Cooling bed controlled cooling device for hot-rolled micro-alloyed steel bars

A technology of micro-alloying and controlled cooling, which is applied in cooling bed, metal rolling, temperature control, etc., can solve the problems that are not conducive to the formation of fine pearlite structure, the precipitation of micro-alloy elements, and the slow cooling rate of air-cooling process. Achieve the effect of finely controlling the cooling process, refining the lamellar spacing, and increasing the pearlite content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to illustrate the cooling bed controlled cooling device for a hot-rolled micro-alloyed steel bar of the patent of the present invention, the specific implementation is set forth as follows.

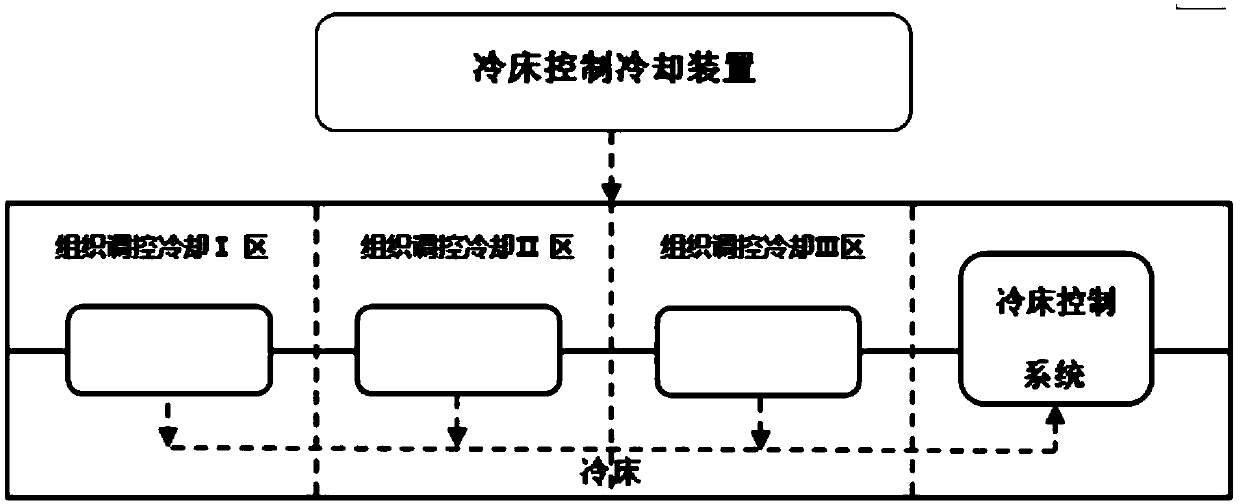

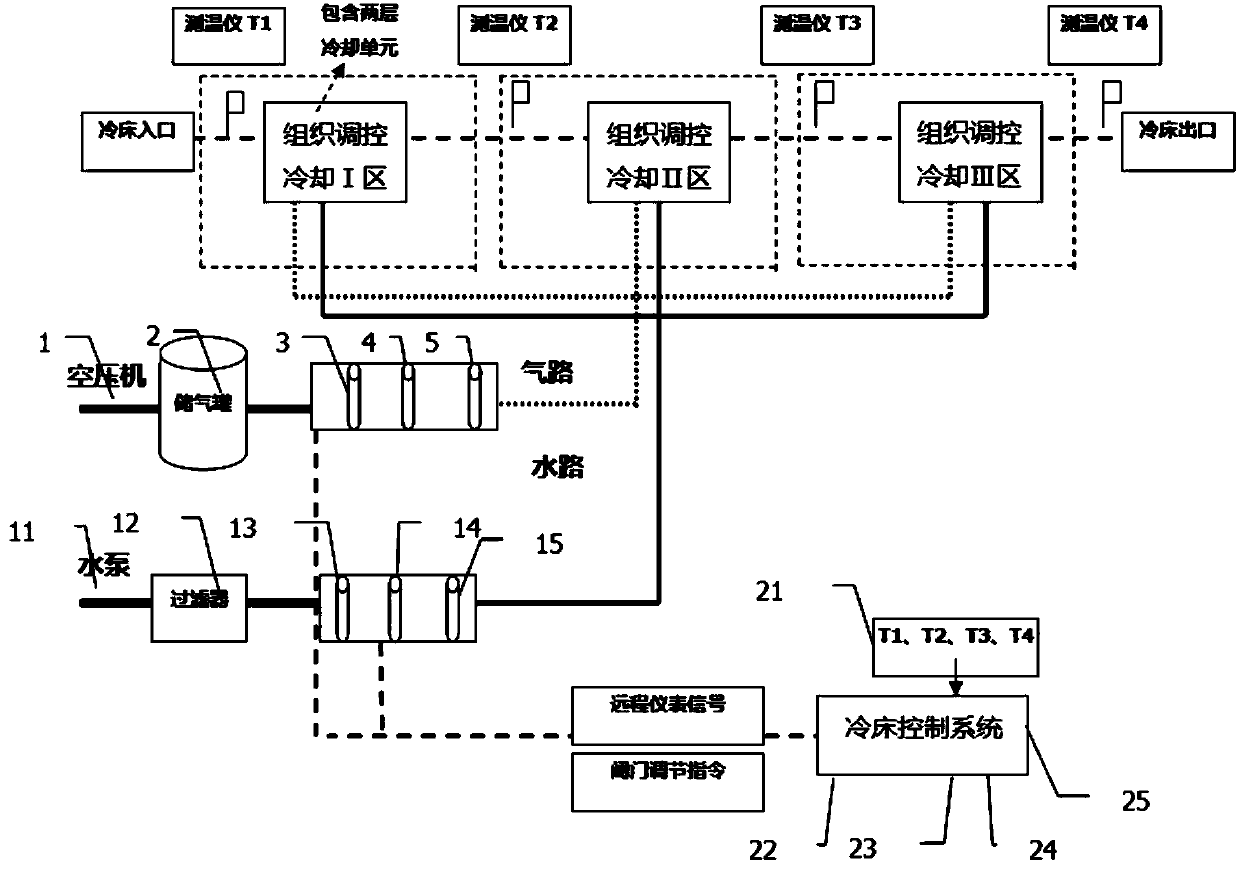

