Patents

Literature

91results about How to "Effective suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

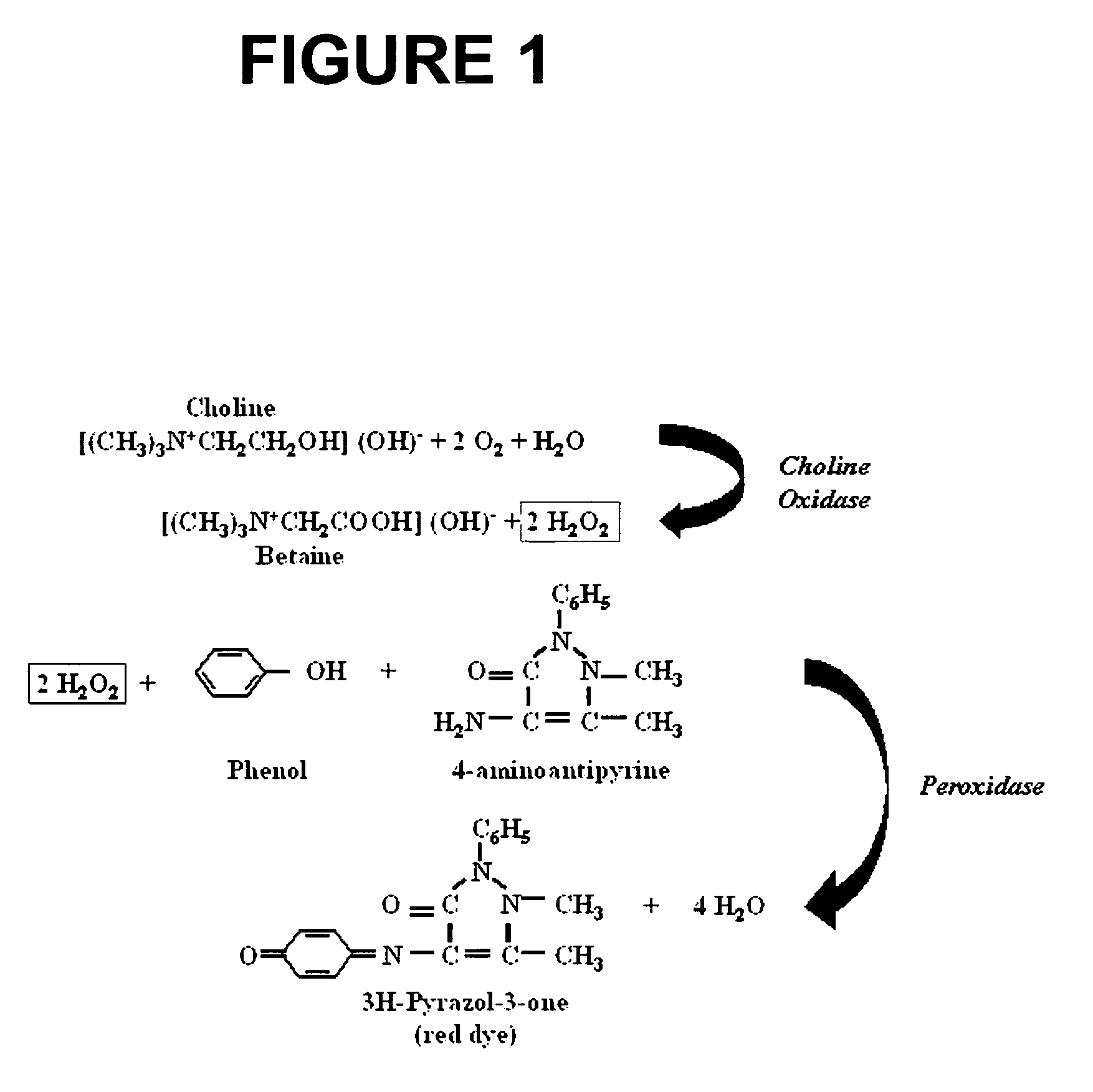

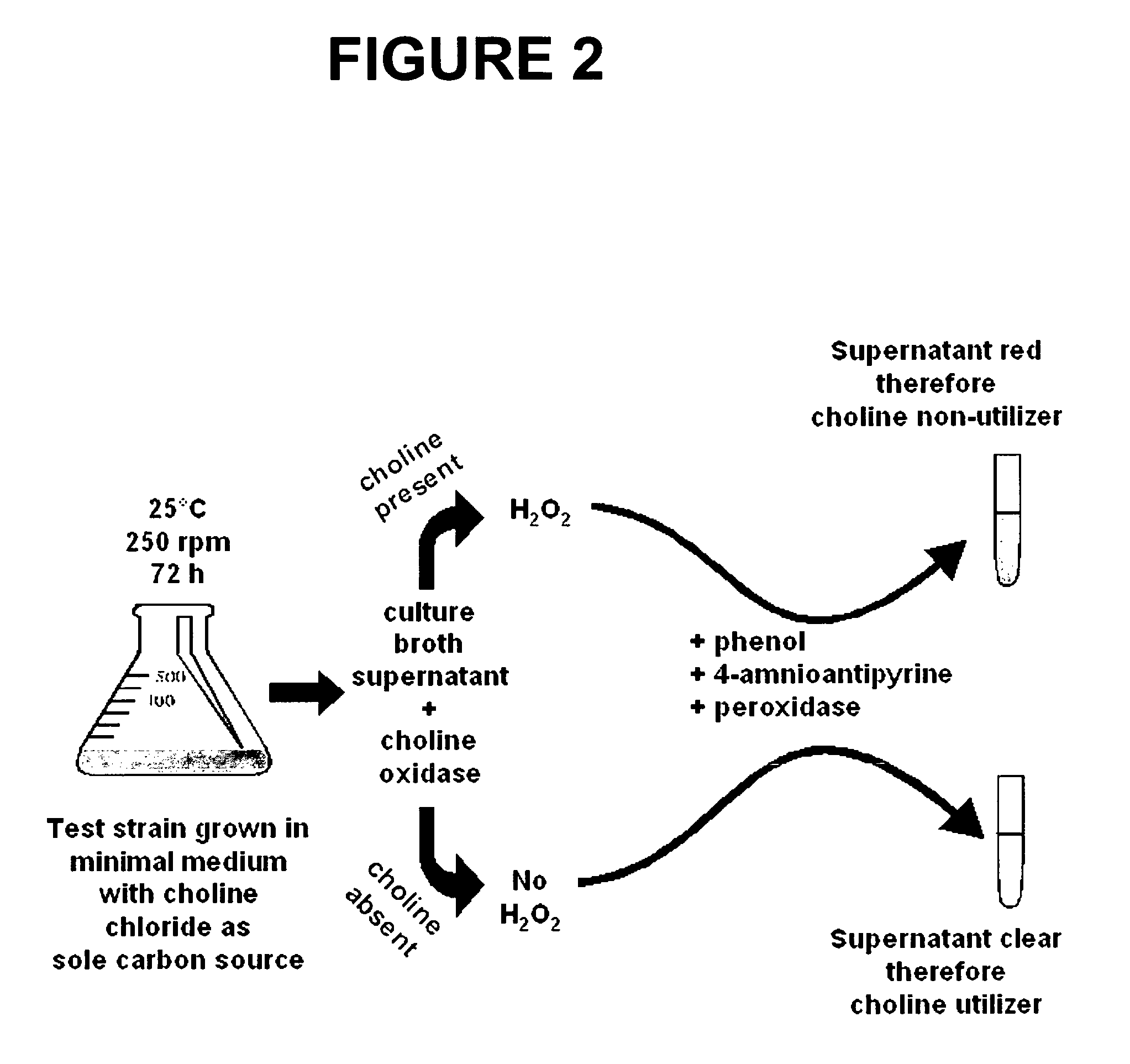

Choline-utilizing microbial strains for biologically controlling fusarium head blight

InactiveUS7601346B1Effective suppressionEffective controlBiocideBacteriaTriticeaeFusarium ear blight

Three choline utilizing strains of microorganisms isolated from the anthers of wheat, Aureobasidium pullulans strain AS 55.2, Arthrobacter species strain OH 221.3, and Pseudomonas species strain AS 64.4, are superior antagonists of F. graminearum. These microorganisms are effective for suppression and control of FHB in cereals, particularly in wheat and barley.

Owner:AGRI THE UNITED STATES OF AMERICAS AS REPRESENTED BY THE SEC OF +1

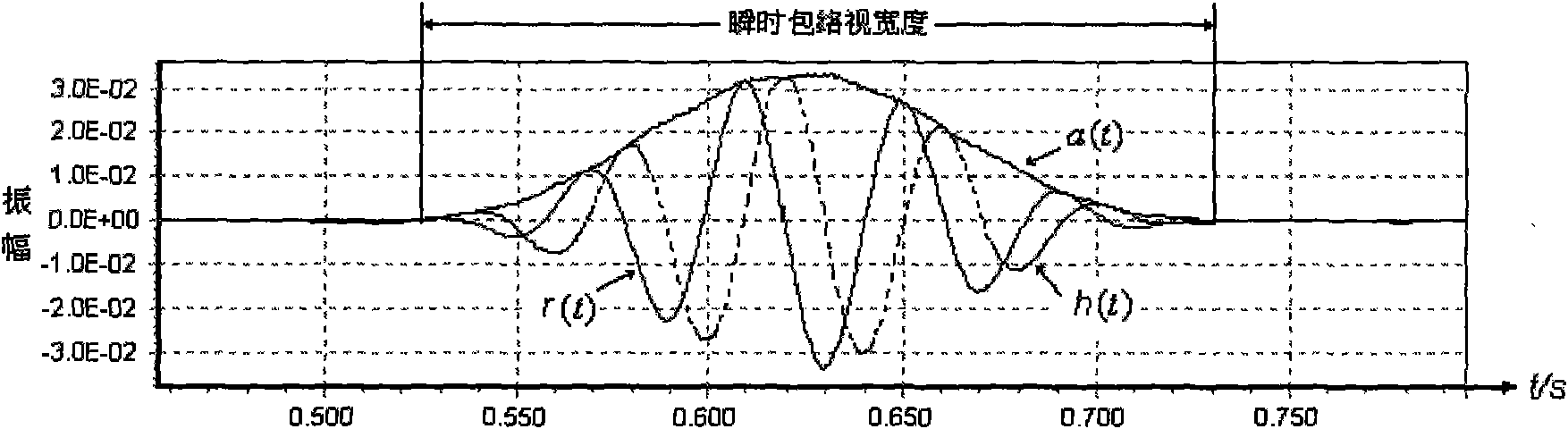

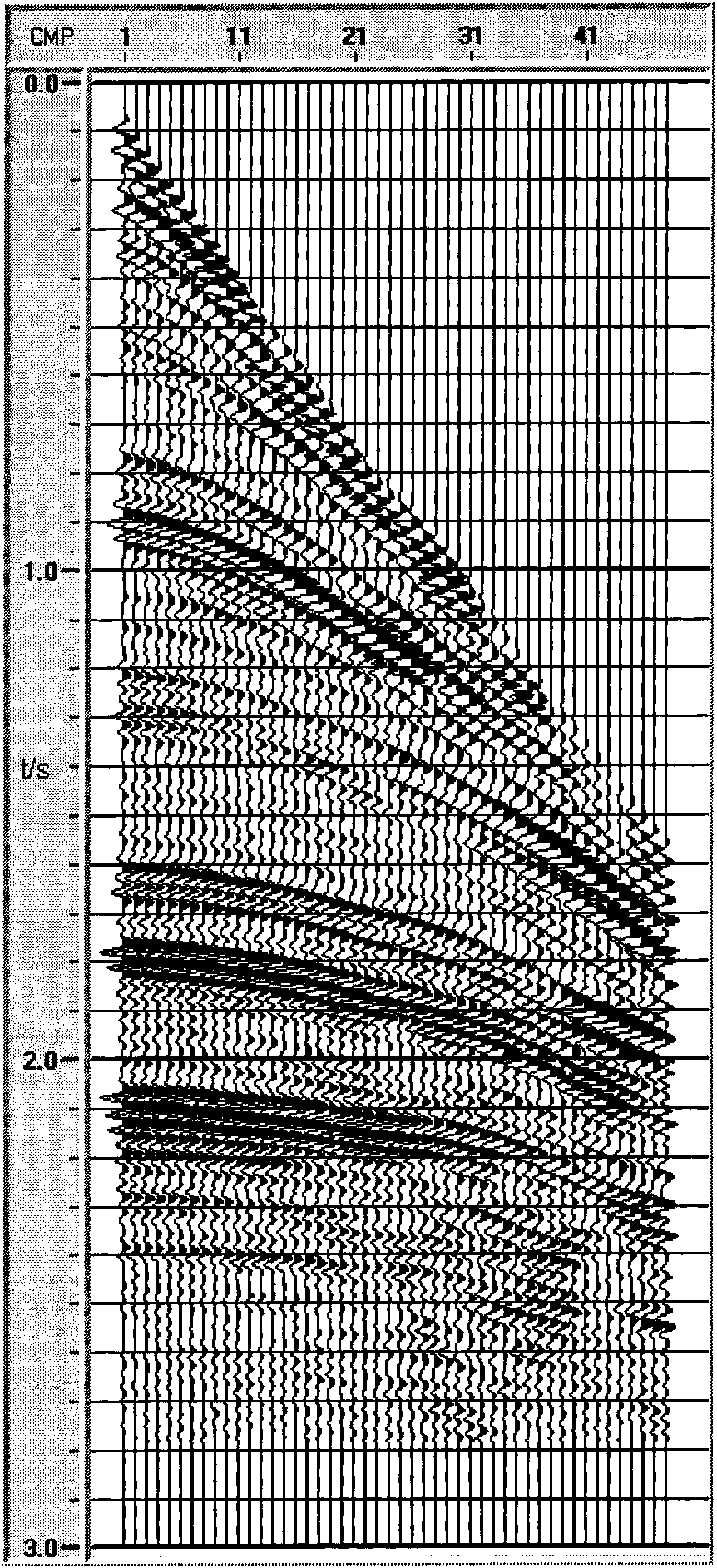

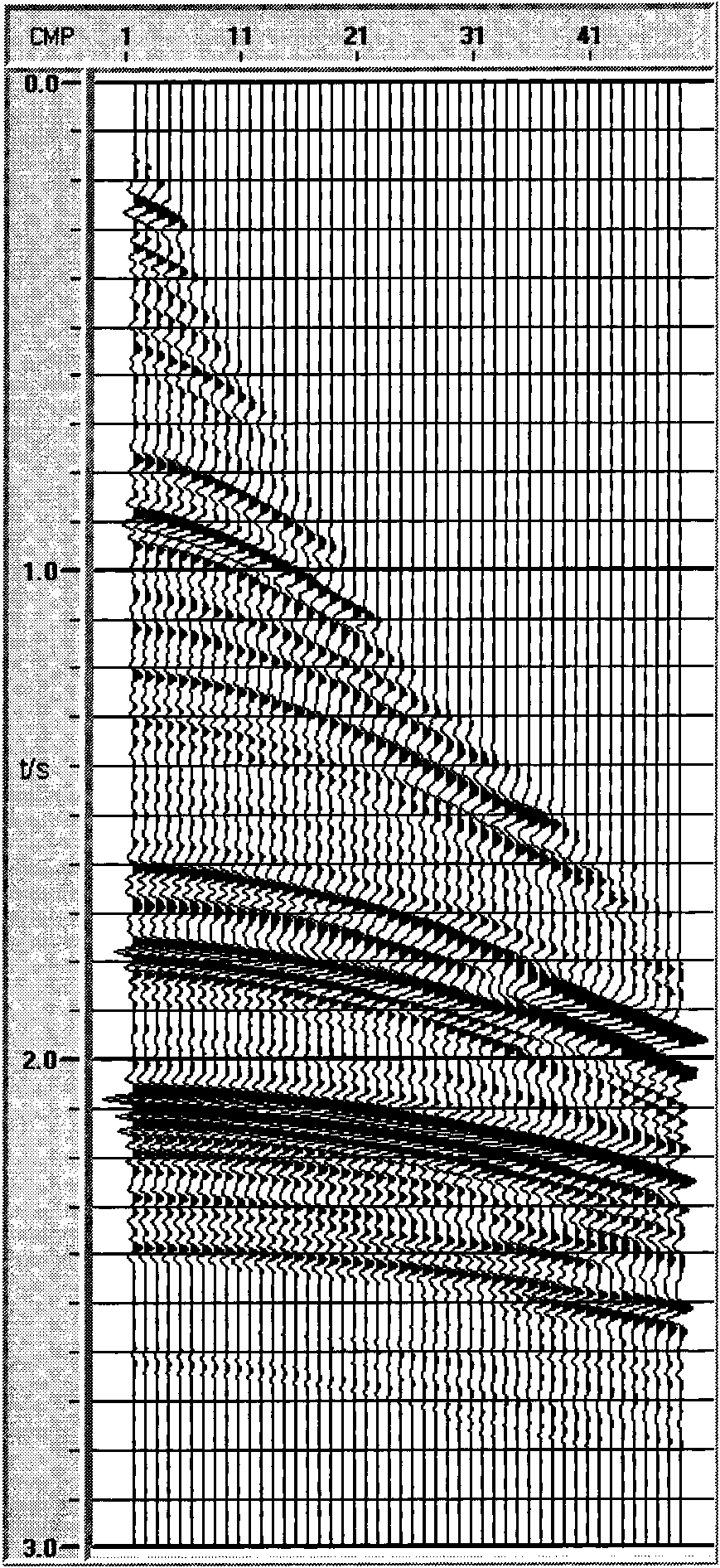

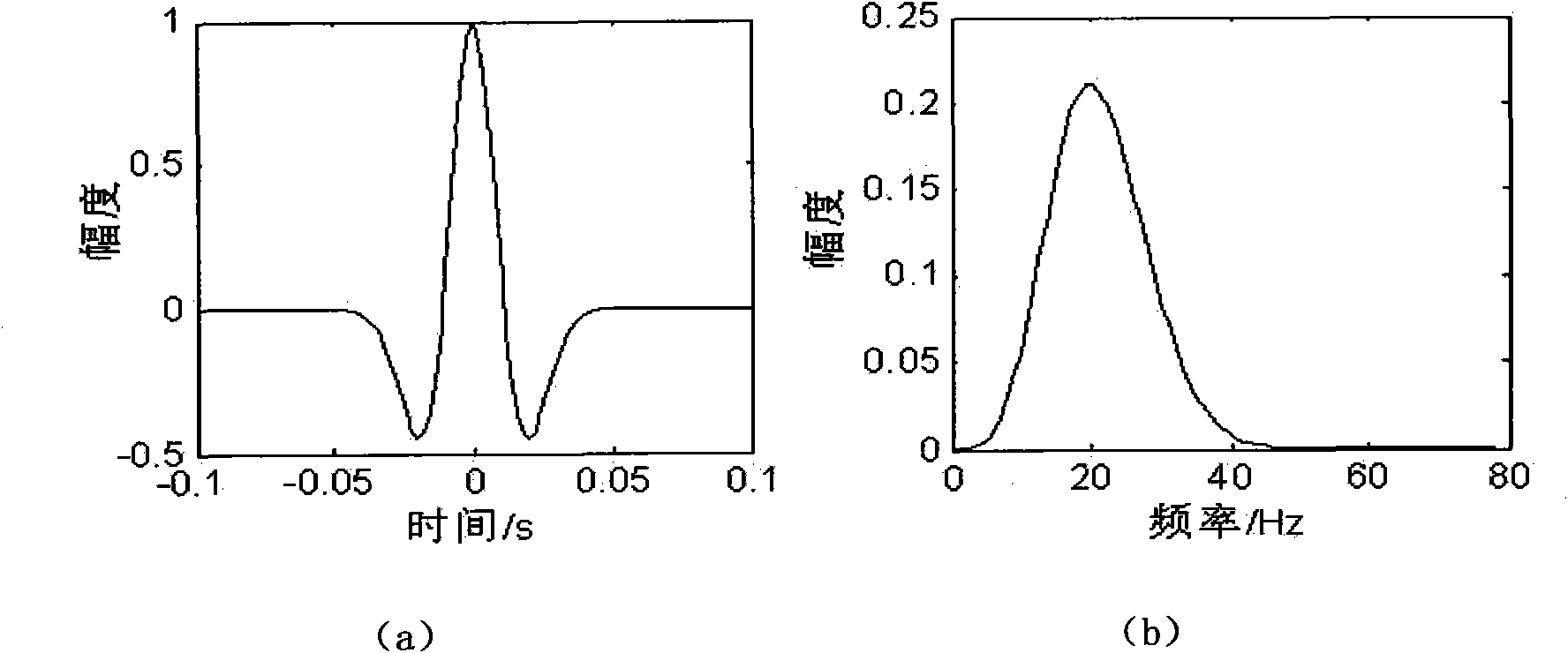

Two-dimensional filtering method for a plurality of gathers of digital seismic signal

InactiveCN102053276AEffective suppressionImprove applicabilitySeismic signal processingDigital signal processingPhase function

The invention belongs to the technical field of digital signal processing such as seismic exploration data processing and electronic signal processing, and particularly relates to a method for performing two-dimensional filtering to a digital signal. The method comprises the following steps: collecting data gathers of the digital seismic signal; performing Hilbert transformation to the data gathers of the digital seismic signal to obtain cosine phase function gathers and instantaneous envelope gathers of the digital seismic signal; conducting the two-dimensional filtering on the cosine phase function gathers; performing corresponding multiplication to the cosine phase function gathers after two-dimensional filtering and the instantaneous envelope gathers; and outputting the data gathers of the digital seismic signal after the noise, the interfering signal as well as the aliasing phenomenon are eliminated, so as to achieve the purpose of fidelity processing of the digital seismic signal.

