Testing device and testing method capable of simulating pipeline blasting fracture morphology

A technology of blasting fracture and testing device, which is applied in the direction of measuring device, using one impact force to test the strength of materials, instruments, etc., to achieve the effect of good toughness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

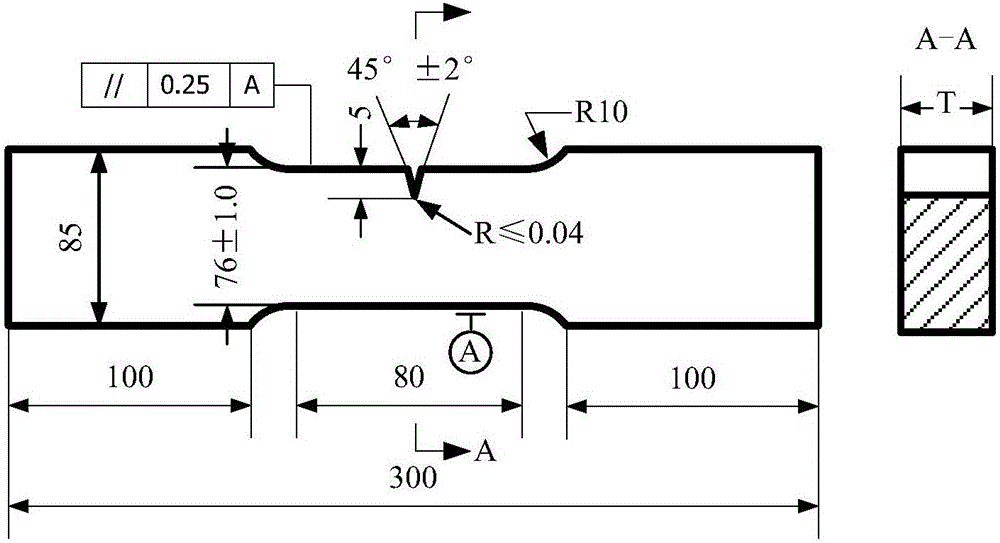

[0031] The present invention is described in further detail below in conjunction with accompanying drawing:

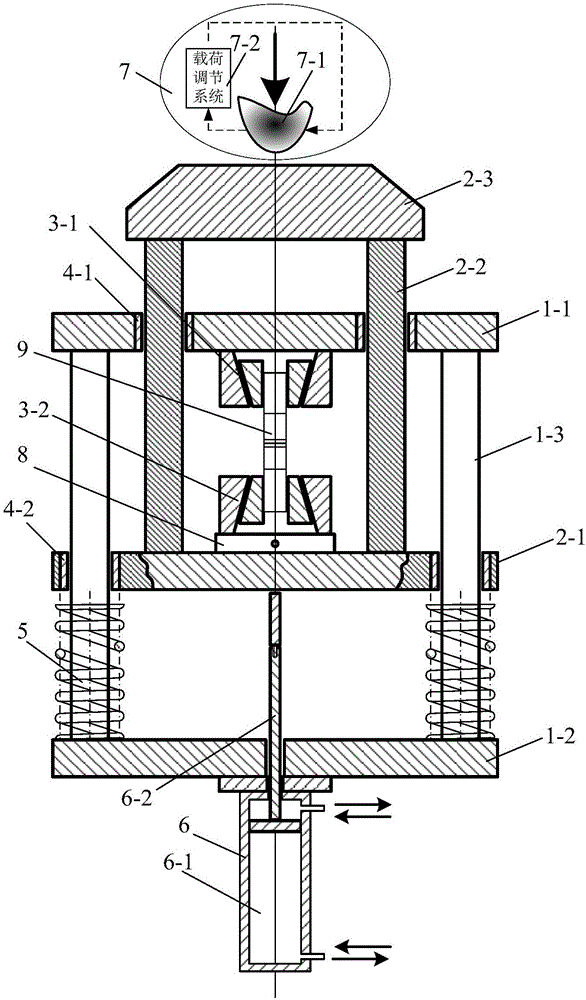

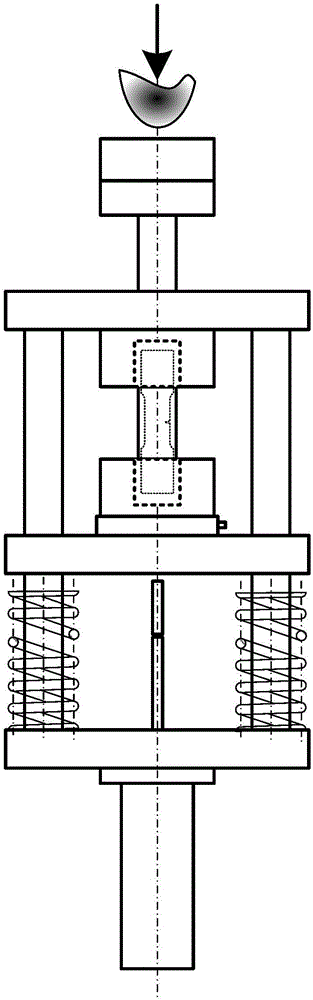

[0032] see figure 1 , the test device for simulating the fracture surface of pipeline blasting in the present invention includes a supporting device, a high-speed impact stretching device, a clamping device, a sliding bearing, a shock absorbing device 5, an ejection mechanism 6, a high-speed loading device 7, and a data acquisition system 8.

[0033] The support device is composed of an upper base plate 1-1, a lower base plate 1-2, and a support column 1-3. Both the upper base plate 1-1 and the lower base plate 1-2 are rectangular; the upper base plate 1-1 and the lower base plate 1-2 are connected by four circular support columns 1-3 with the same size and structure, and the support columns 1-3 are evenly distributed in the At the four corners of the upper base plate 1-1 and the lower base plate 1-2. Two bearing holes are symmetrically opened on the upper center lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com