Operation control device and method of vacuum pumps

A technology of operation control and vacuum pump, which is applied in the direction of pump control, mechanical equipment, pump components, etc., can solve the problems of increasing pump failure frequency, pump and ancillary facility maintenance frequency and maintenance man-hours, energy consumption and maintenance cost increase, so as to promote maintenance Work efficiency, reduce power consumption, significant cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, the present invention will be described in detail with reference to embodiments shown in the accompanying drawings. However, the dimensions, materials, shapes, relative positions, etc. of the components described in these embodiments are merely illustrative, and should not be construed as limiting the scope of the present invention unless any special statement is made.

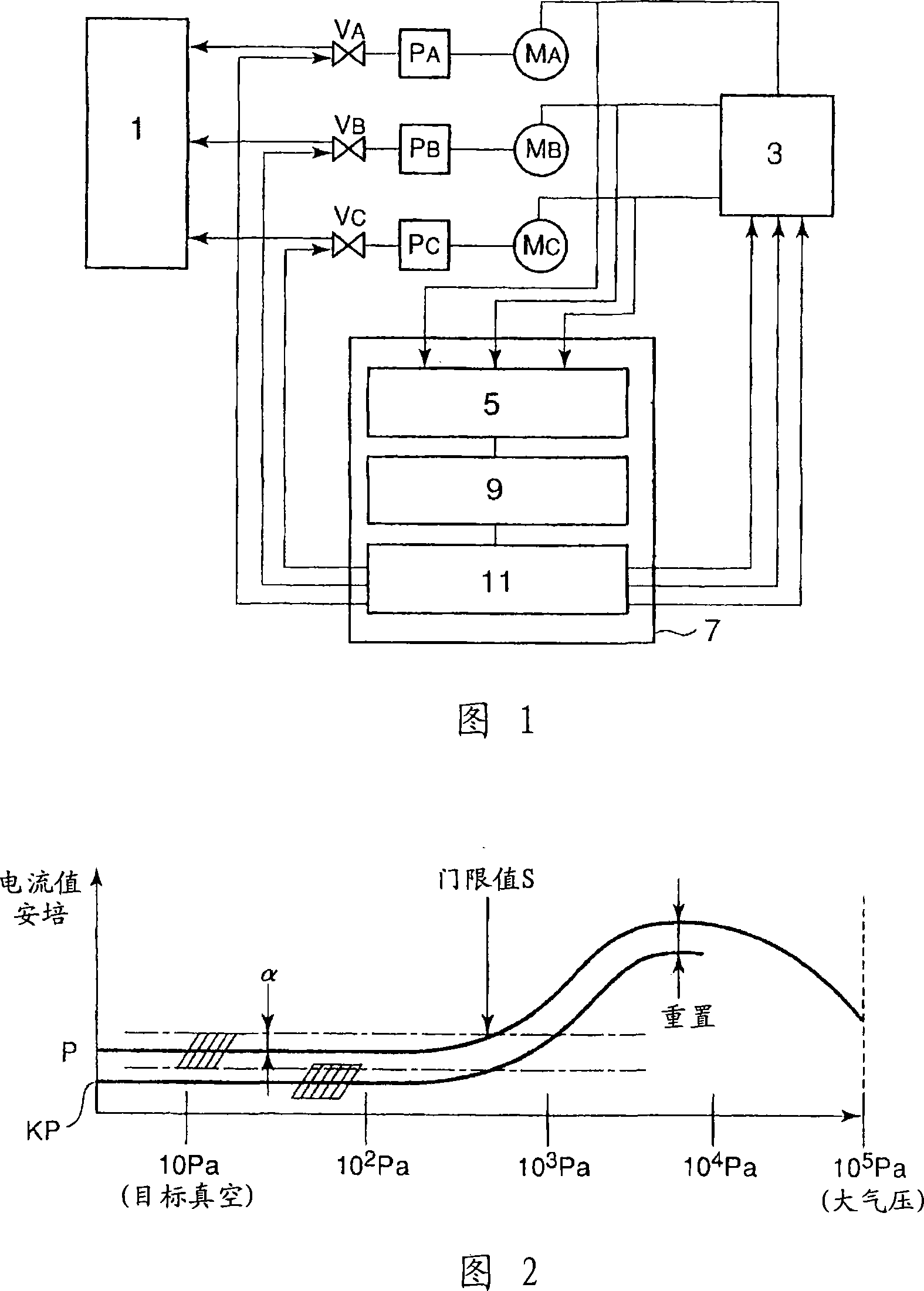

[0034] Fig. 1 has shown the overall composition of the present invention, wherein vacuum cabinet 1 is made of three vacuum pumps P A ,P B and P c stress reliever. Vacuum pump P A ,P B and P c respectively by motor M A , M B and M C drive. In the vacuum cabinet 1 with each vacuum pump P A ,P B and P c Place the solenoid on / off valve V between A , V B and V C . Each vacuum pump P A ,P B and P C It is a rotary displacement (volume) type, such as a scroll type or a vane type.

[0035] Each motor M A , M B and M C Powered by power supply 3. Because each motor M A , M B an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com