Method for preparing stainless steel interleaving paper by wastepaper

A technology of stainless steel and lining paper, applied in the field of papermaking, can solve problems such as increased production costs, unfavorable natural environment, and destruction of forest resources, and achieve the effects of saving electric energy, protecting the natural environment, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

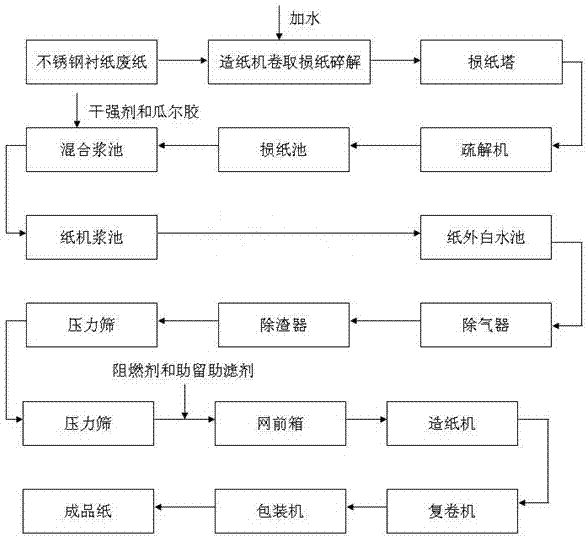

[0030] Such as figure 1 As shown, a method for preparing stainless steel liner paper using waste paper as a raw material includes the following steps:

[0031] Step 1: Use waste paper with stainless steel lining paper as raw material, disintegrate it into slurry in the waste paper pool of the paper machine, and store it in the waste paper tower;

[0032] Step two, the slurry is pumped to the broken paper tank for storage after being decontaminated by a decomposer;

[0033] Step 3: Add dry strength agent and guar gum in proportion to the mixing tank, and pump to the pulp tank of the paper machine after mixing;

[0034] Step 4: Adjust the slurry concentration of the pulp tank of the paper machine to 4%-5%, and then pump it to the white tank outside the paper to dilute it to a concentration of 1%;

[0035] Step 5, remove the gas in the slurry in the deaerator,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com