Owner:CHINA PETROLEUM & CHEM CORP +1

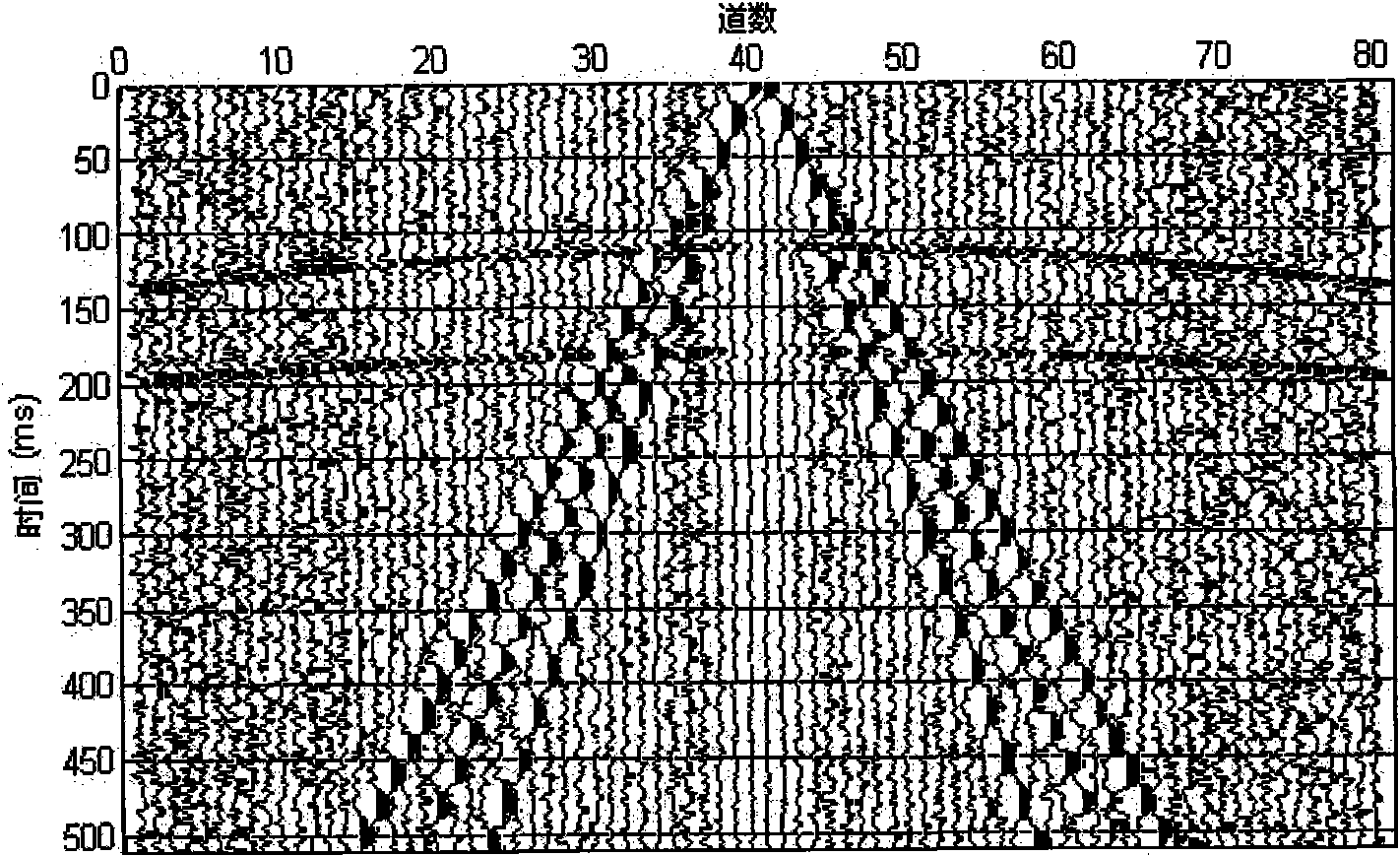

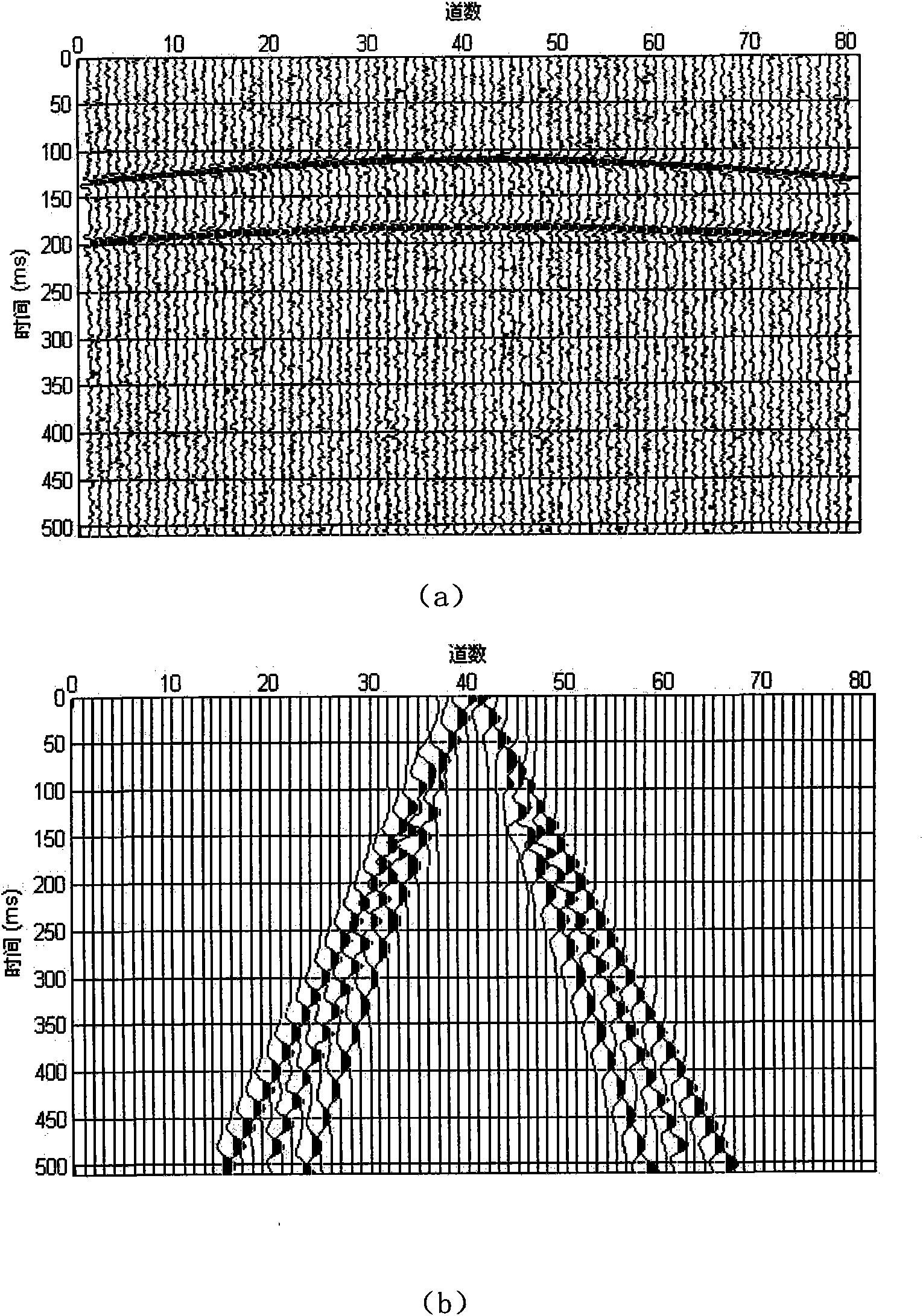

Basis tracking algorithm-based surface wave separation and suppression method

ActiveCN102043165AHigh resolutionThe main frequency parameter is smallSeismic signal processingTime domainTrack algorithm

The invention relates to a basis tracking algorithm-based surface wave separation and suppression method, which comprises the following steps of: adaptively establishing an overcomplete atomic library according to an actual frequency range of a seismic profile and structural characteristics of seismic signals, sparsely decomposing each seismic signal of the seismic profile through the basis tracking algorithm, and screening important atoms capable of approximately reestablishing the seismic signals; and adaptively setting an energy threshold and a main frequency threshold range according to the screened important atoms so as to find atoms forming a surface wave from the decomposed result of each seismic signal, and subtracting the seismic signals from surface wave components reestablished by the surface wave atoms to obtain the seismic signals after the surface wave is suppressed. The method has the characteristic of adaptively matching signals, and can reflect local characteristics of time domain and frequency domain of the seismic signals simultaneously; and compared with the one-dimensional Fourier transform filter surface wave suppression method, the method can effectively suppress the surface wave, and slightly damages an effective signal.

