Water plant removing equipment operating in combination with unmanned ship and working method of water plant removing equipment

A technology of joint operations and working methods, applied in water conservancy projects, cleaning of open water surfaces, agriculture, etc., can solve problems such as damage to ships, damage to water ecological environment, infringement of water surface space, etc., and achieve the effect of easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

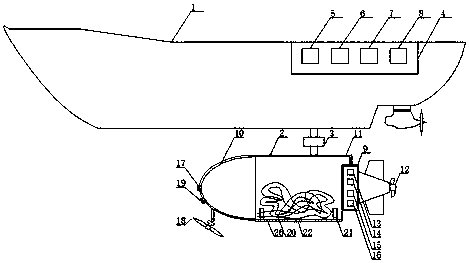

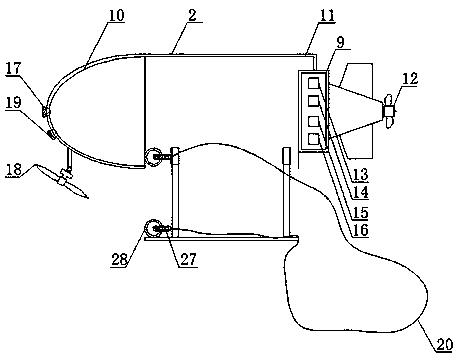

[0044] Such as figure 1 , 2As shown in , 3, a water weed removal equipment that works in conjunction with an unmanned ship includes an unmanned ship 1, a clearing device body 2, and a connection mechanism 3. The unmanned ship 1 includes a first control mechanism 4, and the first control mechanism 4 includes The first processor 5, the first driving device 6, the first navigation device 7 and the first positioning device 8, the first processor 5 is respectively connected with the first driving device 6, the first navigation device 7 and the first positioning device 8, The first navigation device 7 is used to generate the first navigation route of the unmanned ship 1, the first driving device 6 is used to drive the unmanned ship 1 to sail, and the first positioning device 8 is used to obtain the first position information of the unmanned ship 1, The cleaning device body 2 includes a second control mechanism 9, a cutting part 10, a storage part 11 and a screw propulsion mechanism...

Embodiment 2

[0054] Such as Figure 4 Shown, a kind of working method of the aquatic weed removal equipment of joint operation with the unmanned ship, comprises the following working steps:

[0055] a) The second processor 13 sets a preset water area in the second navigation device 15;

[0056] b) The second navigation device 15 automatically generates the travel route of the clearing device body 2 in the preset water area and sends the travel route to the second processor 13;

[0057] c) The second processor 13 outputs a travel signal to the second drive device 14, and the second drive device 14 drives the screw propulsion mechanism 12 to travel along the travel route;

[0058] d) The underwater camera 17 sends the shooting picture to the second processor 13 in real time;

[0059] e) the second processor 13 judges whether there are preset aquatic plants in the received picture;

[0060] f) if so, the second processor 13 extracts the location information of the roots of the preset aquat...

Embodiment 3

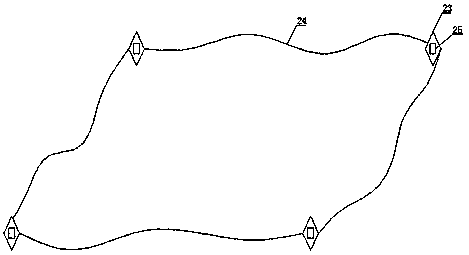

[0071] Such as Figure 7 As shown, step b also includes:

[0072] The navigation device generates the boundary route of the preset area and sends the boundary route to the first processor 5;

[0073] The first processor 5 outputs the second navigation signal to the first driving device 6, and the first driving device 6 drives the unmanned ship 1 to sail along the boundary route;

[0074] In the above process, the unmanned ship 1 arranges the warning mechanism on the boundary route, and the warning mechanism intercepts the water surface in the preset area.

[0075] Unmanned ship 1 arranges the warning mechanism on the border route and also includes:

[0076] When the unmanned ship 1 deploys the warning mechanism for the first time, the third positioning device 25 sends the third position information of the electronic buoy 23 to the first processor 5, and the first processor 5 records the third position information respectively;

[0077] The first processor 5 judges whether t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com