Hardening and tempering type anti-acid pipeline steel and manufacturing method thereof

A manufacturing method and pipeline steel technology, applied in the field of pipeline steel and its manufacturing, can solve the problems of unpublished performance of hydrogen-induced cracking resistance test performance, unknown acid resistance performance, high addition of Mn element, etc., to achieve excellent strength and toughness, suppress Effect of grain growth and elimination of band structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

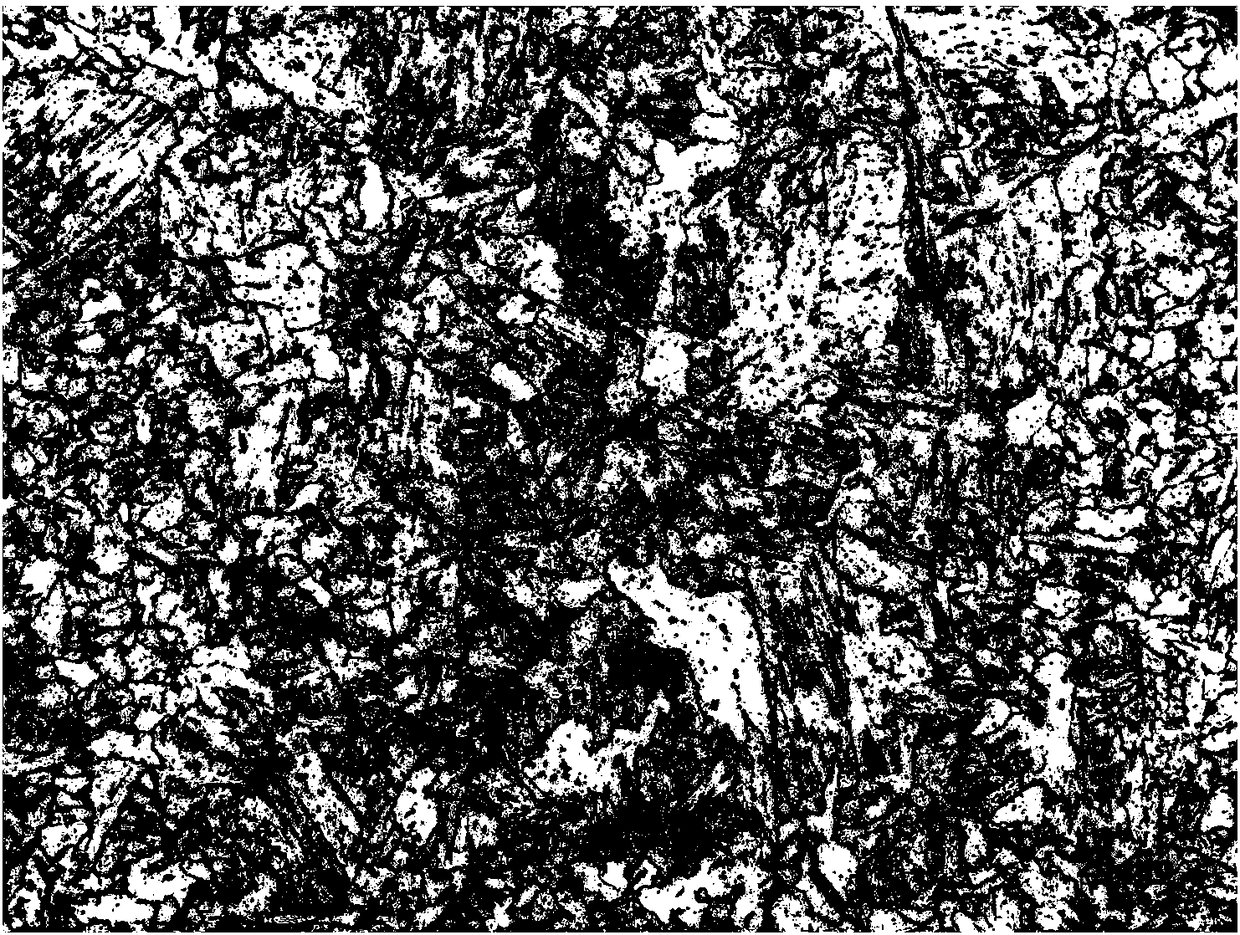

Image

Examples

Embodiment 1-6

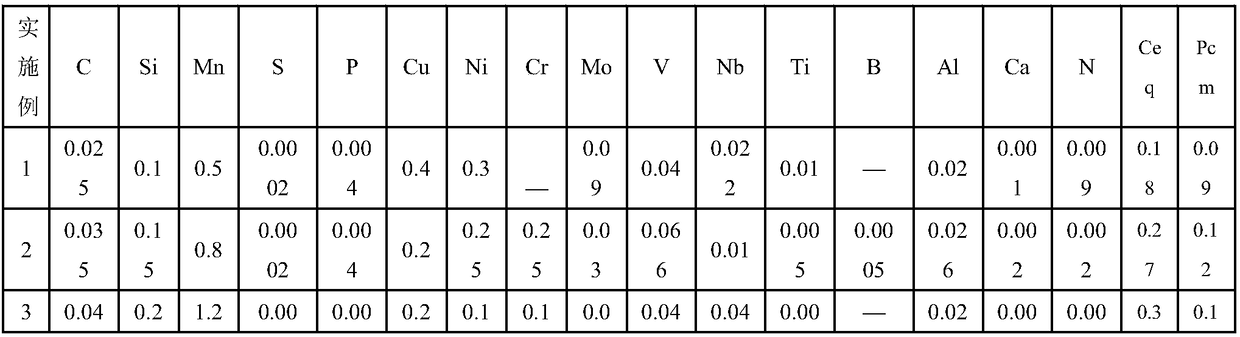

[0049] Table 1 lists the mass percentages of each chemical element in the quenched and tempered acid-resistant pipeline steel of Examples 1-6.

[0050] Table 1. (wt%, the balance is Fe and other unavoidable impurities)

[0051]

[0052]

[0053] The manufacturing method of quenched and tempered acid-resistant pipeline steel of embodiment 1-6 adopts the following steps to obtain:

[0054] (1) Smelting and casting;

[0055] (2) Slab reheating: control the reheating temperature to 1130-1150°C;

[0056] (3) Rough rolling: control the final rolling temperature of rough rolling to 920-1050°C;

[0057] (4) Finish rolling: control the start rolling temperature of finish rolling to be 750-880°C, and the finish rolling temperature to be 700-820°C;

[0058] (5) Cooling: first carry out water cooling, and control the cooling rate of water cooling to 20-60°C / s; the stop temperature of water-cooling is 200-540°C; then carry out air-cooling and natural cooling;

[0059] (6) Quenchi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Charpy impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com