Owner:PETROCHINA CO LTD

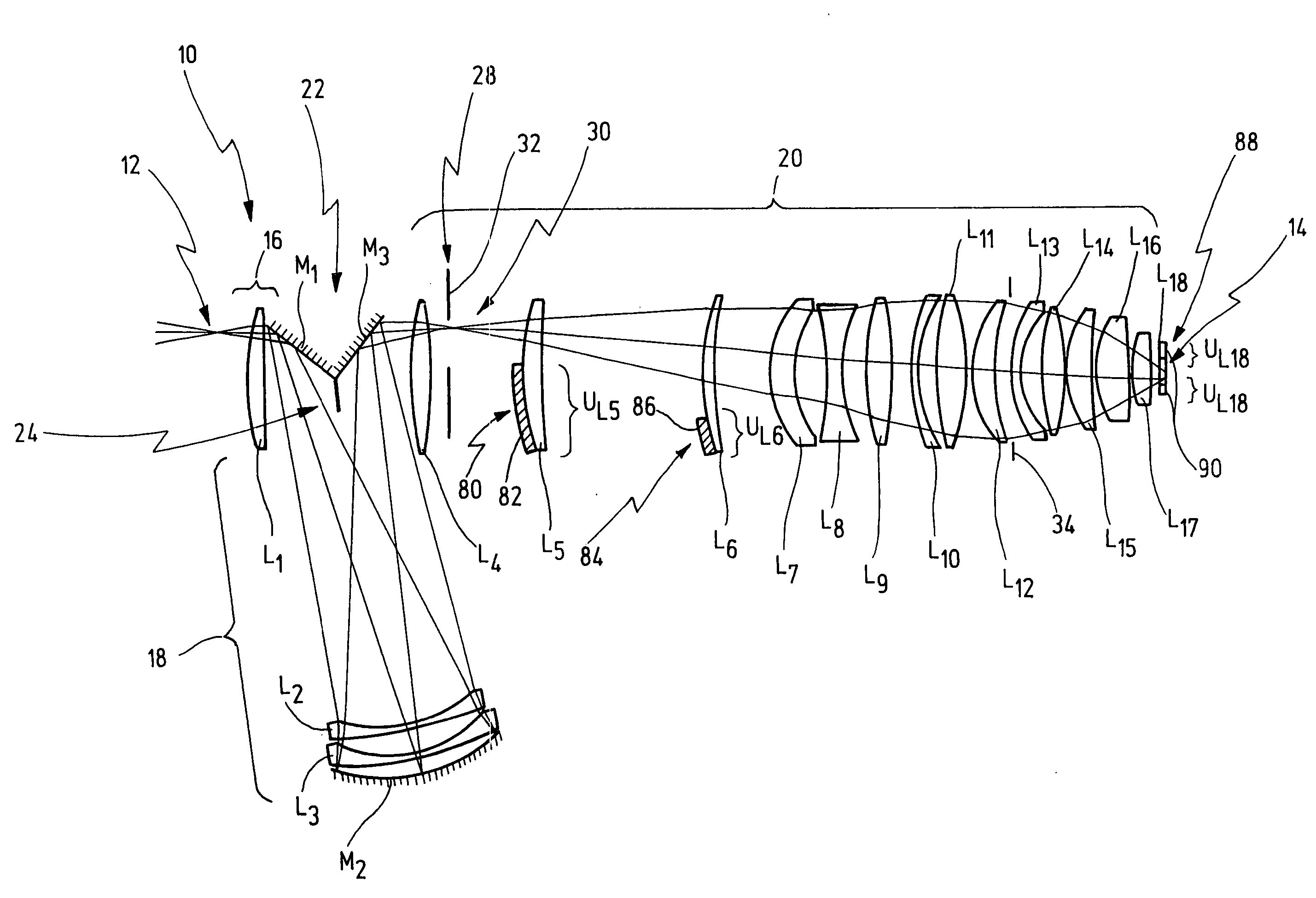

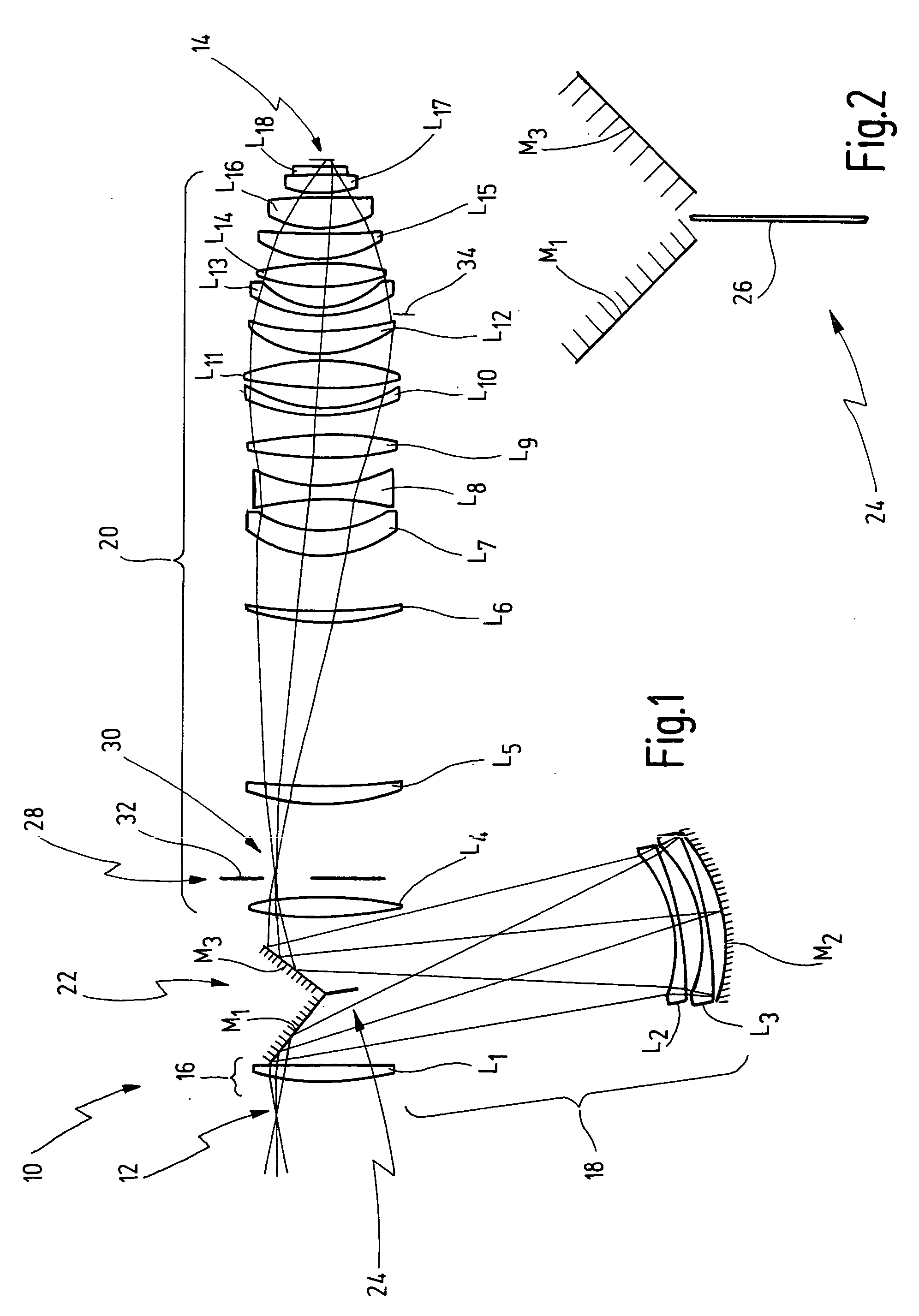

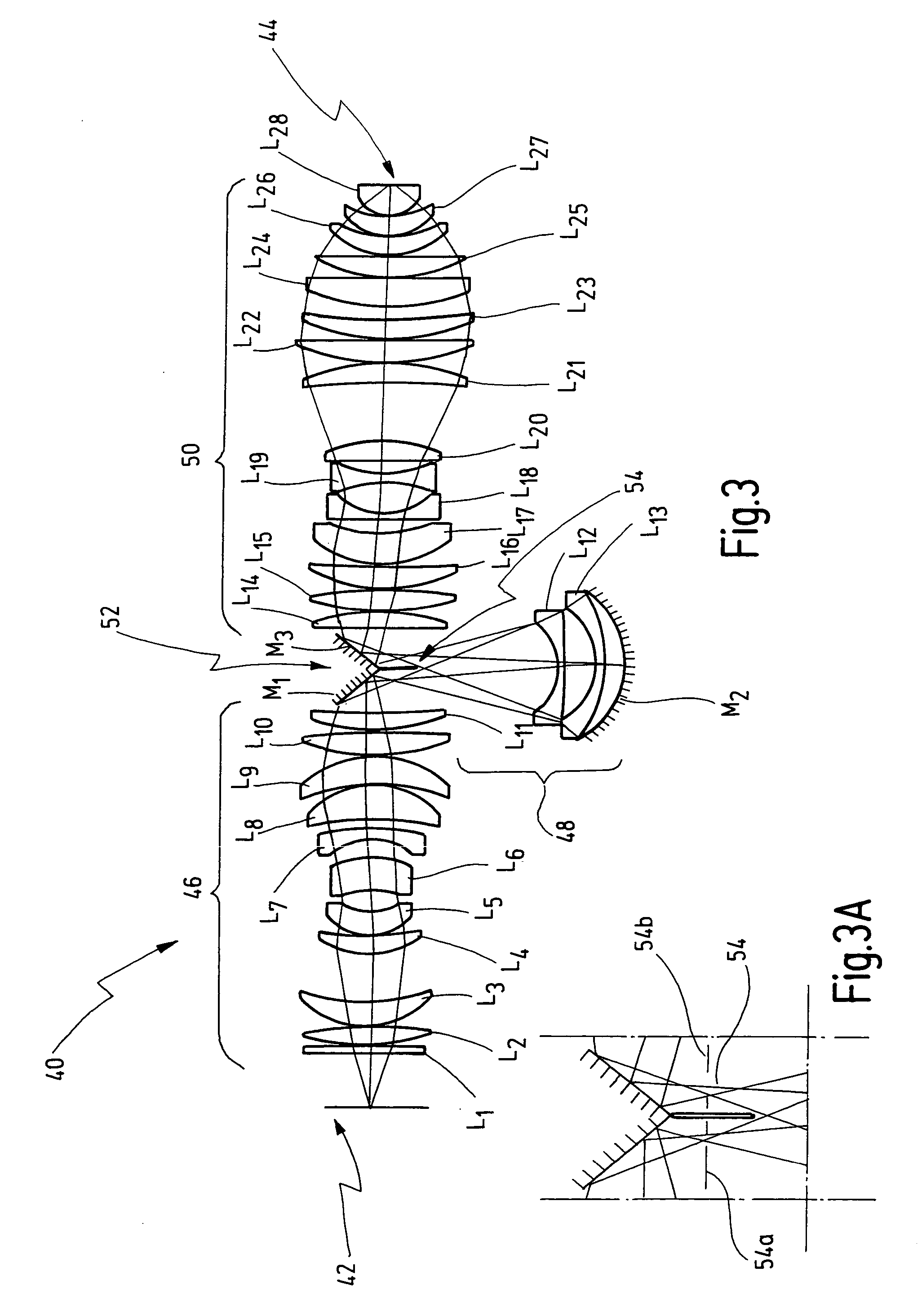

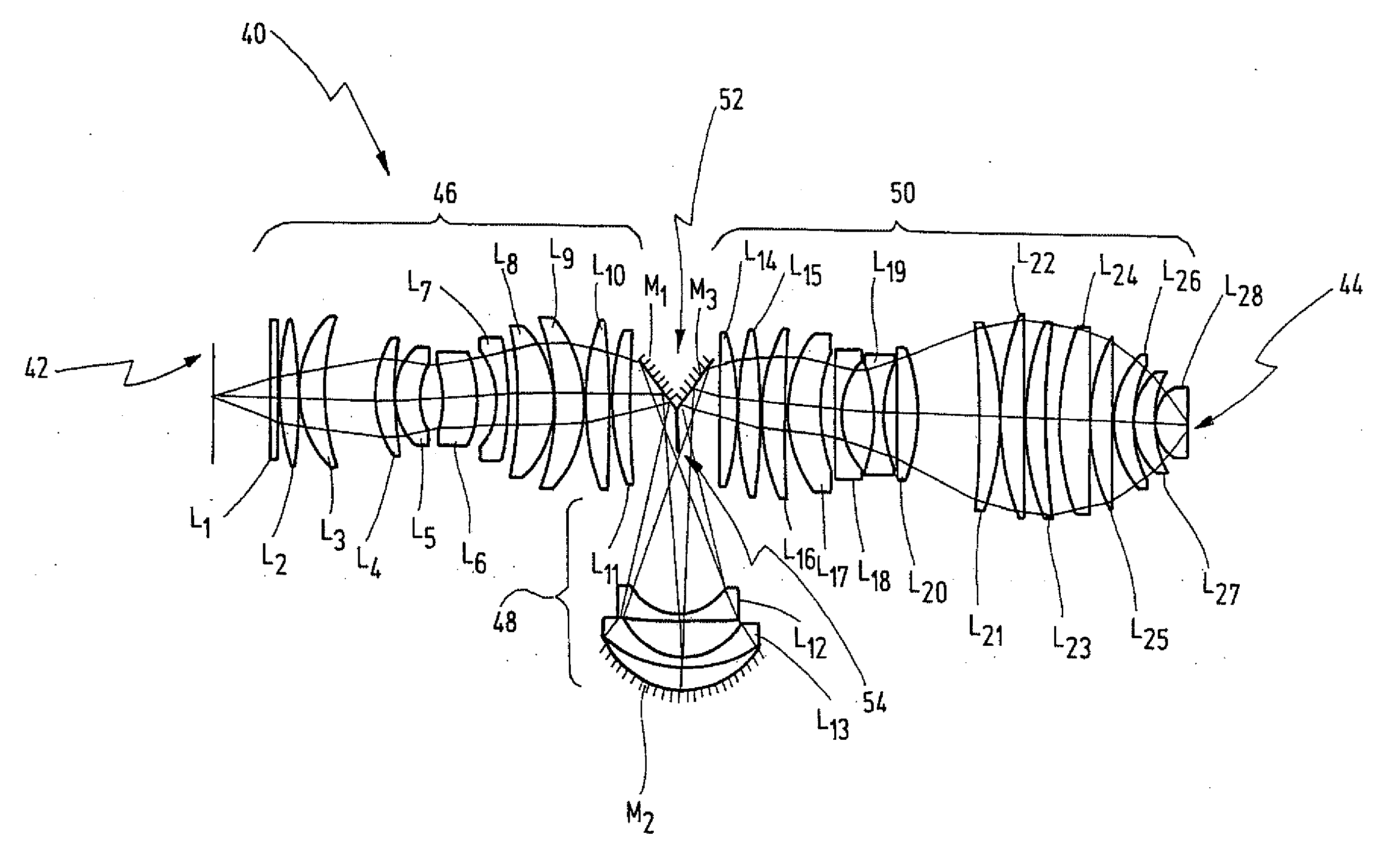

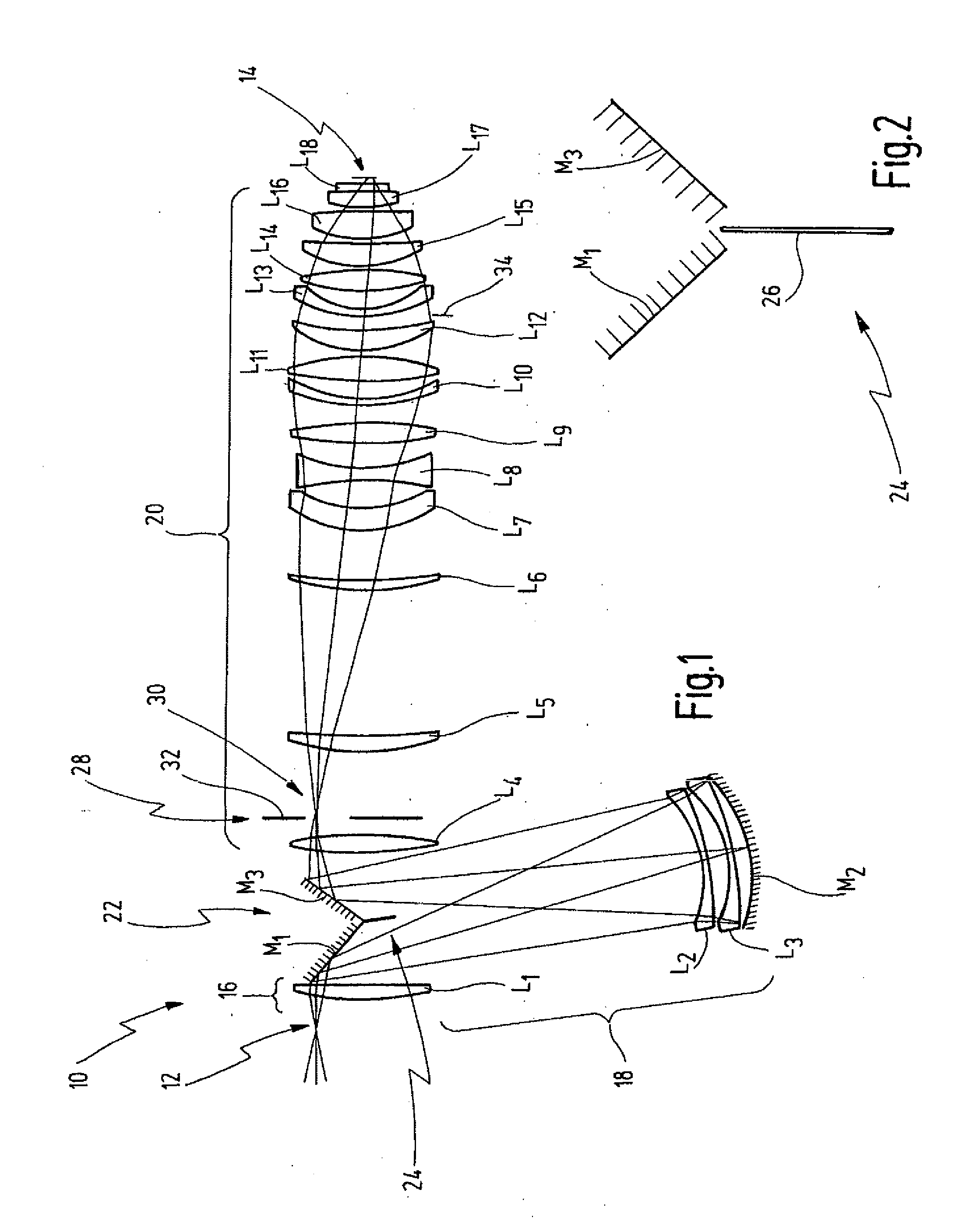

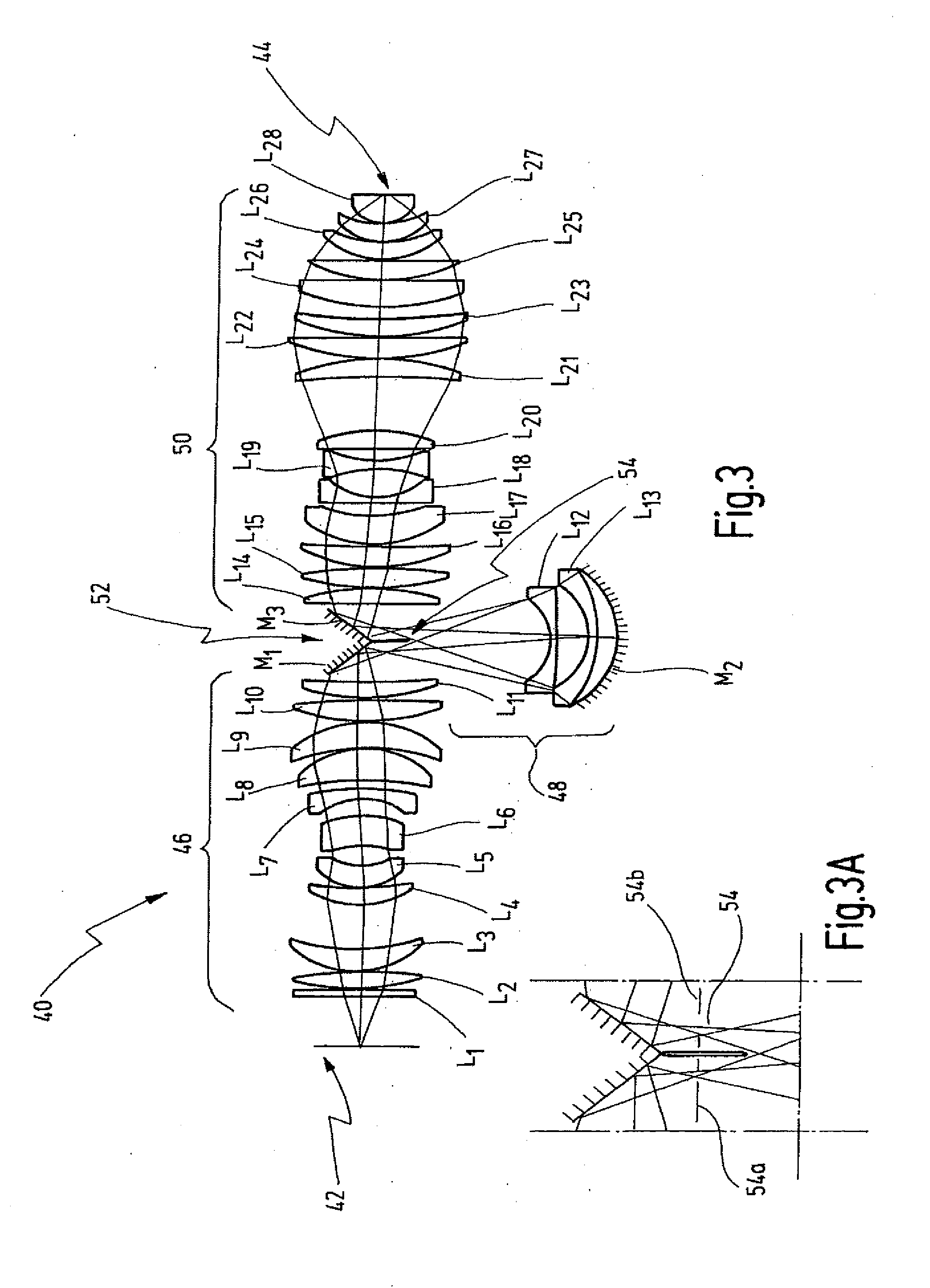

Microlithography projection objective

InactiveUS20090115986A1Improve imaging effectEffective lightingPhotomechanical exposure apparatusMicrolithography exposure apparatusComputer scienceImage plane

Microlithography projection objectives for imaging into an image plane a pattern arranged in an object plane are described with respect to suppressing false light in such projection objectives.

Owner:CARL ZEISS SMT GMBH

Chinese medicine for preventing and treating virosis of livestock and poultry

The invention relates to traditional Chinese medicine for preventing and curing livestock and poultry virosis, which comprises and is made from the following raw materials by weight proportion: 8-12 proportions of goldthread root, 6-10 proportions of flos lonicerae, 8-12 proportions of forsythiae, 10-15 proportions of manyflower glorybower root, 10-15 proportions of dandelion, 5-8 proportions of liquorice, 10-15 proportions of lespedeza, 5-8 proportions of atractylodes sinensis and 10-15 proportions of grifola. The combined use of medicines of the invention can prevent and cure livestock and poultry virosis safely and effectively, eliminate accumulation of viruses in livestock and poultry, promote growth of livestock and poultry, and has particular effect in preventing and curing of hog plague, foot-and-mouth disease, angiostrongyliasis, Gongxingti, streptococcus, mildew, oedema, heart disorderly inflammation and mixed infection, wherein, the preventing rate is as high as over 95 percent and the recovery rate is as high as 90 percent.

