Crossed tapered quantum dot as well as preparation method and application thereof

A quantum dot and cone technology, applied in the field of cross-cone quantum dots and their preparation, can solve the problems of complex process, unfavorable industrial production, poor process continuity, etc., and achieve the effect of improving luminous efficiency, wide application range and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

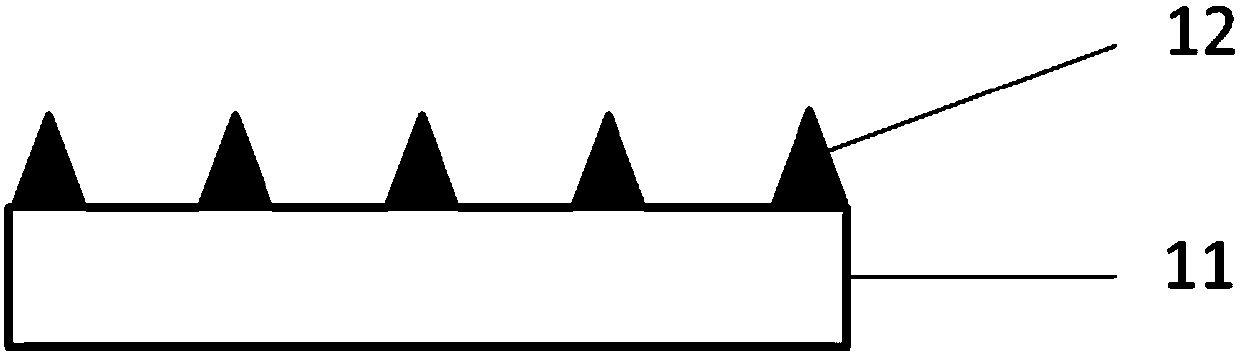

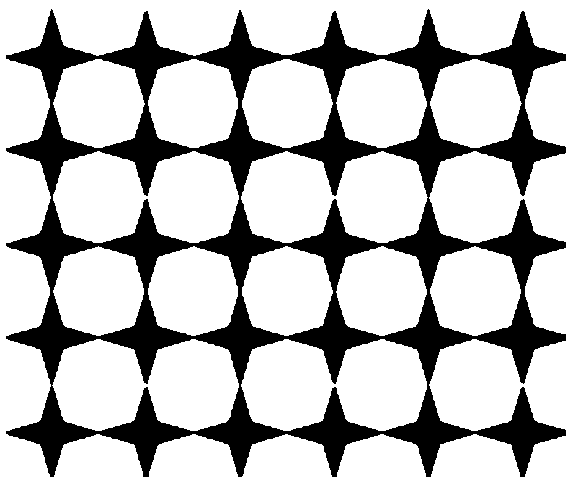

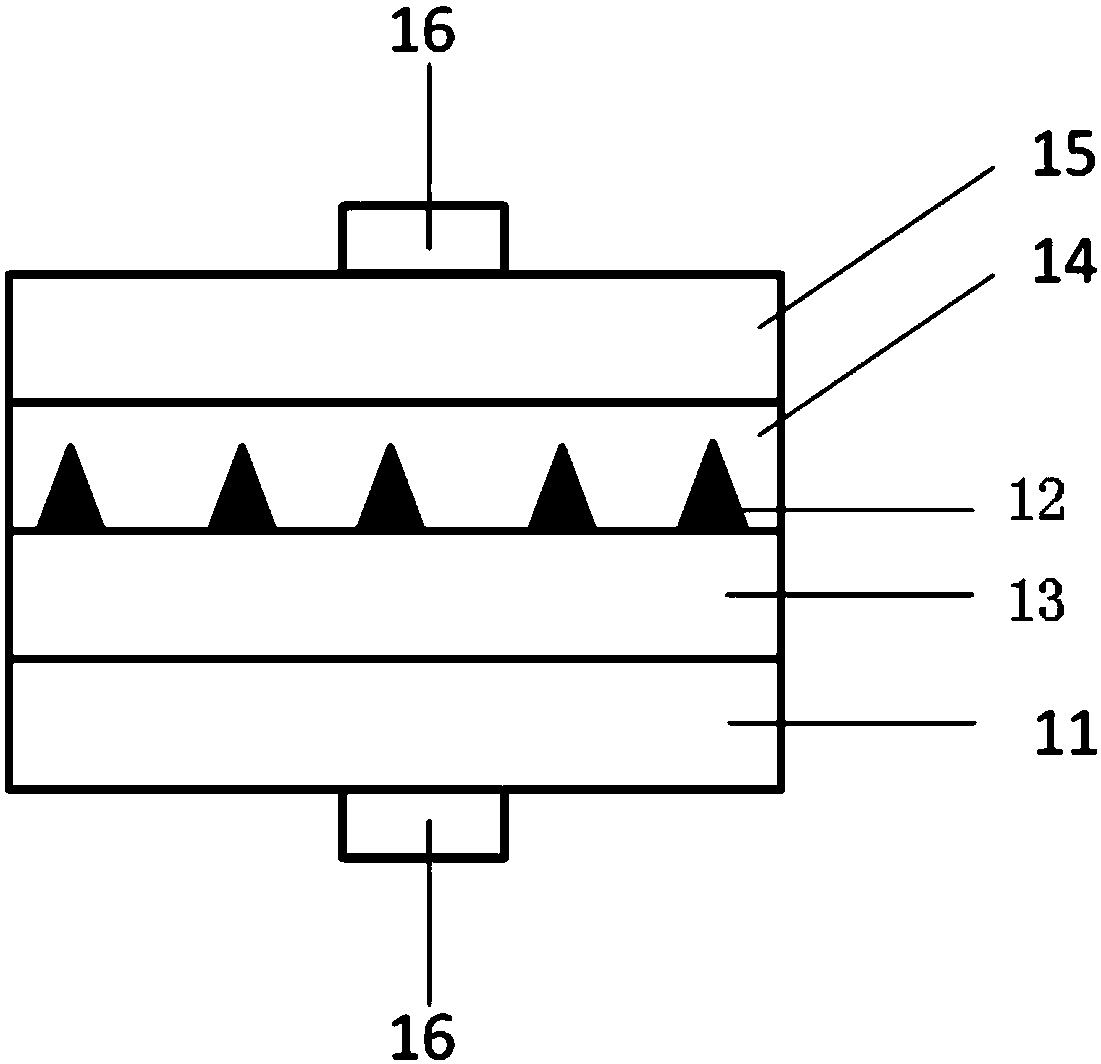

[0038] A preparation method for cross-conical quantum dots, comprising the following steps:

[0039] (1) Prepare a placeable NiO / substrate and SiO 2 The concave mold of the nano-microsphere and the convex mold matched with it are ready for use; the depth of the concave mold is slightly greater than the sum of the thickness of the substrate, the diameter of the nano-microsphere and the height of the convex mold;

[0040] (2) Put the substrate into deionized water, ultrasonically clean it at room temperature for 3-5 minutes, remove the dirt particles on the surface of the substrate, and then wash it with acetone and ethanol in sequence to remove the organic matter on the surface, and dry it with a spin dryer;

[0041] (3) Place the substrate in the concave mold, and then spread a layer of SiO with a diameter of 300nm on the substrate 2 Nano microspheres, the nano microspheres just cover the upper surface of the substrate;

Embodiment 2

[0047]A preparation method for cross-conical quantum dots, comprising the following steps:

[0048] (1) Prepare a placeable NiO / substrate and SnO 2 The concave mold of the nano-microsphere and the convex mold matched with it are ready for use; the depth of the concave mold is slightly greater than the sum of the thickness of the substrate, the diameter of the nano-microsphere and the height of the convex mold;

[0049] (2) Put the substrate into deionized water, ultrasonically clean it at room temperature for 3-5 minutes, remove the dirt particles on the surface of the substrate, and then wash it with acetone and ethanol in sequence to remove the organic matter on the surface, and dry it with a spin dryer;

[0050] (3) The substrate is placed in the concave mold, and then a layer of SnO with a diameter of 350nm is spread on the substrate. 2 Nano microspheres, the nano microspheres just cover the upper surface of the substrate;

Embodiment 3

[0055] A preparation method for cross-conical quantum dots, comprising the following steps:

[0056] (1) Prepare a concave mold that can place NiO / substrate and ZnO nano microspheres and a convex mold that fits with it, for subsequent use; the depth of the concave mold is slightly greater than the thickness of the substrate, the diameter of the nanospheres and the convex mold. The sum of the height of the mold;

[0057] (2) Put the substrate into deionized water, ultrasonically clean it at room temperature for 3-5 minutes, remove the dirt particles on the surface of the substrate, and then wash it with acetone and ethanol in sequence to remove the organic matter on the surface, and dry it with a spin dryer;

[0058] (3) The substrate is placed in the concave mold, and then a layer of ZnO nanospheres with a diameter of 500nm is spread on the substrate, and the nanospheres just cover the upper surface of the substrate;

[0059] (4) Evaporate Ni metal mask material on the concav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com