Drop weight tear test system and method thereof

A drop weight tear test and hammer head technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of poor accuracy and repeatability of test results, large dimensional tolerances, etc., and achieve easy operation, good stability, system The effect of low energy consumption

Active Publication Date: 2014-01-15

BC P INC CHINA NAT PETROLEUM CORP +1

View PDF5 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

and D p Accurate testing is directly related to the sample size and notch size and type, but in the current standards such as API RP 5L3, GB/T 8363, AS

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

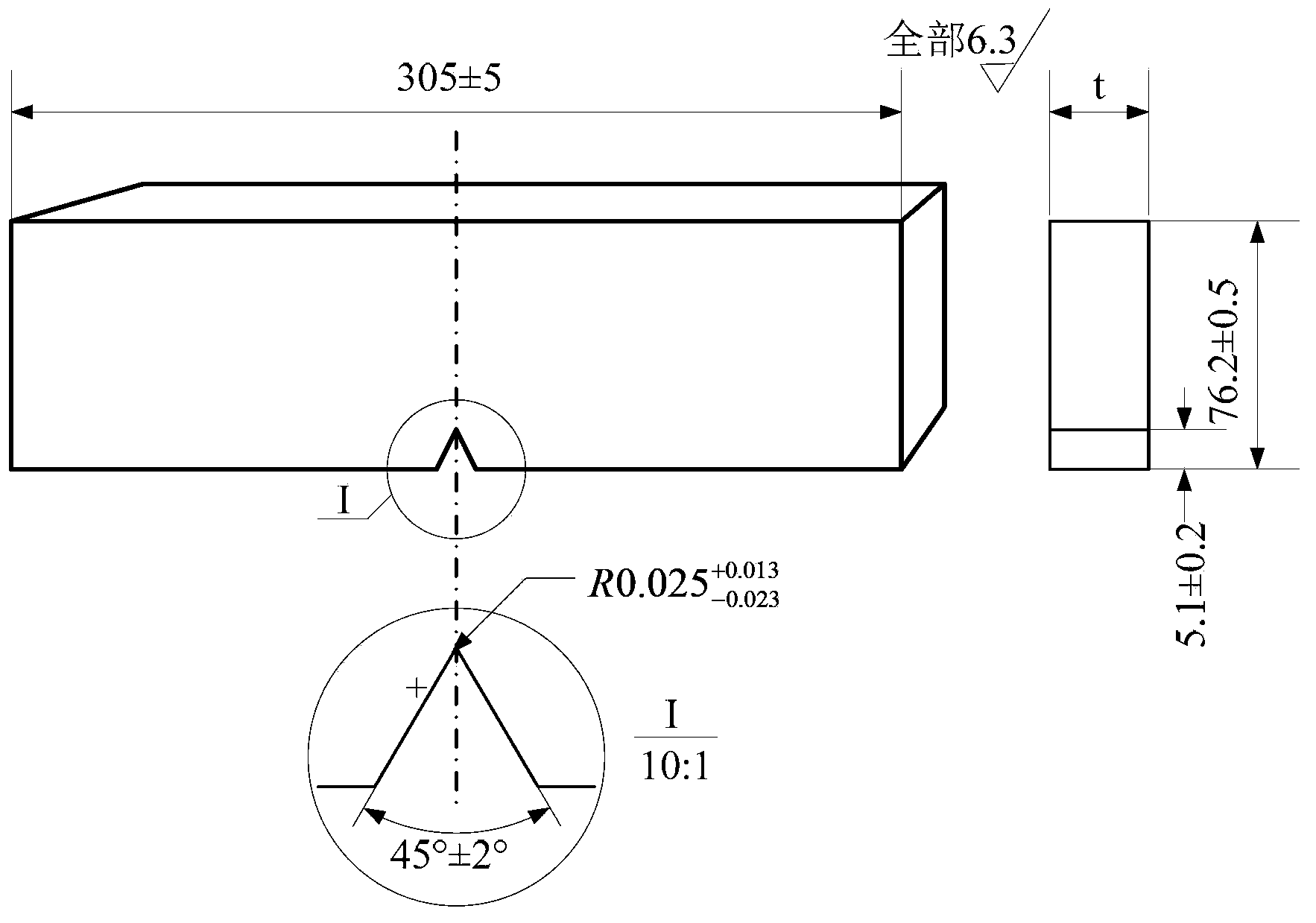

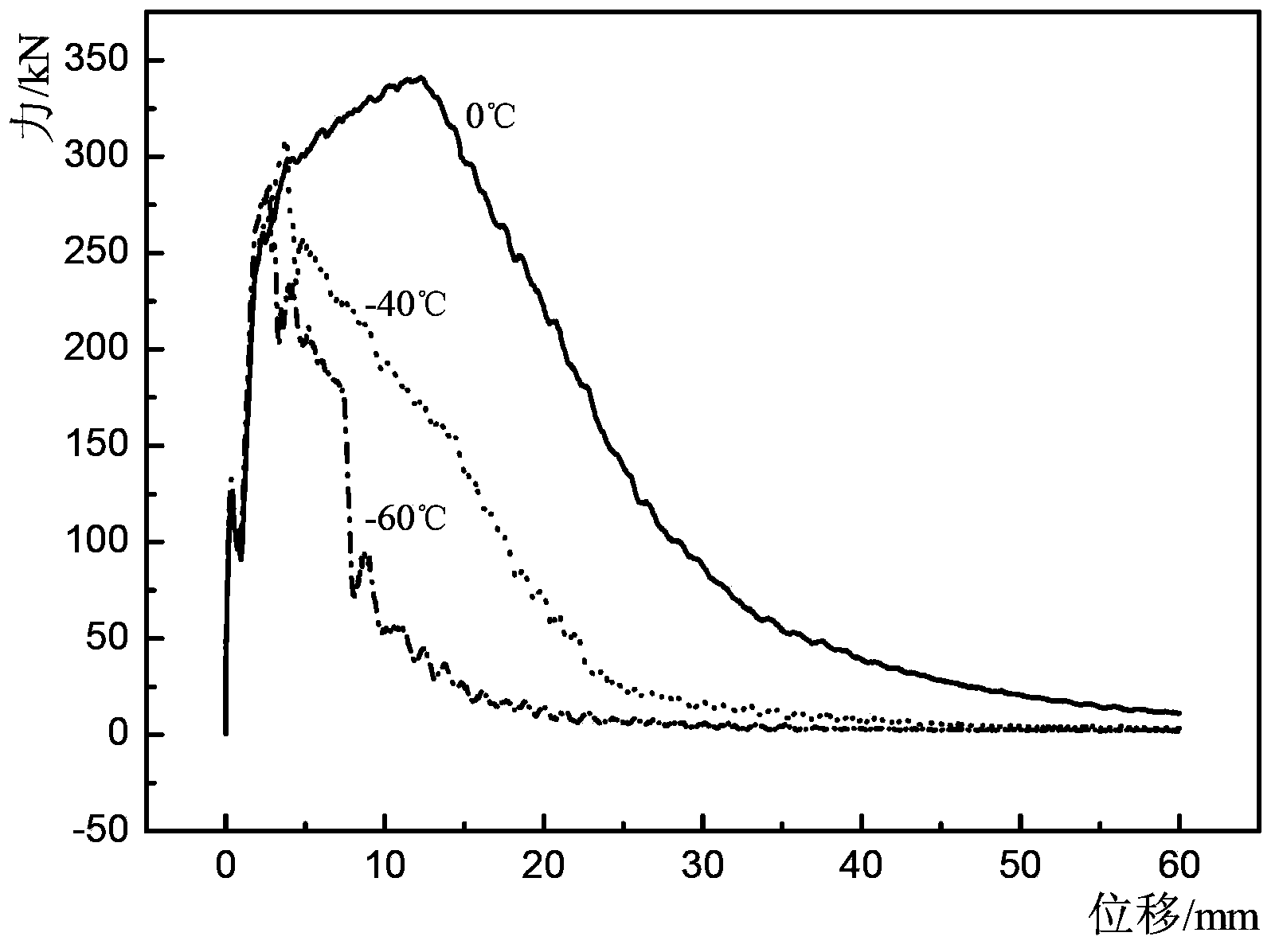

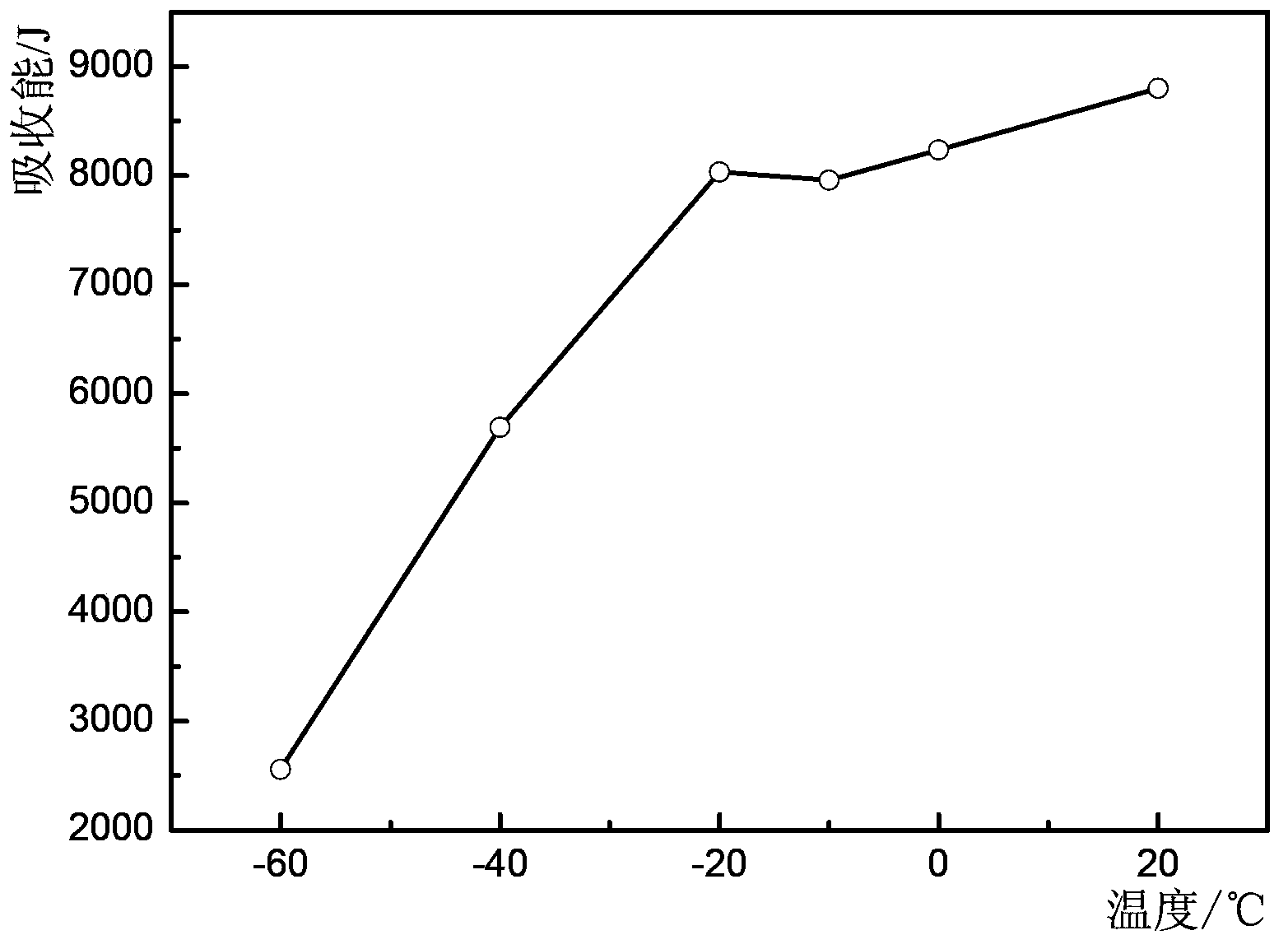

The invention discloses a drop weight tear test system and a method thereof, wherein the system comprises a mainframe, a hammering device, a lifting and releasing device and an energy testing and controlling device. The energy testing and controlling device is arranged on the mainframe and the hammering device, for