Method for preparing mica titanium material

A technology of mica titanium and sericite powder, which is applied in the field of preparation of mica titanium pearlescent materials by chemical deposition, which can solve the problems of less mineral deposits, high cost, and expensive raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

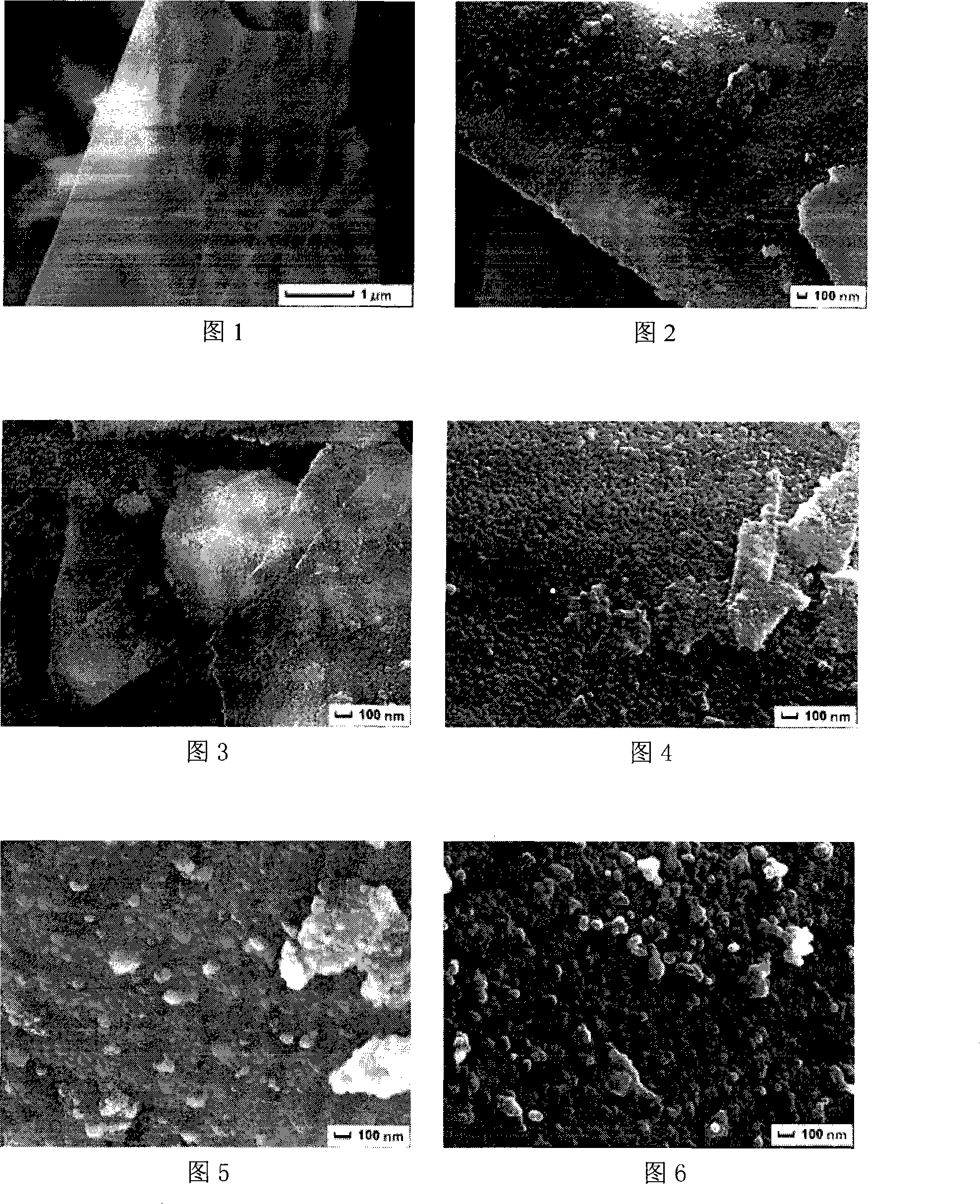

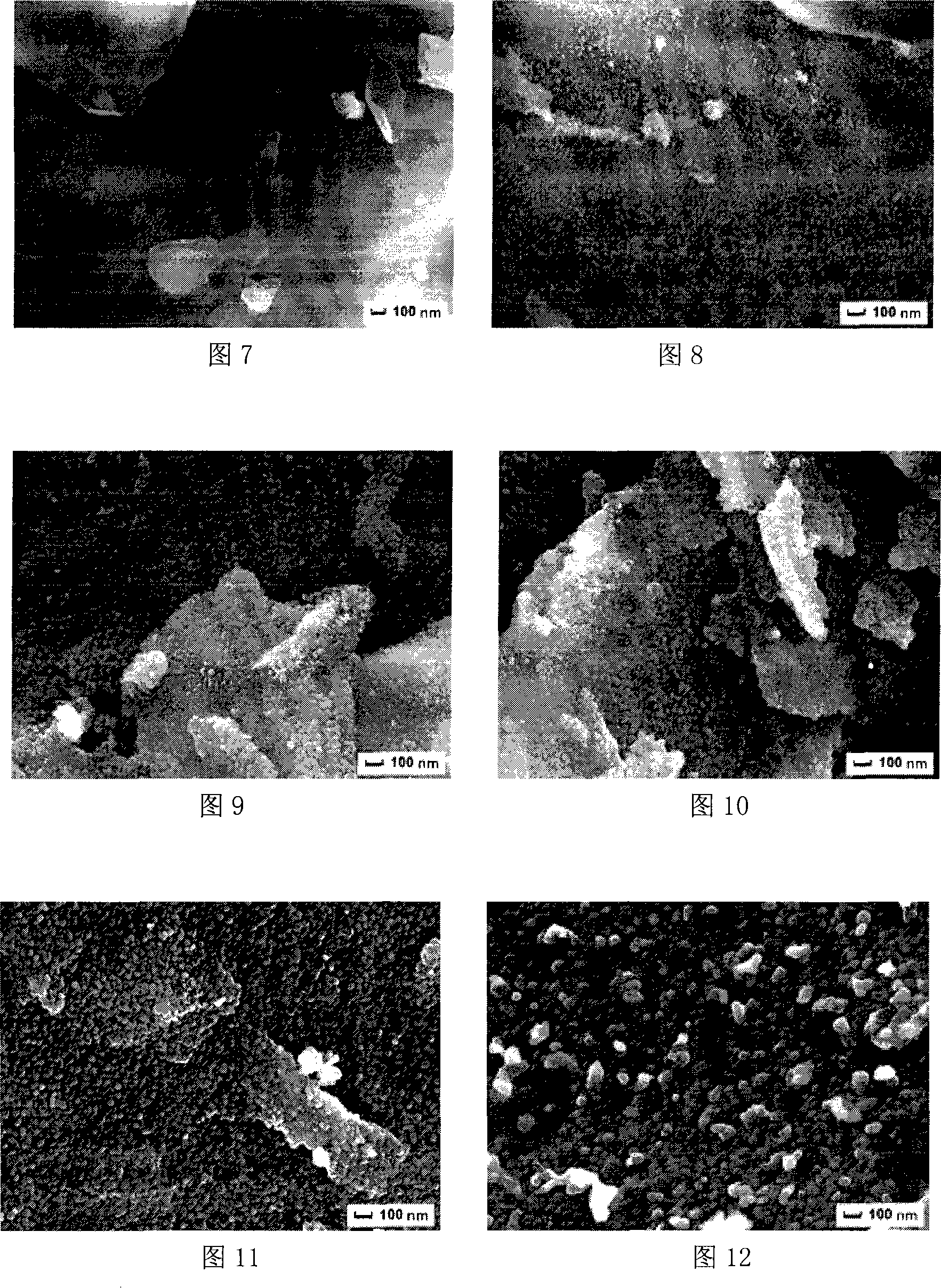

Image

Examples

example 1

[0023] Mix the sericite powder and the mixed acid at a mass ratio of 1:10, soak in a water bath at 70°C for 4 hours, then wash with water until the conductivity of the filtrate is less than 10ms / s, and dry it for use, wherein the mixed acid is made of 2.5wt% Phosphoric acid and 2.5wt% sulfuric acid are mixed according to the volume ratio of 1:1.

[0024] Evenly disperse the pretreated 100g sericite powder in 800g distilled water, place it in a water bath at 85°C, add dilute hydrochloric acid to keep the pH value of the solution at 2.0, slowly add 16wt% TiCl 4 solution 8.4ml, so that the reaction generated TiO 2 : The mass ratio of sericite is 1: 100, and NaOH solution is added dropwise at the same time, so that the pH value of the system is maintained at 2.0, reacted for 2h, and then washed with distilled water until the conductivity of the filtrate is less than 10ms / s. Dry at 100°C for 18 hours, put it into a muffle furnace and slowly raise the temperature to 900°C, and roas...

example 2

[0026] Mix the sericite powder and the mixed acid at a mass ratio of 1:10, soak in a water bath at 70°C for 4 hours, then wash with water until the conductivity of the filtrate is less than 10ms / s, and dry it for use, wherein the mixed acid is made of 2.5wt% Phosphoric acid and 2.5wt% sulfuric acid are mixed according to the volume ratio of 1:1.

