Cold press guiding device for wooden door production

A guide device, cold press technology, applied in applications, household components, household appliances, etc., can solve problems such as door panel defects, delayed wooden door production efficiency, and uneven door panel pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

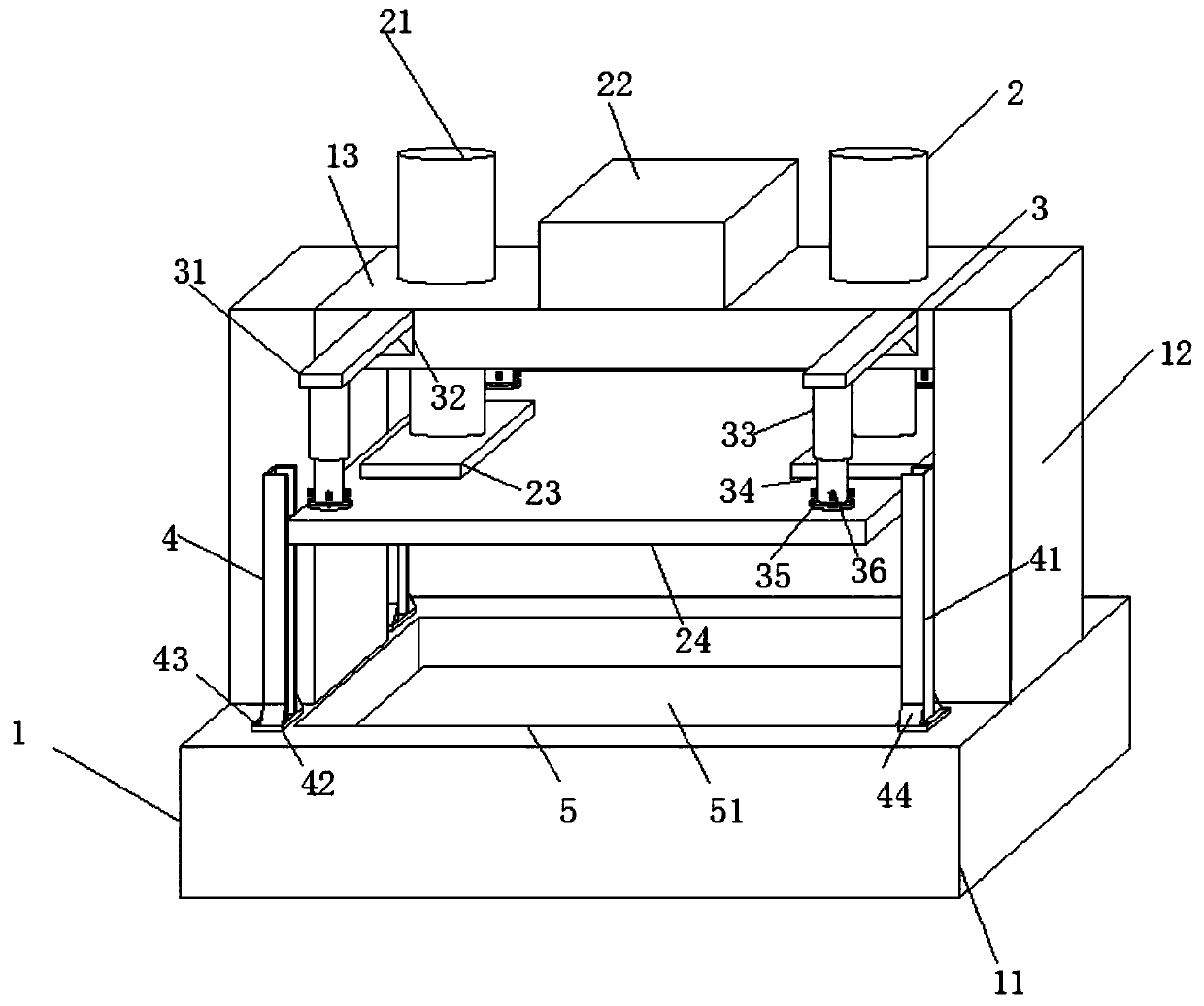

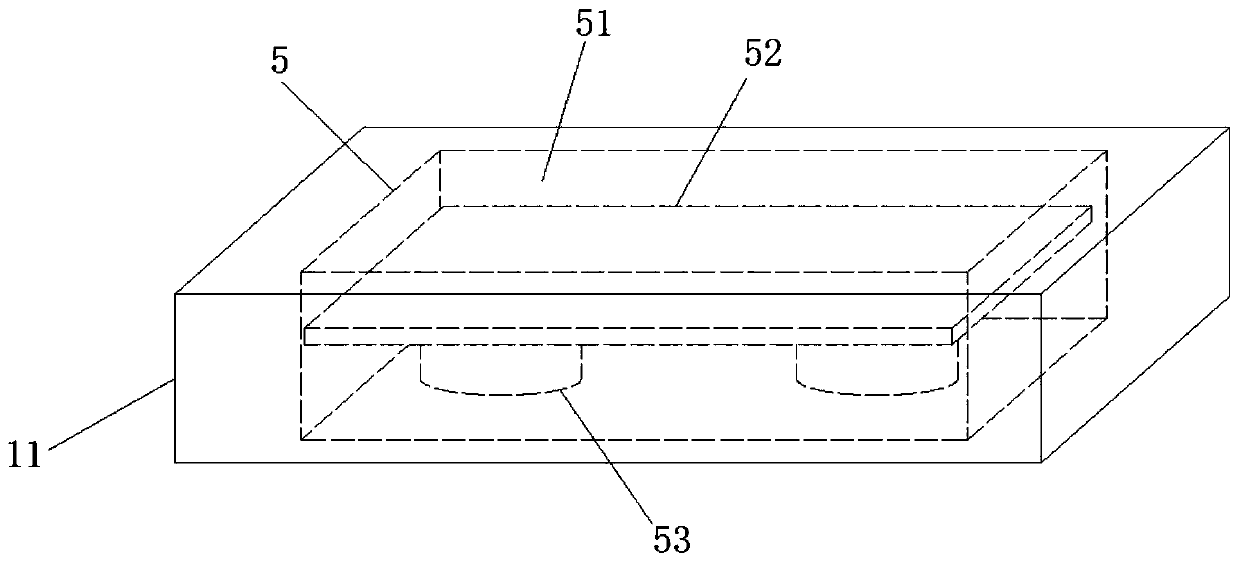

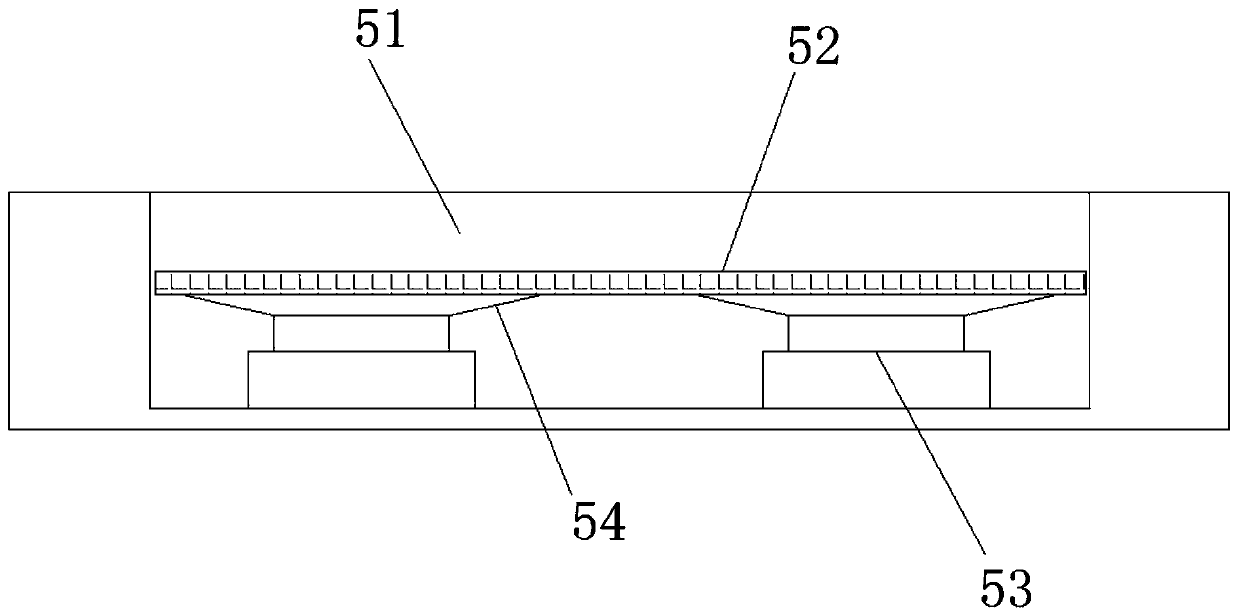

[0027] Embodiment 1: as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a cold press guide device for wooden door production, including a cold press 1, an extrusion structure 2 is connected to the cold press 1, and the top of the cold press 1 Both sides are connected with a guide structure 3, a placement structure 5 is set up directly below the extruding structure 2, and auxiliary structures 4 are set up on both sides of the extruding structure 2;

[0028] The cold press 1 includes an extruding platform 11, the two ends of which the top of the extruding platform 11 is far away from each other are fixedly connected with a column 12, and the inner wall of the end of the column 12 away from the extruding platform 11 is fixedly connected with a beam 13 , the crossbeam 13 is fixedly connected with an extruded structure 2 in a position close to the two columns 12;

[0029] The extruding structure 2 includes hydraulic rods 21. There are two h...

Embodiment 2

[0039] In Embodiment 2, the connecting column 33 and the movable column 34 are replaced with an electric telescopic rod, one end of the electric telescopic rod is slidably suspended and connected to the extension plate 31, and the other end is hinged on the connecting plate 35, and the electric telescopic rod can not only squeeze The pressing plate 24 is positioned to make the pressing plate 24 operate more stably, and can provide auxiliary pressure to the pressing plate to a certain extent, so that the pressing effect is better and the operation is convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com