Polypropylene resin composition, special material for aluminum-plated casting polypropylene film, aluminum-plated casting polypropylene film as well as preparation method and application of aluminum-plated casting polypropylene film

A technology of polypropylene resin and composition, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of excessive dosage of additives, achieve good transparency, good mechanical properties, and corona attenuation The effect of improving retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

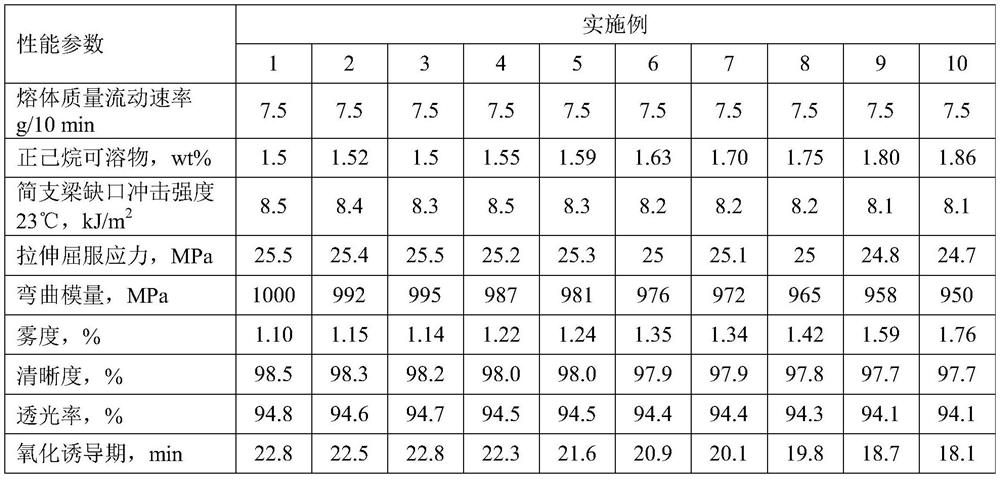

Examples

Embodiment 1

[0140] (1) Preparation of special material for aluminized cast polypropylene film

[0141] First dry compound the main antioxidant, secondary antioxidant, halogen absorber, reinforcing agent, barrier agent and anti-adhesive agent to obtain compounding aids, and then compound the compounding aids with ethylene-propylene random copolymer Melting and blending, and then sending it into an extruder for co-rotating twin-screw extrusion and granulation to obtain a special material for aluminum-coated cast polypropylene film.

[0142] The conditions of melt blending include: the blending temperature is 45°C, the blending time is 3min, operated under a nitrogen blanket, N 2 The pressure is 0.15MPa;

[0143] The conditions for extrusion granulation include: the granulation temperature is 210° C., the cutting water temperature is 63° C., and the screw speed is 180 rpm.

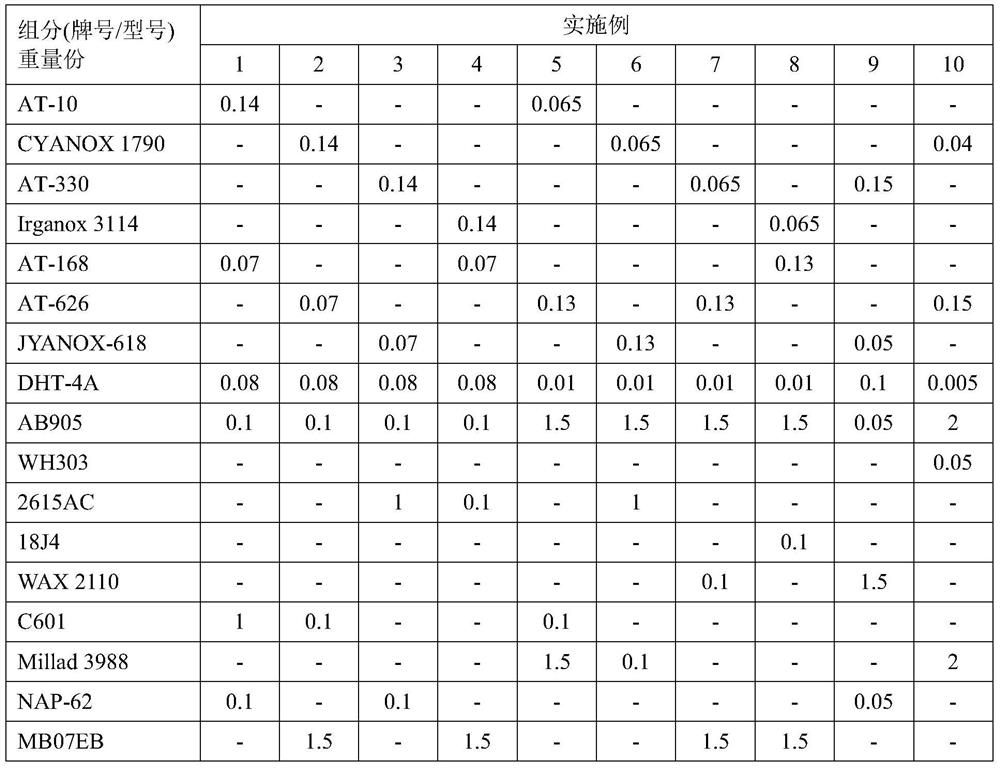

[0144] Wherein, based on 100 parts by weight of the ethylene-propylene random copolymer, see Table 1 for each raw ma...

Embodiment 2-10

[0148] According to each step of Example 1, the aluminum-coated cast polypropylene film special material and the aluminum-coated cast polypropylene film were respectively prepared. The difference is the raw materials and dosage in the compounding auxiliary agent, see Table 1 for details.

[0149] Raw materials and consumption of compounding auxiliary agent in each embodiment of table 1

[0150]

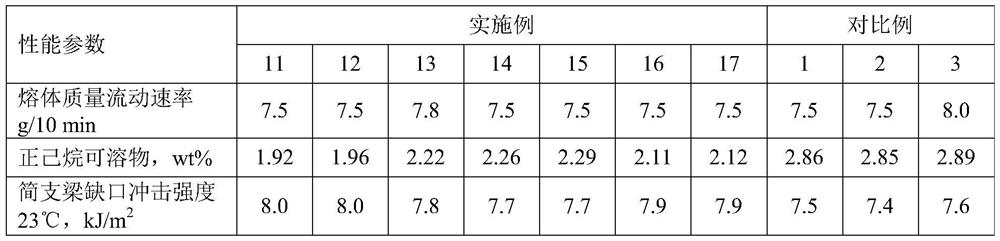

Embodiment 11

[0152] According to the method of Example 1, the difference is that "1 part by weight of C601" is replaced by "2 parts by weight of C601".

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com