Method for hot cleanout and paraffin removal of oil well

An oil well and hot washing technology, which is applied to cleaning equipment, earthwork drilling, wellbore/well components, etc., can solve the problems of long recovery period of pumping wells and formation pollution of oil wells, and achieve the effect of reducing wax cleaning cost and investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A conventional pumping unit with a theoretical displacement of 1 cubic meter per hour is used to pump oil.

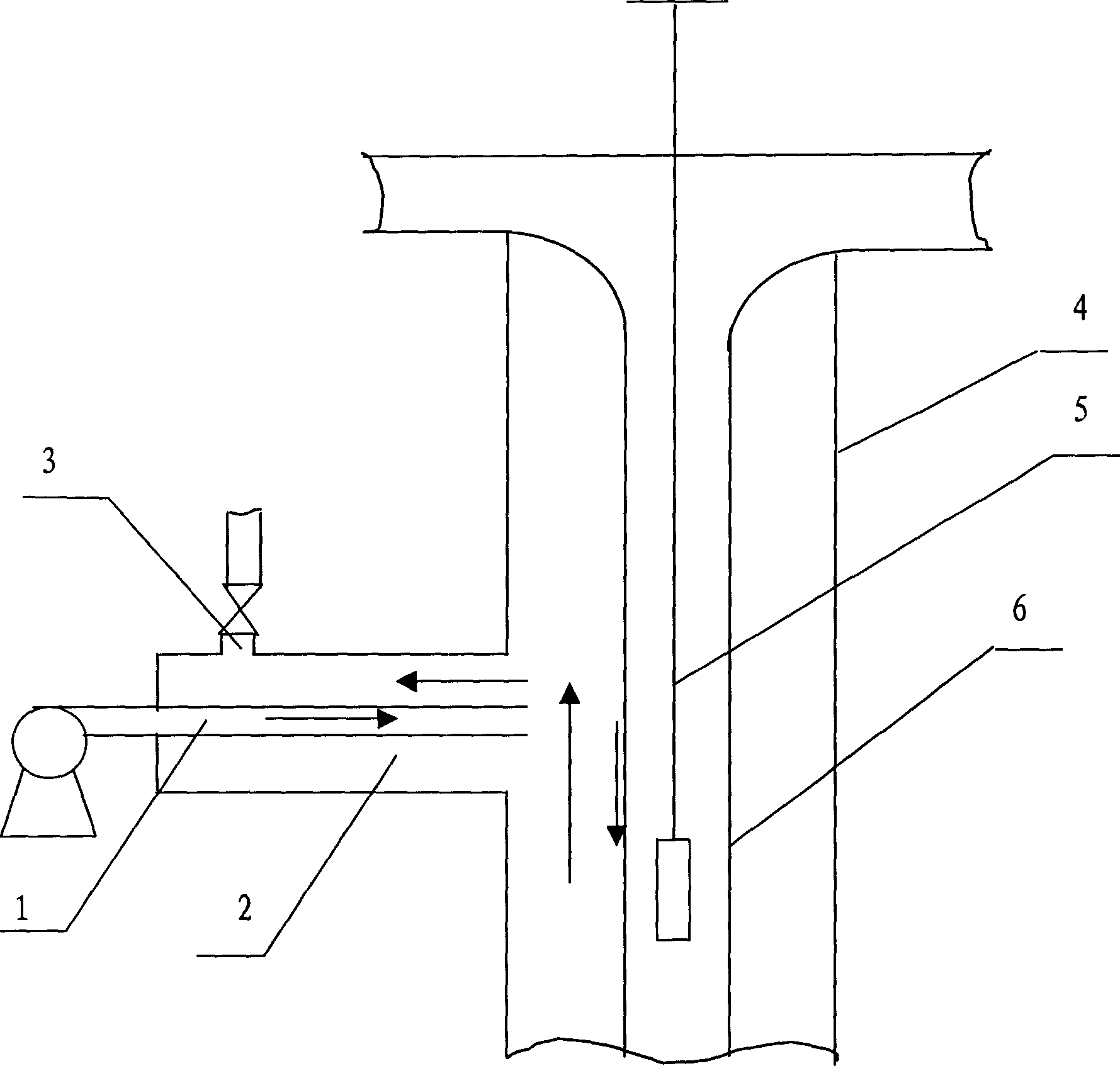

[0033] Put the water tank boiler into 8m 3 For water, the oil well casing gas is used to preheat the water to 70-90°C, and the gas in the casing is controlled to be discharged so that the internal pressure of the casing is lower than the rated pressure of the hot water pump. The above-mentioned hot water heated to 70-90°C is reheated to 100-120°C through the boiler car. Insulate the wellhead, use the water inlet pipe in the double-pipe structure to inject the above-mentioned superheated water at 100-120°C into the casing 4 for 5 minutes, the superheated water will flow down the outer wall of the oil pipe 6, and control the water flow to 0.8-1.2m 3 / hour, which is similar to the theoretical discharge of the pumping unit, so that part of the wax is melted. At the same time, the natural gas in the oil well is collected through the gas header in the double-pipe st...

Embodiment 2

[0037] Put the water tank boiler into 8m 3 For water, the oil well casing gas is used to preheat the water to 70-90°C, and the gas in the casing is controlled to be discharged so that the internal pressure of the casing is lower than the rated pressure of the hot water pump. Insulate well at the wellhead, stop the pumping unit, and reheat the above-mentioned hot water heated to 70-90°C to 100-120°C through the boiler car. Use the water inlet pipe in the double-pipe structure to inject the above-mentioned 100-120°C superheated water into the casing, and continuously inject 3-4 cubic meters of 100-120°C superheated water to melt all the wax deposits in the oil well. Start the pumping unit, and at the same time, continuously inject superheated water of 100-120 degrees, and the water injection flow rate is 1 cubic meter per hour, so as to ensure that the melted wax is completely discharged from the oil pipe to avoid re-waxing.

[0038] The above-mentioned embodiment 2 is suitable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com