Crystallization method, crystallization apparatus, processed substrate, thin film transistor and display apparatus

a crystallization apparatus and substrate technology, applied in the direction of crystal growth process, manufacturing tools, instruments, etc., can solve the problems of reducing the thickness of the substrate plate, the inability of the transistor to be suitable for the display apparatus, and the inability to optimize the light intensity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] Embodiments according to the present invention will now be described hereinafter with reference to the accompanying drawings.

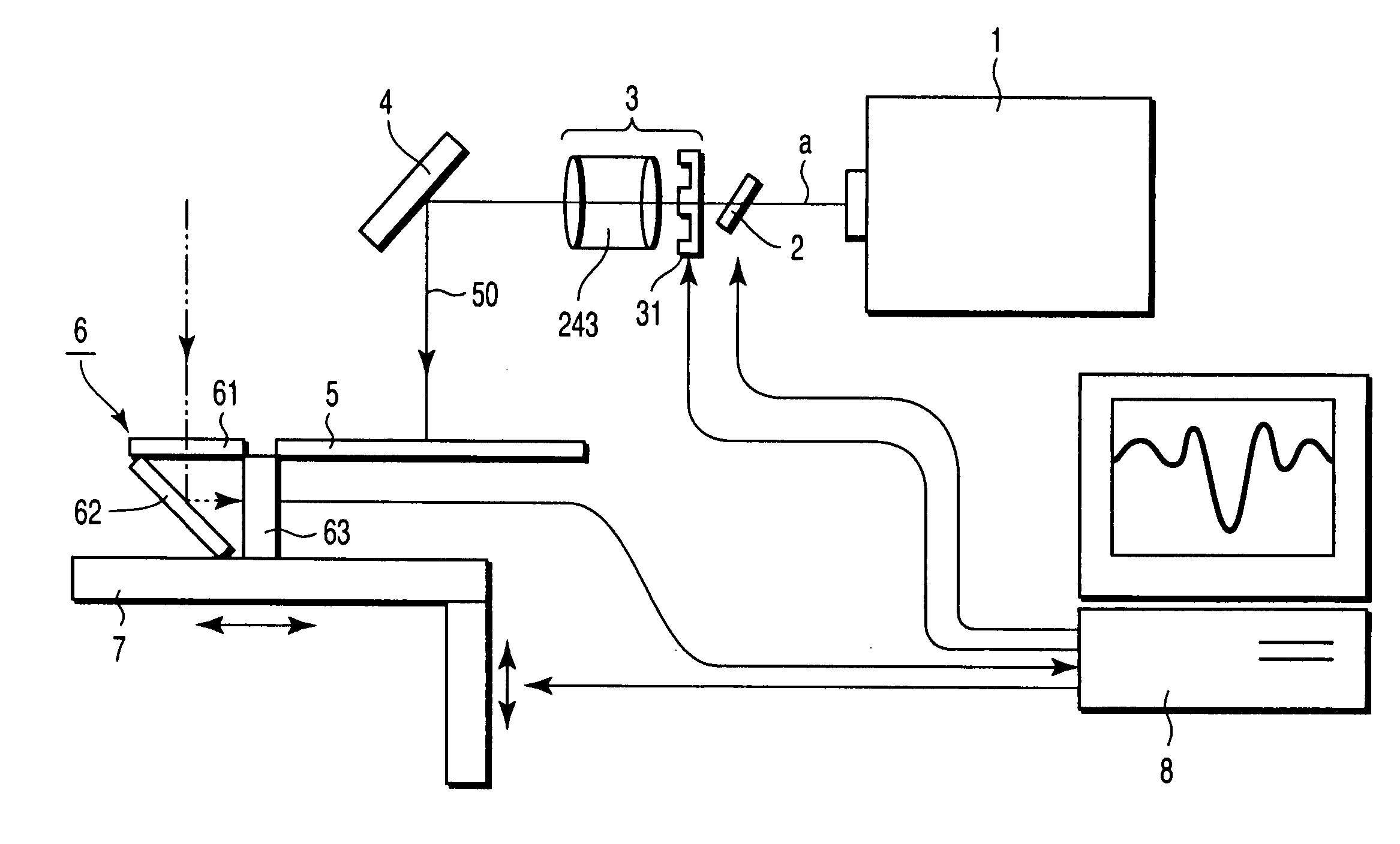

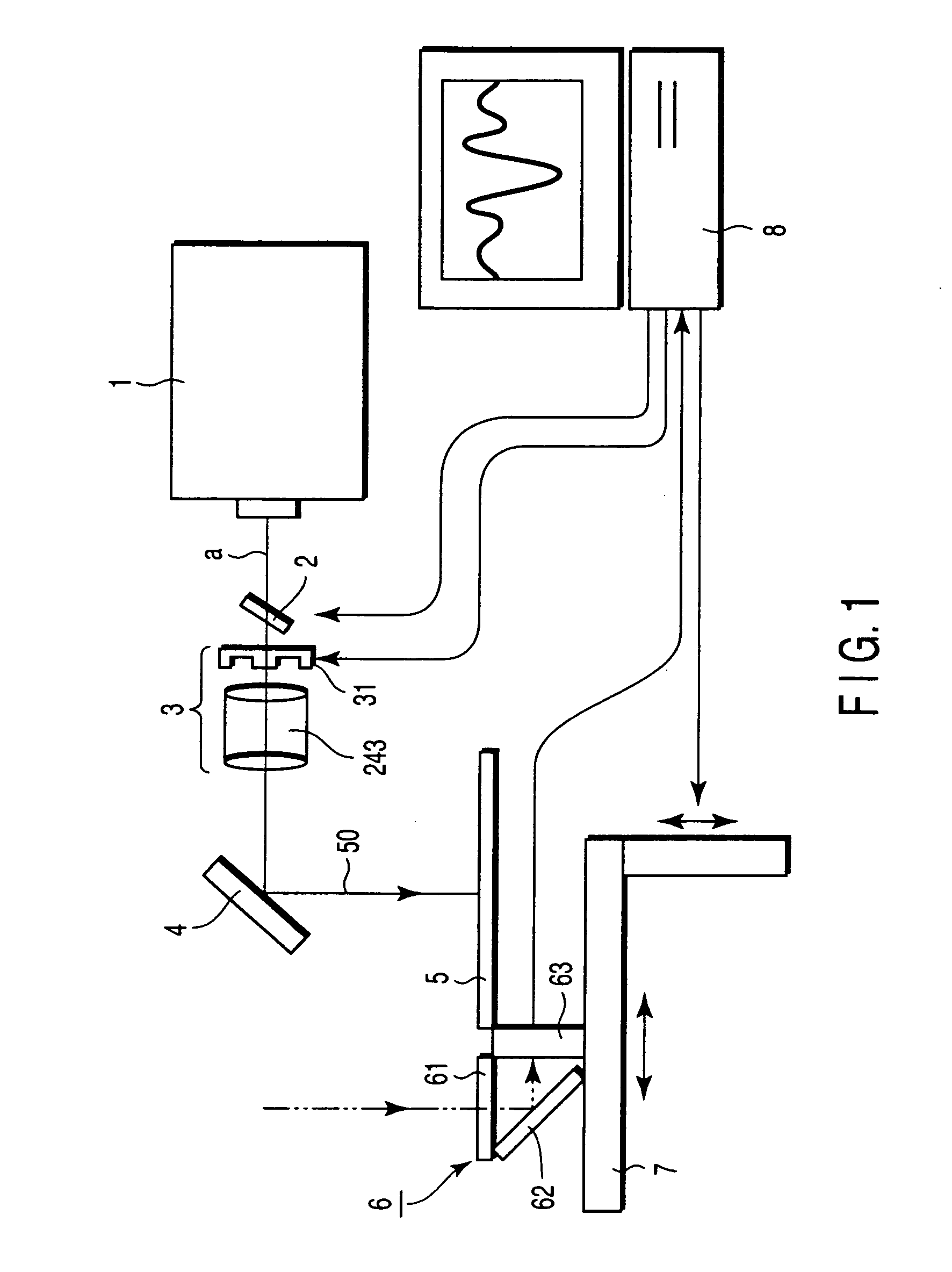

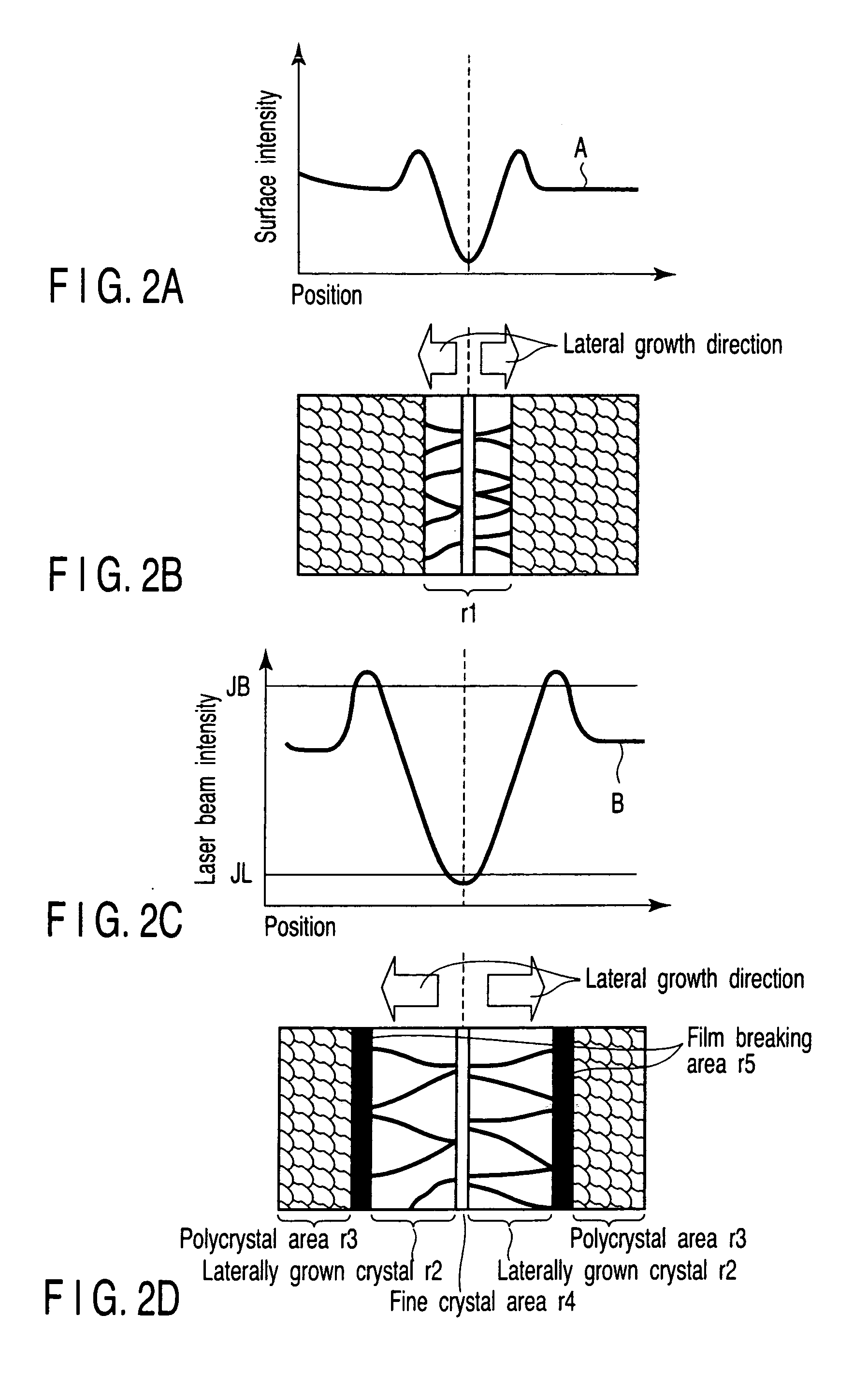

[0108]FIG. 1 is a schematic view showing a laser crystallization apparatus embodying the present invention. In a laser crystallization apparatus, an attenuator 2 and a beam profile modulation portion 3 are arranged at a starting end of an optical axis a of a laser beam source 1 containing the homogenization optical system, and a semiconductor substrate 5 is provided at a trailing end through a mirror 4. Further, a beam profile measurement portion 6 is provided to be aligned with the semiconductor substrate 5, and the semiconductor substrate 5 and the beam profile measurement portion 6 are fixed to a moving stage 7.

[0109] Furthermore, a control personal computer 8 as a controller is set, the beam profile measurement portion 6 is connected on an input side of the personal computer 8, and control systems of the attenuator 2, the beam profile modulation p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Light | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com