Carbon fiber fuzzing quantity testing device and carbon fiber fuzzing quantity testing method

A carbon fiber and fluffing technology, which is applied in the fiber field, can solve the problems that affect the reliability of the results, and do not consider the influence of tow broadening on the test results of carbon fiber fluffing characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

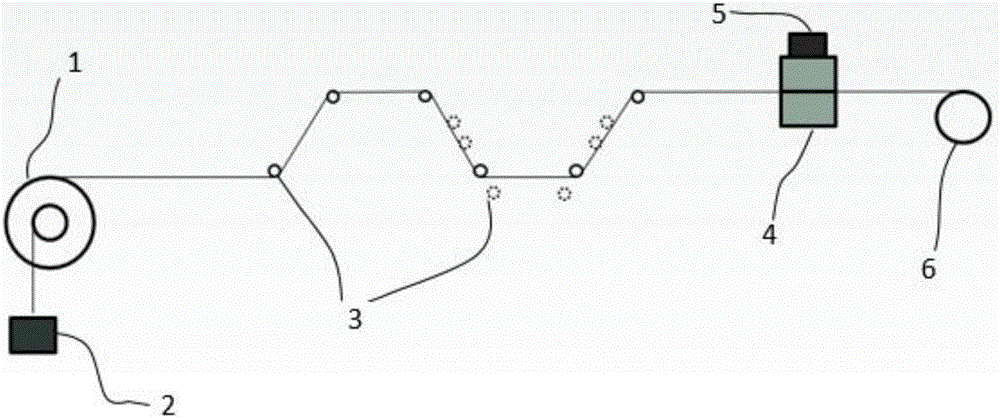

[0033] The invention provides a carbon fiber fluff collecting device, which is characterized in that: it comprises a tow unwinding device, a tow unfolding device, a fluff adsorption device and a winding device sequentially connected according to the traveling direction of the carbon fiber;

[0034] The tow unwinding device is provided with a falling weight;

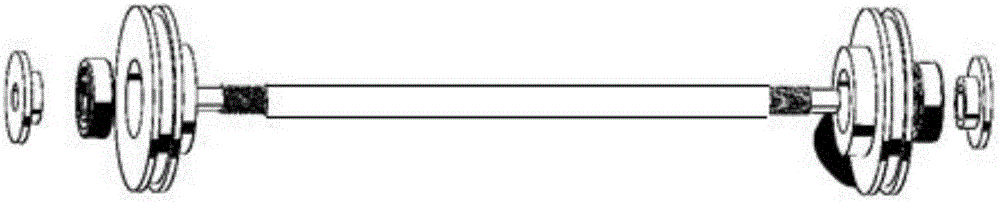

[0035] The tow spreading device comprises several spreading rods;

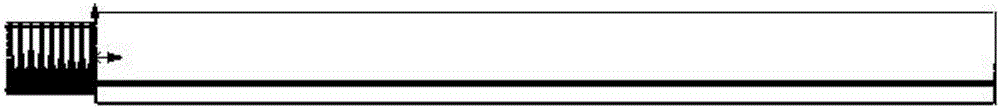

[0036] The fluff absorption device comprises a sponge and a pressure weight placed on the upper surface of the sponge.

[0037] The invention provides a carbon fiber fluff collecting device, which comprises a tow unwinding device, a tow unfolding device, a fluff adsorption device and a winding device connected in sequence according to the traveling direction of the carbon fiber.

[0038] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a carbon fiber fluff collection device according to an embodiment of the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com