Black phosphorus film as well as preparation method and application thereof

A black phosphorus and thin film technology, applied in the field of two-dimensional materials, can solve the problems of difficulty in realizing large-scale preparation and industrialization of black phosphorus materials and devices, inability to control the thickness and size of black phosphorus films, and difficulty in controlling the size and thickness of black phosphorus. , to achieve the effect of convenient large-scale research and development and application, low price of raw materials, and good photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

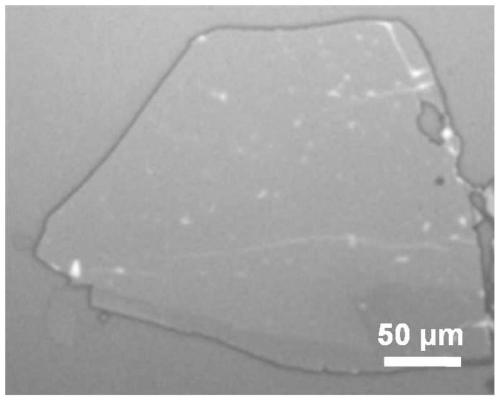

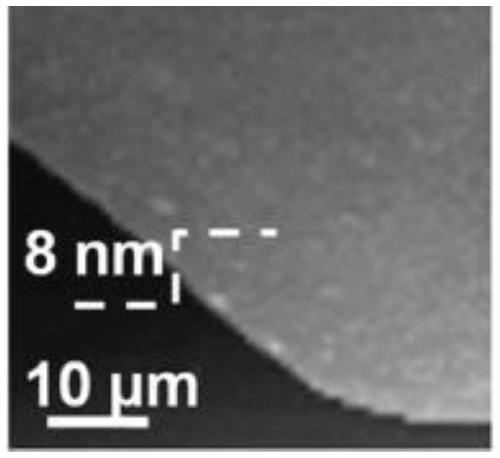

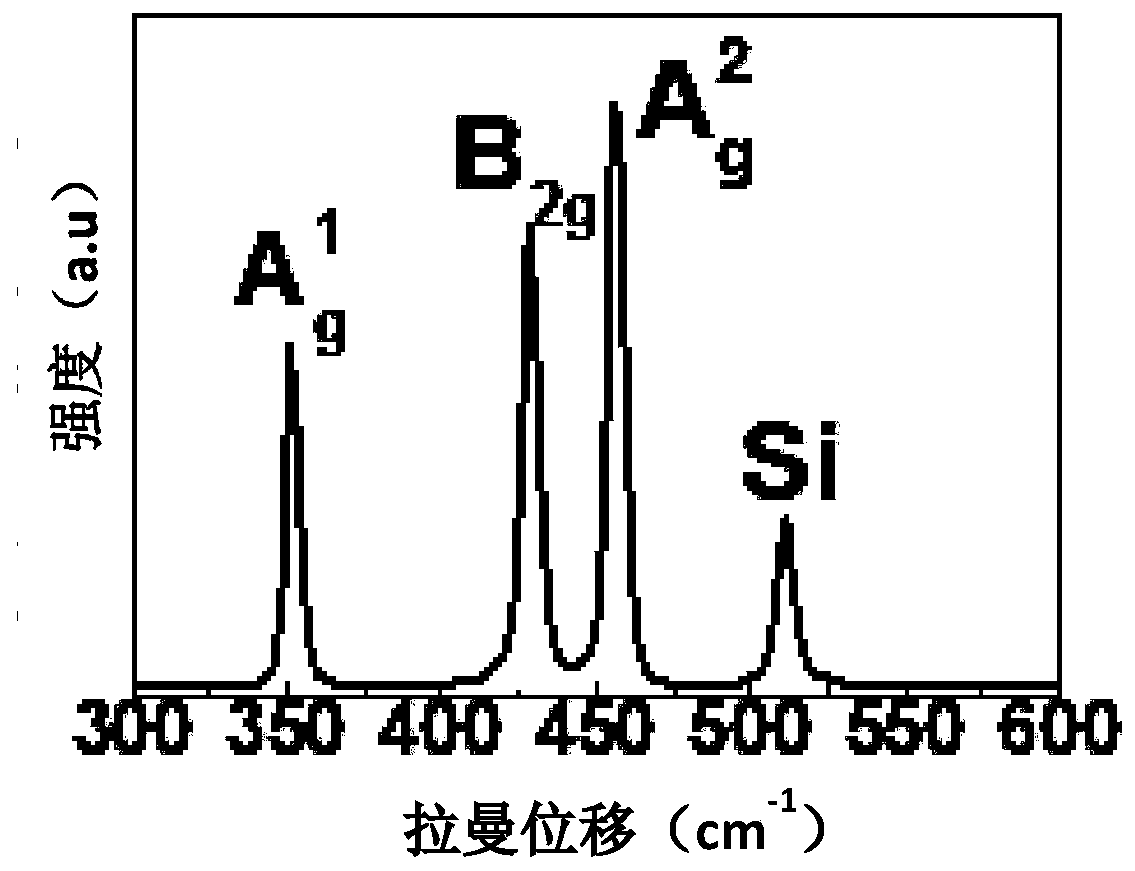

[0044] The invention provides a method for preparing a black phosphorus film, comprising:

[0045] S100: placing a growth substrate, a phosphorus-containing precursor, and a mineralizer in a vacuum-tight reaction chamber, wherein the growth substrate and the phosphorus-containing precursor are placed in different regions of the vacuum-tight reaction chamber ;

[0046] S200: heating the reaction chamber and keeping it warm, causing the mineralizer to react with the phosphorus-containing gas partially derived from the phosphorus-containing precursor, and forming an induced nucleation point for inducing black phosphorus crystallization on the growth substrate or Induced nucleation layer;

[0047] S300: Lowering the temperature of the reaction chamber, depositing the phosphorus-containing gas on the growth substrate, and epitaxially growing the black phosphorus film under the induction of the induced nucleation point or the induced nucleation layer.

[0048] In the embodiment of...

Embodiment 1

[0096] This embodiment discloses a method for preparing a black phosphorus thin film, which specifically includes:

