Tyre sulfuration process

A tire vulcanization and process technology, which is applied in the field of vulcanization technology, can solve the problems of reduced physical properties of rubber materials, impact on tire quality, and long curing time, etc., to improve tire quality, improve equipment utilization, and save steam or superheated water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

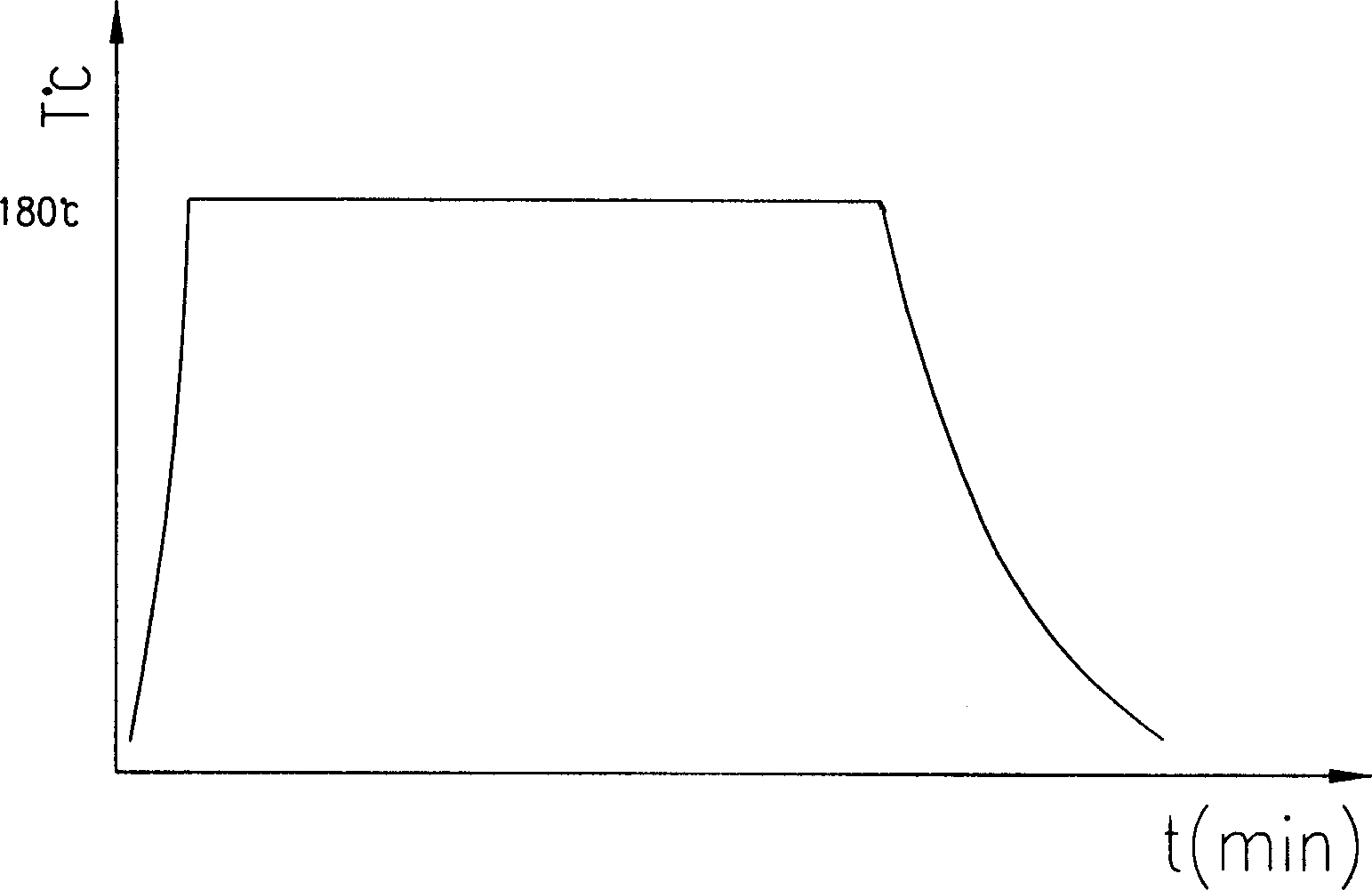

Method used

Image

Examples

Embodiment 1

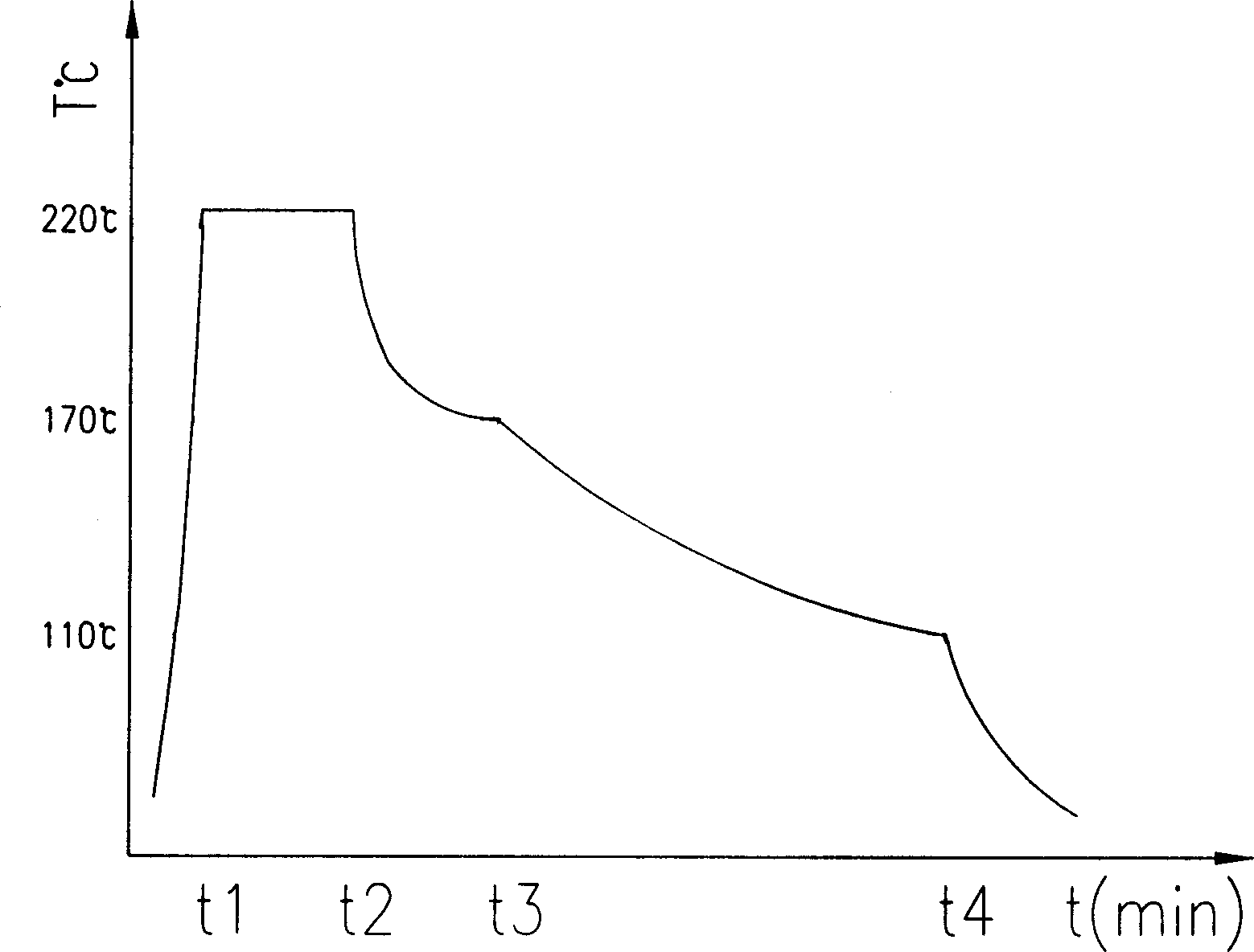

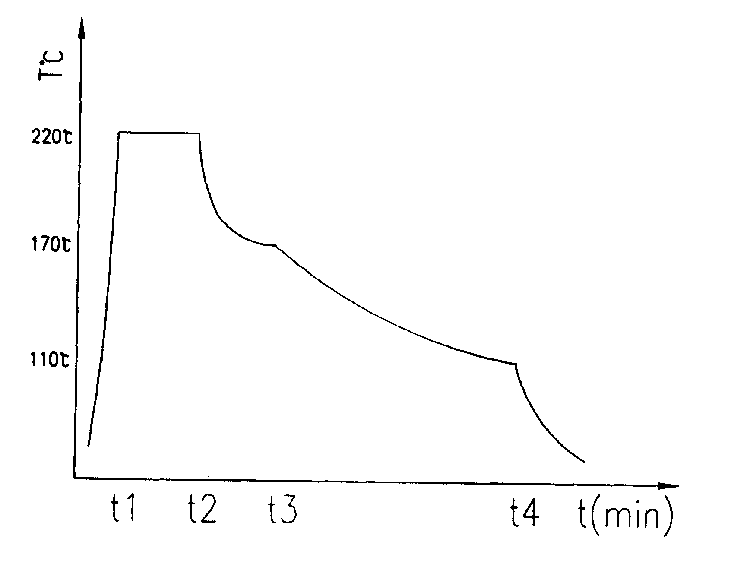

[0015] For 63.5″ tires, high-temperature steam at about 220°C is introduced for about 2 minutes during the vulcanization induction period. Then, in the pre-vulcanization stage, steam is released, and when the temperature drops below 160°C, superheated steam at about 220°C is intermittently introduced. Water circulates in the capsule to make the temperature inside the capsule fluctuate within 10°C above and below the set temperature of 170°C, and keep the pressure for about 5 minutes. During the normal vulcanization stage, when the pressure is kept constant, no steam or overheating Water, keep the pressure for about 44 minutes. The