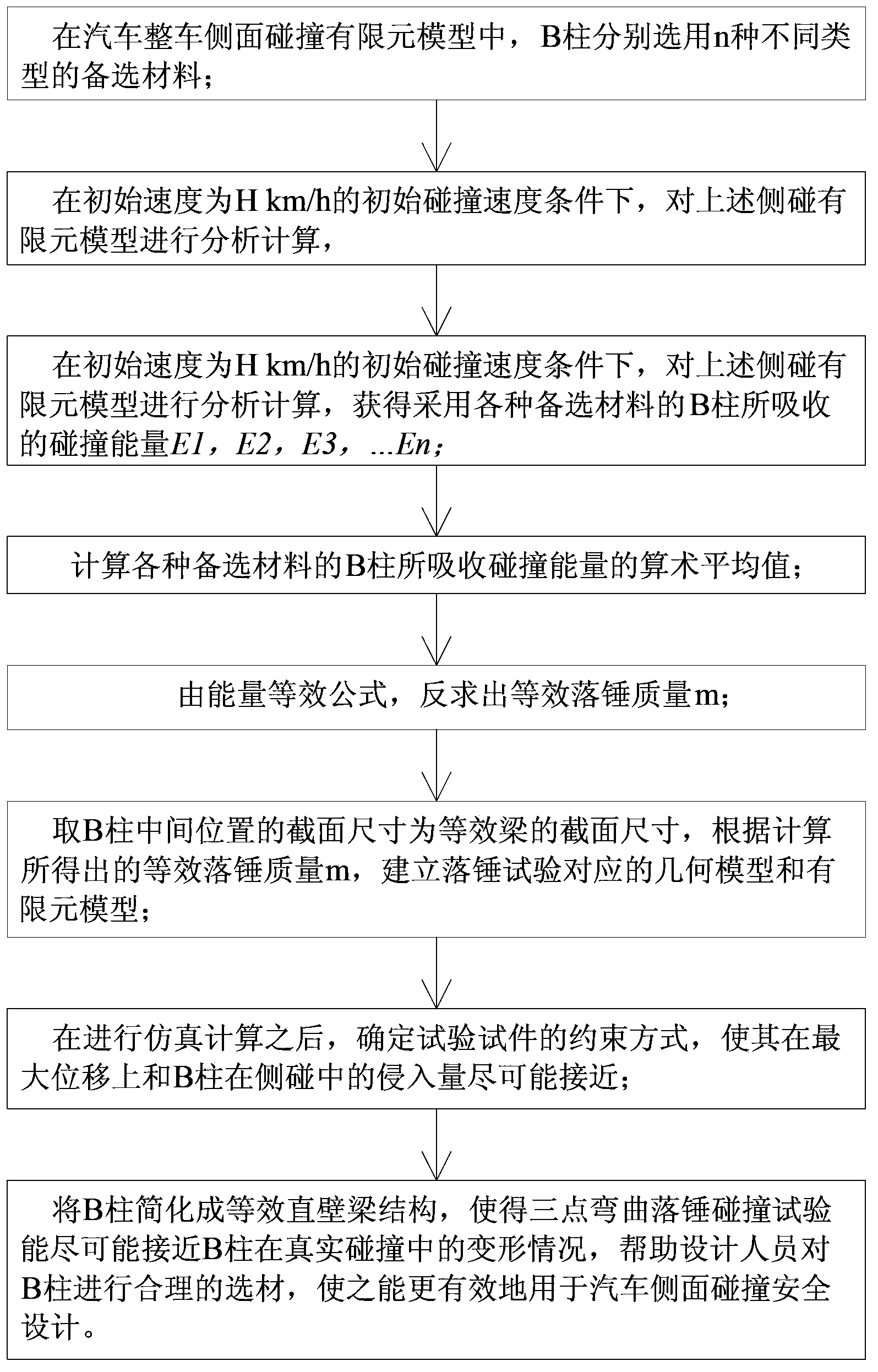

Three-point bending drop collision test method and device for equivalently simplifying beam

A technology of crash test and three-point bending, which is applied in the field of crash test, can solve the problems of heavy dropping weight and flat parts, etc., and achieve the effect of reliable action, easy control and good test consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0088] 1. Test conditions:

[0089] Test equipment: piezoelectric sensors, semiconductor strain gauges, resistive strain gauges, displacement sensors, high-speed cameras.