Owner:张爱民

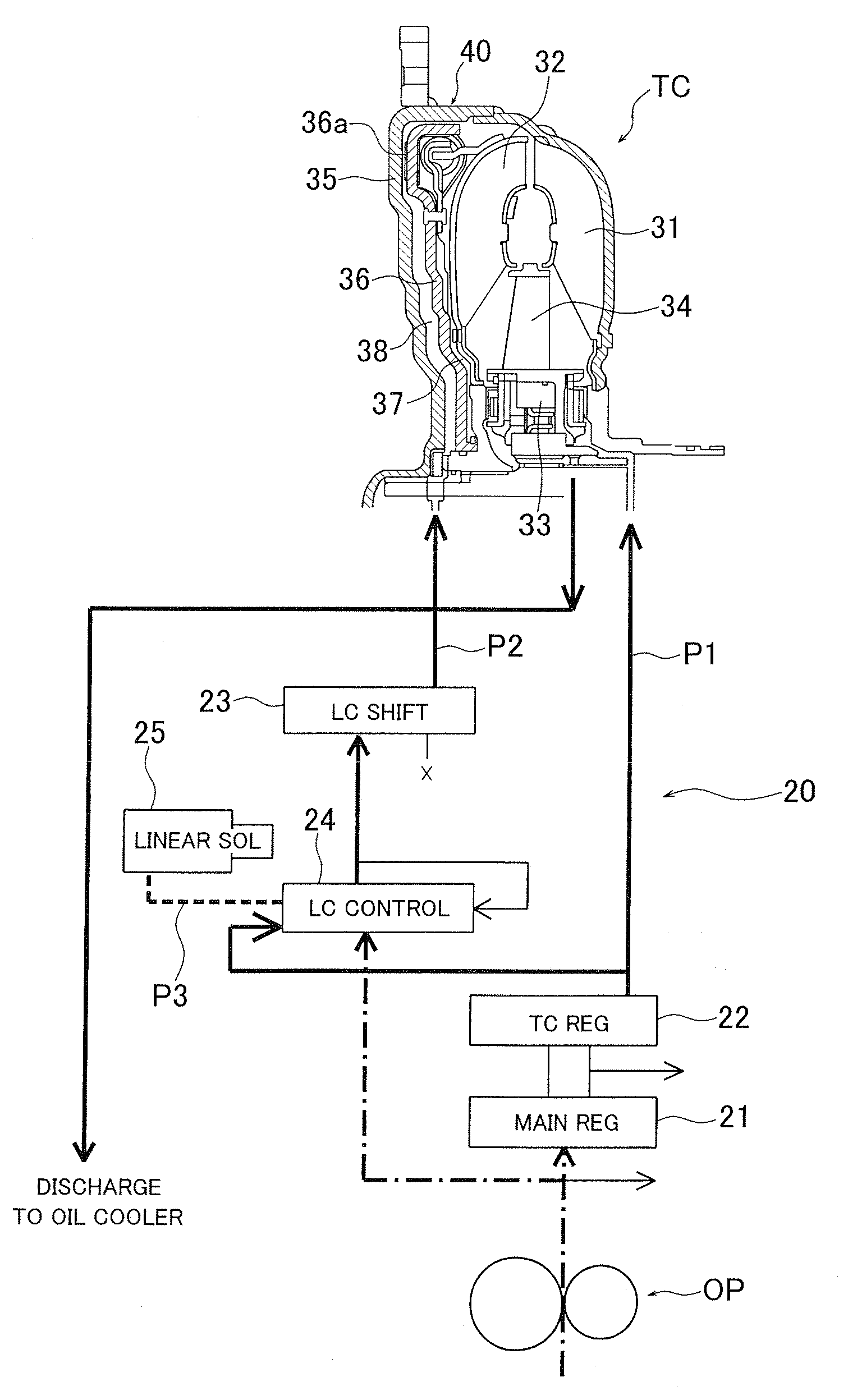

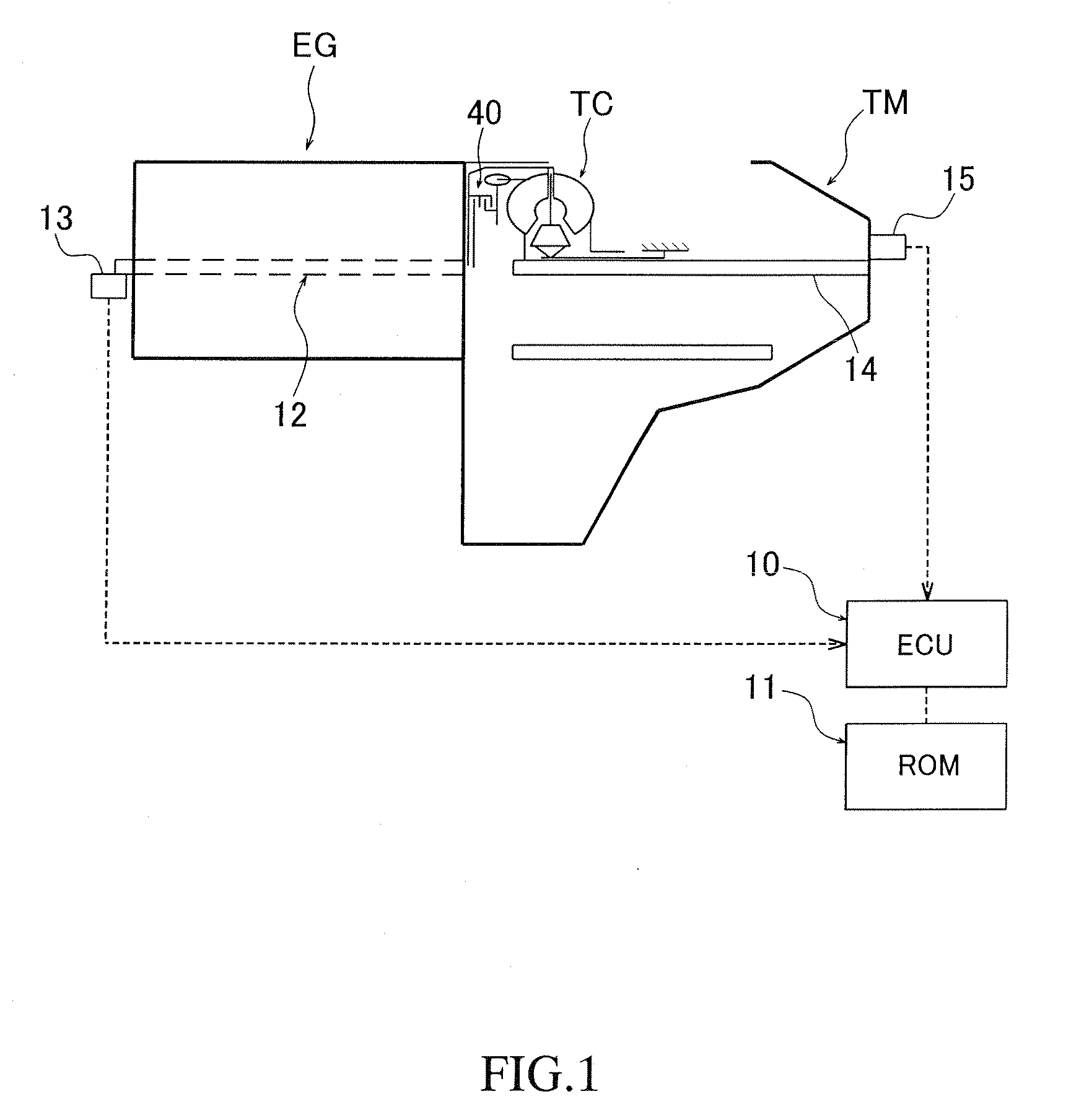

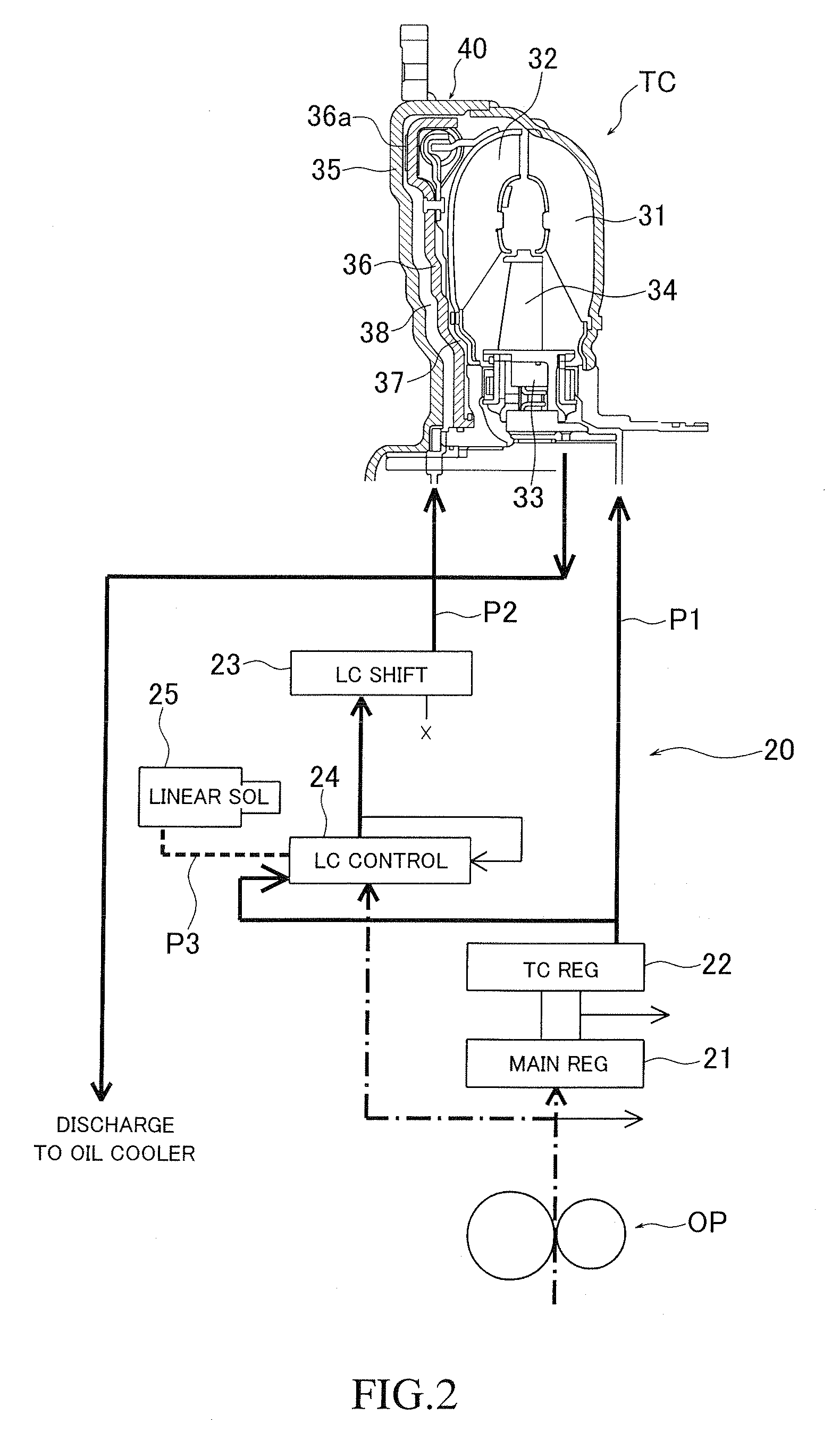

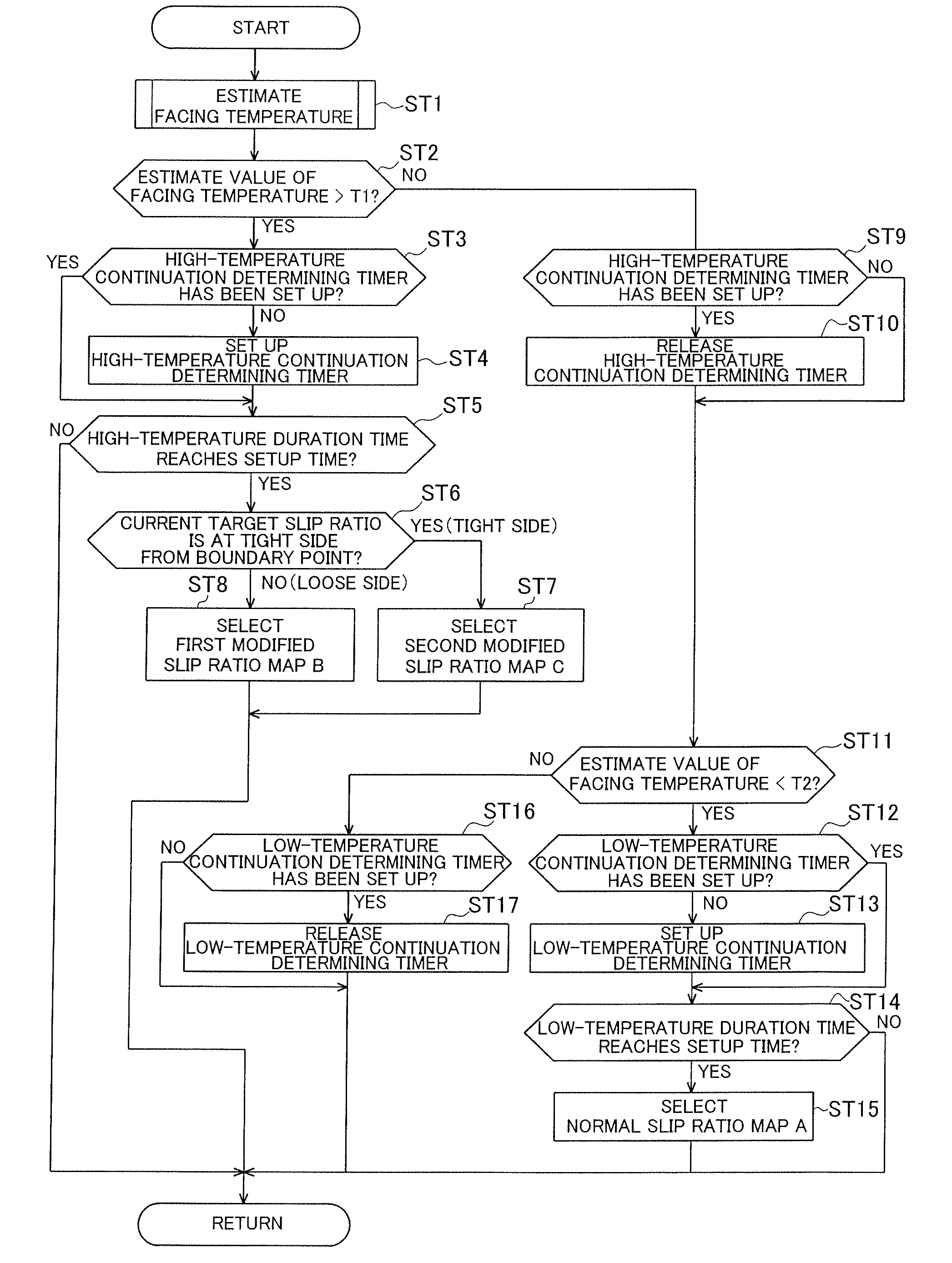

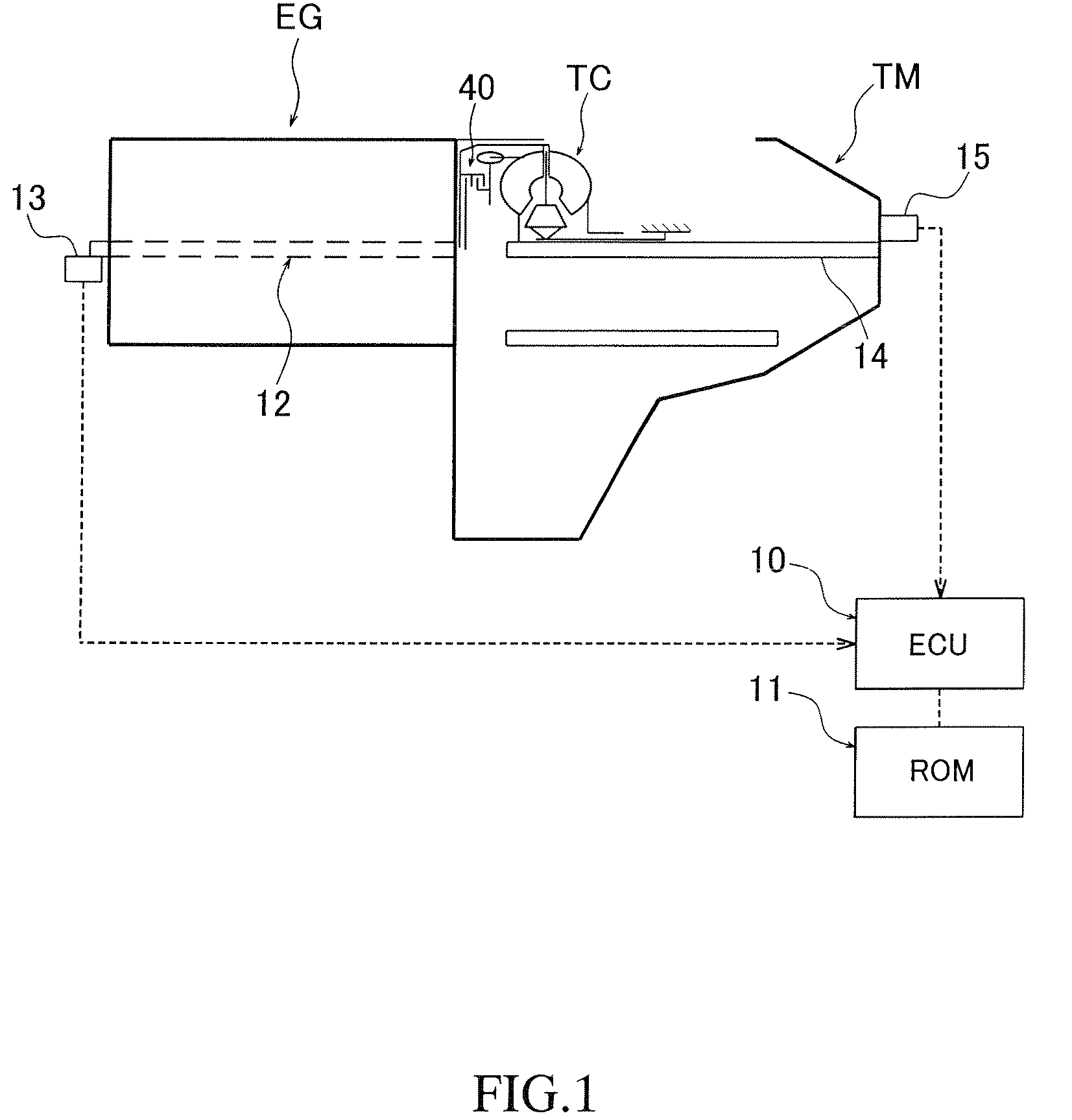

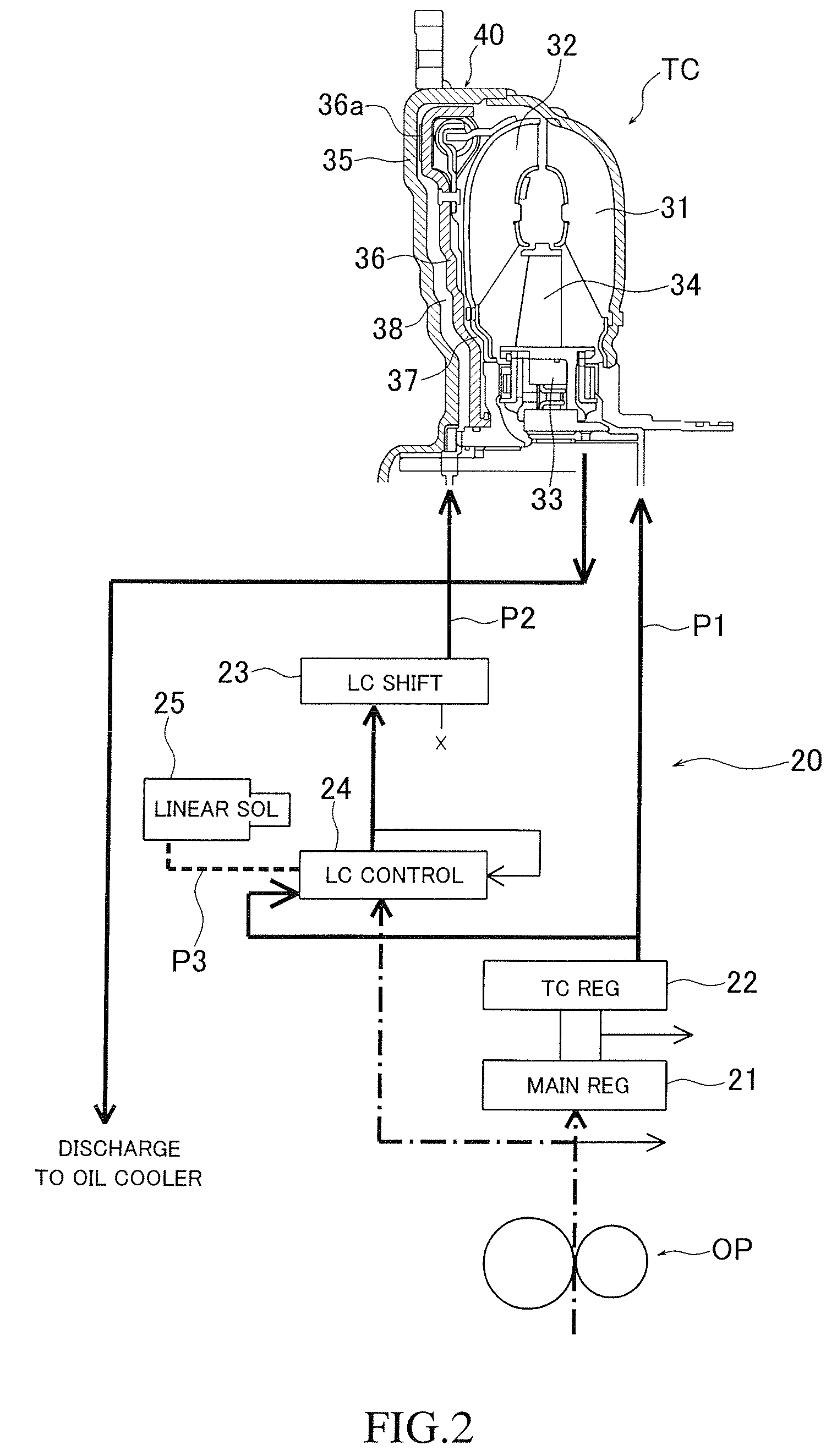

Control device of lock-up clutch

ActiveUS20100312444A1Curb riseIncrease temperatureDigital data processing detailsGearing controlClutch controlThreshold temperature

A control device for controlling an engagement state of a lock-up clutch is provided. A plurality of target slip ratio maps include a normal slip ratio map having a characteristic line of a target slip ratio defined in accordance with an engine load at a normal vehicle running condition and a modified slip ratio map having a characteristic line of the target slip ratio to become a facing calorific value lower than a facing calorific value corresponding to the slip ratio retrieved from the normal slip ratio map. In the case where an estimate value of the facing temperature continues to exceed first threshold temperature for more than predetermined time when to carry out slip control using the normal slip ratio map, control to switch the target slip ratio map from the normal slip ratio map to the modified slip ratio map is carried out.

