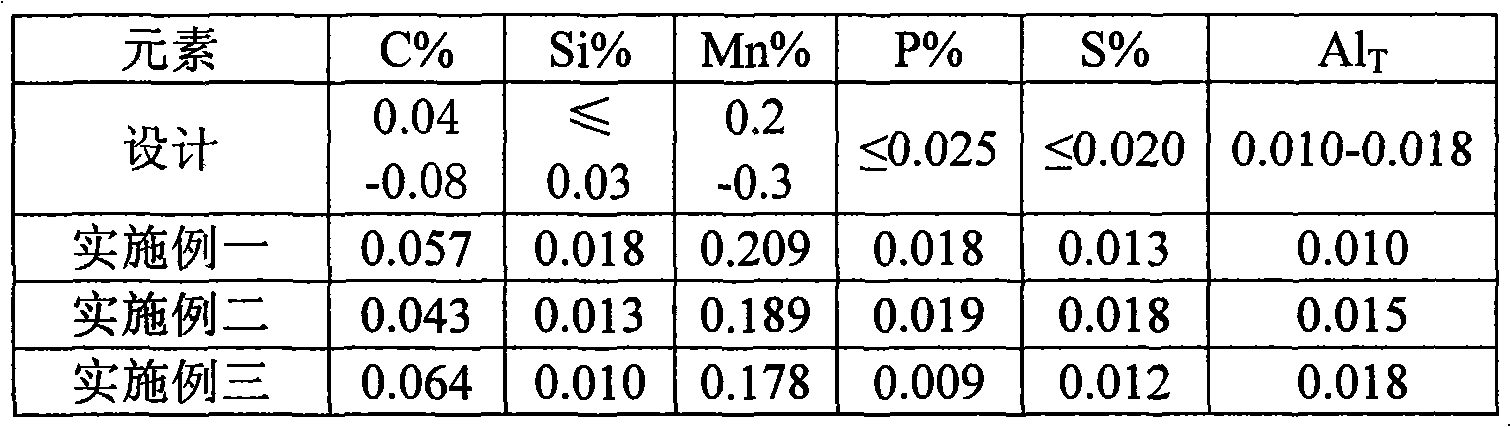

[0015] The present invention will be further described below in conjunction with Embodiment 1-3. The composition distribution ratio of specific embodiment sees the following table 1:

[0016] The component distribution ratio of the present invention of table 1, component is % by weight, and balance is

[0017]

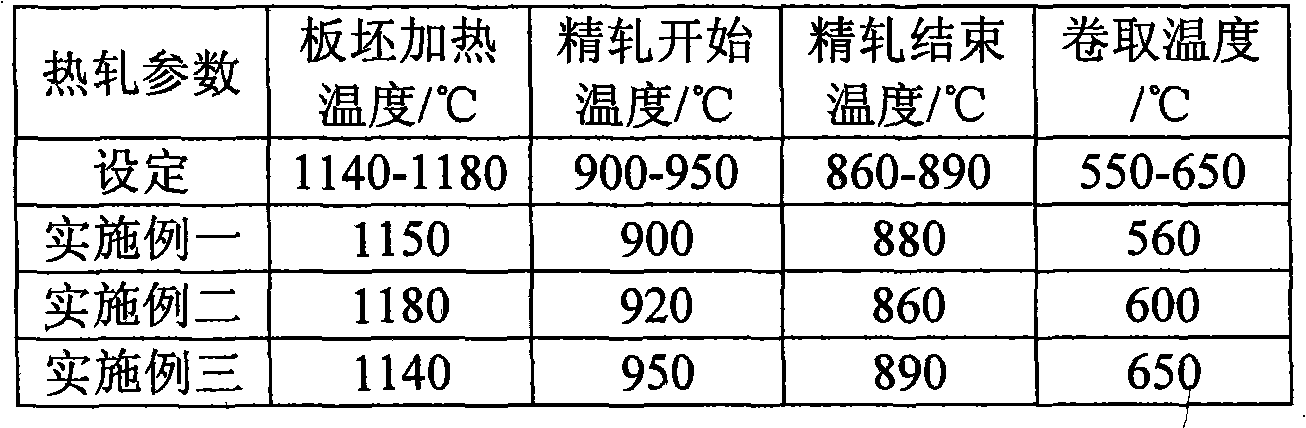

[0018] According to the requirements of the material composition design of the present invention, pre-desulfurization of molten iron is adopted, combined top-bottom blowing of converter, refining in LF furnace, low-carbon steel mold slag is used for continuous casting, Ar protection casting is used throughout the process, and continuous casting slabs are cast. After the continuous casting slab is reheated in the heating furnace, it is rolled on a continuous hot rolling mill. The process control is shown in Table 2 below, and the product thickness is 1.5-4.0mm.