[0021] Such as figure 1 As shown, a schematic structural diagram of a cooling bed control cooling device for hot-rolled microalloyed steel bars according to the present invention is mainly composed of 3 cooling sections and a set of cooling bed control system. The valves, flowmeters and infrared thermometers equipped with remote signal functions realize the control of the cooling speed of the three cooling sections.

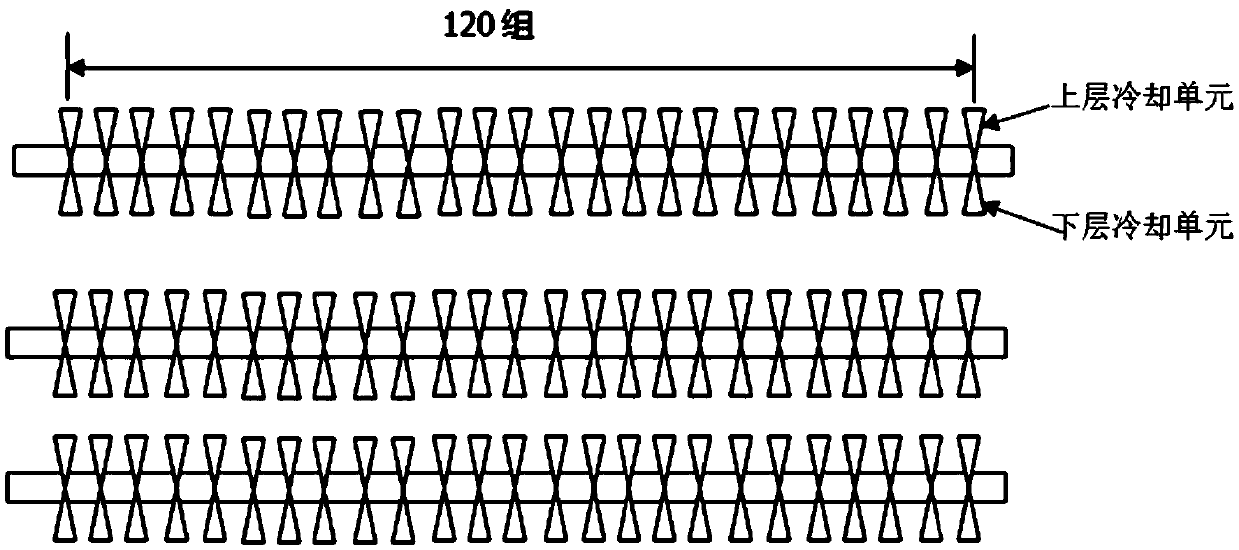

[0022] The three cooling sections are respectively three tissue-regulated cooling zones, which are tissue-regulated cooling zone I, tissue-regulated cooling zone II, and tissue-regulated cooling zone III. The length of each tissue-regulated cooling zone is 120m, covering the entire length of the cooling bed.

[0023] Such as figure 2 Shown is a process con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com