Recycling device for oil in oil absorption felt

A recycling device and oil-absorbing felt technology, applied in the direction of manufacturing tools, presses, etc., can solve the problems of low recycling rate and recycling efficiency, liquid recycling problems, etc., to improve the recycling rate and recycling work efficiency, simple structure, and increase friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

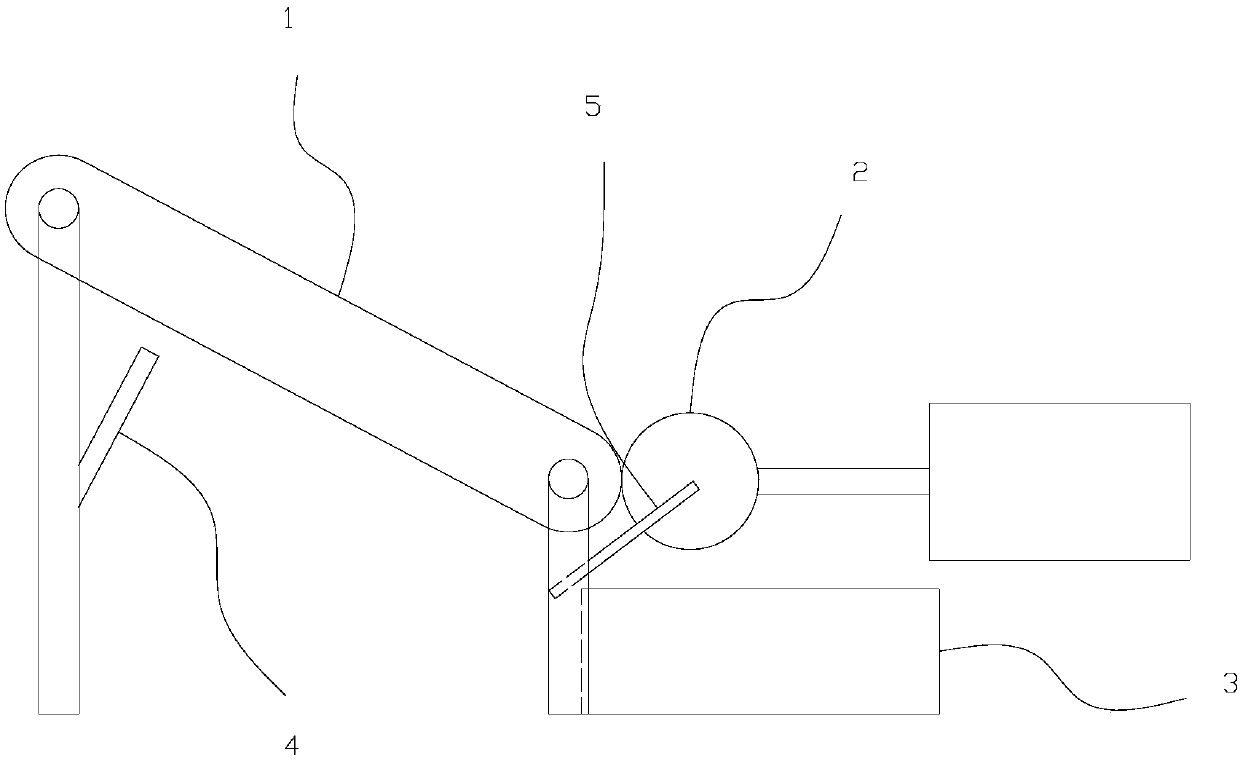

[0016] The present invention as figure 1 As shown, it includes a conveyor belt 1, a squeeze roller 2, a drive mechanism of the squeeze roller 2 and a recovery box 3, and the conveyor belt 1 is transported obliquely downward, and the squeeze roller 2 is in contact with the lower end of the conveyor belt 1, which is convenient The squeezed fluid runs off and won't stick to other things. Squeeze roller 2 is made of elastic material, can conveniently leave certain extrusion space for oil-absorbing felt,

[0017] The driving mechanism of the squeeze roller 2 is an air cylinder or a hydraulic cylinder, and the squeeze roller is arranged on the piston rod of the air cylinder or the hydraulic cylinder,

[0018] The recovery box 3 is located directly below the contact point between the squeeze roller 2 and the conveyor belt 1, so that the squeezed liquid can fall into it. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com