[0097] (1) Formation of induced nucleation sites or induced nucleation layers

[0098] a) Provide multiple silicon dioxide growth substrates, red phosphorus and mineralizers, the mineralizers include tin iodide, tin and gold, wherein the gold is uniformly arranged on the silicon dioxide growth substrates A layer of gold film, the thickness of the gold film is 5-180nm;

[0099] b) placing the tin iodide, tin and red phosphorus at the low-temperature end in the vacuum-sealed reaction chamber, and placing the growth substrate at the high-temperature end in the vacuum-sealed reaction chamber, wherein multiple growth substrates are stacked and arranged at intervals;

[0100] c) heating the reaction chamber to 750°C at a rate of 10°C / min, and keeping it warm for 1h;

[0101] Wherein, the mass ratio of the tin iodide, tin and red phosphorus is 1:(2-10):(10-100).

[...

Embodiment 2

[0112] This embodiment discloses a method for preparing a black phosphorus thin film, which specifically includes:

[0113] (1) Formation of induced nucleation sites or induced nucleation layers

[0114] a) Provide multiple silicon dioxide growth substrates, white phosphorus and mineralizers, the mineralizers include tin iodide, tin and gold, wherein the gold is a layer evenly arranged on the silicon dioxide growth substrates A gold film, the thickness of the gold film is 5-180nm;

[0115] b) placing the tin iodide, tin and red phosphorus at the low-temperature end in the vacuum-sealed reaction chamber, and placing the growth substrate at the high-temperature end in the vacuum-sealed reaction chamber, wherein multiple growth substrates are stacked and arranged at intervals;

[0116] c) heating the reaction chamber to 650°C at a rate of 20°C / min, and keeping it warm for 2.5h;

[0117] Wherein, the mass ratio of the tin iodide, tin and white phosphorus is 1:(2-20):(10-200).

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com