[0027] Evenly disperse the pretreated 100g sericite powder in 800g distilled water, place it in a water bath at 85°C, add dilute hydrochloric acid to keep the pH value of the solution at 2.0, slowly add 16wt% TiCl 4 solution 42ml, so that the TiO generated by the reaction 2 : The mass ratio of sericite is 5: 100, and NaOH solution is added dropwise to maintain the pH value of the system at 2.0, react for 2h, and then wash with distilled water until the conductivity of the filtrate is less than 10ms / s. Dry at 100°C for 18 hours, put it in a muffle furnace and slowly raise the temperature to 900°C, and roast for 1 hour to get the prod...

example 3

[0029] Mix sericite powder and mixed acid at a mass ratio of 1:10, soak in a water bath at 70°C for 6 hours, then wash with water until the conductivity of the filtrate is less than 10ms / s, and dry it for use, wherein the mixed acid is made of 2.5wt% Phosphoric acid and 2.5wt% sulfuric acid are mixed according to the volume ratio of 1:1.

[0030] Evenly disperse the pretreated 100g sericite powder in 800g distilled water, place it in a water bath at 85°C, add dilute hydrochloric acid to keep the pH value of the solution at 2.0, slowly add 16wt% TiCl 4 solution 84ml, so that the TiO generated by the reaction 2 : The mass ratio of sericite is 1: 10, and NaOH solution is added dropwise at the same time, so that the pH value of the system is maintained at 2.0, reacted for 2h, and then washed with distilled water until the conductivity of the filtrate is less than 10ms / s. Dry at 100°C for 18 hours, put it in a muffle furnace and slowly raise the temperature to 900°C, and roast for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com