[0090] Test material: DP780, 1.38mm

[0091] Collision speed: 12m / s

[0092] Hammer head weight: 18.3kg

[0093] 2. Test results:

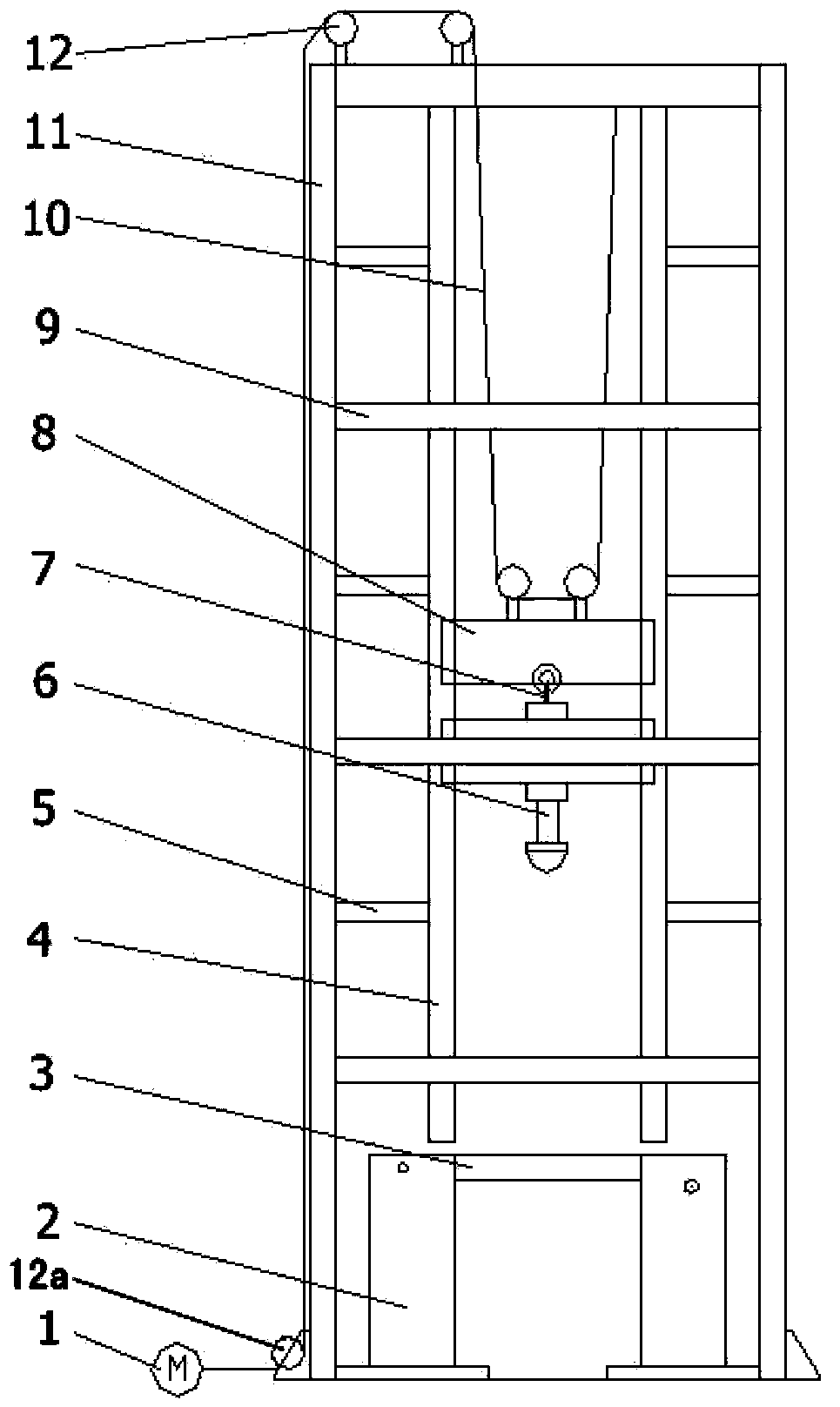

[0094] In the drop weight test, it is necessary to arrange the test bench and the impact hammer head as follows: Image 6 shown.