Owner:HONDA MOTOR CO LTD

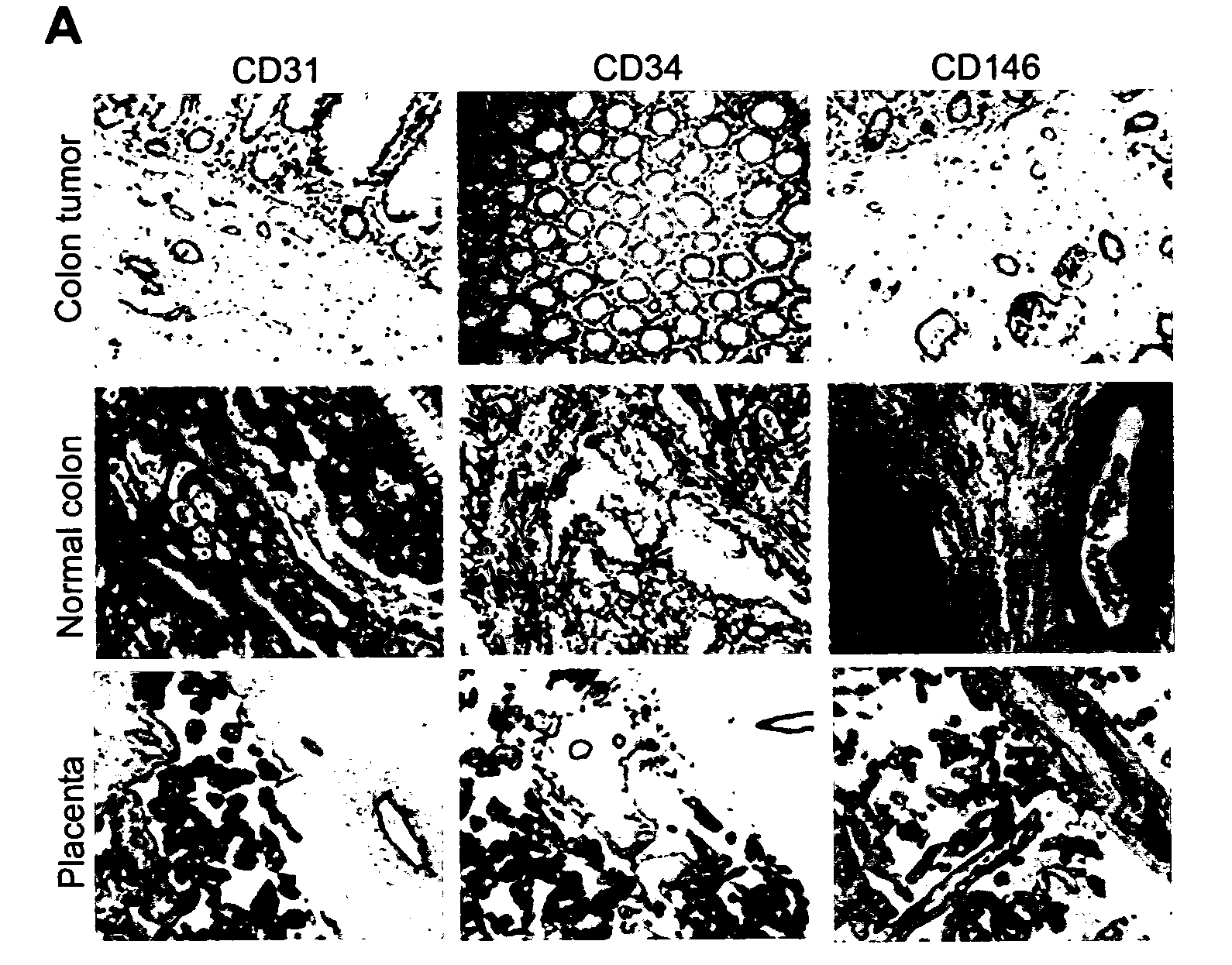

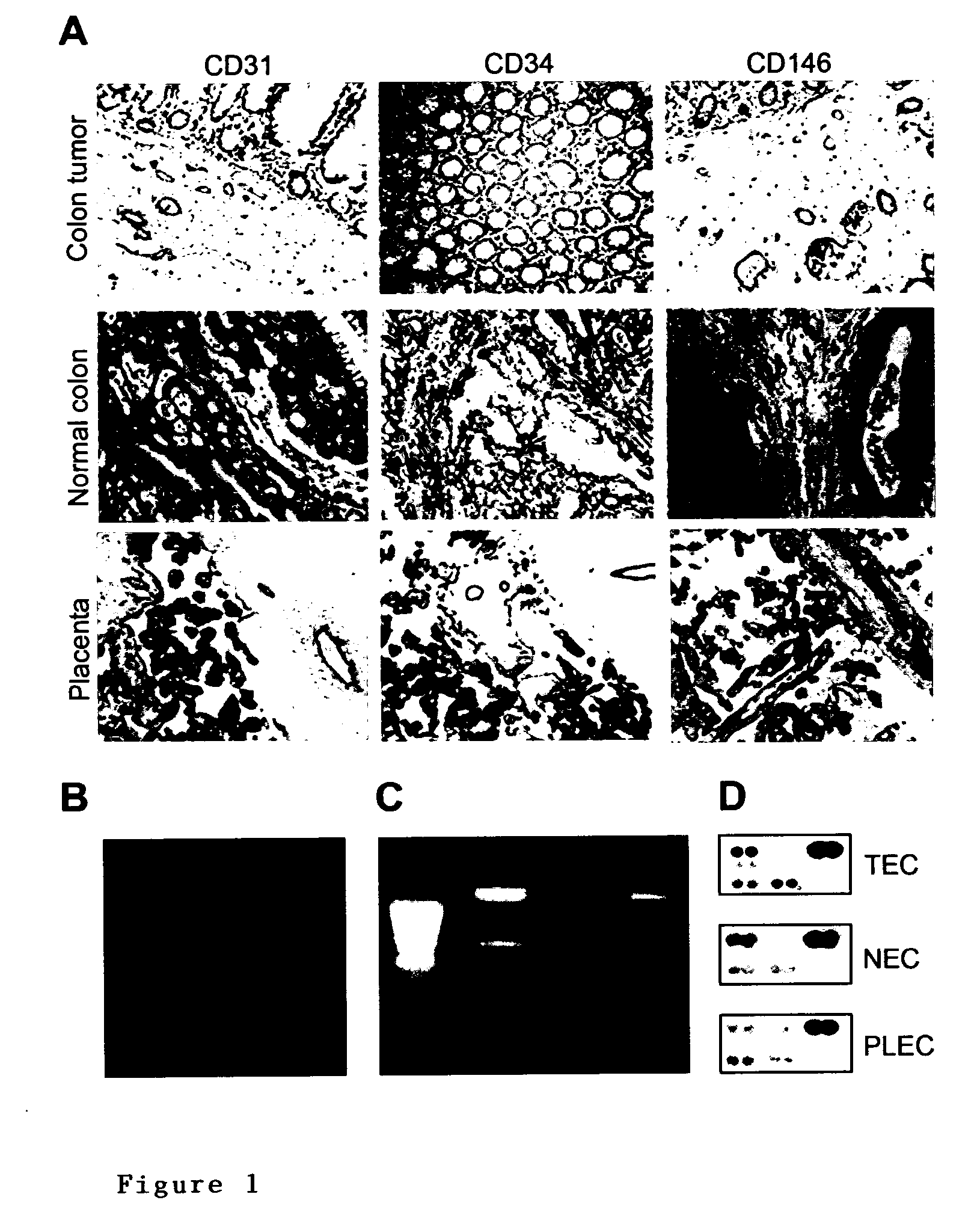

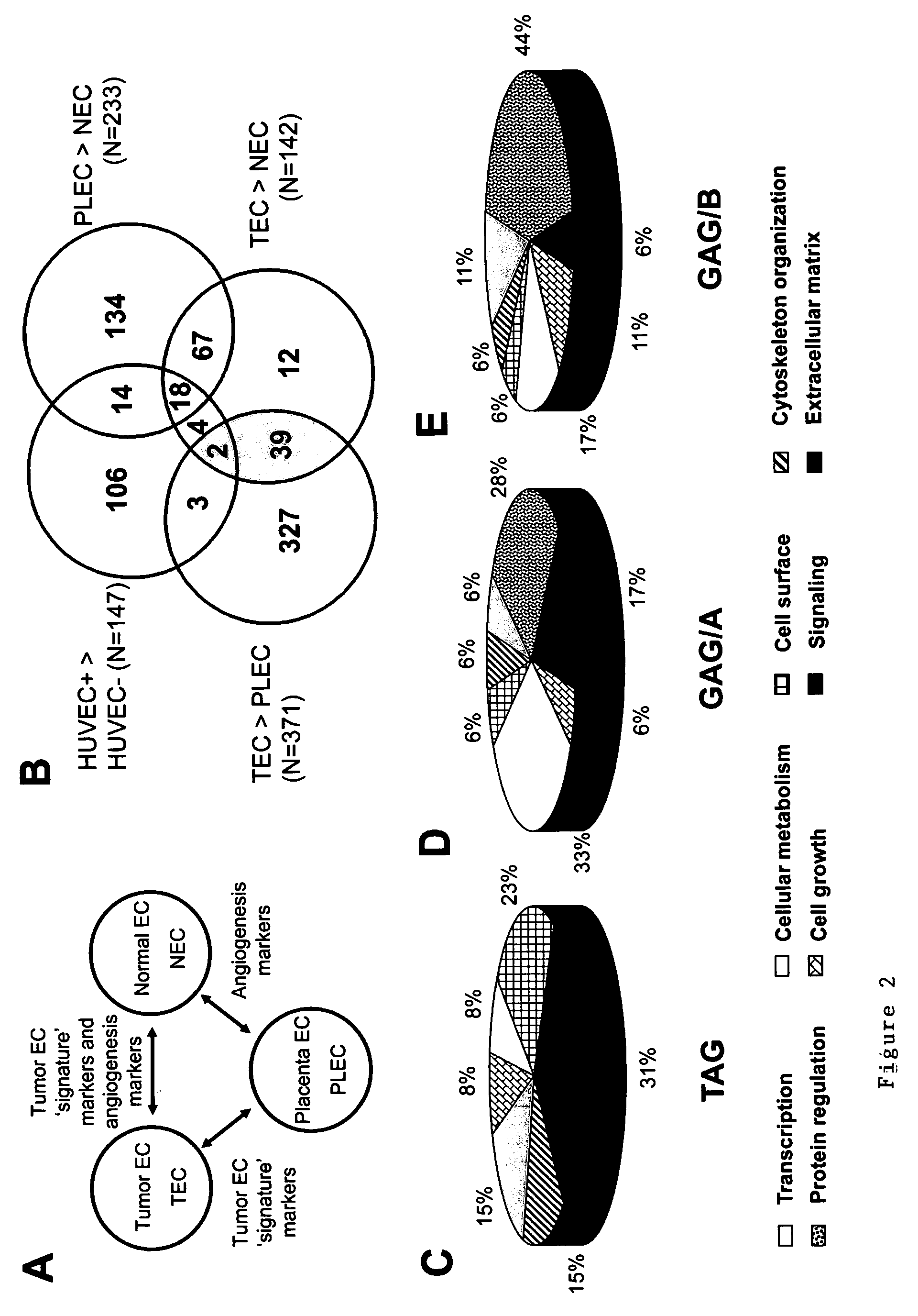

Tumor angiogenesis associated genes and a method for their identification

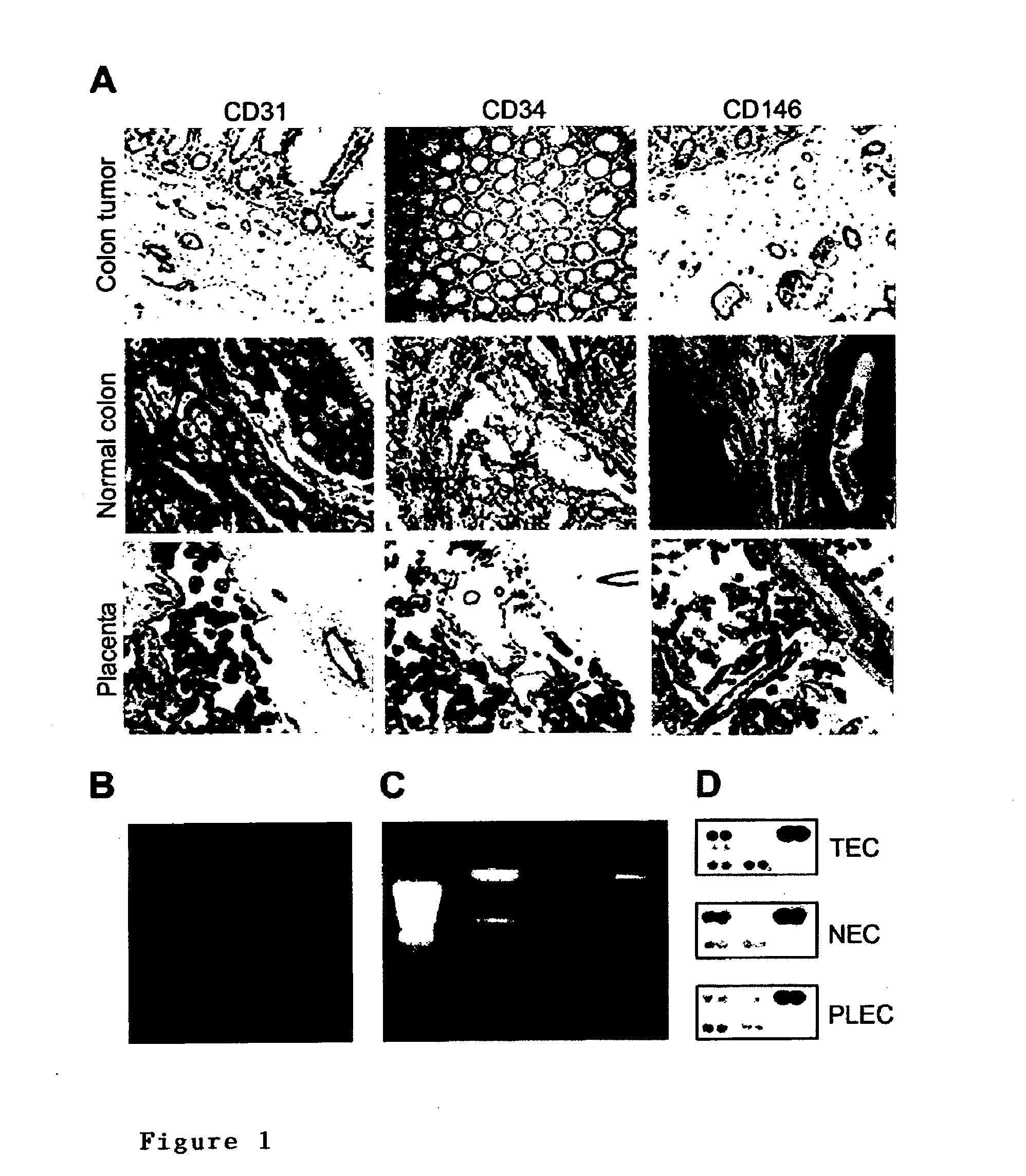

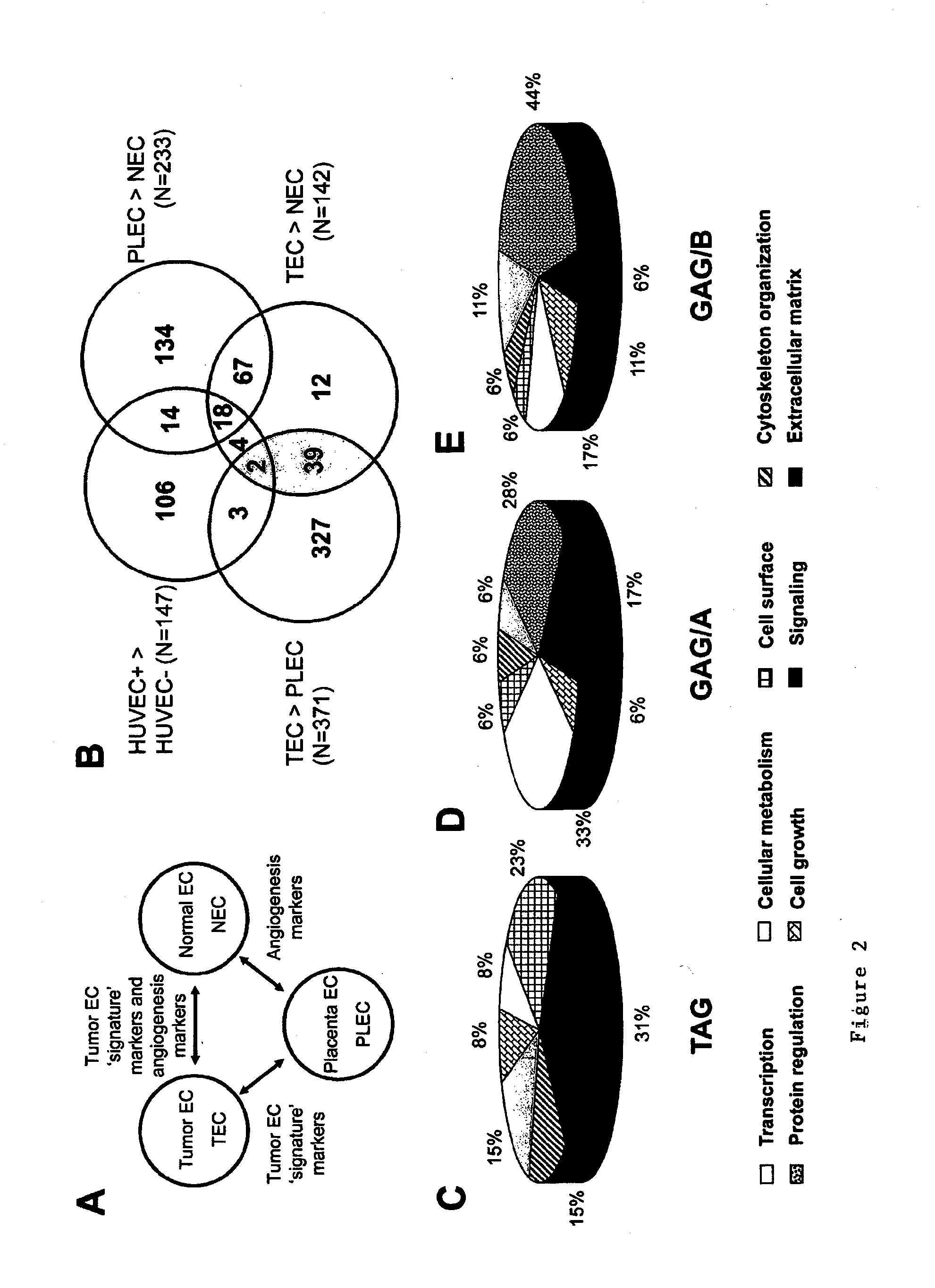

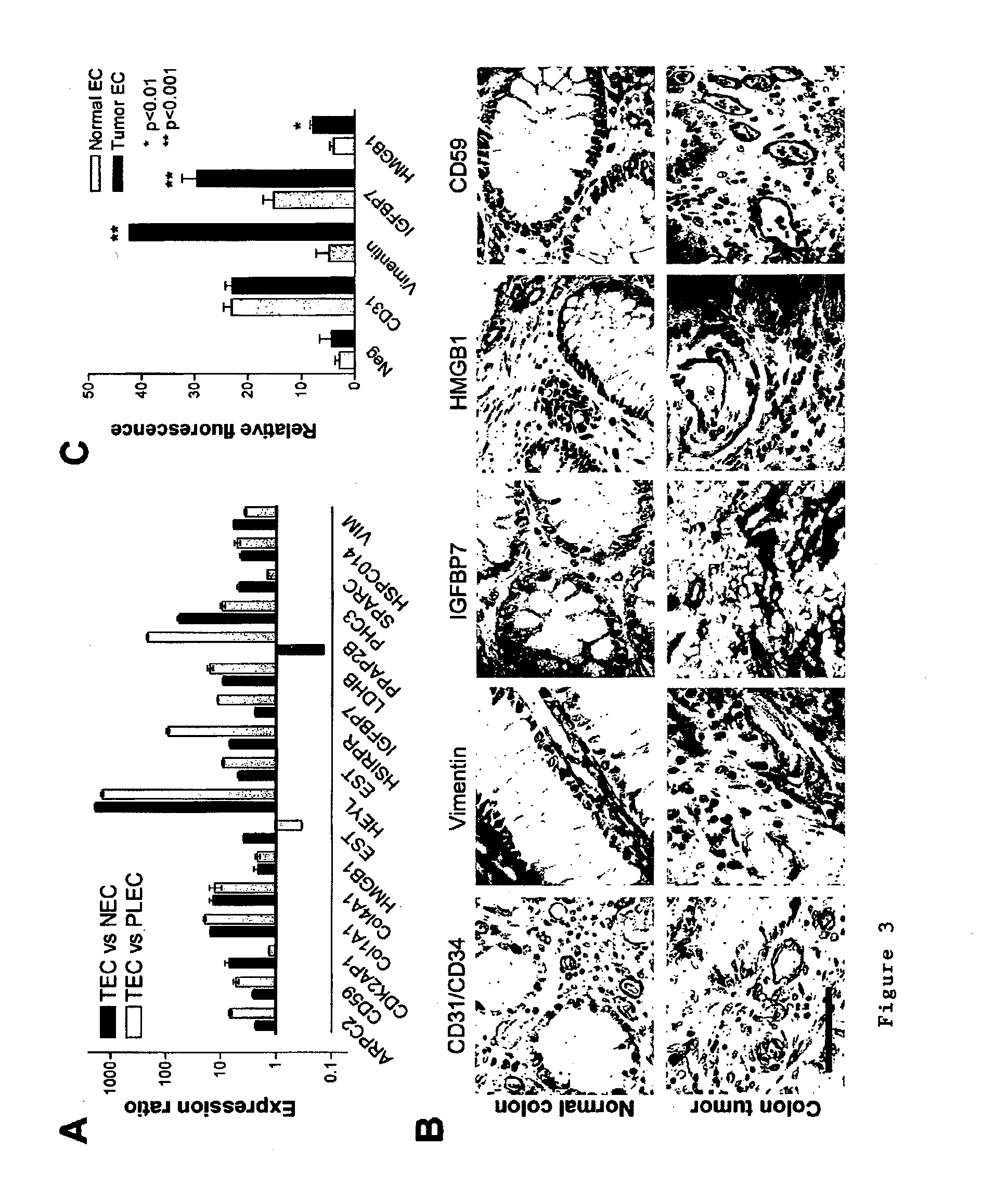

InactiveUS20090035312A1Inhibit angiogenesisReduced microvessel densityOrganic active ingredientsFungiAbnormal tissue growthMouse tumor

Methods of identifying specific target molecules for design of anti-angiogenic and vascular targeting approaches are disclosed. Transcriptional profiles of tumor endothelial cells were compared with that of normal resting endothelial cells, normal but angiogenically activated placental endothelial cells, and cultured endothelial cells. Although the majority of transcripts were classified as general angiogenesis markers, 17 genes were identified that show specific overexpression in tumor endothelium. Antibody targeting of four cell-surface expressed or secreted products (vimentin, CD59, HMGB1 and IGFBP7) inhibited angiogenesis in vitro and in vivo. Finally, targeting endothelial vimentin in a mouse tumor model significantly inhibited tumor growth and reduced microvessel density. The results demonstrate the utility of the identification and subsequent targeting of specific tumor endothelial markers for anticancer therapy.

