Copious cooling asymmetrical rolling method for preparing entropy alloy foil in high-performance CrCoNi

A technology of asynchronous rolling and entropy alloying, used in metal rolling, metal rolling, rolls, etc., can solve the problem of no way to achieve, and achieve the effect of improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

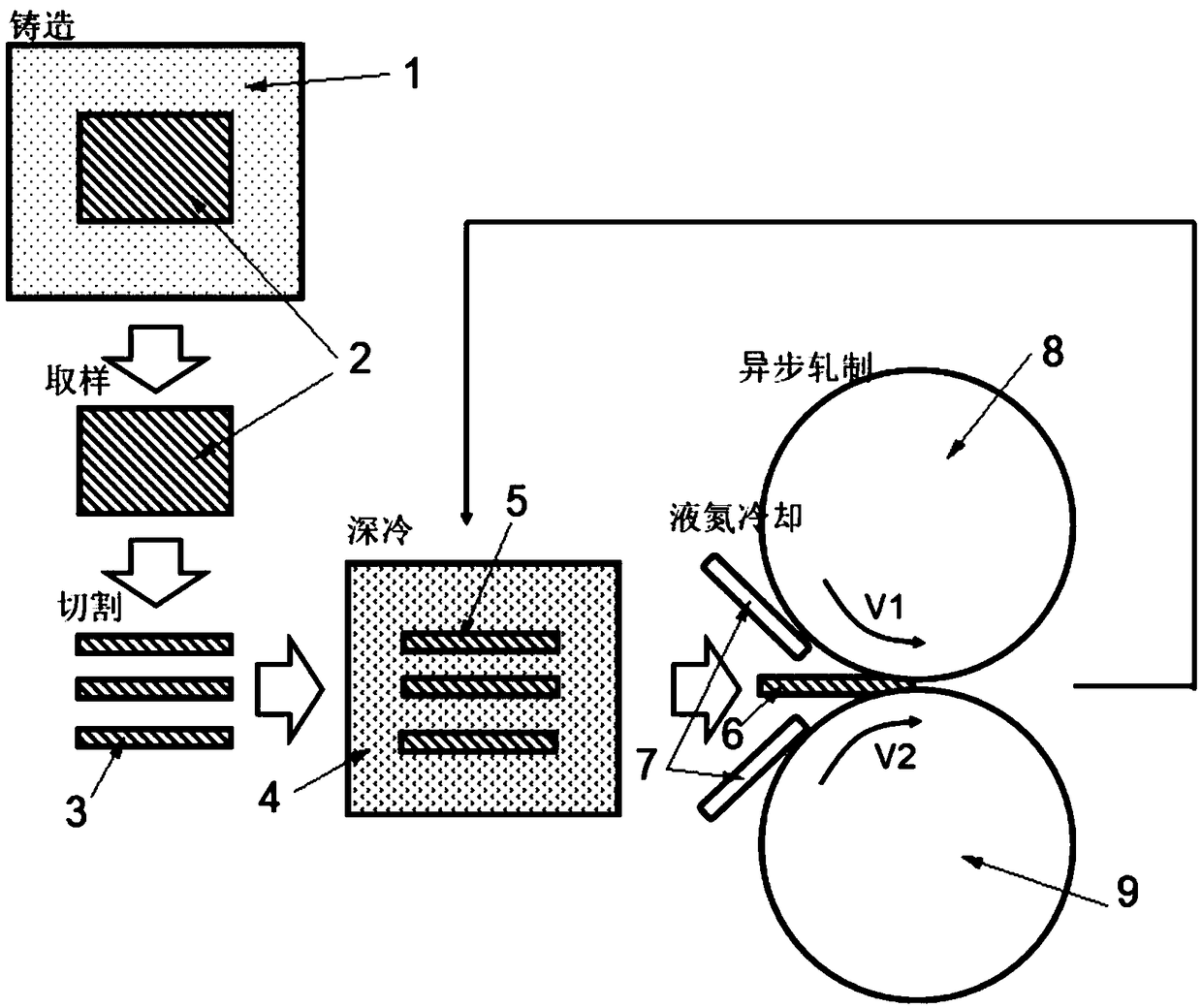

Method used

Image

Examples

application example 1

[0030] The 150 μm thick medium entropy alloy CrCoNi foil is prepared by cryogenic asynchronous rolling, and the steps are as follows:

[0031] The first step: using cast CrCoNi alloy rods as raw materials.

[0032] Step 2: cutting the CrCoNi alloy rod into thin sheets by wire cutting, the thickness of the sheet is 1.0 mm.

[0033] Step 3: Put the flakes into a cryogenic box for cryogenic treatment. The holding time is 10 minutes, and the temperature of the cryogenic box is set at -190°C.

[0034] Step 4: Turn on the liquid nitrogen spray guns on the left and right sides to cool the roll.

[0035] Step 5: Take out the cryogenically cooled CrCoNi alloy sample and perform cryogenic asynchronous rolling. During the asynchronous rolling process, keep liquid nitrogen to cool the rolls. The rolling speed is 6m / min, and the rolling differential speed ratio is set to 1.6. The single pass reduction rate is 10%. The roll is made of high-speed steel material.

[0036] Step 6: Put the...

application example 2

[0038] The 20 μm thick medium entropy alloy CrCoNi foil is prepared by cryogenic asynchronous rolling, and the steps are as follows:

[0039] The first step: using cast CrCoNi alloy plate as raw material.

[0040] Step 2: cutting the CrCoNi alloy sheet into thin slices by wire cutting, the thickness of the sheet is 0.3 mm.

[0041] Step 3: Put the flakes into a cryogenic box for cryogenic treatment. The holding time is 10 minutes, and the temperature of the cryogenic box is set at -150°C.

[0042] Step 4: Turn on the liquid nitrogen spray guns on the left and right sides to cool the roll.

[0043] Step 5: Take out the cryogenically cooled CrCoNi alloy sample and perform cryogenic asynchronous rolling. During the asynchronous rolling process, keep liquid nitrogen to cool the rolls. The rolling speed is 18m / min, and the rolling differential speed ratio is set to 1.4. The single pass reduction rate is 8%. The roll is made of high-speed steel material.

[0044] Step 6: Put th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com