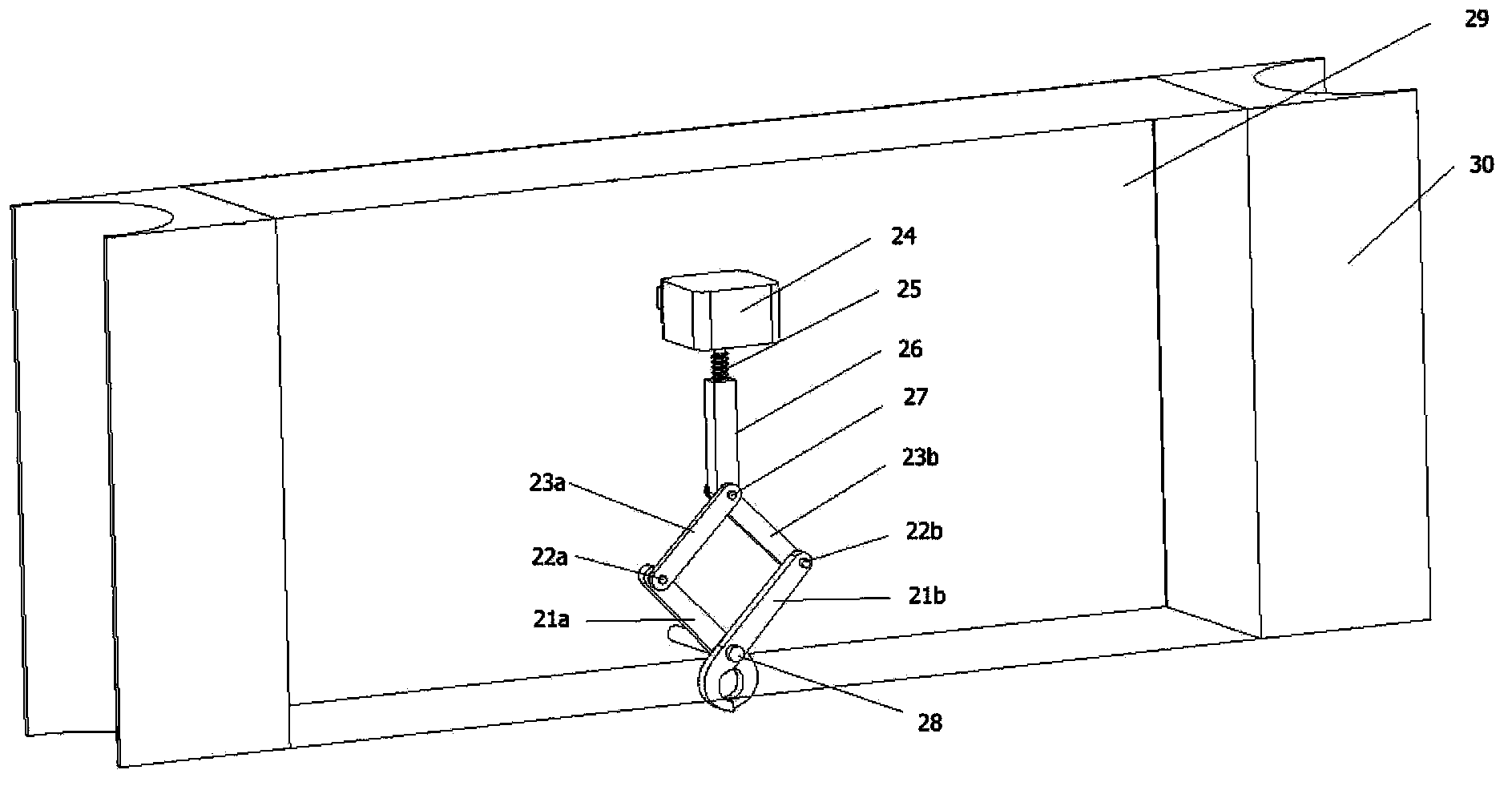

[0095] A set of resistive strain gauges and a set of semiconductor strain gauges are installed on the outer surface of the thin neck of the hammer head to measure the stress of the hammer head neck, which is also the contact force when the hammer head collides with the test specimen.

[0096] In addition, a piezoelectric sensor is installed inside the impact hammer head of the hammer head.

[0097] First raise the drop hammer to the specified height, then control the grapple device to release the grapple, the hammer head falls freely along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com