Automatic wire plugging structure of flat-wire motor stator

A motor stator, automatic technology, applied in the direction of electric components, manufacturing motor generators, electrical components, etc., can solve the problems of reducing the motor slot full rate, low production efficiency, low motor slot full rate, etc., to improve insulation reliability, Improve productivity, eliminate the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

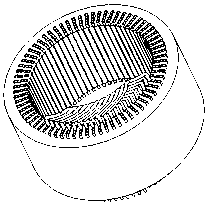

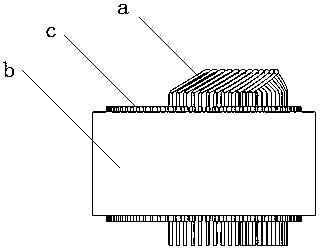

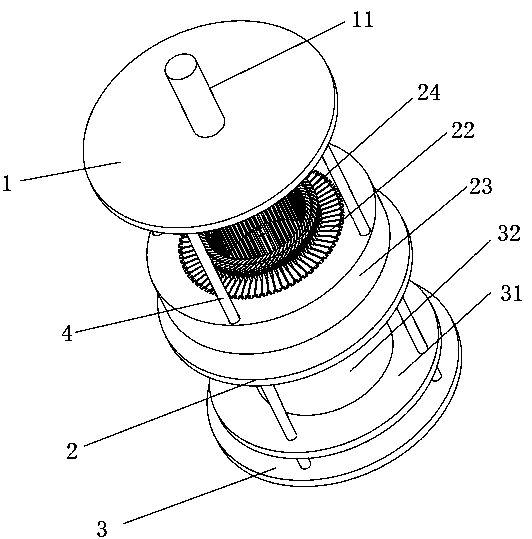

[0022] Such as image 3 and 4 As shown, the flat wire motor stator automatic wire insertion structure disclosed by the present invention includes four vertical guide posts 4 and a first support base 1 and a second support base 2 mechanically fixed on the guide posts in turn from top to bottom. and the third support base 3; the guide post above the third support base 3 is provided with a sliding base 31 carrying a stator core 32, and the sliding base 31 can move up and down along the guide post; the second support base 2 A ring-shaped slide pin guide rail 21 is fixed on the slide pin guide rail 21. A number of slide pins 22 that can slide radially on the slide pin guide rail are placed on the slide pin guide rail. A gap for placing the winding coil 24 is formed between adjacent slide pins The opening wire slot; the outer side of the sliding pin 22 is also nested with a sliding extrusion body 23 that can slide up and down along the guide post 4, acting on the sliding pin 22 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com