Internal combustion engine structure with superheated water being sprayed into cylinder

An in-cylinder injection, internal combustion engine technology, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of wasting energy consumption, exhaust heat loss in the cylinder, limiting the improvement of the thermal efficiency of the internal combustion engine, etc. Longevity and effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

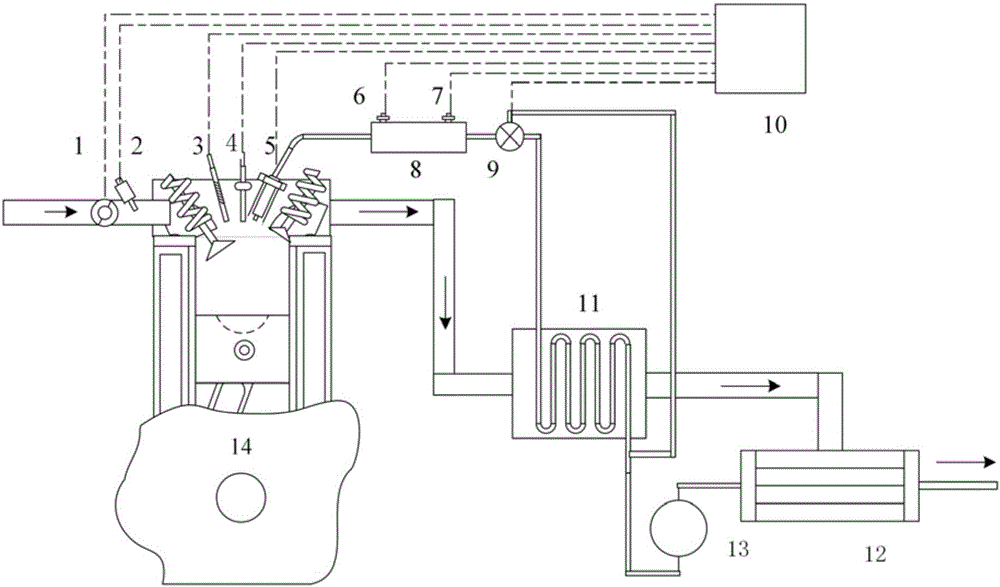

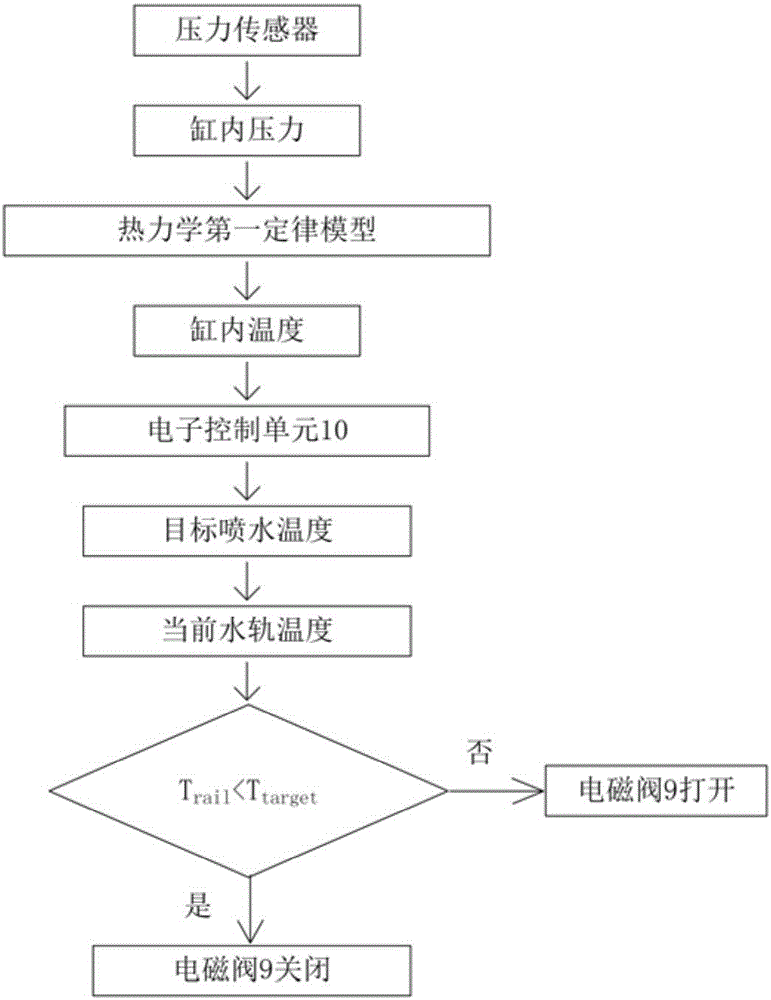

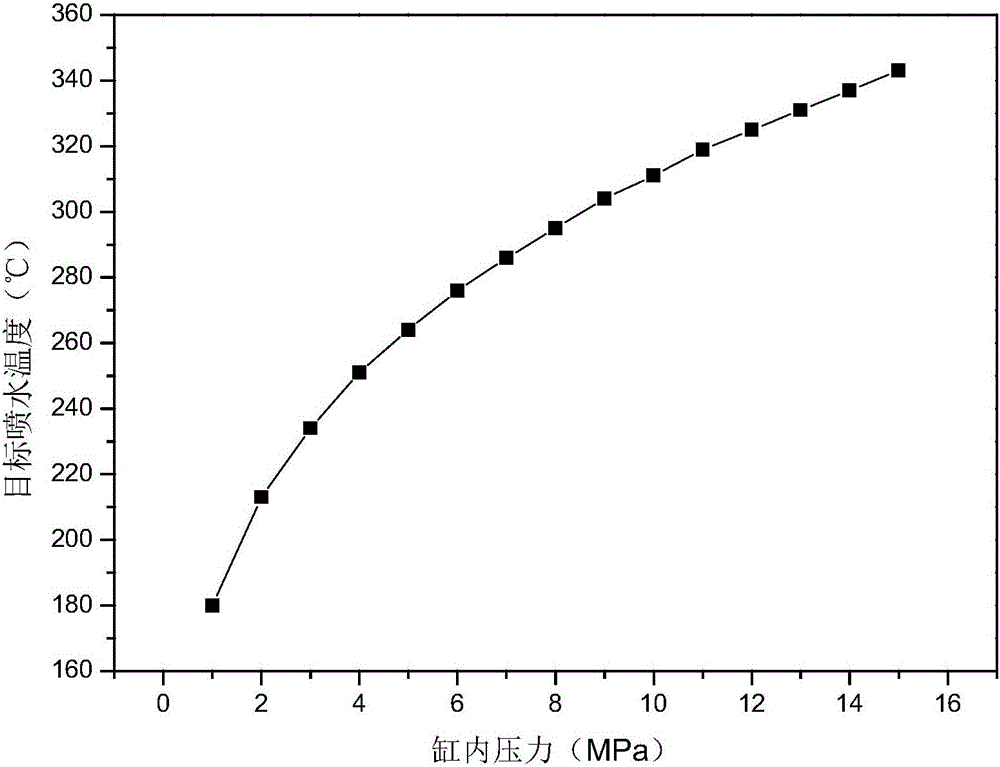

[0020] refer to figure 1 , an internal combustion engine structure for injecting superheated water in the cylinder, including a throttle valve 1, a fuel injector 2, a pressure sensor 3, a spark plug 4, a water spray nozzle 5, a thermocouple 6, a rail pressure sensor 7, a high-pressure water rail 8, and three Through solenoid valve 9, electronic control unit 10, heat exchanger 11, condenser 12, high-pressure water pump 13, internal combustion engine cylinder block 14, condenser 12 is connected to the exhaust output end of the internal combustion engine cylinder block, and the output end of condenser 12 is connected to the heat exchange The input end of the device 11 and the first input end of the three-way electromagnetic valve 9, the output end of the heat exchanger 11 is connected to the second input end of the three-way electromagnetic valve 9, and the output end of the three-way electromagnetic valve 9 is connected to the high-pressure water rail 8, The high-pressure water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com