Owner:MAASTRICHT UNIVERSITY

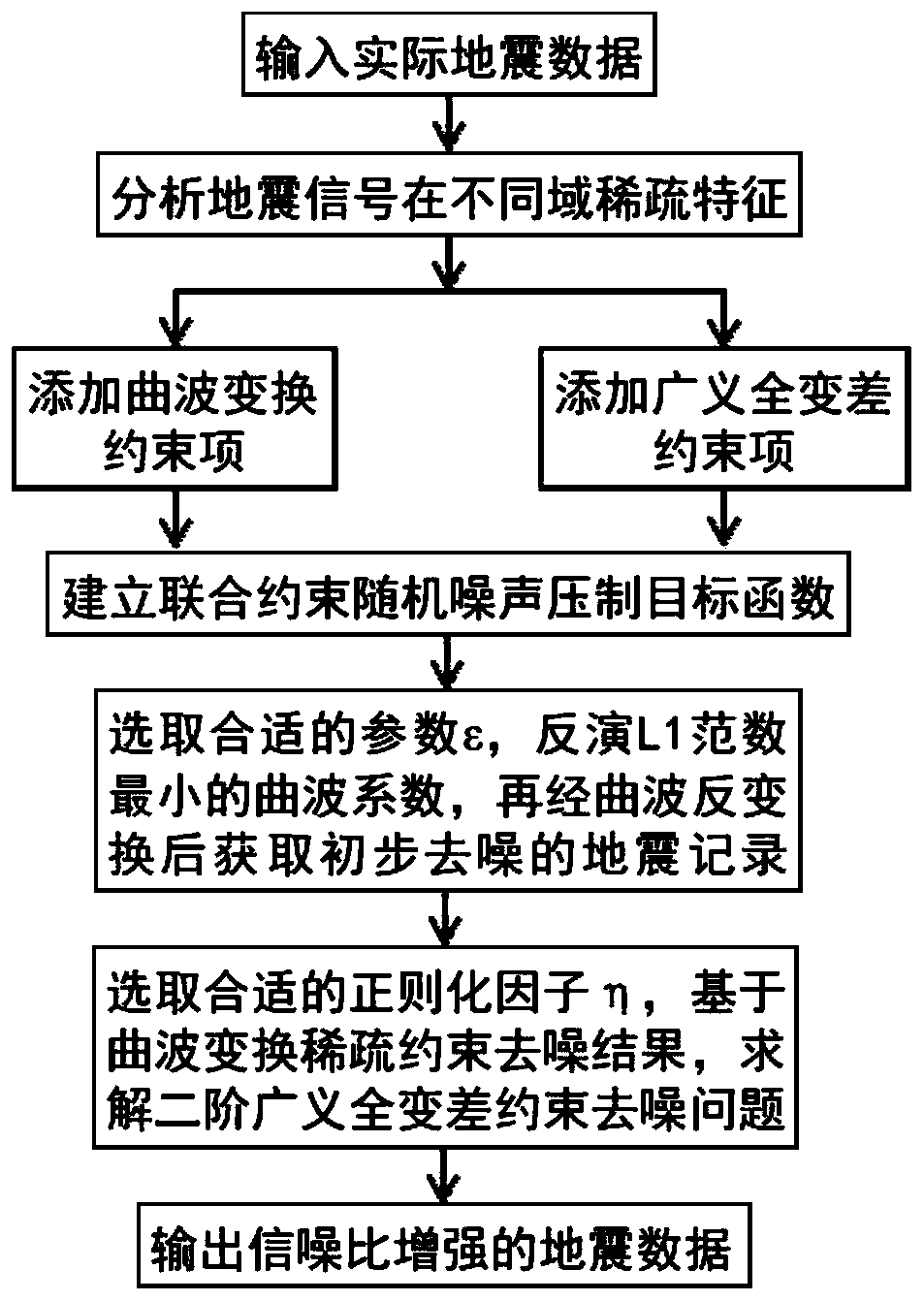

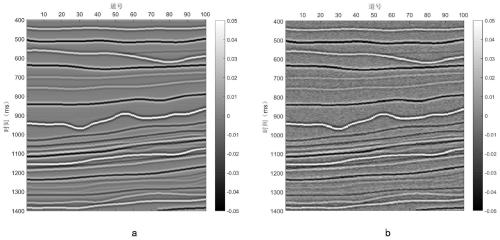

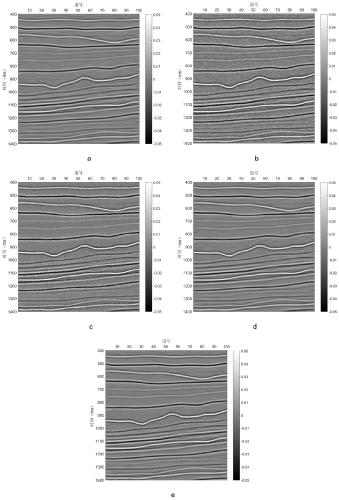

Joint constraint random noise suppression method based on sparse regularization

ActiveCN111158051AEffective suppressionImprove signal-to-noise ratioSeismic signal processingRandom noiseNoisy data

The invention relates to a joint constraint random noise suppression method based on sparse regularization, and belongs to the technical field of geophysical exploration. The method specifically comprises the following steps: S1, inputting an original seismic record, and constructing an objective function of curvelet transform-second-order generalized total variation joint constraint denoising according to sparse features of noisy data in a curvelet domain and an image gradient domain; S2, converting the L1-L2 norm regularization model containing the curvelet transform constraint term into a standard basis pursuit noise reduction problem, and inverting a curvelet coefficient with the minimum L1 norm to obtain a seismic record after preliminary denoising; and S3, taking the preliminarily denoised seismic record as an input image, solving a denoising problem of the second-order generalized total variation constraint to realize random noise suppression of the joint constraint, and finallyoutputting seismic data with an enhanced signal-to-noise ratio. According to the method, the denoising effect on random noise in the seismic data is improved, and weak signal energy can be effectively protected, so that high-quality processing of subsequent seismic data and the reliability of a seismic geological interpretation result are guaranteed.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

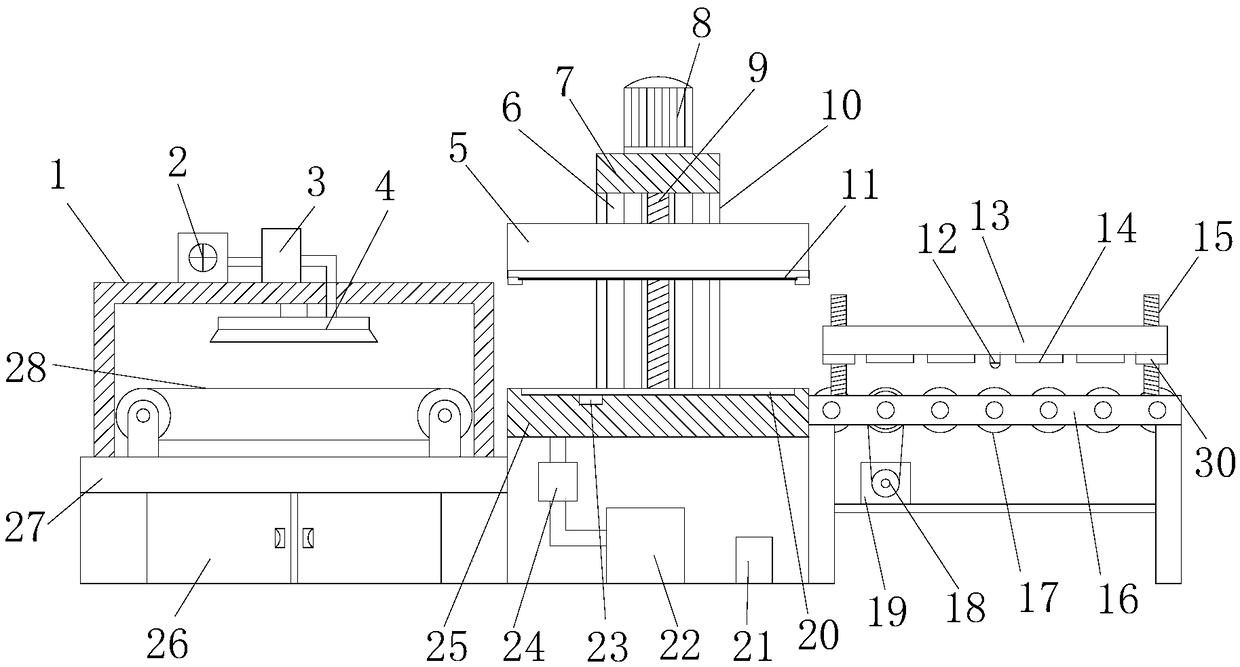

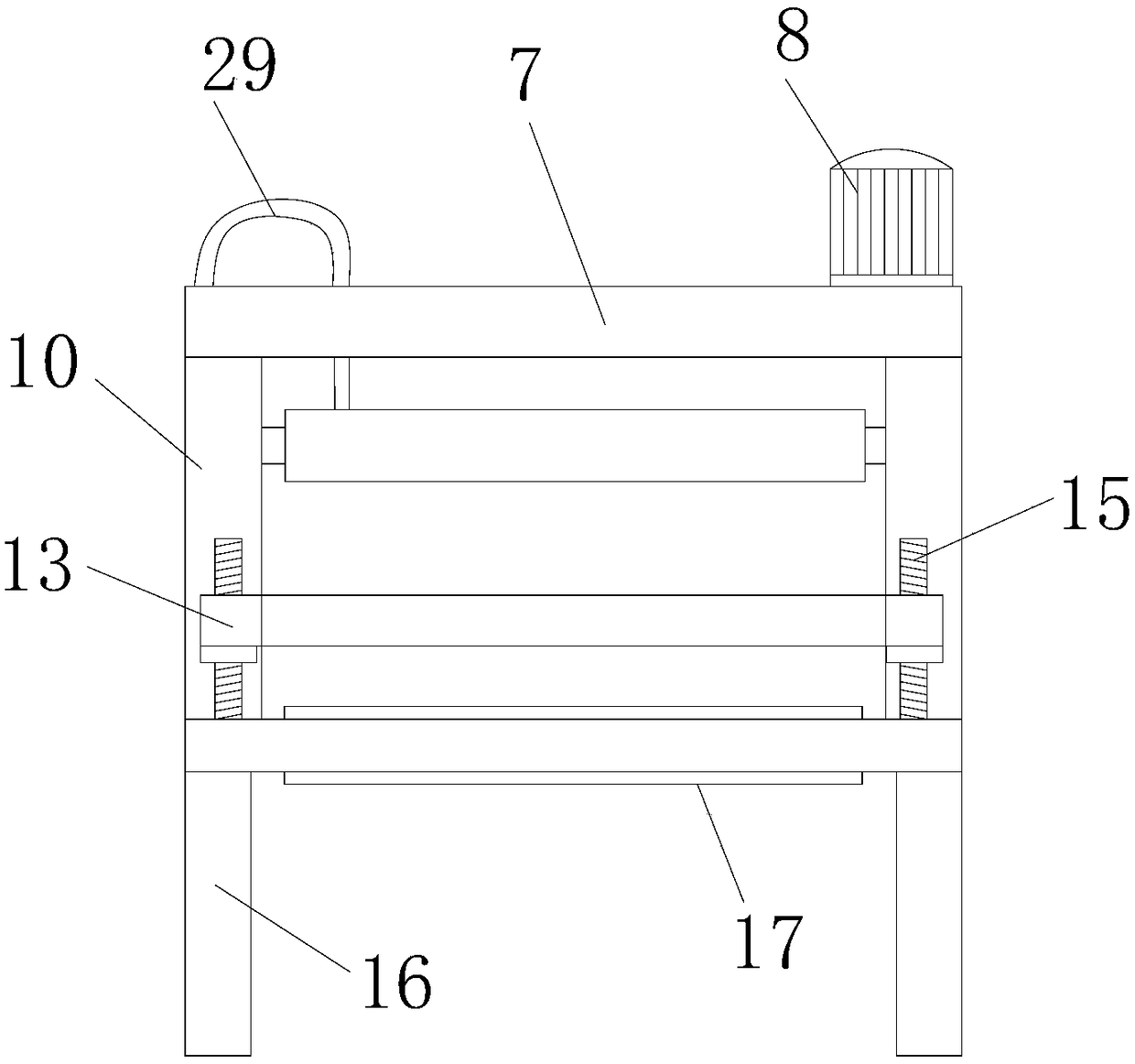

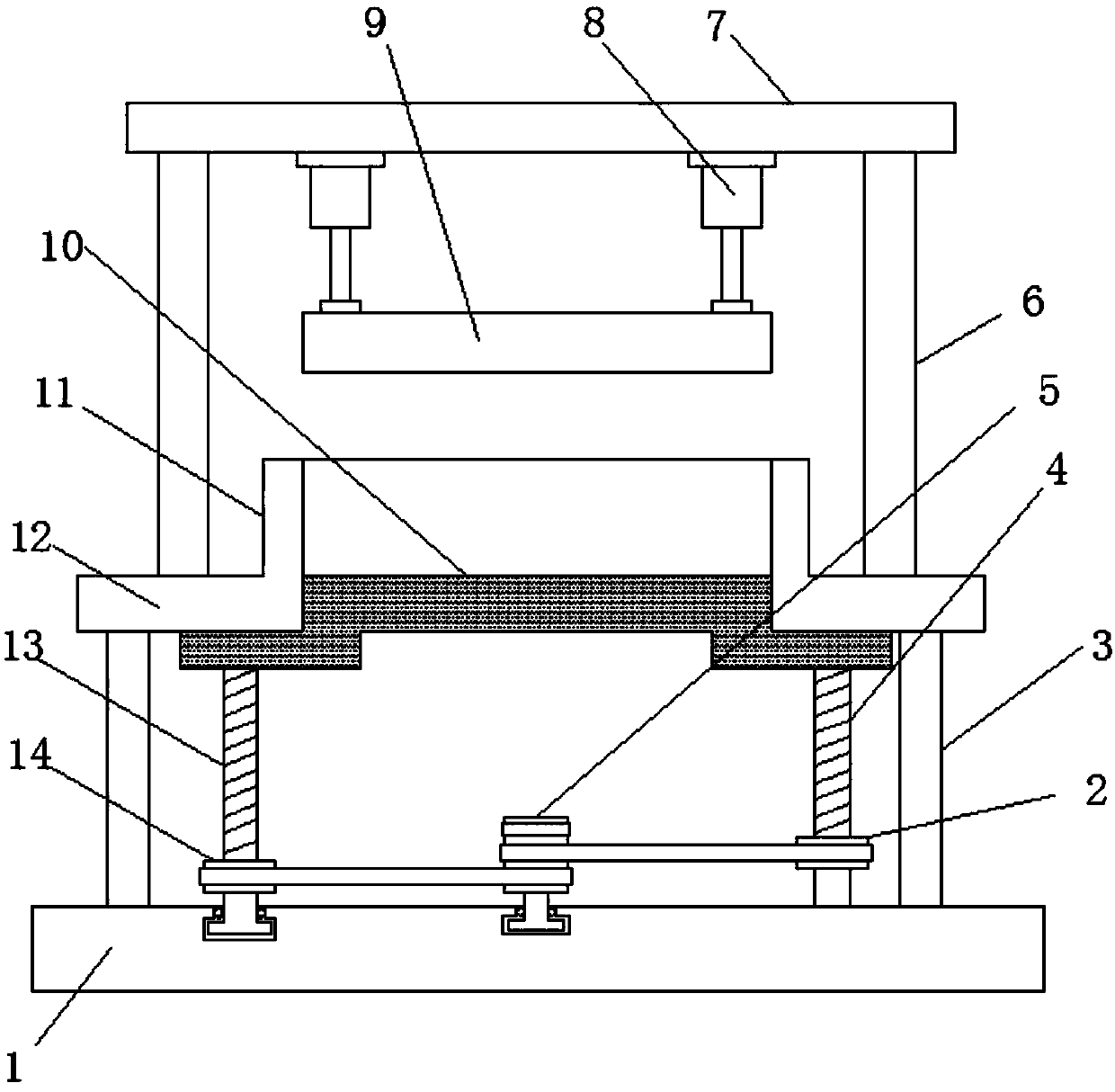

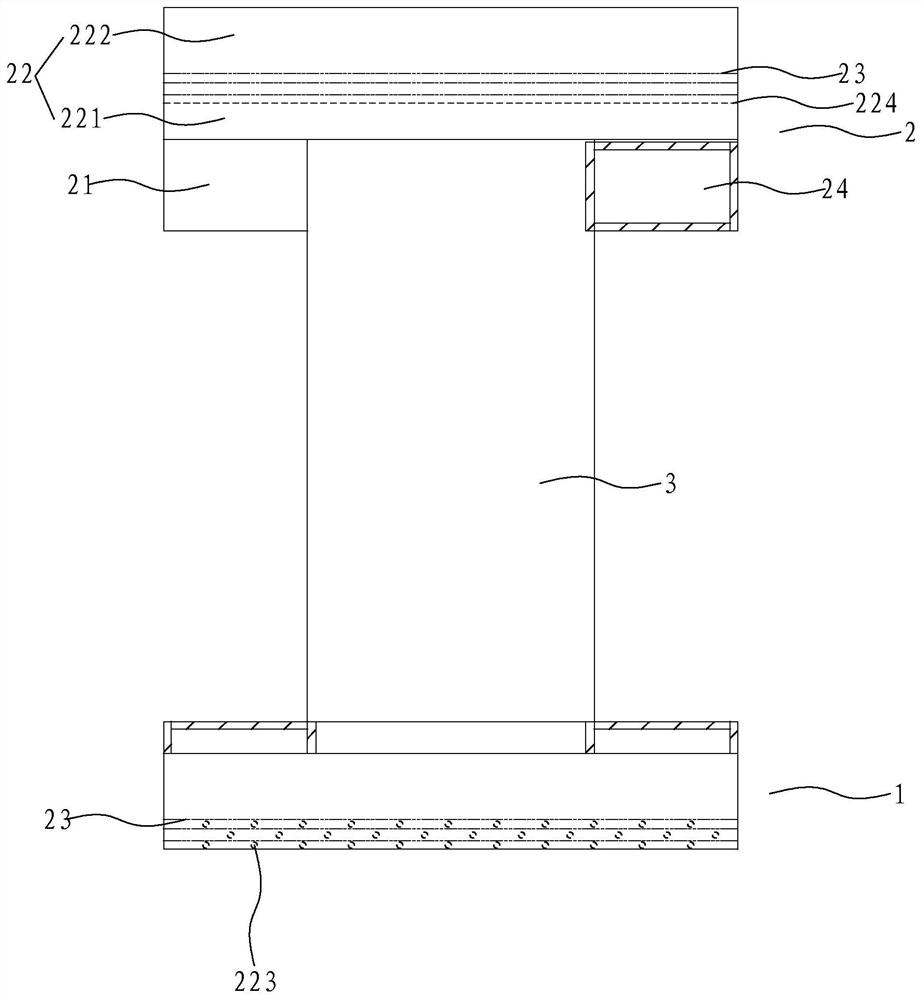

Highly-efficient laminating machine used for production of solar cell panel

InactiveCN108608713AReduce replacementLow costDispersed particle filtrationControlling laminationEngineeringWorkbench

The invention discloses a highly-efficient laminating machine used for production of a solar cell panel. The highly-efficient laminating machine comprises a preheating device, a laminating device anda cooling device, wherein the preheating device comprises a support and a preheating platform; a plurality of driving rollers are arranged in the middle of the support; the driving rollers are in engaged connection through gears; a first driving device used for driving the driving rollers is arranged in the lower part of the support; the left and right sides of the upper part of the support are respectively provided with a thread guide pillar; the upper part of each thread guiding pillar is provided with a nut seat; the preheating platform is slidably arranged at the upper parts of thread guide pillars through the nut seats; the left side of the preheating device is provided with the laminating device; the laminating device comprises a sealing pressure head and a workbench; baffle plates are respectively and fixedly arranged above two sides of the workbench; the upper ends of baffle plates are fixedly connected with a cross beam; and the sealing pressure head is slidably arranged between the baffle plates. The highly-efficient laminating machine provided by the invention has the advantages of simple structure, diversified functions, high degree of automation, high production efficiency, high product yield and easy promotion.

