Yield strength 225MPa-level earthquake-resistant construction steel and production method thereof

A yield strength and production method technology, applied in the field of construction steel, can solve the problems of not being able to adapt to large-scale production, poor weather resistance and welding performance, and complicated production process flow, so as to improve weather resistance and welding performance. , The effect of large grain size and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The earthquake-resistant construction steel with a yield strength of 225 MPa and its production method of the present invention will be further described in detail below in conjunction with specific examples.

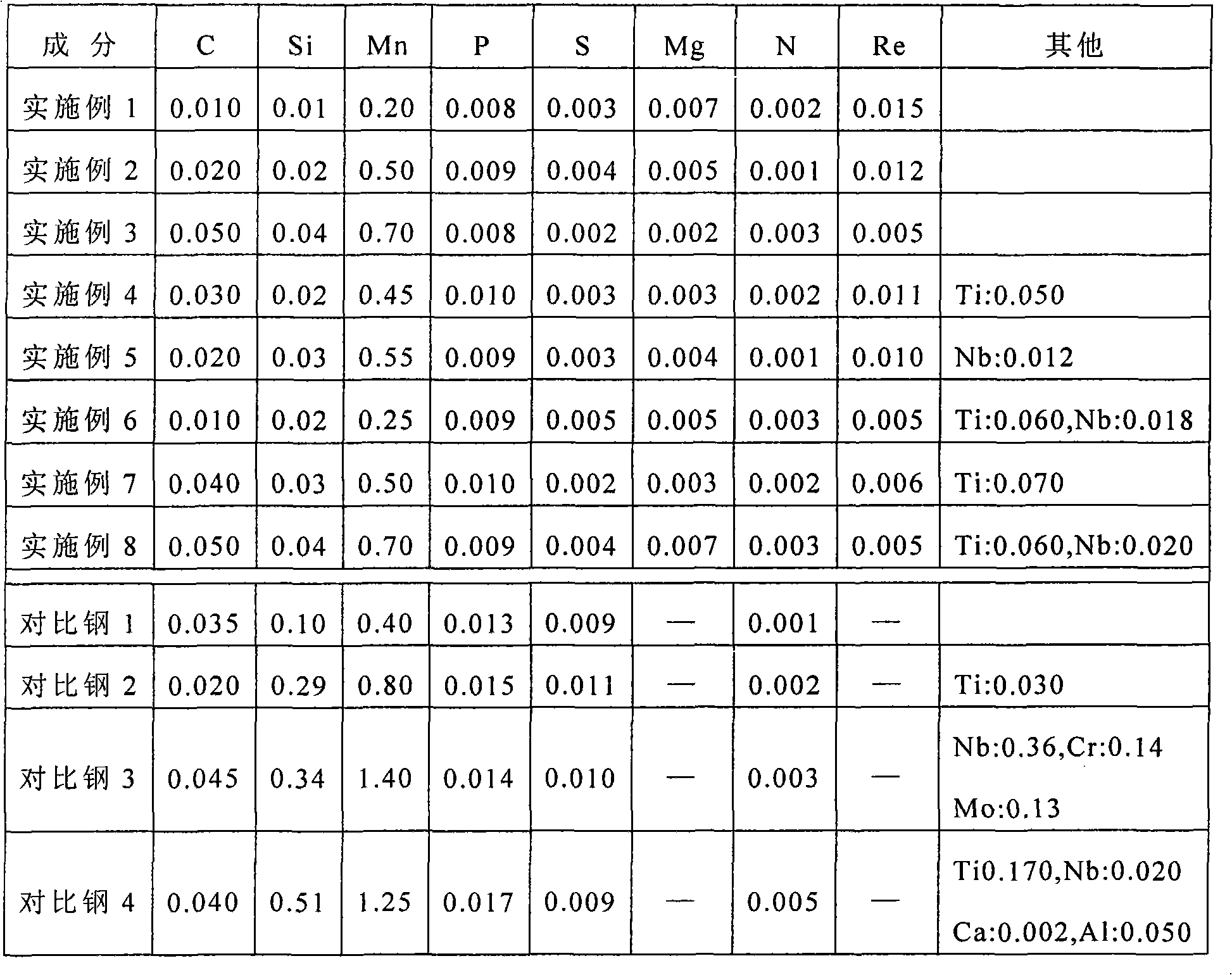

[0024]Table 1 has listed the chemical composition weight percentages of the anti-seismic construction steels of Examples 1 to 8 of the present invention (the balance is Fe and unavoidable impurities), and the composition weight percentages of commercially available common construction steels (contrast steels) (The balance is Fe and unavoidable impurities).

[0025] Table 1:

[0026]

[0027] The steel products in the above-mentioned Examples 1-8 are produced according to the usual ultra-pure steel process, through hot metal desulfurization, converter top and bottom blowing, adding Mg alloy during vacuum treatment, adding Re alloy during continuous casting for alloying, continuous casting, thermal Roll and cool to room temperature. During hot rolling, the bil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield point | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com