Process for efficiently preprocessing lignocellulose

A lignocellulose and pretreatment technology, which is applied in fiber raw material treatment, textile and papermaking, fermentation, etc., can solve the problems of accelerated hemicellulose hydrolysis, high cost, and slow degradation speed, so as to save energy use and energy Reasonable use and the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

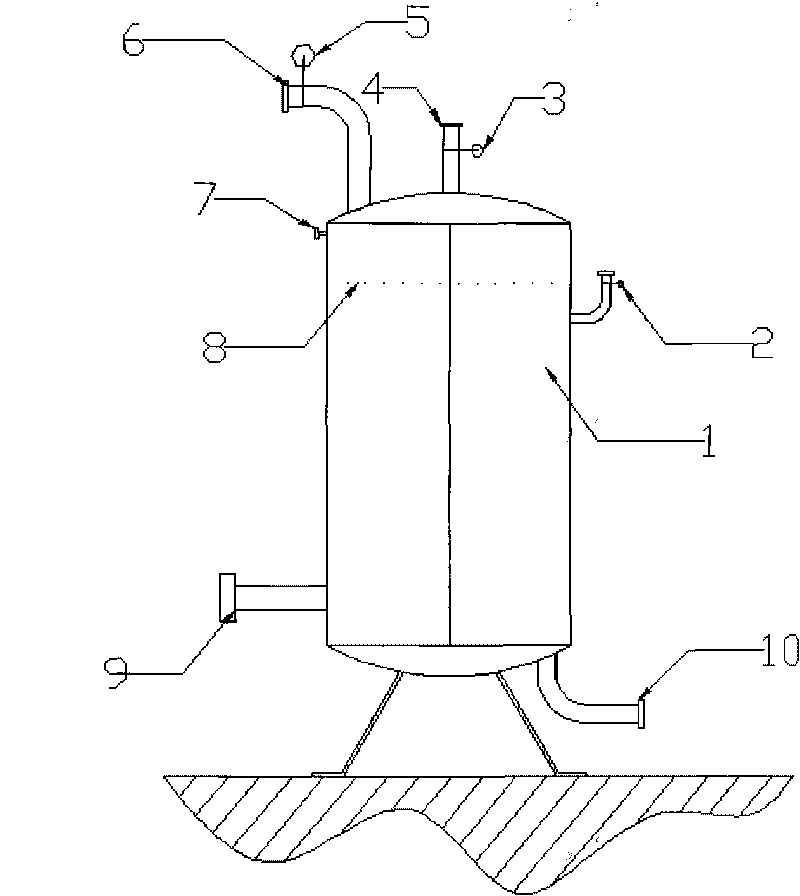

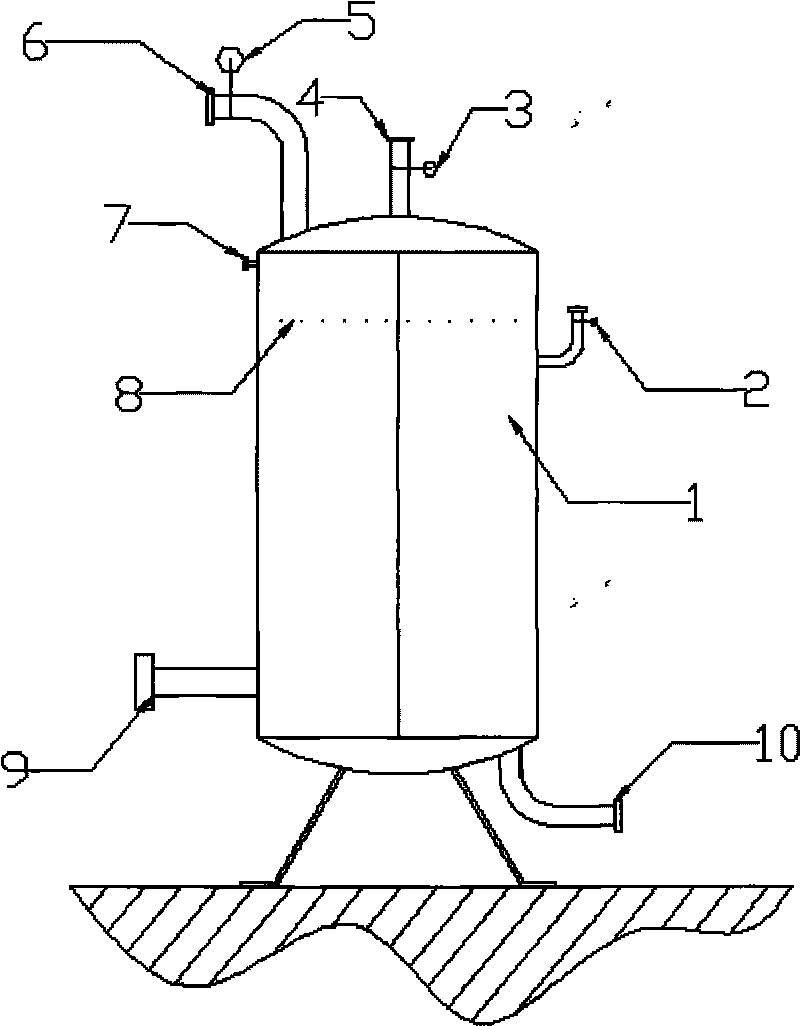

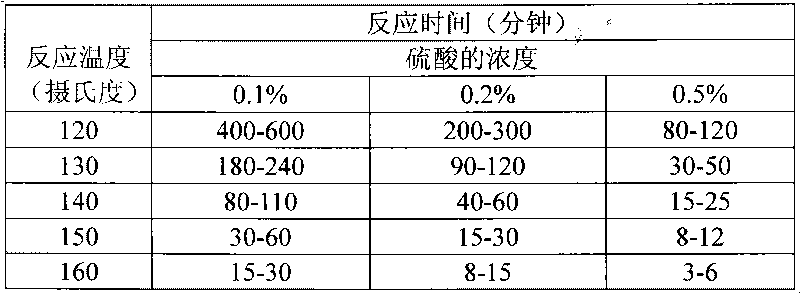

[0030] Add 0.2 gram of 98% sulfuric acid in advance in the medicine adding pipeline 2 of the flash reactor. Put 50 grams of dry wheat straw into the cooking equipment, feed 1MPa steam at about 180°C for about 20 seconds, add 200 grams of supercritical superheated water at 215°C, and form the pressure of the superheated water at the temperature (about 2.2 Mpa), after reacting for about 15 minutes, open the discharge valve of the cooking equipment and the slurry input pipeline 9 of the flash reaction kettle, so that the material, water and steam enter the flash reaction kettle under the effect of pressure difference, and discharge The pressure valve 3 is automatically opened, and the steam is released from the steam output pipe 4. When the pressure of the reaction vessel is released to the pressure set by the pressure relief valve of 0.6MPa, and the temperature is close to 160°C, the pressure relief is stopped, and the reaction condition is maintained for 5 minutes. , and then f...

Embodiment 2

