Preparation method and application of two-dimensional ultrathin Fe3O4 single crystal nanosheet

A single-crystal nanometer and ultra-thin technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., to achieve the effect of ultra-high photoresponsivity, performance improvement, and wide spectral response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

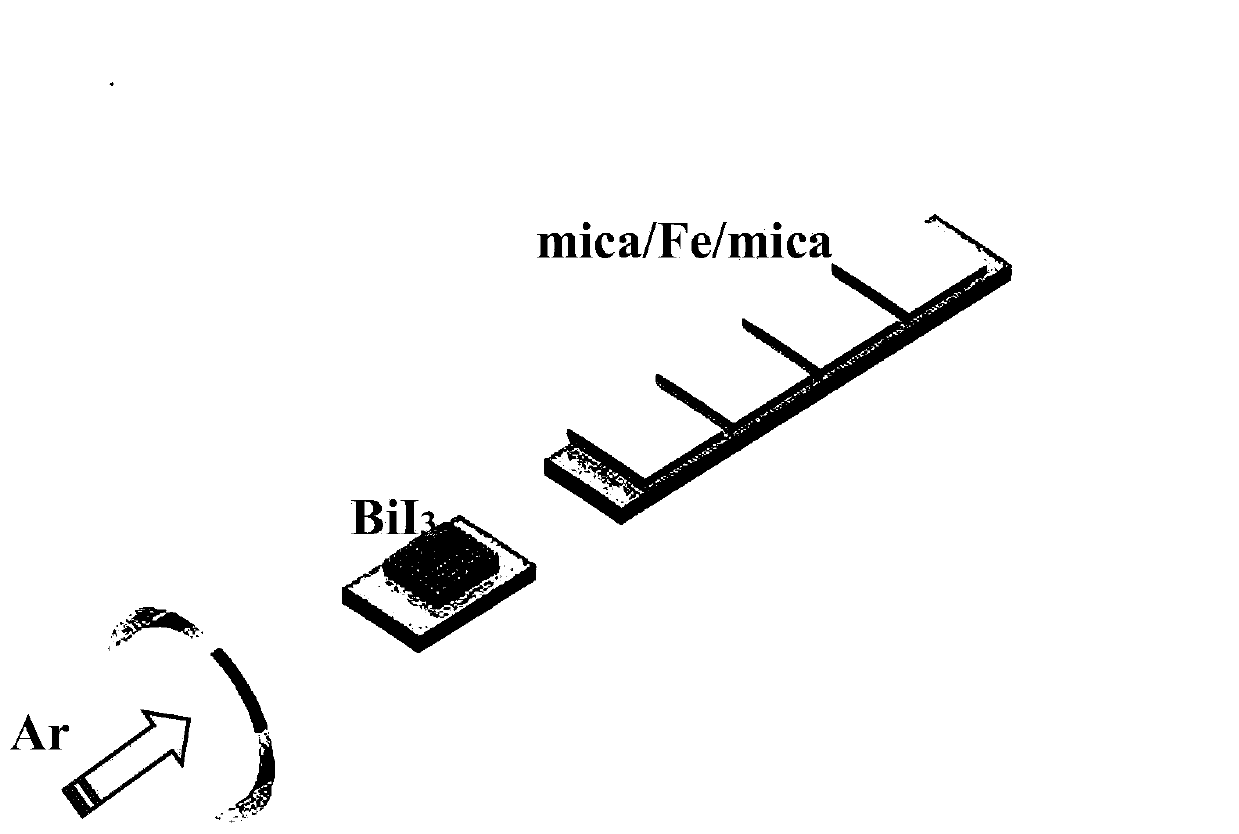

[0034] A two-dimensional ultra-thin Fe 3 O 4 The preparation method of monocrystalline nanosheets includes the following steps:

[0035] Step 1: Add 10mg of BiI 3 Powder placed in Al 2 O 3 In the quartz boat, place the quartz boat in the center of the first heating zone, place the naturally oxidized iron foil between the upper and lower mica sheets, and then place the mica sheet in the center of the second heating zone downstream of the quartz tube;

[0036] Step 2: Evacuate the inside of the quartz tube to below 1 Pa, and pass in 500 sccm of Ar gas to remove the residual air in the tube and keep the pressure in the tube at a normal pressure environment, and then continue to pass in Ar gas as the carrier gas at a flow rate of 50 sccm;

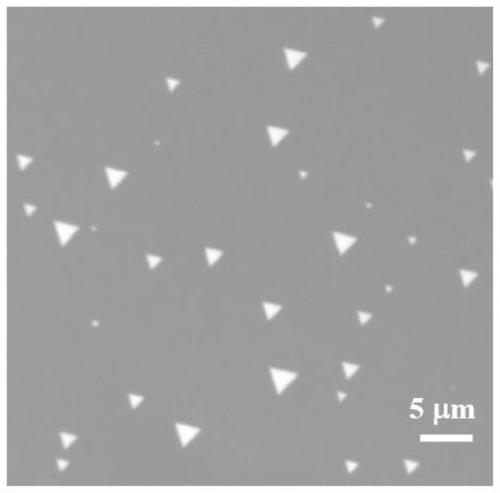

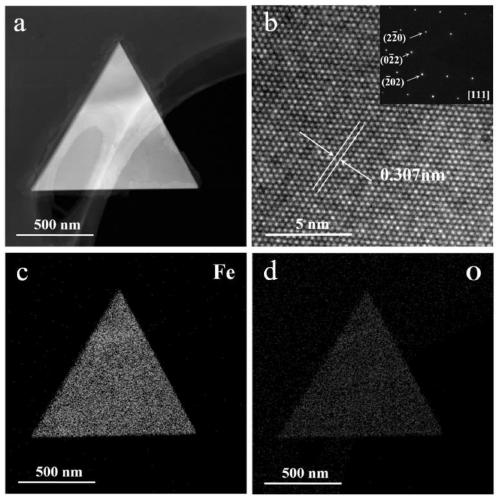

[0037] Step 3: Raise the second heating zone to 400°C, keep it for 20 minutes, then heat the first heating zone to 470°C, react for 10 minutes, cool to room temperature naturally after the reaction, take out the substrate, and then prepare the substrat...

Embodiment 2

[0041] Prepare two-dimensional ultra-thin Fe according to the steps of Example 1. 3 O 4 For single crystal nanosheets, only adjust the temperature of the first heating zone and the second heating zone in step 3 to 520°C and 420°C, respectively, and keep it for 1 hour, the other steps remain unchanged

[0042] Fe prepared in this example 3 O 4 The AFM scan of single crystal nanosheets is as follows Image 6 Shown.

Embodiment 3

[0044] A two-dimensional ultra-thin Fe 3 O 4 The preparation method of monocrystalline nanosheets includes the following steps:

[0045] Step 1: Add 10mg of BiI 3 Powder placed in Al 2 O 3 In the quartz boat, place the quartz boat in the center of the first heating zone, and place the mica substrate covered with naturally oxidized iron foil in the center of the second heating zone downstream of the quartz tube;

[0046] Step 2: Evacuate the inside of the quartz tube to below 1 Pa, and pass in 500sccm of Ar gas to remove the residual air in the tube and keep the pressure in the tube at a normal pressure environment, and then continue to pass in Ar gas as the carrier gas at a flow rate of 75sccm;

[0047] Step 3: Raise the second heating zone to 390℃, keep it for 20min, then raise the first heating zone to 460℃, react for 20min, cool to room temperature naturally after the reaction, take out the mica substrate, and then prepare it on the substrate The two-dimensional ultra-thin Fe 3 O ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com