High-tenacity steel plate for ocean engineering and manufacturing method thereof

A marine engineering and high toughness technology, applied in the field of marine engineering steel, can solve the problems of high content and high production cost, and achieve the effect of less alloying elements, low cost and strong feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

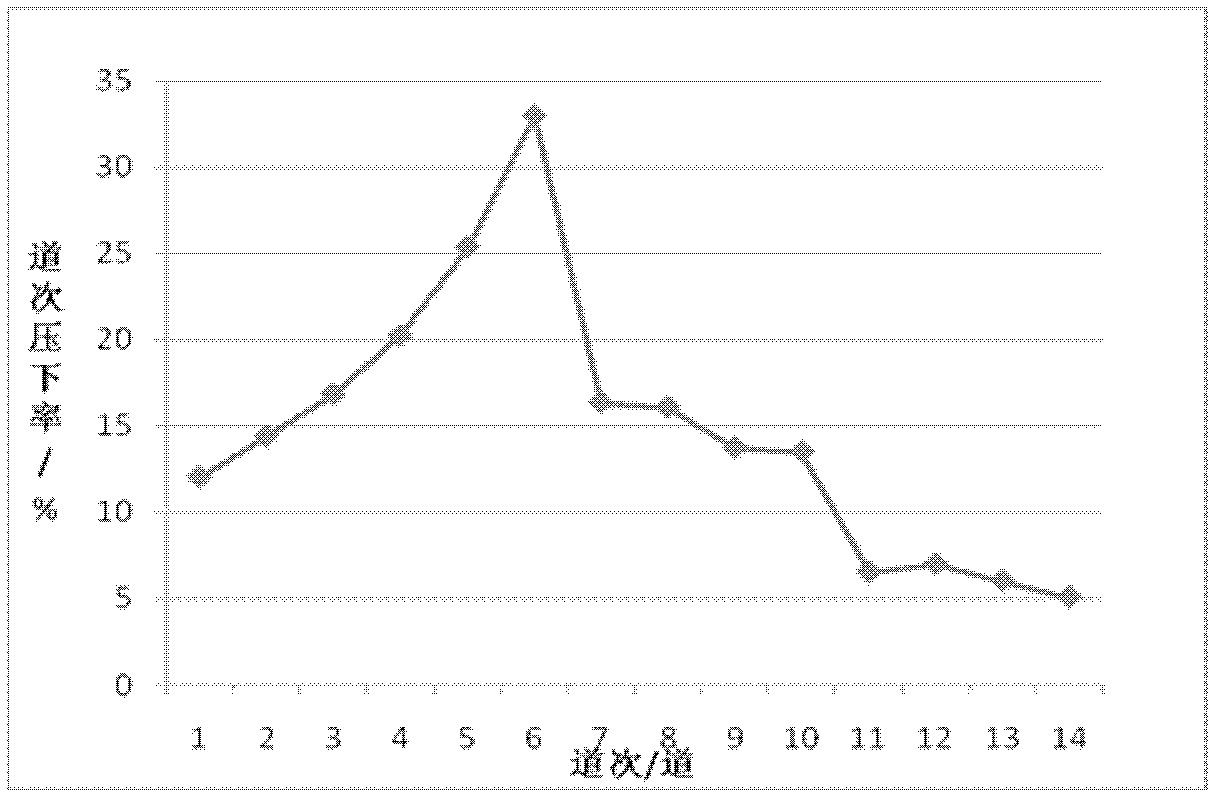

[0048] The thickness of low-cost high-strength marine engineering steel plate is 30mm, and its chemical composition is: C 0.04%, Si0.24%, Mn1.52%, Alt0.034%, Nb0.048%, V0.052%, Ti0.015% , Mo0.33%, Ni0.3%, Cu0.21%, P0.01%, S0.0029%, and the rest are iron Fe and unavoidable impurities. The billet size is 300*2400*2700mm, the steel plate size is 30*2600*24900mm, and the segregation of the low-magnification inspection center of the cast billet is C-class 0.5. Table 1 is the controlled rolling and controlled cooling process parameters under this composition, and Table 2 is in the The mechanical properties obtained under the process parameters. Table 3 Aging impact performance and Z-direction performance of steel plates. attached figure 1 Rolling regulations for 30mm thick steel plate, attached figure 2 , attached image 3 And attached Figure 4 It is the microstructure of 30mm thick steel plate. It can be seen that the structure of the steel plate is mainly composed of massi...

Embodiment 2

[0056] The thickness of low-cost high-strength marine engineering steel plate is 50mm, and its chemical composition is: C 0.06%, Si0.18%, Mn1.49%, Alt0.039%, Nb0.046%, V0.05%, Ti0.014% , Mo0.36%, Cu0.22%, Ni0.4%, P0.009%, S0.0024%, and the rest are iron Fe and unavoidable impurities. The size of billet is 300*2400*3550mm, the size of steel plate is 50*2500*20448mm, the segregation of casting billet low-magnification inspection center is C class 0.5, table 4 is the controlled rolling and controlled cooling process parameters under this composition, table 5 is in this composition The mechanical properties obtained under the process parameters. Table 6 Aging impact performance and Z-direction performance of steel plates. Table 7 shows the results of the drop weight test on the steel plate. The measured non-plastic transition temperature TNDT of the 50mm thick steel plate is -60°C. Table 8 -40°C impact energy of welded joints when the line energy is 50kJ / cm. attached Figure 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com