[0033] Add 0.4 gram of 98% sulfuric acid in advance to the medicine adding pipeline 2 in the flash reactor. Put 30 grams of dry wheat straw into the cooking equipment, feed 1MPa steam at about 180°C for about 15 seconds, add 200 grams of supercritical superheated water at 215°C, and form the pressure of the superheated water at the temperature (about 2.2 Mpa), after reacting for about 12 minutes, open the discharge valve of the cooking equipment and the slurry input pipeline 9 of the flash reaction kettle, so that the material, water and steam enter the flash reaction kettle under the effect of pressure difference, and discharge The pressure valve 3 is automatically opened, and the steam is released from the steam output pipe 4. When the pressure of the reaction vessel is released to the pressure of 0.6MPa set by the pressure relief valve, and the temperature is close to 160°C, the pressure relief is stopped, and the reaction condition is maintained for 1 minute. , and then fi...

Embodiment 3

[0036] Add 0.3 gram of 98% sulfuric acid to the pipeline 2 of the medicine in the flash reactor. Put 10 grams of dry wheat straw into the cooking equipment, feed 1MPa steam at about 180°C for about 10 seconds, add 200 grams of supercritical superheated water at 215°C, and form the pressure of the superheated water at the temperature (about 2.2 Mpa), after reacting for about 10 minutes, open the discharge valve of the cooking equipment and the slurry input pipeline 9 of the flash reaction kettle, so that the material, water and steam enter the flash reaction kettle under the effect of pressure difference, and discharge The pressure valve 3 is automatically opened, and the steam is released from the steam output pipe 4. When the pressure of the reaction vessel is released to the pressure set by the pressure relief valve of 0.6MPa, and the temperature is close to 160°C, the pressure relief is stopped, and the reaction condition is maintained for 2 minutes. , and then fine-tuning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com