Method for rectifying iodine-containing hydriodic acid feed liquid

A technology of hydriodic acid and feed liquid, which is applied in the field of chemical engineering and can solve problems such as rectification of hydriodic acid that is difficult to contain iodine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

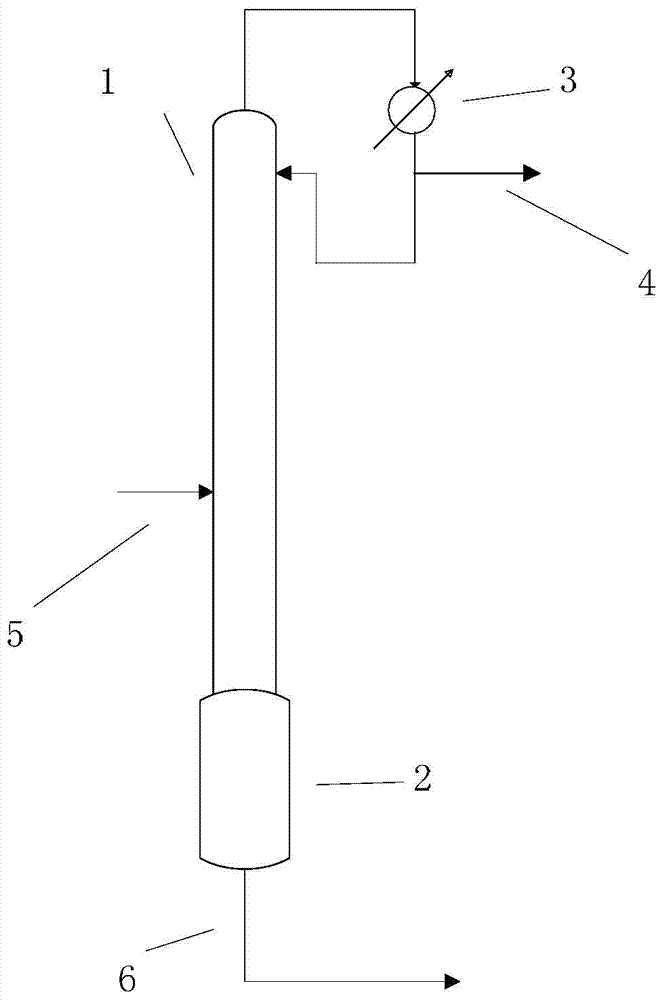

[0024] like figure 1 As shown, in this embodiment, the inner diameter of the packed tower 1 is 5cm, the inner packing is a glass spring packing of Ф3mm*20mm, the height of the packing layer is 1.25m, and the feeding port of the feed liquid containing iodohydroiodic acid is 1m away from the top of the tower ; The rectifying kettle 2 has a volume of 2L and is equipped with a heating jacket with a power of 1kW. The mol ratio of each component in the iodine hydroiodic acid feed liquid to be rectified is: HI:H 2 O:I 2 =1:7.10:1.50.

[0025] Before the rectification treatment of the above-mentioned iodine-containing hydroiodic acid feed liquid, first add iodine-free hydroiodic acid in the rectifying still 2, the molar ratio of each component in the hydroiodic acid is HI:H 2 O=1:5.0. Implement start-up operation on the rectification equipment, start the heating device of the rectification kettle and the condensation reflux device 3 at the top of the tower, and operate in the tota...

Embodiment 2

[0028] like figure 1 As shown, in this embodiment, the inner diameter of the packed tower 1 is 10cm, the inner packing is glass spring packing of Ф3mm*30mm, the height of the packing layer is 2.0m, and the feeding port of the feed liquid containing iodohydroiodic acid is 1.5m away from the top of the tower ; The rectifying kettle 2 has a volume of 3.5L and is equipped with a heating jacket with a power of 3kW. The mol ratio of each component in the iodine hydroiodic acid feed liquid to be rectified is: HI:H 2 O:I 2 =1:10.00:1.10.

[0029]Before the rectification treatment of the above-mentioned iodine-containing hydroiodic acid feed liquid, first add iodine-free hydroiodic acid in the rectifying still 2, the mol ratio of each component in the hydroiodic acid is HI H 2 O=1:6.0. Implement start-up operation on the rectification equipment, start the heating device of the rectification kettle and the condensation reflux device 3 at the top of the tower, and operate in the tota...

Embodiment 3

[0033] like figure 1 As shown, in this embodiment, the inner diameter of the packed tower 1 is 15cm, the inner packing is glass spring packing of Ф3mm*30mm, the height of the packing layer is 2.0m, and the feeding port of the feed liquid containing iodohydroiodic acid is 1.0m from the top of the tower ; The rectifying kettle 2 has a volume of 16L and is equipped with a heating jacket with a power of 6kW. The mol ratio of each component in the iodine hydroiodic acid feed liquid to be rectified is: HI:H 2 O:I 2 =1:4.23:1.70.

[0034] Before the rectification treatment of the above-mentioned iodine-containing hydroiodic acid feed liquid, first add hydroiodic acid containing a small amount of iodine in the rectifying still 2, the mol ratio of each component of hydroiodic acid is HI:H 2 O:I 2 =1:4.80:0.40. Implement start-up operation on the rectification equipment, start the heating device of the rectification kettle and the condensation reflux device 3 at the top of the towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com