Automatic feeding device for mixed plastic color master batches

A technology of automatic feeding and mixing of plastics, applied in the directions of packaging, transportation and packaging, containers, etc., can solve the problem of reducing the efficiency of masterbatch and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

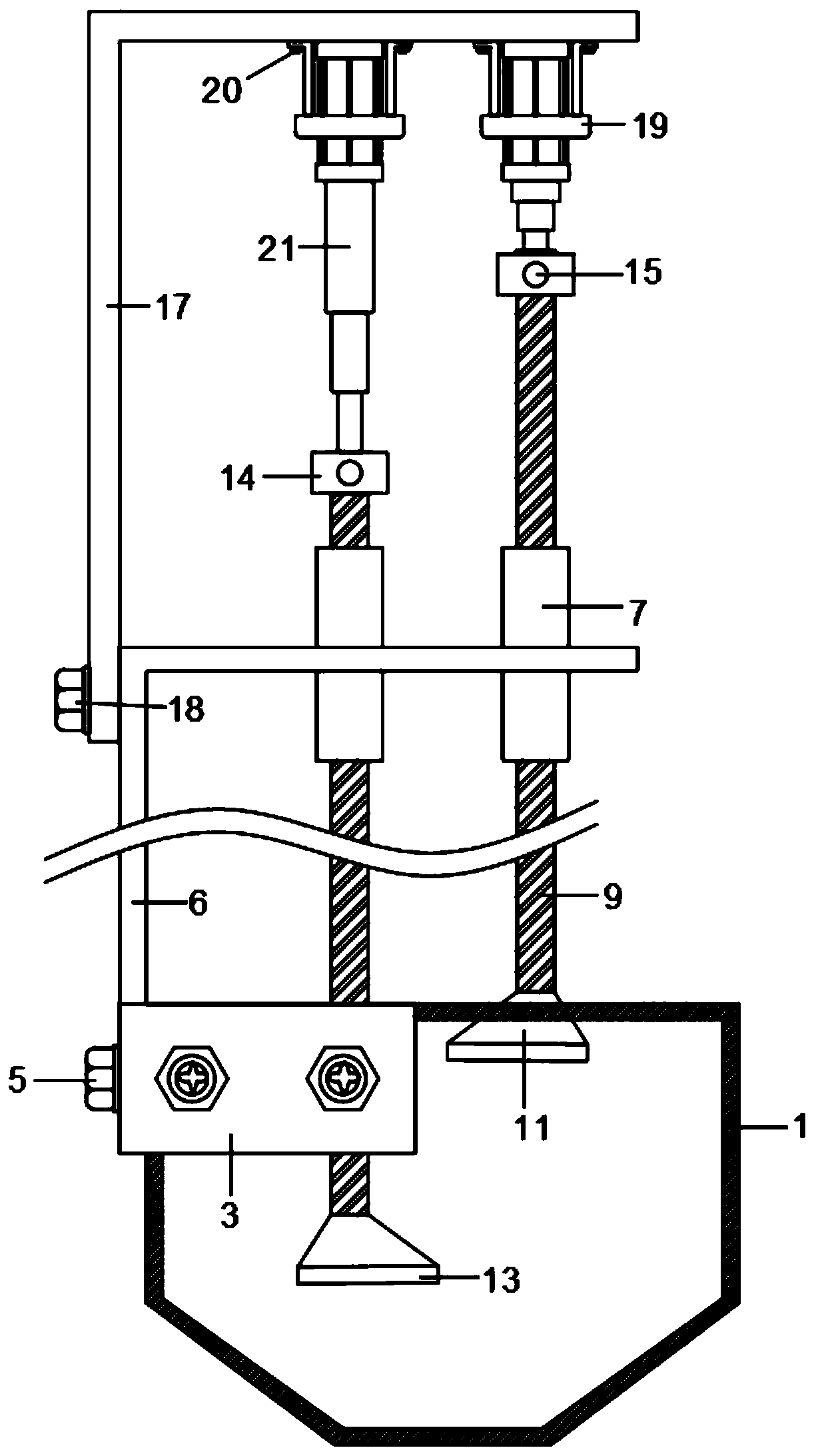

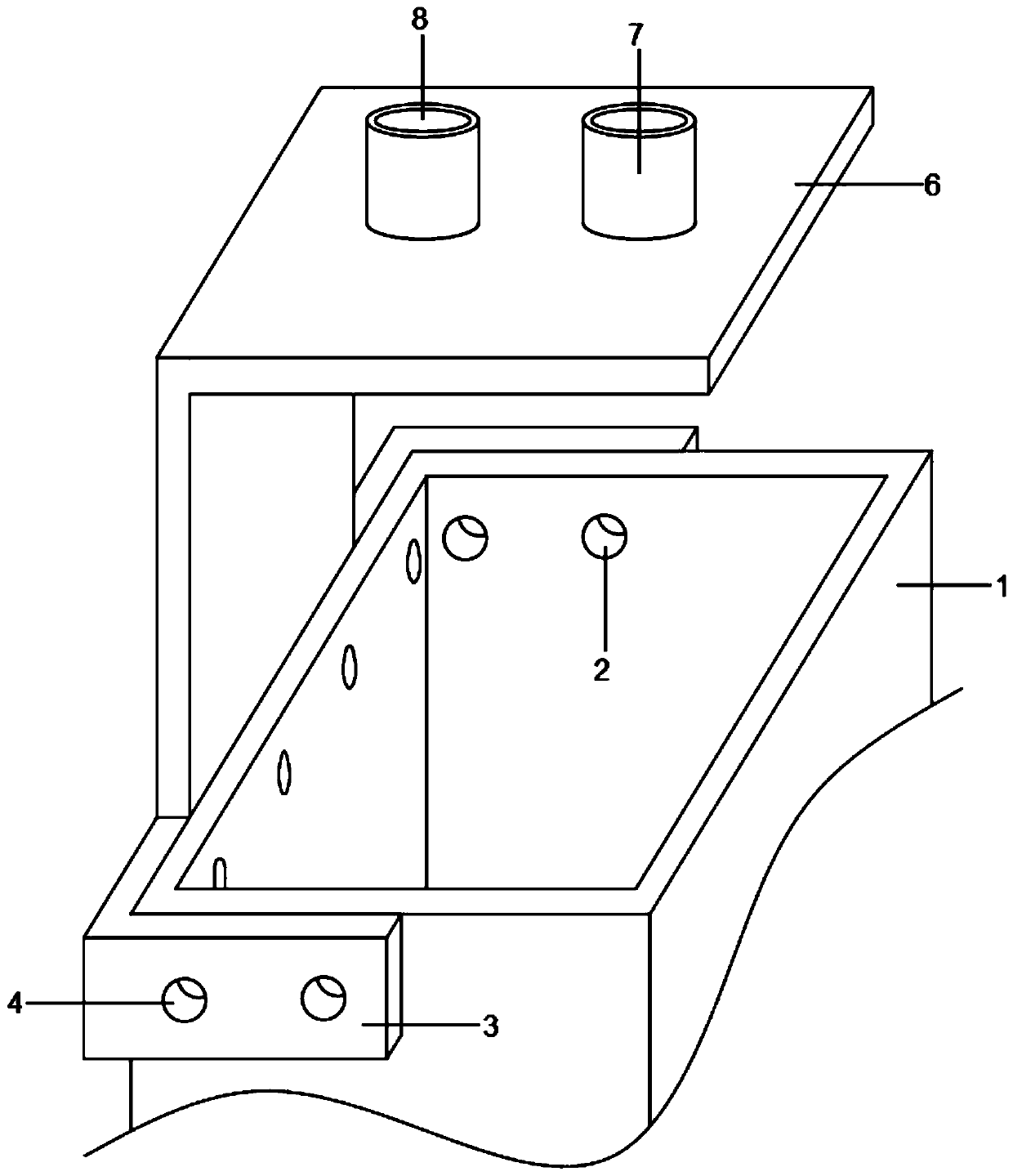

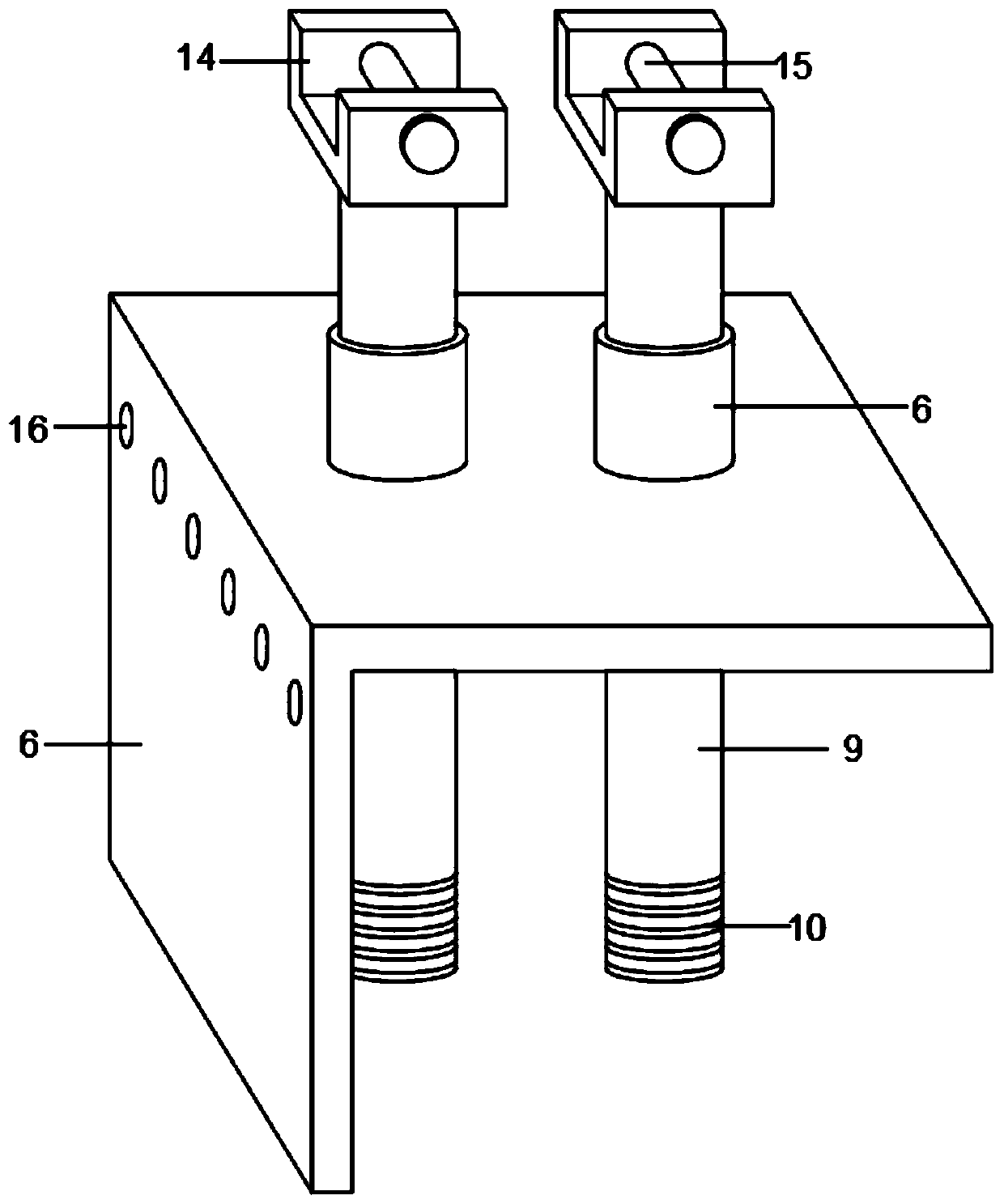

[0022] Such as Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: an automatic feeding device for mixing plastic color masterbatches, including a feeding funnel 1, one side outer wall at the top of the feeding funnel 1 and one side of a U-shaped limiting plate 3 The inner wall is in contact, the feeding funnel 1 is located on the inner wall of the No. 1 connecting groove 2, and a number of No. 1 connecting grooves 2 are drilled on the inner wall, and the inner wall of the U-shaped limiting plate 3 is drilled with a number of No. 2 connecting grooves 4 , the U-shaped limiting plate 3 is located in each No. 2 connecting groove 4 and is inserted with a No. 1 limiting bolt 5. The top of the U-shaped limiting plate 3 is far away from the end of the feeding funnel 1 and the No. 1 L-shaped limiting plate. The bottom of the position plate 6 is fixedly connected, and the side of the No. 1 L-shaped limit plate 6 top away from the U-shaped limit plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com