acquiring hammering energy of the hammering device. The hammering device comprises a swing rod, a hammerhead and an impact blade, one end of the swing rod is fixedly connected with a central shaft of the mainframe, the other end is fixedly connected with the hammerhead, the impact blade is fixed on the central position on the internal side of the top of the hammerhead, and a sample anvil block is arranged on a tangential position of a hammerhead movement track. The method comprises: placing a sample on the sample anvil block; once horizontally punching and breaking the sample with the hammerhead from the back side of a sample gap; and testing force-time and displacement-time curves in a punching and breaking process by the energy testing and controlling device, and calculating and displaying drop weight tear energy of the sample. The system and the method implement large-scope measurement of breaking-resistant energy of pipeline steel or a steel pipe, and have advantages of low detection energy consumption, accurate test result and simple test.

Description

technical field [0001] The invention relates to the technical field of metal material testing, in particular to a drop weight tearing test system and a method thereof. Background technique [0002] With the rapid growth of the world's demand for energy, the construction of oil and gas pipelines tends to use large-diameter, high-strength pipeline steel and steel pipes to ensure that the pipelines are in service and run under high pressure. In this case, how to control the ductile crack propagation of pipelines It is necessary to consider the safety factor. Therefore, it is necessary to predict and control the crack growth resistance of the material, that is, the crack arrest toughness, in the design of pipeline fracture resistance. Pipeline crack arrest prediction methods are usually based on Charpy absorbed energy (CVN), falling weight tear (DWTT) absorbed energy and full-scale burst tests. The CVN value test results of pipeline steel and steel pipe are generally not more ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/303

Inventor 何小东冯耀荣韩新利蔺卫平霍春勇李娜王亚龙布鲁克

Owner BC P INC CHINA NAT PETROLEUM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com