High-toughness hot-rolled high-strength steel with yield strength being 800 MPa and manufacturing method of high-toughness hot-rolled high-strength steel

一种屈服强度、制造方法的技术,应用在结构钢领域,能够解决钢坯易产生裂纹、困难、增加工艺流程和制造成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

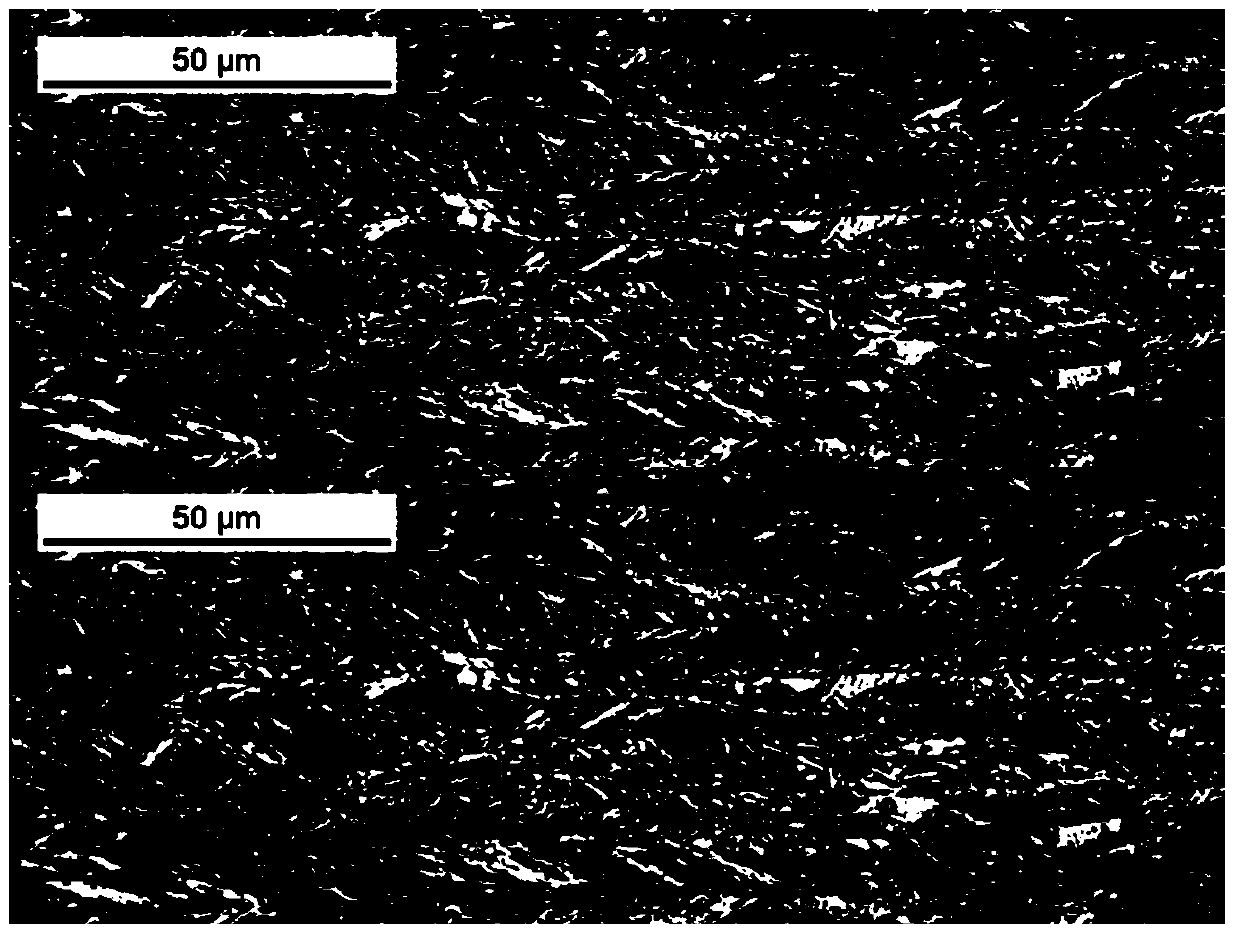

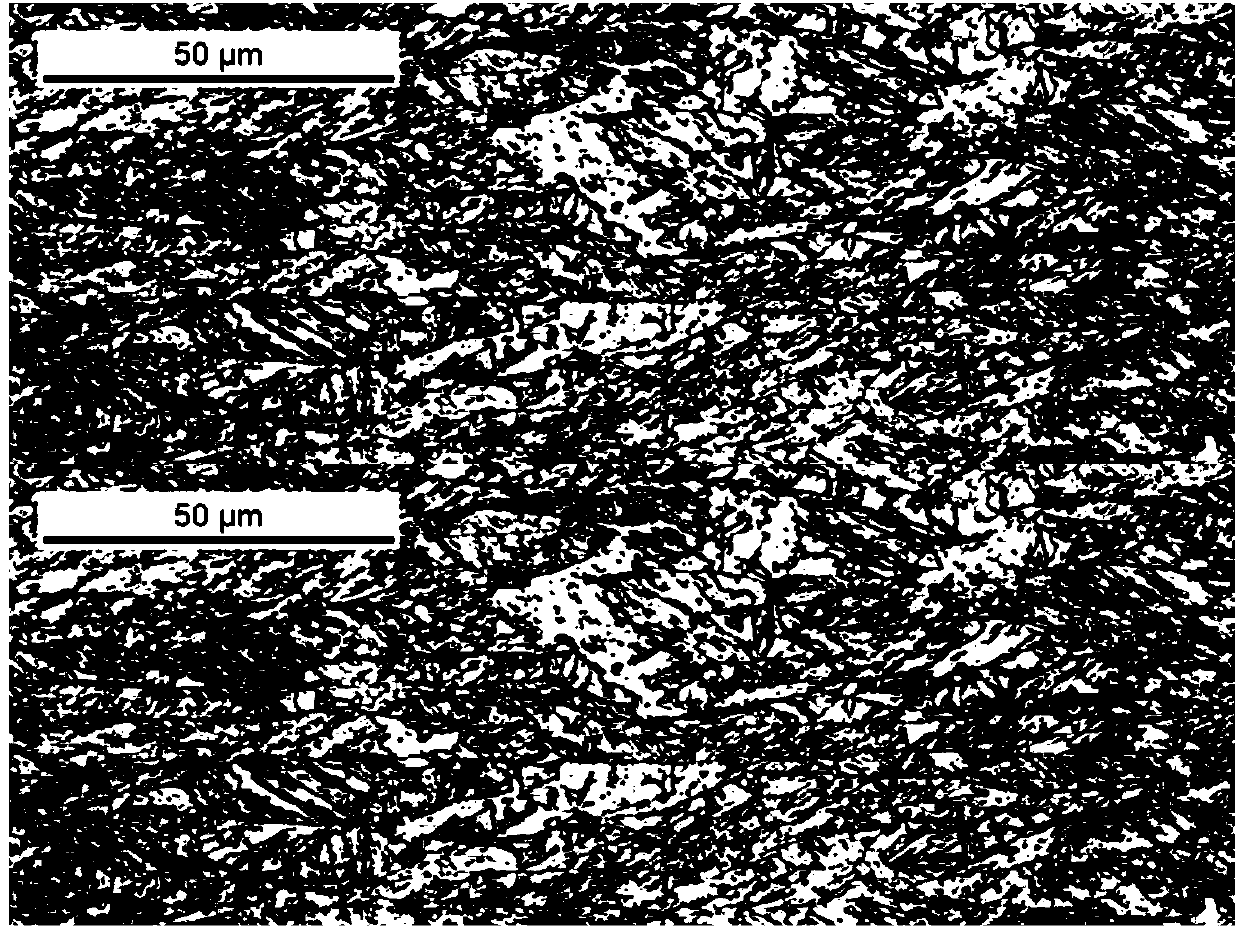

[0051] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0052] Examples of steel components of the present invention are shown in Table 1, Table 2 is the manufacturing process of the steel examples of the present invention, and Table 3 is the mechanical properties of the steel examples of the present invention.

