Method of joining tantalum clade steel structures

a technology of clade steel and clade, which is applied in the direction of manufacturing tools, welding/soldering/cutting articles, transportation and packaging, etc., can solve the problems of high cost of the basic tantalum clad steel section, difficult and expensive fabrication, and brittle and non-corrosion resistant phases in the tantalum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

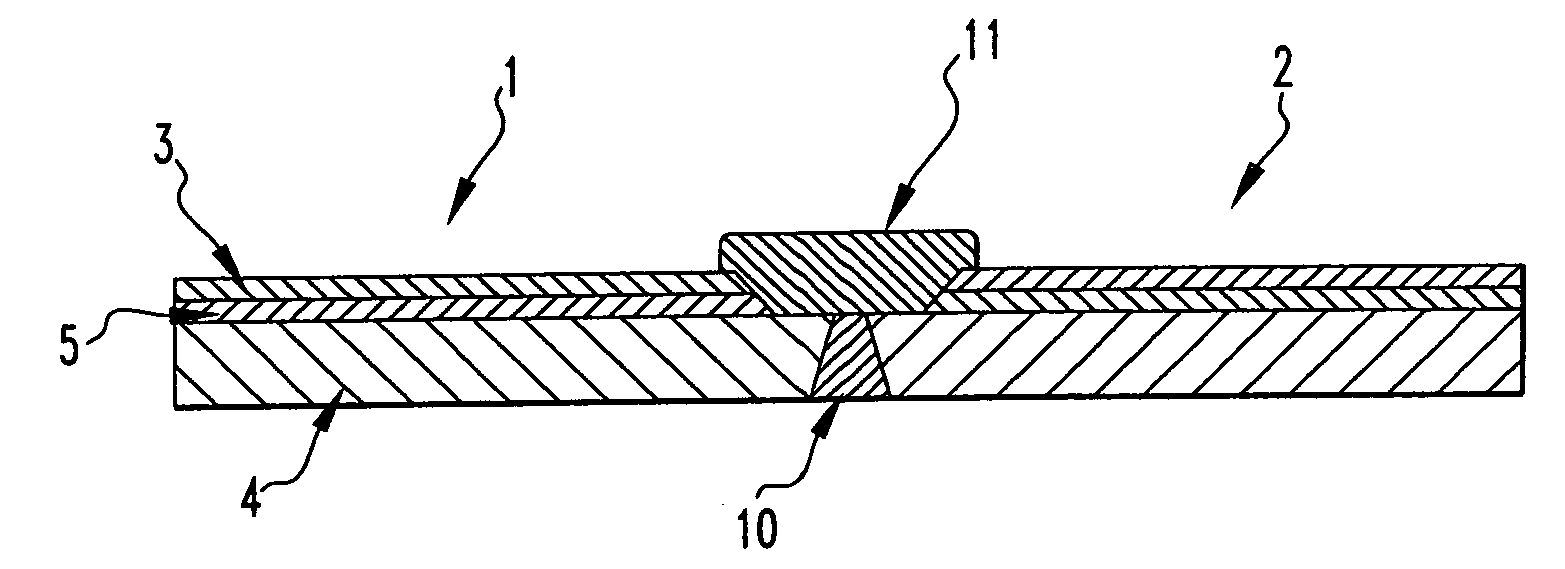

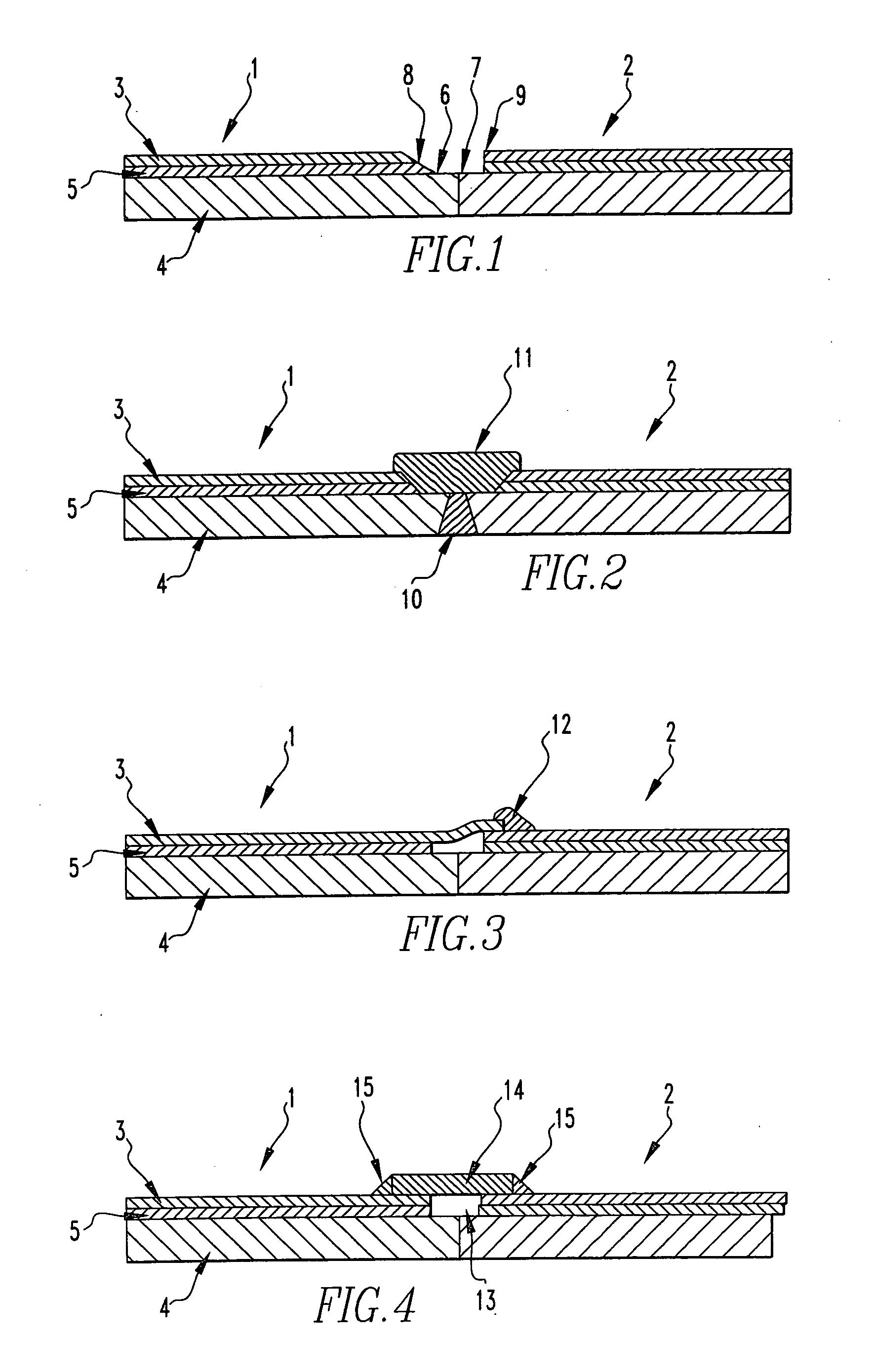

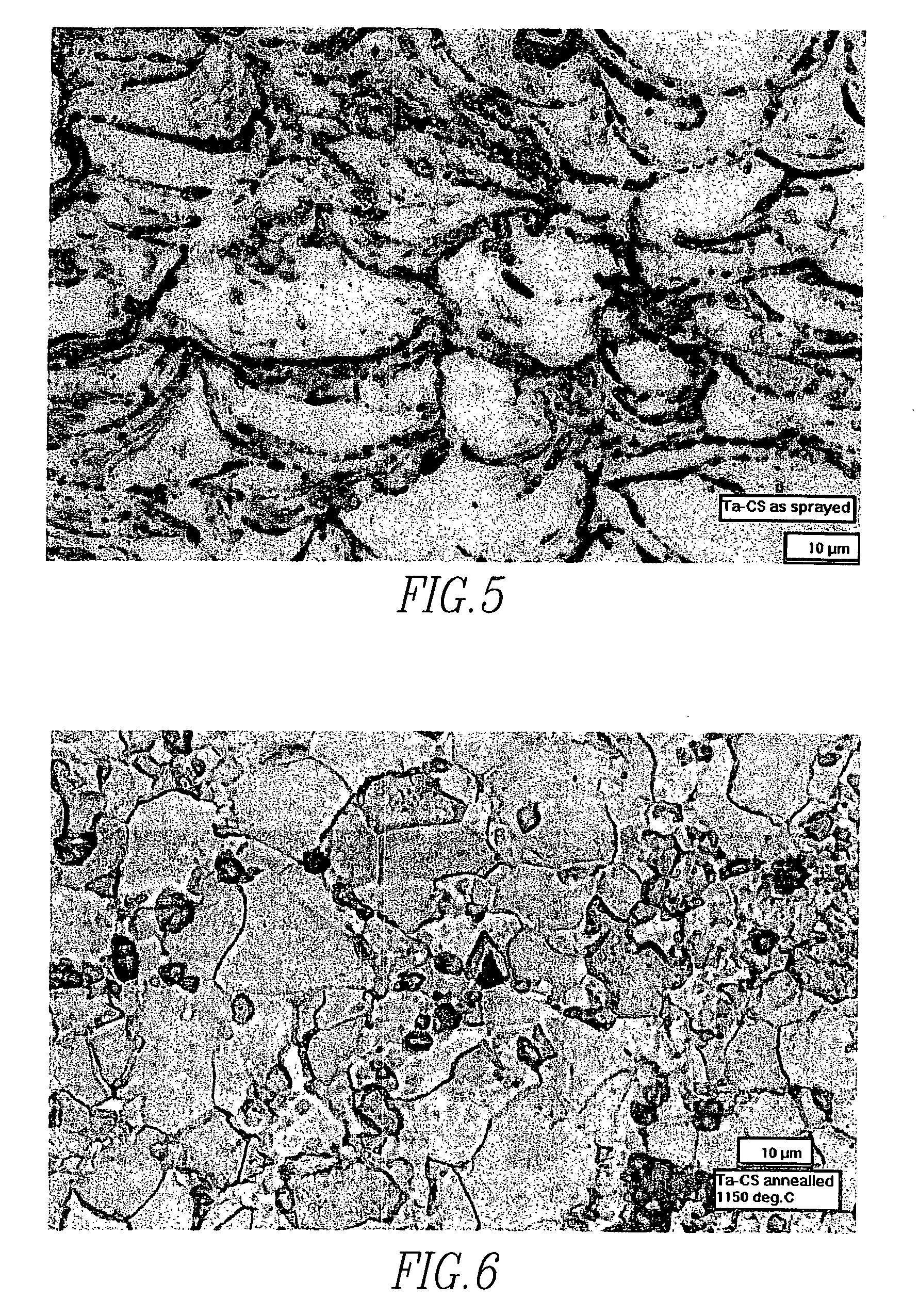

[0017]The present invention is broadly directed to a process for joining tantalum clad steel structures comprising:[0018]a) providing a first tantalum clad section, said first tantalum clad section comprising a tantalum layer over a steel layer, with a bonding layer optionally therebetween, with a portion of said steel layer in an edge region not being covered by said tantalum layer or said bonding layer,[0019]b) providing a second tantalum clad section, said second tantalum clad section comprising a tantalum layer over a steel layer, with a bonding layer optionally therebetween, with a portion of said steel layer in an edge region not being covered by said tantalum layer or said bonding layer,[0020]c) locating said steel edge regions adjacent each other,[0021]d) welding the steel edge regions together,[0022]e) cold spraying a tantalum powder onto the welded edge regions and over the tantalum layers adjacent said edge regions thereby joining the tantalum clad steel sections.

[0023]Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thicknesses | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com