Owner:ZHANGJIAGANG GUOLONG SOLAR TECH CO LTD

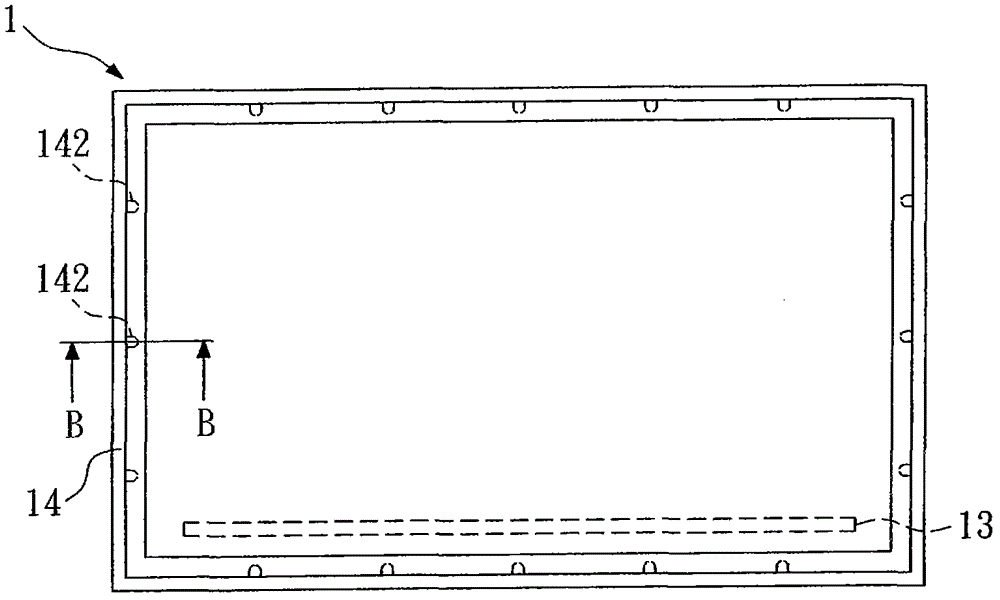

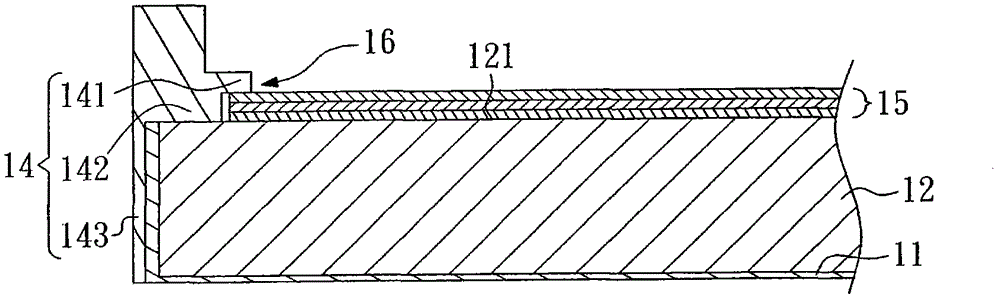

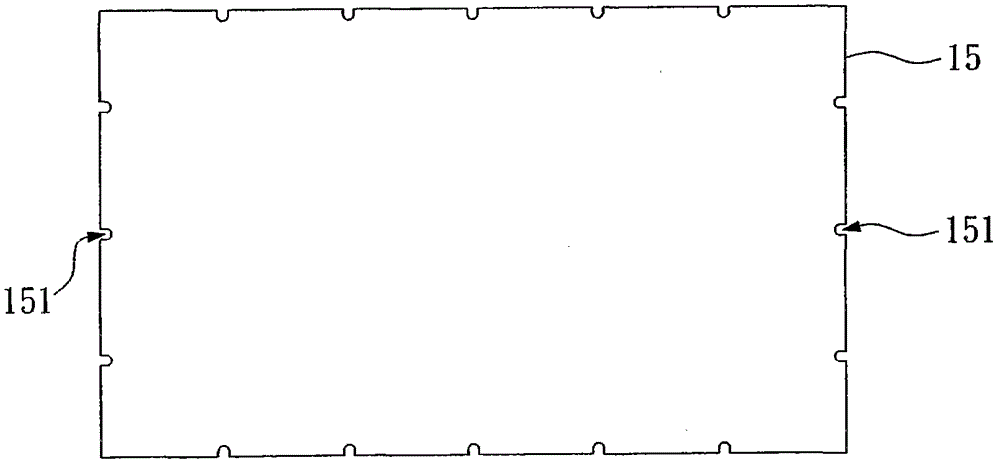

Backlight module

InactiveCN102798033AReduce crackingPrevent prolapseLight fasteningsFixed installationLight guideBackplane

The present invention relates to a backlight module, comprising a back plate, a light guide plate, at least one light source, an optical film, and a glue frame; wherein, the light guide plate is arranged on the back plate, and has at least one light-in surface and one light-out surface; the at least one light source faces to the at least one light-in surface; the optical film is arranged at the light-out surface of the light guide plate; the glue frame is arranged at a periphery of the light guide plate, and has a rib part and a plurality of column parts, the rib part is arranged at a relative position over a periphery of the light-out surface, the column parts are connected with the rib part and arranged between the rib part and the back plate, so that an end face of the column part is lower than the light-out surface. Therefore, the backlight module can reduce processing time and part cost, prevent the problem of fracture and melt of the light guide plate after being heated, and fix the optical film and the light guide plate.

Owner:CHI LIN OPTOELECTRONICS CO LTD

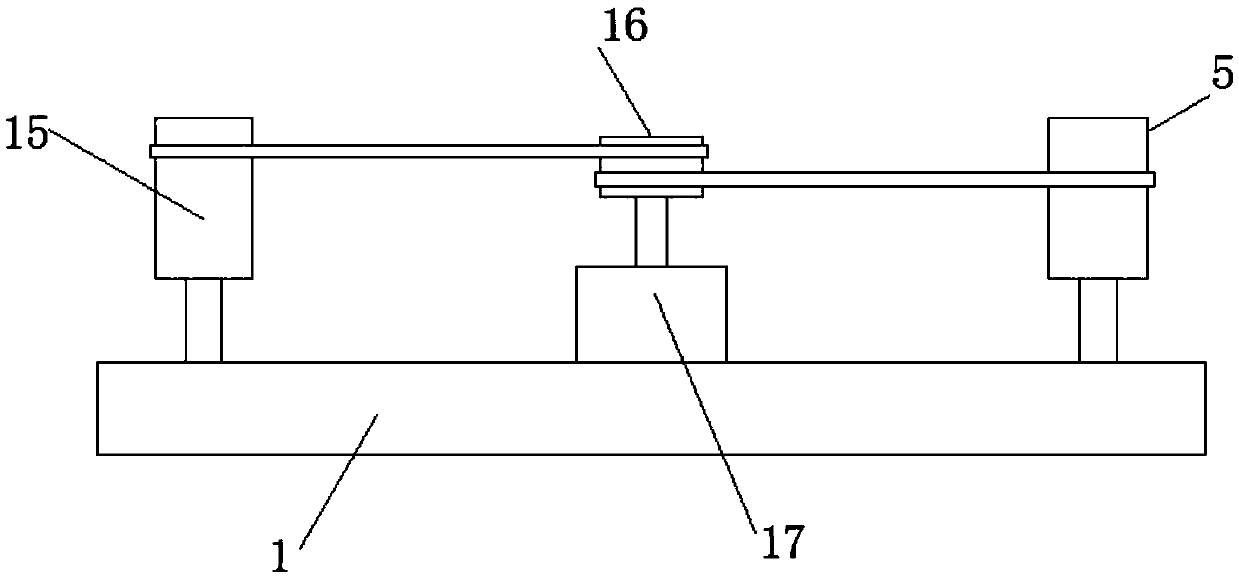

Pressing forming device for regenerated cotton production

The invention discloses a pressing forming device for regenerated cotton production. The pressing forming device comprises a base. First supporting rods, first screws, second screws and a motor are installed at the top end of the base. The number of the first supporting rods is two, the number of the first screws is two, the number of the second screws is two, two rotating shafts are further rotatably mounted at the top end of the base, a first belt pulley and a second belt pulley are mounted at the top ends of the rotating shafts respectively, third belt pulleys are mounted on the first screws, fourth belt pulleys are mounted on the second screws, a fifth belt pulley is mounted on an output shaft of the motor, supporting plate is mounted on the first screws and the second screws jointly,a working table is mounted at the top ends of the first supporting rods jointly, a placing tank is mounted at the top end of the working table, four second supporting rods are mounted at the top end of the working table, and a top plate is mounted at the top ends of the second supporting rods jointly. The pressing forming device is reasonable in structural design and simple to operate, regeneratedcotton can be effectively pressed, and the pressing forming device facilitates taking out of the regenerated cotton, is simple in structure and does not make the regenerated cotton wound easily.

Owner:阳新绿源农业科技有限公司

Control device of lock-up clutch

ActiveUS8682554B2Curb riseIncrease temperatureDigital data processing detailsAutomatic initiationsClutch controlEngineering

A control device for controlling an engagement state of a lock-up clutch is provided. A plurality of target slip ratio maps include a normal slip ratio map having a characteristic line of a target slip ratio defined in accordance with an engine load at a normal vehicle running condition and a modified slip ratio map having a characteristic line of the target slip ratio to become a facing calorific value lower than a facing calorific value corresponding to the slip ratio retrieved from the normal slip ratio map. In the case where an estimate value of the facing temperature continues to exceed first threshold temperature for more than predetermined time when to carry out slip control using the normal slip ratio map, control to switch the target slip ratio map from the normal slip ratio map to the modified slip ratio map is carried out.

Owner:HONDA MOTOR CO LTD

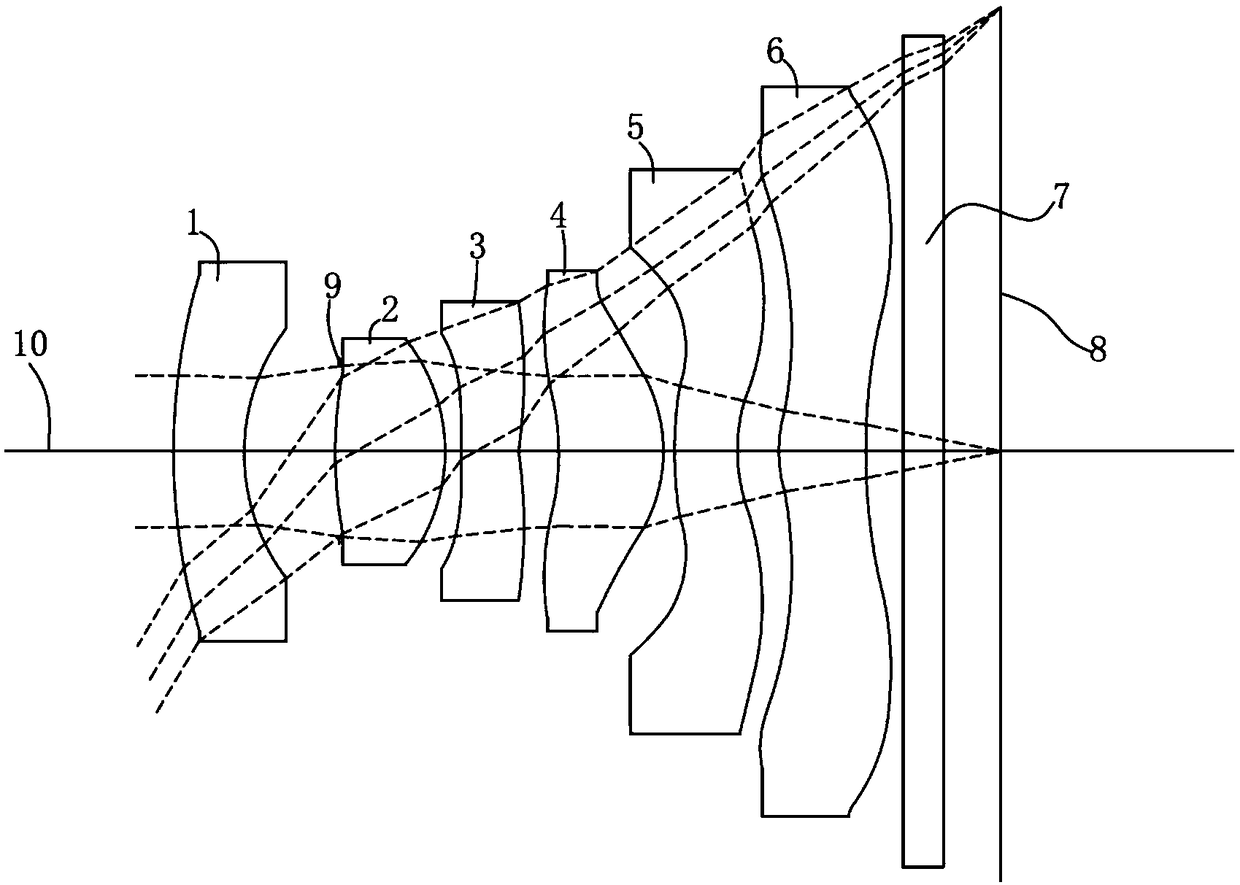

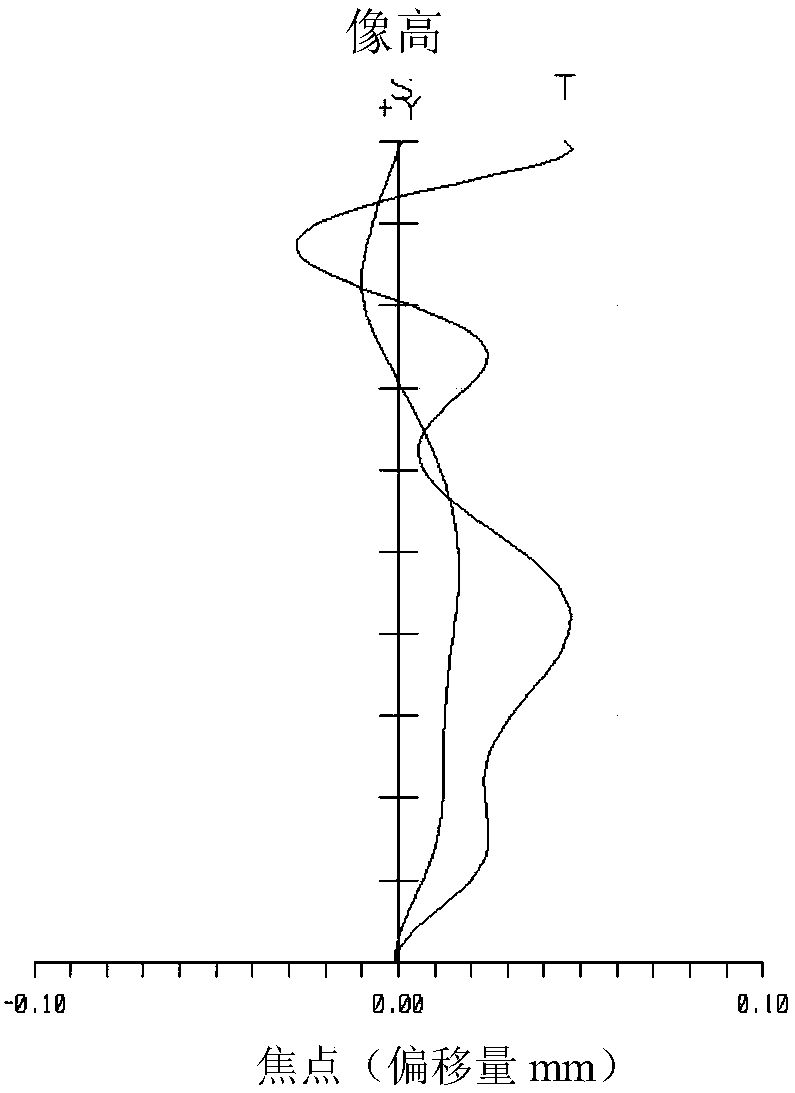

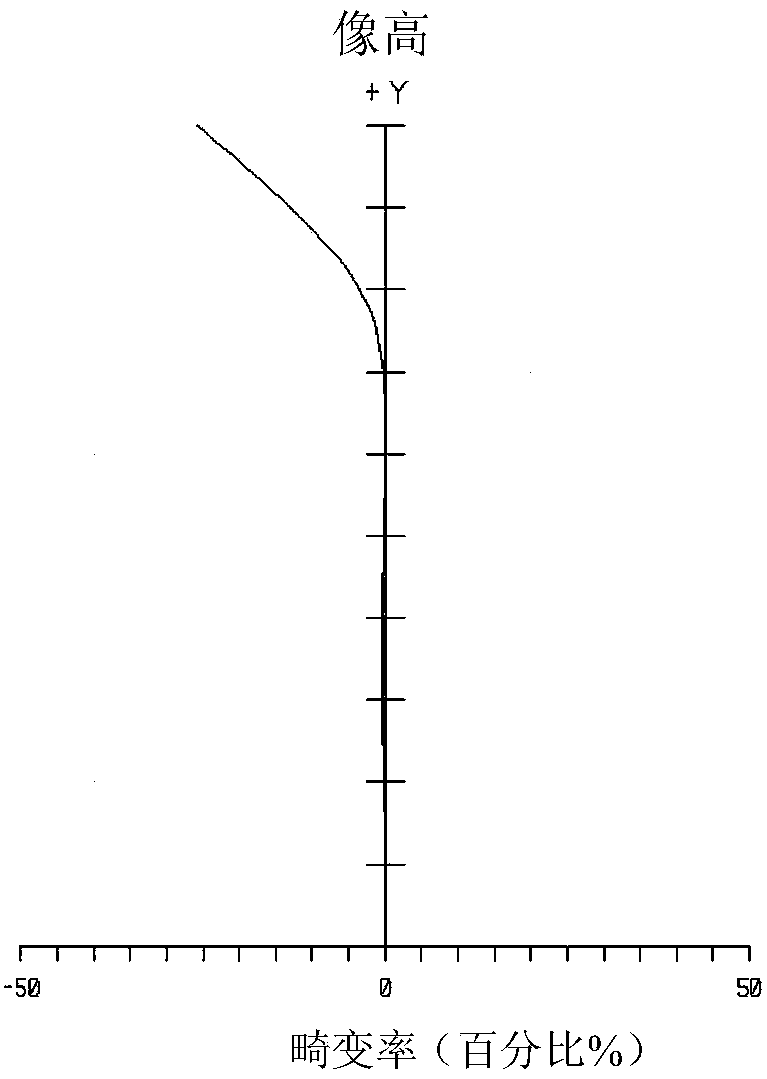

Optical camera

The invention discloses an optical camera which comprises a first lens with negative refraction power, a second lens with positive refraction power, a third lens with refraction power, a fourth lens with refraction power, a fifth lens with negative refraction power and a sixth lens with refraction power in sequence from the object side to the image side along the optical axis of the camera. The object side face of the second lens is a convex face, the image side face of the second lens is a convex face, the position, close to the optical axis, of the object side face of the fifth lens is a convex face, the position, close to the optical axis, of the image side face of the fifth lens is a concave face, the position, outward away from the optical axis, of the concave face of the fifth lens is provided with at least one convex face, the position, close to the optical axis, of the image side face of the sixth lens is a concave face, and the position, away from the optical axis, of the image side face of the sixth lens is provided with at least one inflection point. The optical camera meet the condition that (R51+R52) / (R51-R52) is larger than 1.8 and smaller than 4. By means of the technical scheme, through the reasonable profile structure and proper lens internal distribution, the best optimization is conducted on a system. The large field angle is obtained, the total length of thesystem can be effectively restrained, the current light and portable requirements are met.

Owner:GUANGDONG XUYE OPTOELECTRONICS TECH

Anti-tightening pull-ups and manufacturing process thereof

ActiveCN111603314ANot easy to produce large areas of strangulationHigh expressionAbsorbent padsBaby linensMechanical engineeringRubber band

The invention relates to the field of disposable hygienic products, in particular to anti-tightening pull-ups. The anti-tightening pull-ups comprise a front waistline, a rear waistline and an absorption main body. The rear waistline comprises a base material layer; the upper end of the base material layer extends out of the absorption main body to form an extension part; the extension part is provided with a plurality of rubber bands along the width direction; elastic sheets are arranged at the left end and the right end of the absorption main body on the base material layer respectively; theelastic sheets extend to cover the two sides of the absorption main body and are bonded with the absorption main body; the portions, covering the absorption main body, of the elastic sheets achieve elasticity loss in a spot breaking mode, spot breaking areas are formed at the spot breaking portions; and the sides, away from the absorption main body, of the elastic sheets are bonded with the base material layer. The technical problems that in the prior art, the waistline of a pair of three-piece pull-ups needs to be subjected to rubber band breaking, consequently, perforation and wrinkling areirregular, and the appearance presentation degree is poor are solved. Correspondingly, the invention further provides a manufacturing process of the anti-tightening pull-ups.

