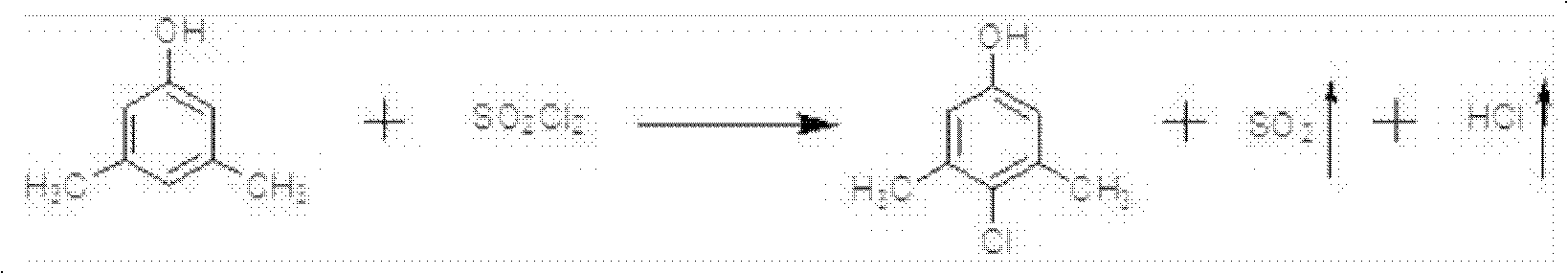

Continuous kettle type chlorination technology

A continuous kettle and process technology, applied in organic chemistry, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as increased workload, incomplete chlorination, conversion of target products, etc., to reduce the frequency of equipment maintenance, The effect of increased contact area and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

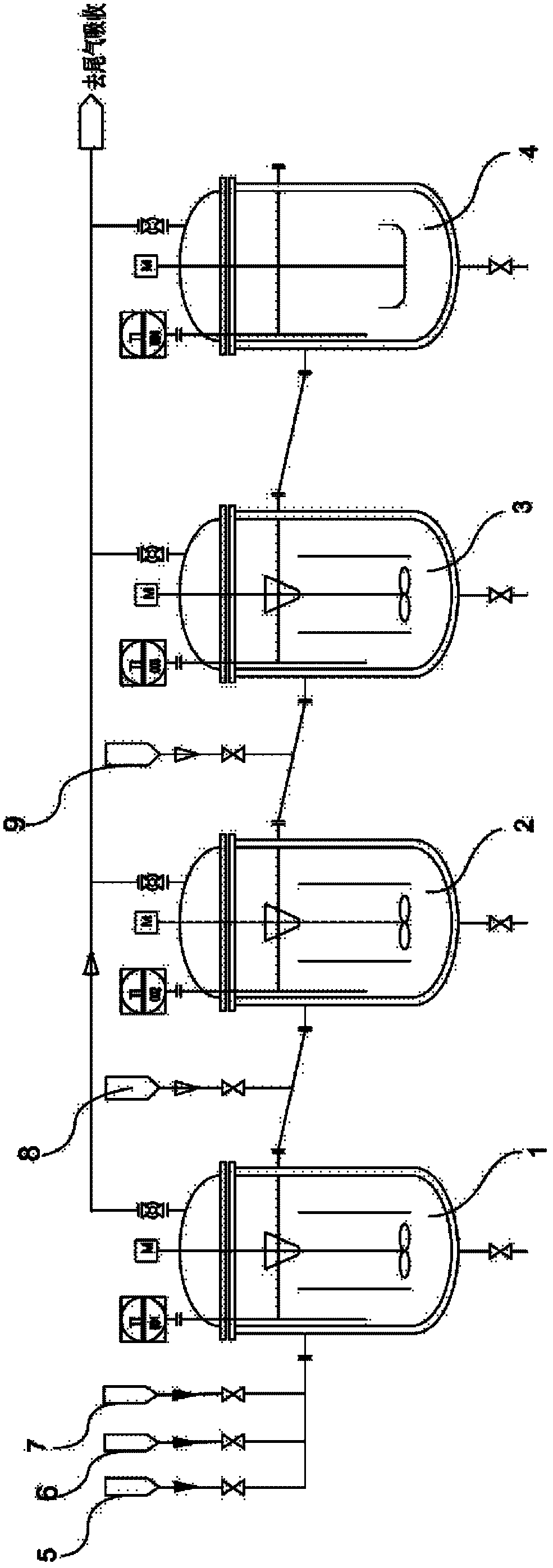

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] A certain amount of solvent tetrachlorethylene will be added to each chlorination kettle as shown in the accompanying drawing, the stirring device will be started, and after the tail gas absorption system is opened, the MX, SO 2 Cl 2 , tetrachlorethylene solvent respectively with 0.7m 3 / h, 0.3m 3 / h and 0.65m 3 The flow rate of / h is continuously added to the chlorination kettle A1 through the feed port. At this time, the reaction temperature is controlled at 35-40°C, and the reaction generates 4-chloro-3,5-xylenol, which is discharged every hour at the feed port. Sampling and analyzing the result once, the conversion rate is 60-80%; when the liquid level reaches the overflow port, the 3 Add SO to the chlorination kettle B2 at a flow rate of / h 2 Cl 2 , the reaction temperature is adjusted to 30~35 DEG C, and the analysis component content is sampled once...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com