Sample with DWTT (drop weight tear test) abnormal fracture preventing function and method for manufacturing sample

A fracture and standard sample technology, applied in the field of samples to avoid abnormal fractures of DWTT and their preparation, can solve the problems of easy occurrence of abnormal fractures, difficulty in crack initiation, and work hardening on the hammer side, so as to eliminate the occurrence of abnormal fractures and reduce the The effect of repeated experiments, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention also discloses a sample preparation method for avoiding abnormal fracture of DWTT, which includes the following steps:

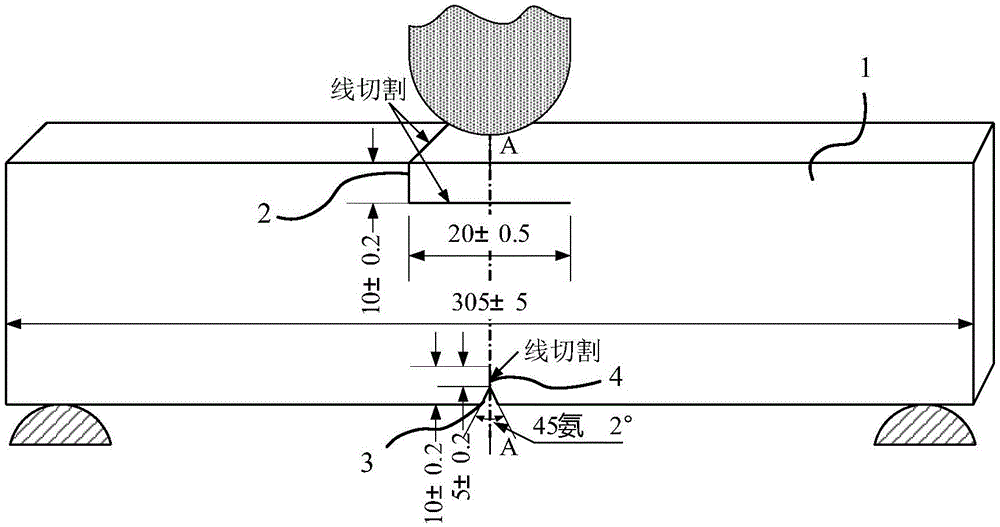

[0027] The first step is to make a standard drop weight sample. First, use sawing and milling methods to process the sample blank, and press a V-shaped notch 3 with a depth of 5±0.5mm and an angle of 45°±2° on one side of the sample blank.

[0028] In the second step, the I-shaped incision 4 is processed. At the root of the V-shaped notch 3, an I-shaped notch 4 is cut by wire EDM.

[0029] In the third step, the L-shaped incision 2 is processed. On the opposite side of the V-shaped notch 3 (hammer side), an L-shaped notch 2 is cut by wire EDM. Among them, the diameter of the molybdenum wire used in the L-shaped incision 2 and the I-shaped incision 4 must be less than or equal to 0.15mm.

Embodiment

[0031] Take the DWTT sample of 33.0mmX80 pipeline steel as an example.

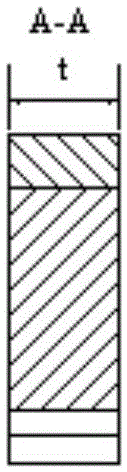

[0032] See figure 1 An example of the present invention provides a sample to avoid abnormal fracture of DWTT. The sample is prefabricated with an L-shaped notch 2 in the middle of the hammer side of the standard sample 1 and an I-shaped notch 4 at the root of the V-shaped notch 3.

[0033] The preparation method is prepared according to the following steps:

[0034] Step 1. Make a standard drop weight sample. First, use the method of sawing and milling to process the sample blank, and press the V-shaped notch 3 with a depth of 5±0.5mm and an angle of 45°±2° at the center line of one side of the sample blank.

[0035] Step two, I-shaped incision 4 processing. At the root of the V-shaped notch 3, an I-shaped notch 4 is cut by wire EDM. The depth of the I-notch in the width direction of the sample is 5±0.2 mm.

[0036] Step three, L-shaped incision 2 processing. On the opposite side of the V-shaped notch 3 (hammer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com