Preparation method for HfS2 signal crystal nanosheet

A single crystal nano, substrate technology, applied in the direction of single crystal growth, nanotechnology, single crystal growth, etc., can solve the problems of limiting HfS research, low yield, difficult to control the number of layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

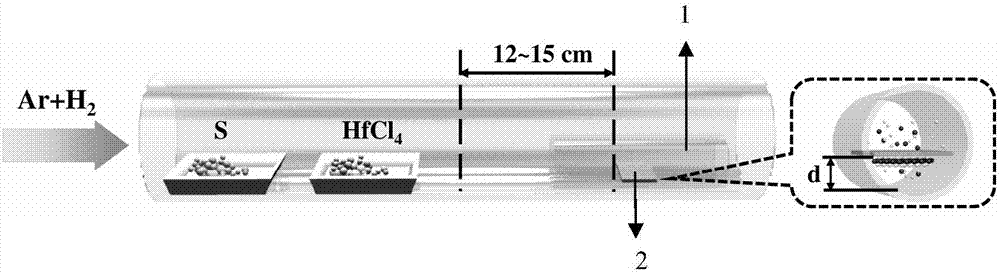

[0032] a HfS 2 A method for preparing a single crystal nanosheet, comprising the following steps:

[0033] Step 1: Put the S source and the Hf source in the upstream area of the quartz tube, place the embedded quartz tube with an inner diameter of 12mm in the downstream area, place the mica substrate in the embedded quartz tube, and place it at a distance of 13cm from the heating center of the quartz tube;

[0034] Step 2: Vacuumize the inside of the quartz tube to 1Pa, and pass Ar gas to remove the residual air in the tube and keep the air pressure in the tube at normal pressure; then pass 15 sccm of Ar and 5 sccm of H into the tube 2 Respectively as carrier gas and shielding gas;

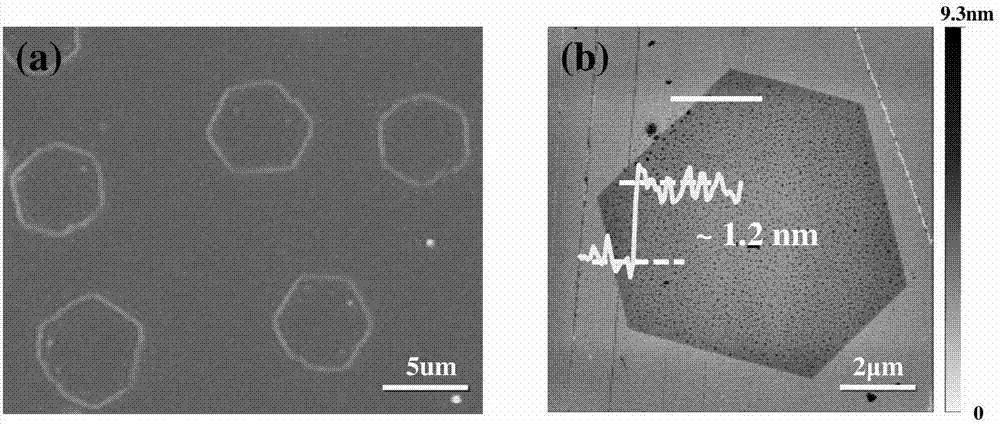

[0035] Step 3: Heat HfCl at 330°C and 220°C respectively 4 and S powder until evaporation, under the condition that the heating center temperature of the quartz tube is 900°C, and the distance d between the mica substrate and the lower wall of the embedded quartz tube is 1.5 mm, react for 10 m...

Embodiment 2

[0039] Example 2. HfS 2 Preparation of Single Crystal Nanosheets

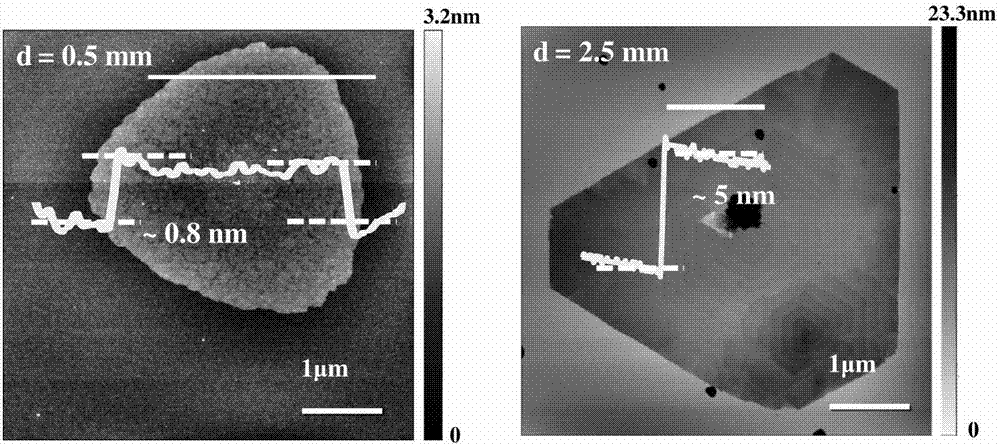

[0040] Prepare HfS according to the steps of Example 1 2 For single crystal nanosheets, the distance d between the mica substrate and the lower wall of the embedded quartz tube in the confinement space is 0.5mm and 2.5mm respectively, and other steps remain unchanged. HfS obtained under this example 2 Atomic force microscope image of a single crystal nanosheet image 3 shown.

Embodiment 3

[0041] Example 3. HfS 2 Preparation of Single Crystal Nanosheets

[0042] Prepare HfS according to the steps of Example 1 2 For single crystal nanosheets, the reaction temperatures were changed to 800°C, 850°C, 940°C and 980°C, respectively, and other steps remained unchanged. HfS obtained under this embodiment 2 The atomic force microscope image of single crystal nanosheets and the statistics of thickness and nucleation density are shown in Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com