X70 pipeline steel hot-rolled plate roll and production method thereof

A hot-rolled coil and production method technology, applied in the field of iron and steel metallurgy, can solve the problems of high Cr content, increased alloy cost, low temperature, etc., and achieve the effect of high toughness, low cost, and high drop-weight tearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]The chemical composition weight percentage of the steel strip is shown in Table 1. The slab heating temperature is 1178°C, and the total time in the furnace is 187min. The first stage of rolling, that is, the rolling in the austenite recrystallization zone, the starting rolling temperature is 1145°C, the reduction rate of the first pass is > 10%, and the reduction rate of the final pass is ≥ 25%. When the thickness of the rolled piece is 40mm When the temperature reaches 930°C on the roller table, the second-stage rolling is carried out, that is, the rolling in the austenite non-recrystallized zone. The final rolling temperature is 828°C. The device is cooled to 470°C at a rate of 20°C / s. Finally, the steel strip can be obtained.

Embodiment 2

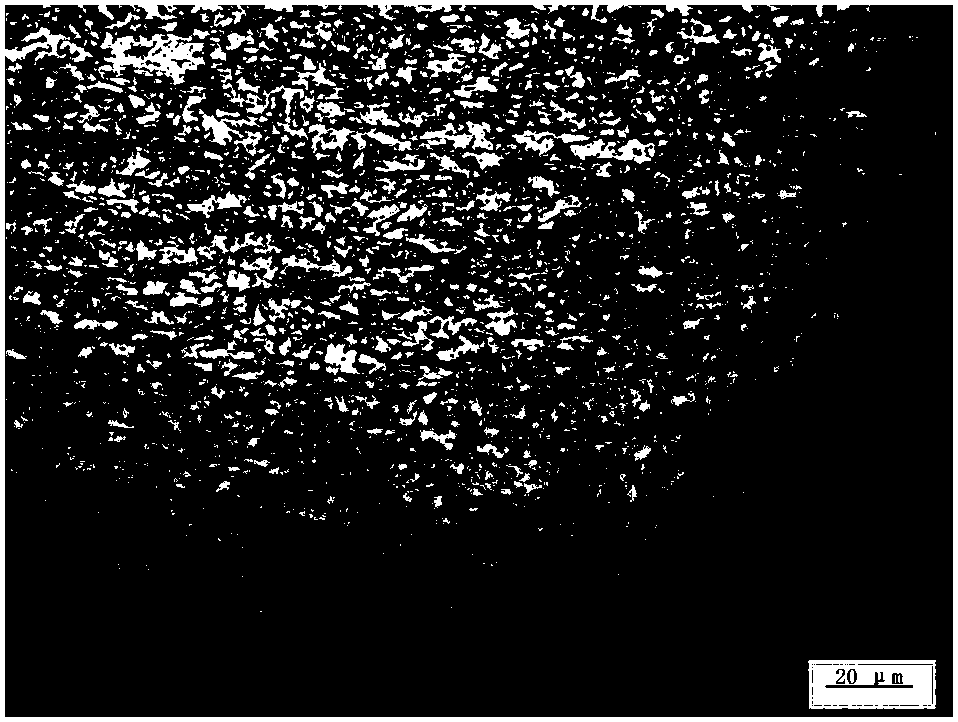

[0047] Embodiment is the same as Example 1, wherein the heating temperature is 1172° C., and the total time in the furnace is 186 minutes. The starting temperature of the first stage of rolling is 1150°C, the thickness of the intermediate billet is 40mm, the starting temperature of the second stage of rolling is 925°C, and the final rolling temperature is 826°C. After rolling, the steel strip enters the high-efficiency density layer Flow cooling device, cooling to 485°C at a speed of 18°C / s. Finally, the steel strip can be obtained. The metallographic structure of the steel strip is shown in figure 1 shown, from figure 1 It can be seen that the fine structure of the steel plate is fine and uniform acicular ferrite.

Embodiment 3

[0049] Embodiment is the same as Example 1, wherein the heating temperature is 1176° C., and the total time in the furnace is 189 minutes. The starting temperature of the first stage of rolling is 1155°C, and the thickness of the intermediate billet is 40mm; the starting temperature of the second stage of rolling is 928°C, and the final rolling temperature is 823°C. After rolling, the steel strip enters the high-efficiency dense layer Flow cooling device, cooling to 456°C at a rate of 22°C / s. Finally, the steel strip can be obtained.

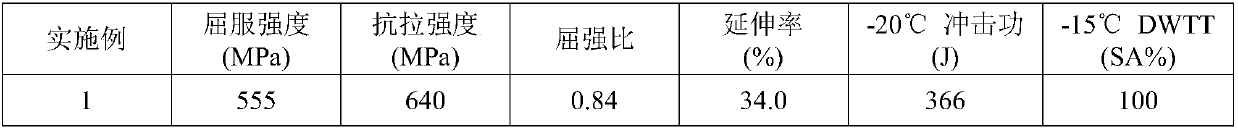

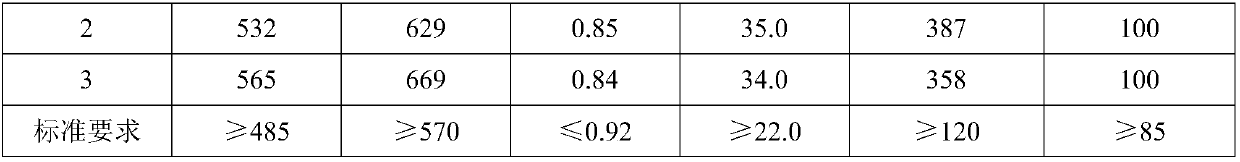

[0050] The steel strips of Examples 1-3 of the present invention were tested for mechanical properties, and the test results are shown in Table 2.

[0051] The steel strips of Examples 1-3 of the present invention were inspected for inclusions and grain size, and the inspection results are shown in Table 3.

[0052] Table 1 The chemical composition (wt%) of the steel strips of Examples 1 to 3 of the present invention

[0053] Example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com