[0019] Table 2 hot rolling process control parameters of the present invention

[0020]

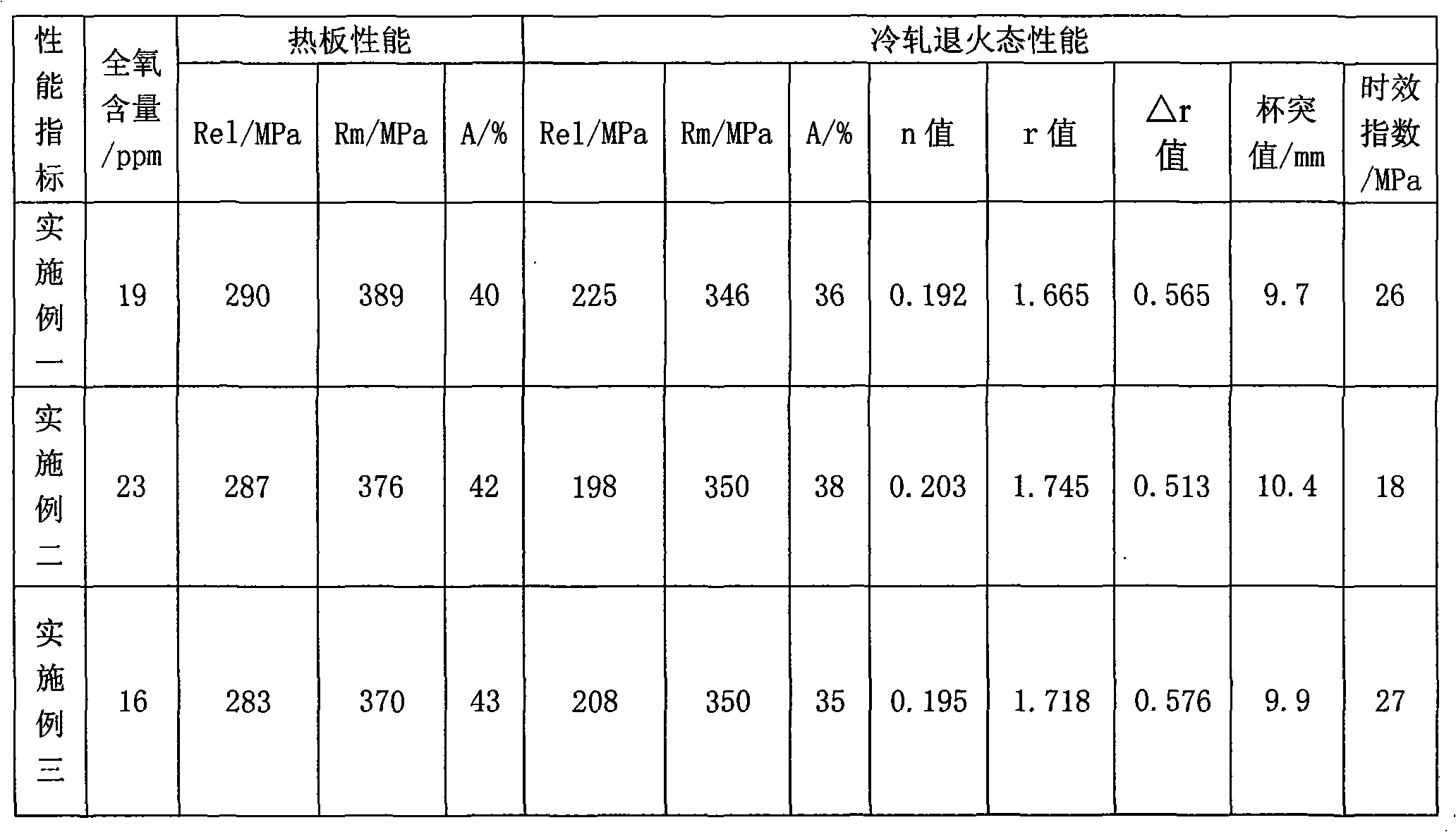

[0021] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com