Drop-weight tear test sample fracture shearing area detection method

A technology of shear area and fracture, applied in the field of inspection and testing, can solve problems such as large tolerance, difficult boundary confirmation, large regional deviation, etc., and achieve the effect of ensuring accuracy and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

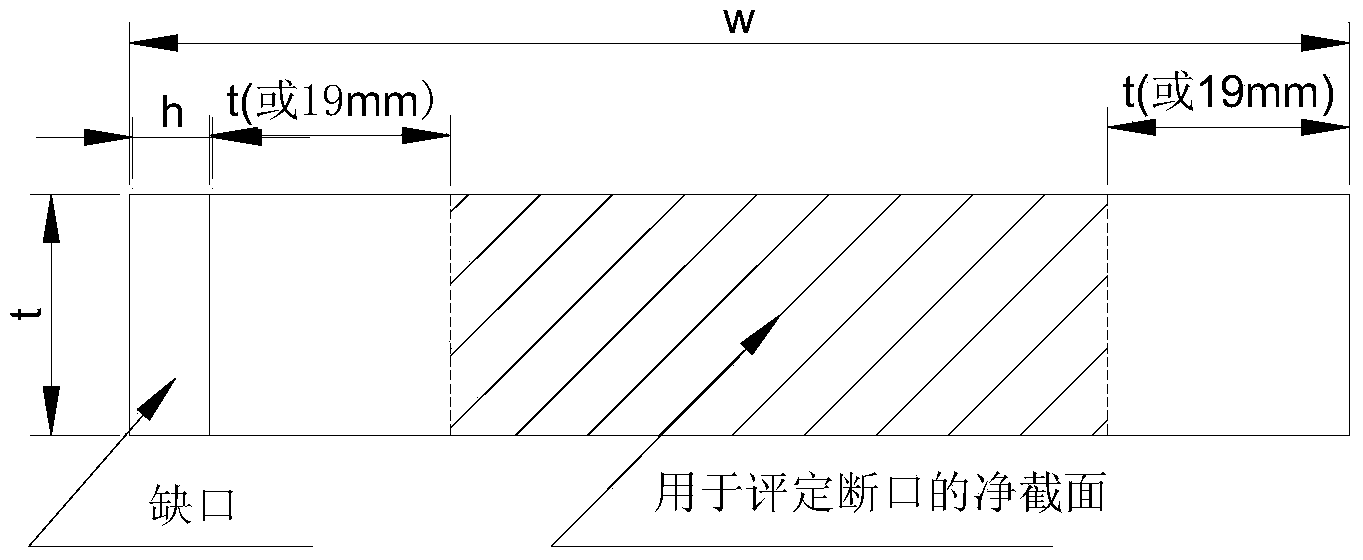

[0024] 1. Measure the thickness t and width w of the sample with a vernier caliper with a resolution of 0.01mm at three positions near the sample notch, and take the average value of the three measurements as the thickness and width of the sample.

[0025] 2. Break the sample, measure the notch depth h with a vernier caliper, and take pictures of the fracture of the DWTT sample with a digital camera.

[0026] 3. Measure the thickness tp of the root of the notch in the sample picture in the AutoCAD interface, then the magnification factor n=tp / t.

[0027] 4. In the AutoCAD interface, measure a sample thickness t from the top of the root of the notch in the sample picture as the starting point of the net section width; measure from the same point at the root of the notch (w-t-h) as the end point of the net section width, two points The part between is the width dimension of the net section, draw the net section;

[0028] For samples with a thickness t>19.0mm, just replace the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com