temperature drops from 170°C to about 120°C. The pressure drop ratio at this stage is less than 1.5%, which can be regarded as the pressure remains basically unchanged. The entire vulcanization process takes about 51 minutes, compared with isothermal etc. The 55 minutes required for the entire vulcanization process, the vulcanization process of this p...

Embodiment 2

[0017] For 45″ tires, during the vulcanization induction period, high-temperature steam at about 200°C is introduced for 2 minutes, and then, in the pre-vulcanization stage, superheated water at about 200°C is intermittently introduced to circulate in the bladder to maintain the temperature inside the bladder at 160°C. ±10°C for about 5 minutes. During the normal vulcanization stage, no high-temperature steam or superheated water is introduced, and the pressure is kept for about 7 minutes. During this process, the temperature drops from 160°C to about 110°C, and the pressure drop rate is very small , it can be considered that the pressure remains basically unchanged. The entire vulcanization process takes about 14 minutes, compared with the 16 minutes required for the entire vulcanization process of isothermal and isobaric pressure, the vulcanization process of this process saves about 2 minutes. The quality of the tire is significantly improved, and no It was found that the sc...

Embodiment 3

[0019] For 55″ tires, high-temperature steam at about 210°C is introduced for 2 minutes during the vulcanization induction period, and then, during the pre-vulcanization stage, high-temperature steam at about 210°C is intermittently introduced to circulate in the bladder, and the temperature is maintained at 170±10°C. It lasts for about 6 minutes. During the positive vulcanization stage, no high-temperature steam or superheated water is introduced, and the pressure is kept for about 34 minutes. During this process, the temperature drops from 170°C to about 110°C, and the pressure drop rate is very small, which can be regarded as The pressure remains basically unchanged. The entire vulcanization process takes about 40 minutes, compared with the 43 minutes required for the entire isothermal and isobaric vulcanization process, this process saves about 3 minutes in the vulcanization process. The quality of the tire is significantly improved, and no over-vulcanization stage has been ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com