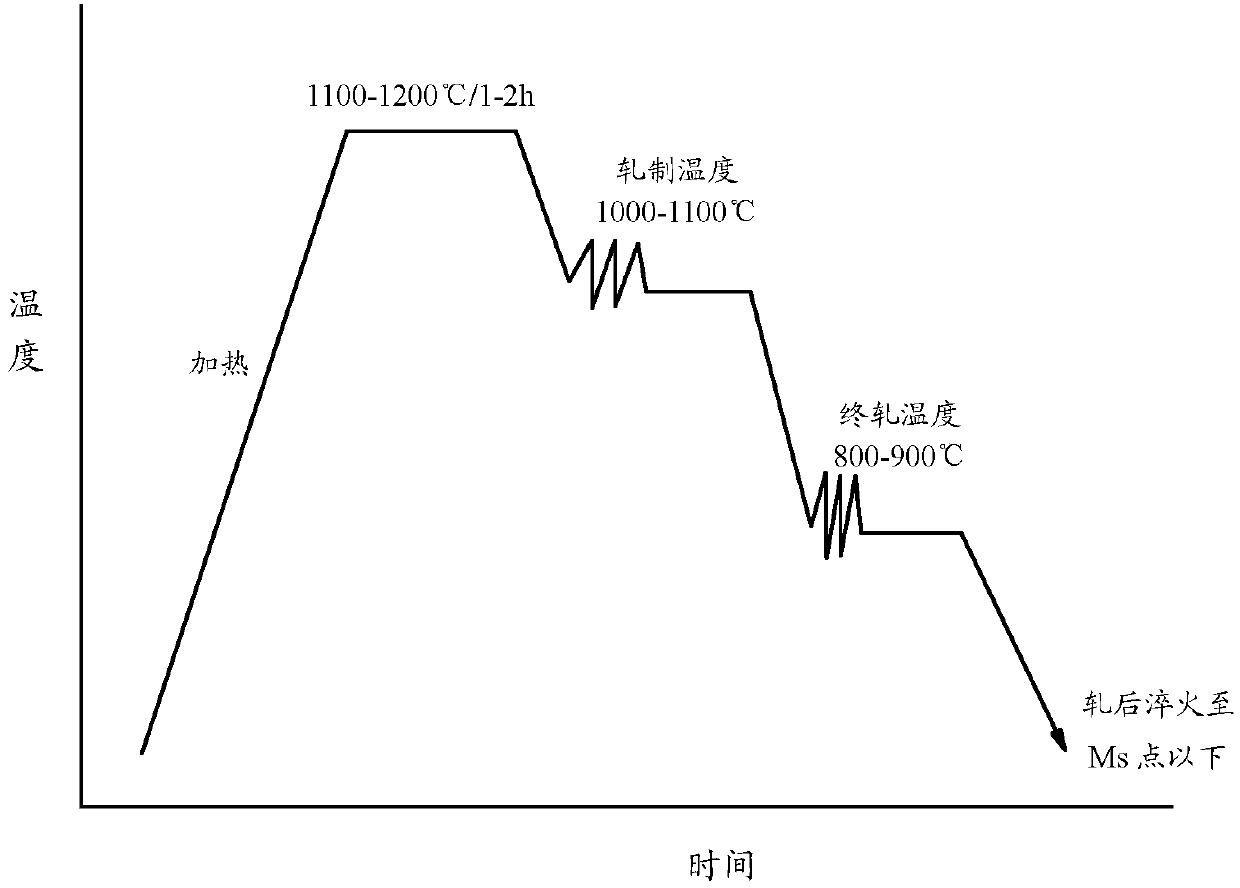

[0053] The process flow of the embodiment of the present invention: converter or electric furnace smelting→vacuum furnace secondary refining→casting billet (ingot)→casting billet (ingot) reheating→hot rolling+on-line quenching process→steel coil; wherein, casting billet (ingot) Heating temperature: 1100-1200°C, holding time: 1-2 hours, rolling start temperature: 1000-1100°C, multiple passes of high pressure above 950°C and cumulative deformation ≥ 50%, and then the intermediate billet is heated to 900 -950°C, then rolling for the last 3-5 passes with cumulative deformation ≥70%; rapid on-line quench...

PUM

| Property | Measurement | Unit |

|---|---|---|

| directional tensile yield strength | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com