Technique for preparing activated carbon from wood raw material by external-heating-free one-step process and carbon activating device

A technology of activated carbon and external heating, applied in the fields of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of waste of heat energy, increase the temperature of the feed end of the converter, and high fuel costs, so as to reduce production costs and save energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

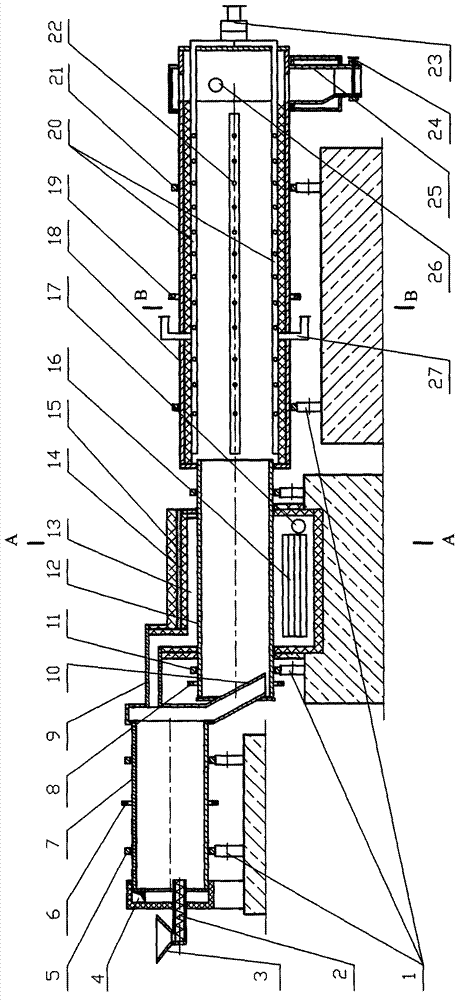

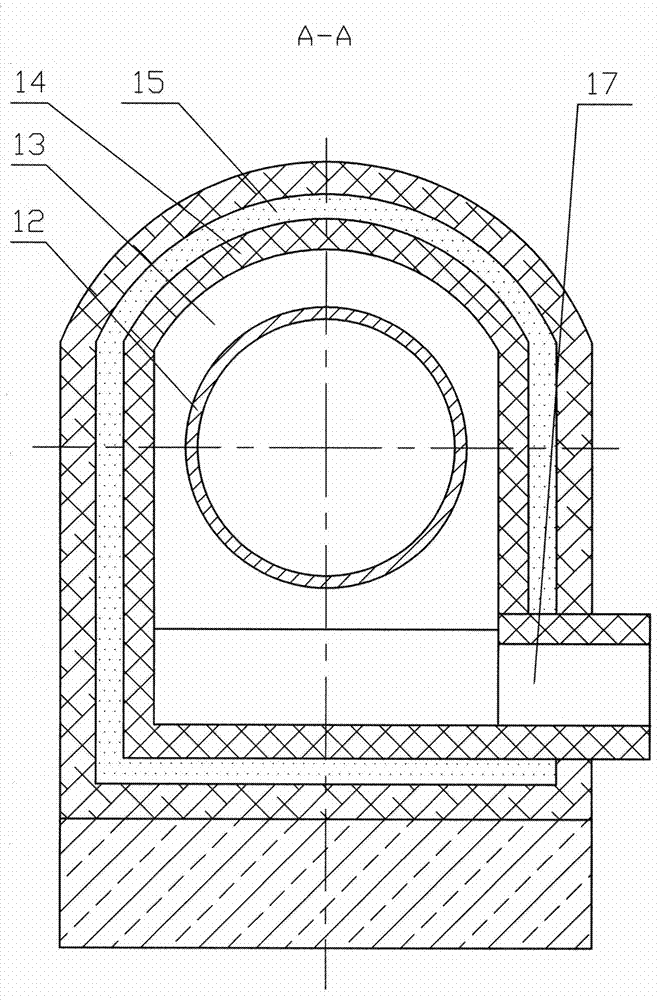

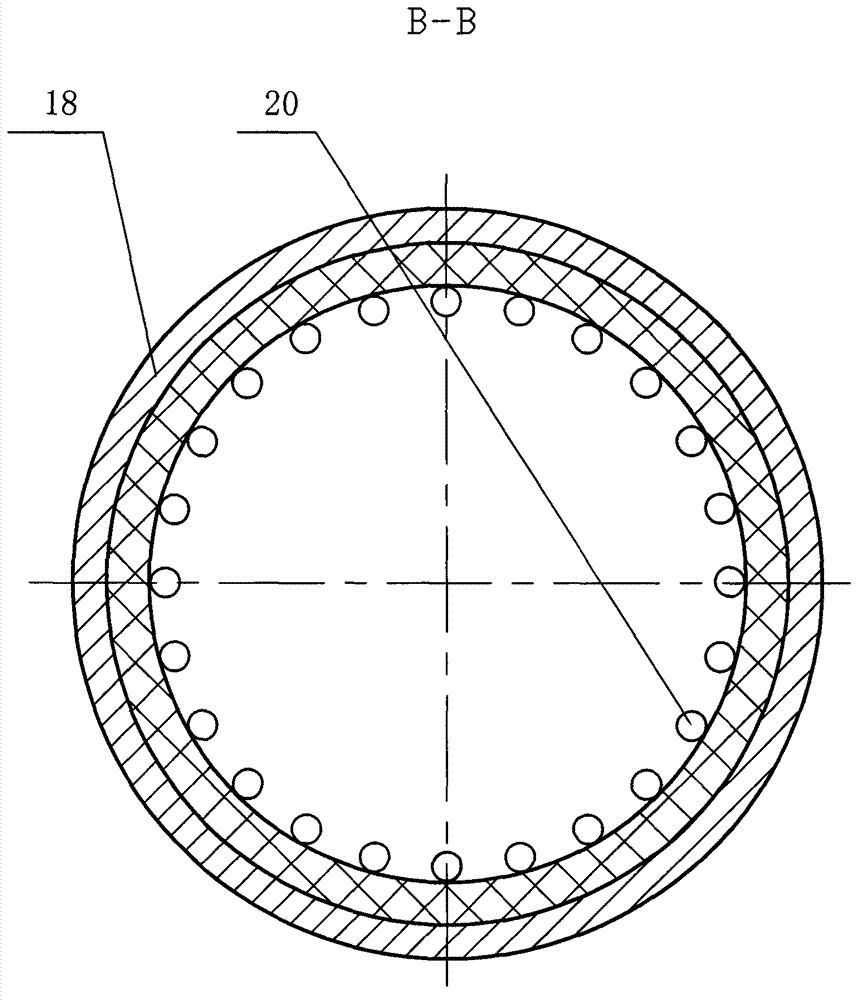

[0011] The fruit shell raw material adopts the process and carbon activation equipment of the present invention to prepare the fruit shell amorphous activated carbon in one step, and the fruit shell raw material such as coconut shell and apricot core shell is crushed to an appropriate particle size with a crusher, and the fruit shell raw material with a certain particle size is conveyed by a screw The machine (2) is added to the internal heat drying converter (7) to dry with the flue gas for heating from the external heat carbonization converter, the water vapor generated by the drying is discharged to the atmosphere from the exhaust gas chimney, and the dried fruit shells fall to the outside. Carbonization is carried out in the thermal carbonization furnace (12), and the combustible gas produced during carbonization passes in the internal heating type activation converter (18), and is ejected from the furnace wall air pipes (20), (22) from the air distribution pipe (27) At the...

example 2

[0013] The sawdust raw material adopts the process and carbon activation equipment of the present invention to prepare powdery activated carbon in one step, and the sawdust is added to the internal heating drying converter (7) by a screw conveyor (2) after removing impurities such as wood blocks, branches, and silt with a screening machine. In the middle, the heating flue gas from the external heat type carbonization converter is used for drying, and the water vapor generated by drying is discharged to the atmosphere from the exhaust gas chimney, and the dried sawdust raw material falls into the external heat type carbonization furnace (12) for carbonization. The combustible gas produced is passed into the internal heating activated converter (18), and is burned with the air ejected from the furnace wall air pipes (20) and (22) from the air distribution pipe (27) to heat the material. At the same time, the material is heated at a high temperature. Activation reaction with steam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| adsorption value of blue | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com