Novel rubber packing plate and production technique thereof

The invention relates to a technology of rubber backing plate and manufacturing process, which is applied in the directions of rails, buildings, fixed rails, etc., and can solve the problems that polyurethane foam cannot meet the elastic coefficient, the uniform dispersion of the backing plate load is poor, and the foam is easy to trap air, etc. Achieve the effect of reducing maintenance frequency, improving weather resistance and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

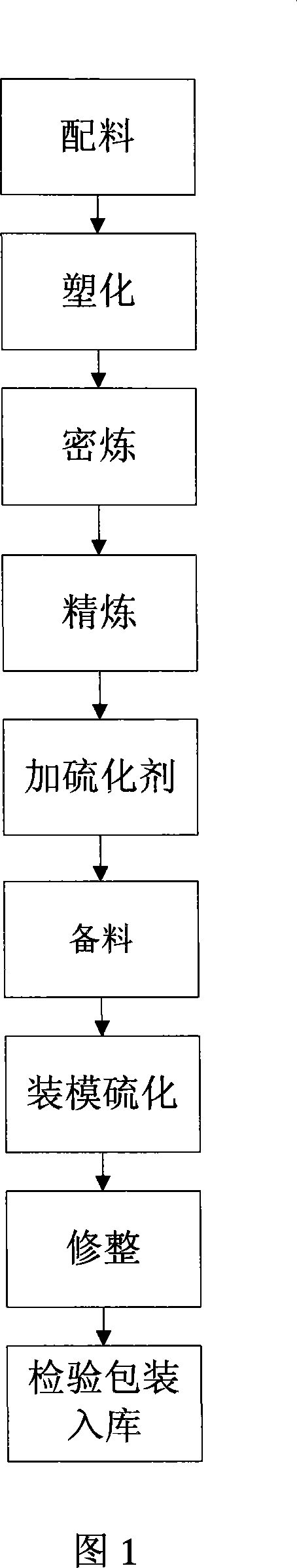

Method used

Image

Examples

Embodiment 1

[0047] Ingredients by mass ratio: EPDM rubber, 80-85; hexadiene, 20-15; sulfur, 2.5; dicumyl peroxide, 0.5; 2-mercaptobenzothiazole, 0.8; Tetramethylthiuram sulfide, 1.2; 4010NA, 2; Paraffin, 1; HAF N330+ISAF N220, 35; SRF N754+FEF N539, 44; Clay, 30; Calcium carbonate, 20; Naphthenic oil, 36.

[0048] The physical properties of the new rubber backing plate produced by selecting the above materials according to the above manufacturing process: hardness, 85 Shore A; tensile strength, 11.8MPa; elongation at break, 237%; compression set, 23% ; Static stiffness, 44KN / mm.

Embodiment 2

[0050] Ingredients by mass ratio: EPDM rubber, 78-85; ethylidene norbornene, 22-15; sulfur, 2.5; dicumyl peroxide, 0.5; 2-mercaptobenzothiazole, 1.2; tetramethylthiuram disulfide, 0.8; 4010NA, 2; paraffin, 1; HAF N330+HAF-LS N326, 40; SRF N754+GPF N660, 37; clay, 30; calcium carbonate, 20; paraffin oil , 38.

[0051] The physical properties of the new rubber backing plate produced by selecting the above materials according to the above manufacturing process: hardness 86 Shore A; tensile strength 11.6MPa; elongation at break 238%; compression set 22%; static stiffness 43KN / mm.

Embodiment 3

[0053] Ingredients by mass ratio: EPDM rubber, 85-90; ethylidene norbornene, 15-10; sulfur, 2; dicumyl peroxide, 1; 2-mercaptobenzothiazole, 0.5; tetramethylthiuram disulfide, 1.5; 4010NA, 2; paraffin, 1; HAF N330+HAF-HS N339, 45; SRF N754+SRF N774, 30; clay, 30; calcium carbonate, 20; naphthene oil, 40.

[0054] The physical properties of the new rubber backing plate produced by selecting the above materials according to the above manufacturing process: hardness 86 Shore A; tensile strength 11.8MPa; elongation at break 256%; compression set 22%; static stiffness 43KN / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com