Owner:FUJIAN HENGAN HLDG CO LTD +2

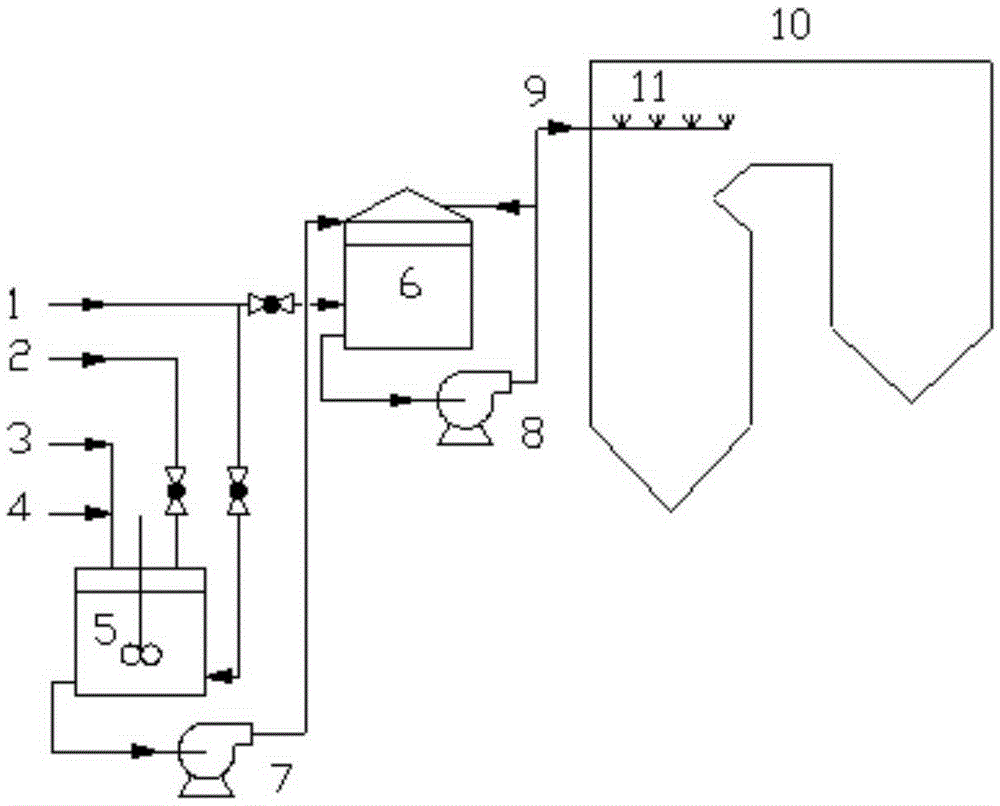

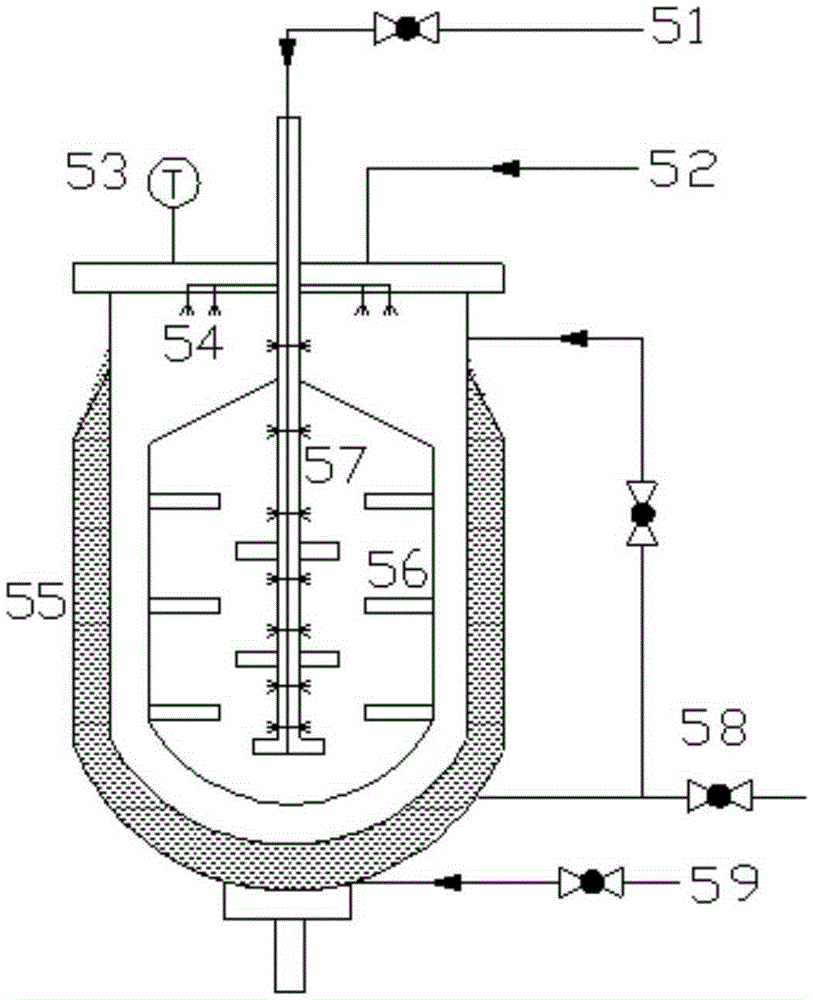

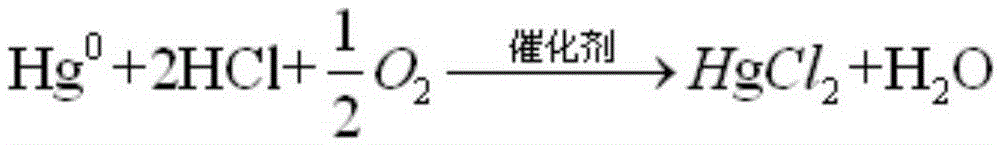

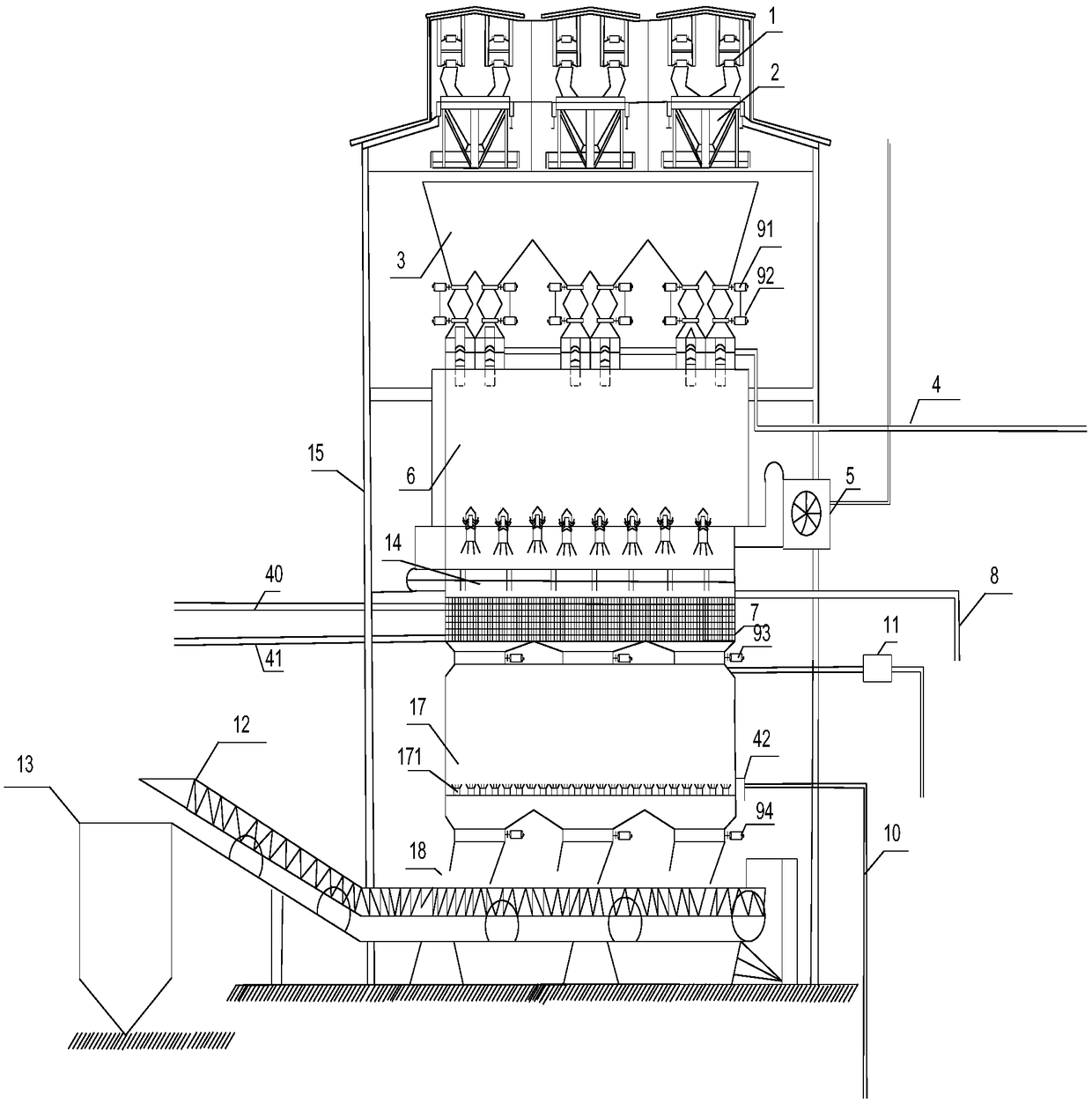

Joint mercury removing method and device based on SNCR

ActiveCN105268300ASimple and economical processReduce initial investment costDispersed particle separationMixersUreaCapital cost

The invention provides a joint mercury removing device based on SNCR. Two kinds of flue gas treatment technologies can be effectively combined, and the purpose of nitrate and mercury removal is achieved while cost is reduced. The device comprises two sets of independent measuring systems, a solution preparing system connected to the output ends of the two sets of measuring systems, a solution conveying system and a solution spraying system, wherein the solution conveying system and the solution spraying system are sequentially connected to the output end of the solution preparing system. The solution spraying system comprises a spraying inlet and a spraying gun. The spraying inlet is formed in a hearth of an SNCR system, and the spraying gun is connected to the spraying inlet and stretches into the hearth. The two sets of measuring systems are used for measuring urea and ammonium chloride solids respectively according to the demanding amount for removing NOx and zero-valent mercury. The mercury removing technology and the SNCR are joined, the advantages of the two technologies are combined, the advanced SNCR technology is developed, additional technological equipment is not added except for the measuring systems based on original facilities, the technology is easier and more convenient to implement and more economical, and capital cost is saved.

Owner:CHINA HUANENG GRP CO LTD +1

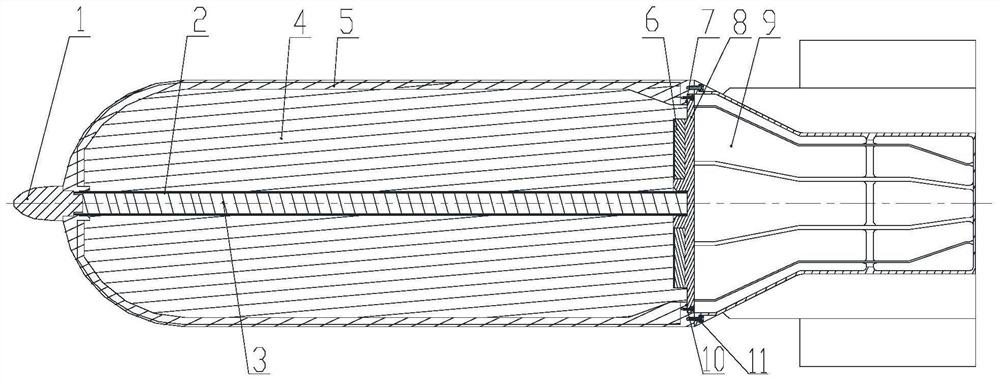

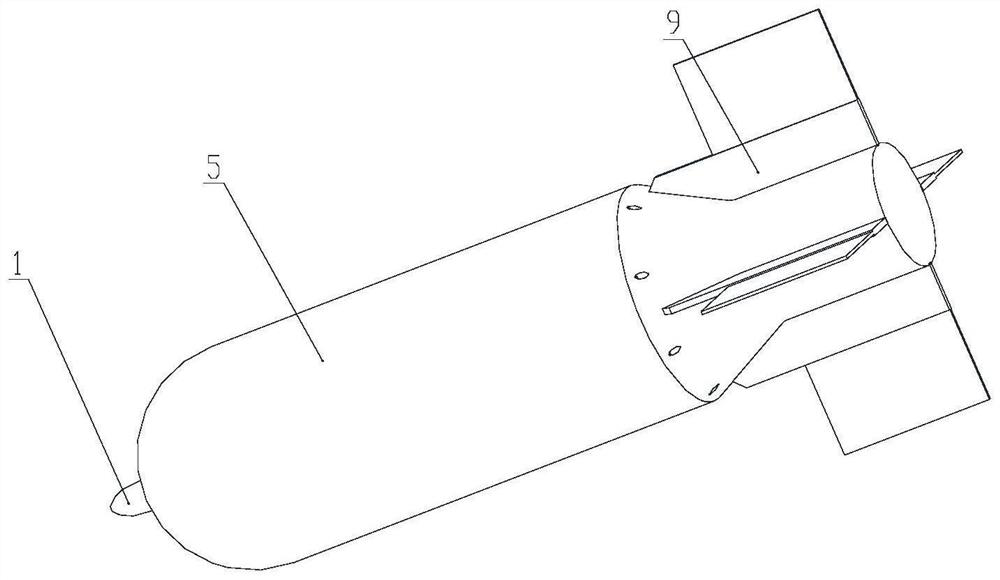

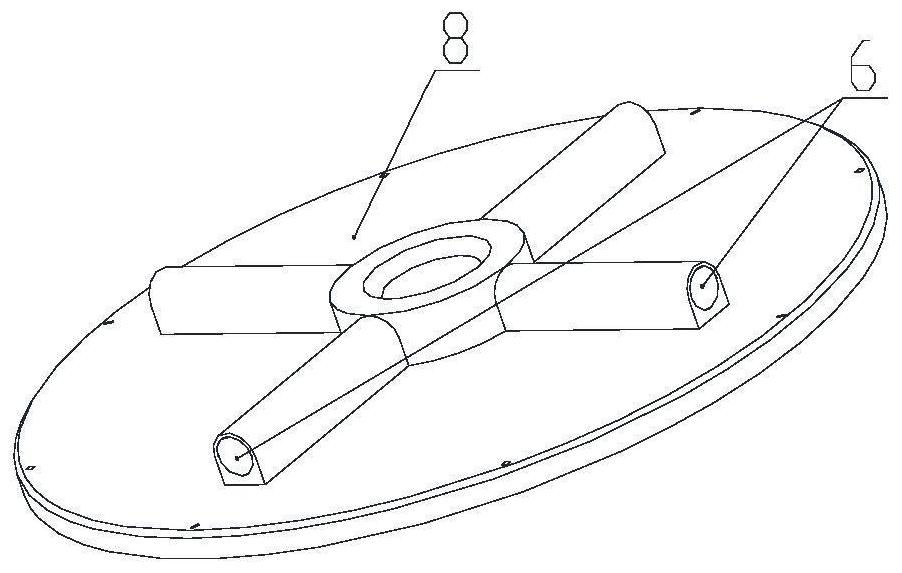

Forest aviation fire extinguishing bomb thrown through gravity and using method

ActiveCN112604210AThe overall structure is simple and reliableNo secondary damageAircraft componentsClimate change adaptationAviationEngineering

The invention discloses a forest aviation fire extinguishing bomb thrown through gravity and a using method, and belongs to the field of technical design of fire extinguishing bombs. The forest aviation fire extinguishing bomb comprises a fuse, a central charging pipe, a central grain, a fire extinguishing agent, a fire extinguishing bomb shell, a tail grain, a sealing ring, a tail end cover, a fastening screw and a tail fin. The fire extinguishing bomb is mounted by a forest aviation fire-fighting helicopter and is thrown at a certain height above a fire scene, when a distance between the fire extinguishing bomb and the ground reaches a preset explosion height, the fire extinguishing bomb is ignited and detonated by firing the fuse, the fire extinguishing agent is uniformly and quickly thrown to the surface of comburent under the action of central charging and tail charging, so that the fire extinguishing purpose is achieved. The forest aviation fire extinguishing bomb is thrown through gravity, and the problem that an existing fire extinguishing bomb is low in hit precision is solved. By means of the charging structure and a large fire extinguishing agent filling ratio, the problems that an existing fire extinguishing bomb is small in coverage area, uneven in fire extinguishing agent distribution and the like are effectively solved. The fire extinguishing bomb can be used for forest fire extinguishing and grassland fire extinguishing.

Owner:湖北航天飞行器研究所

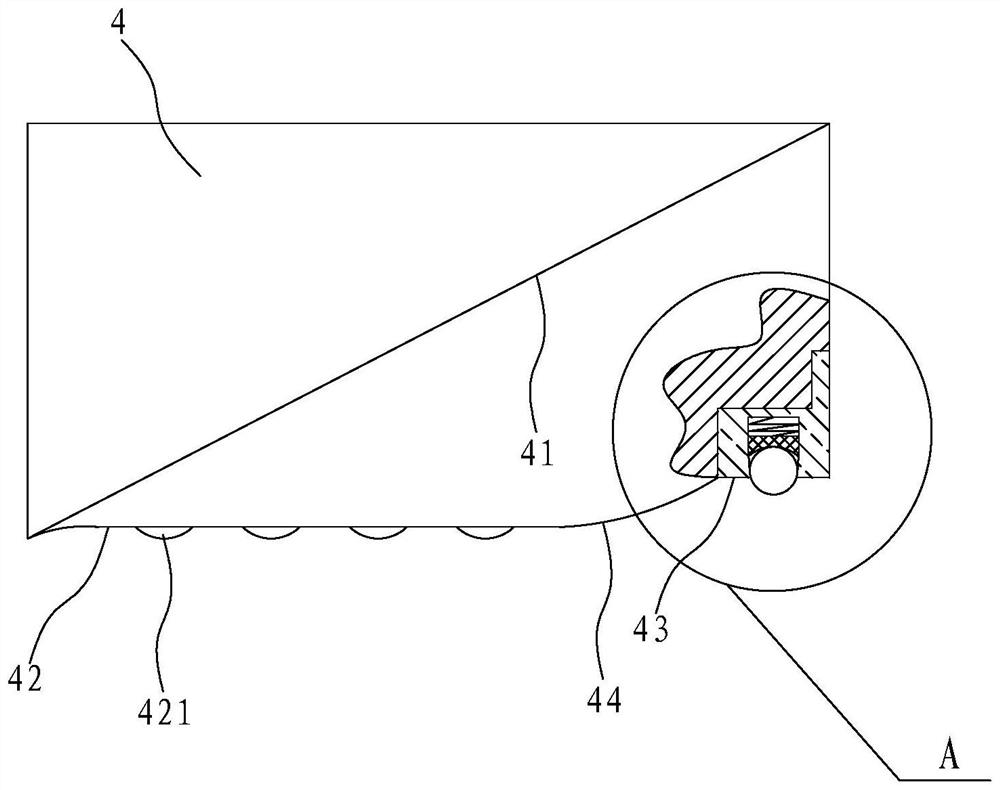

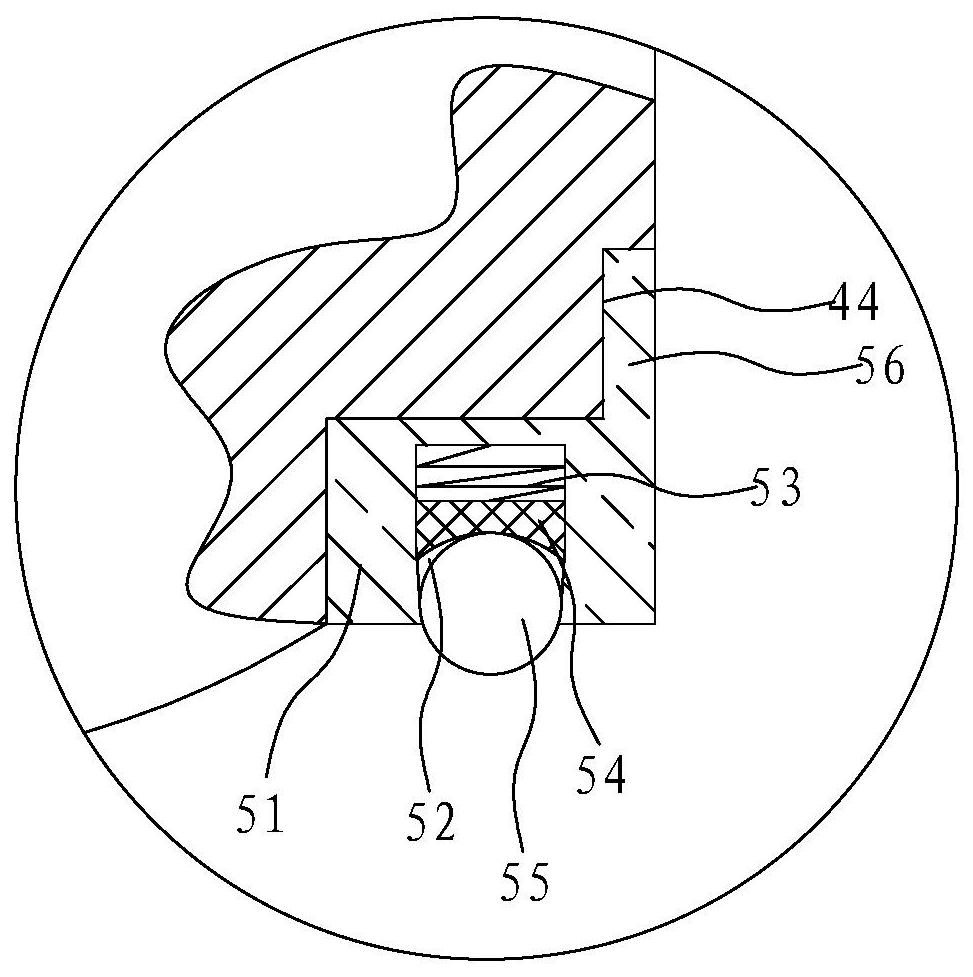

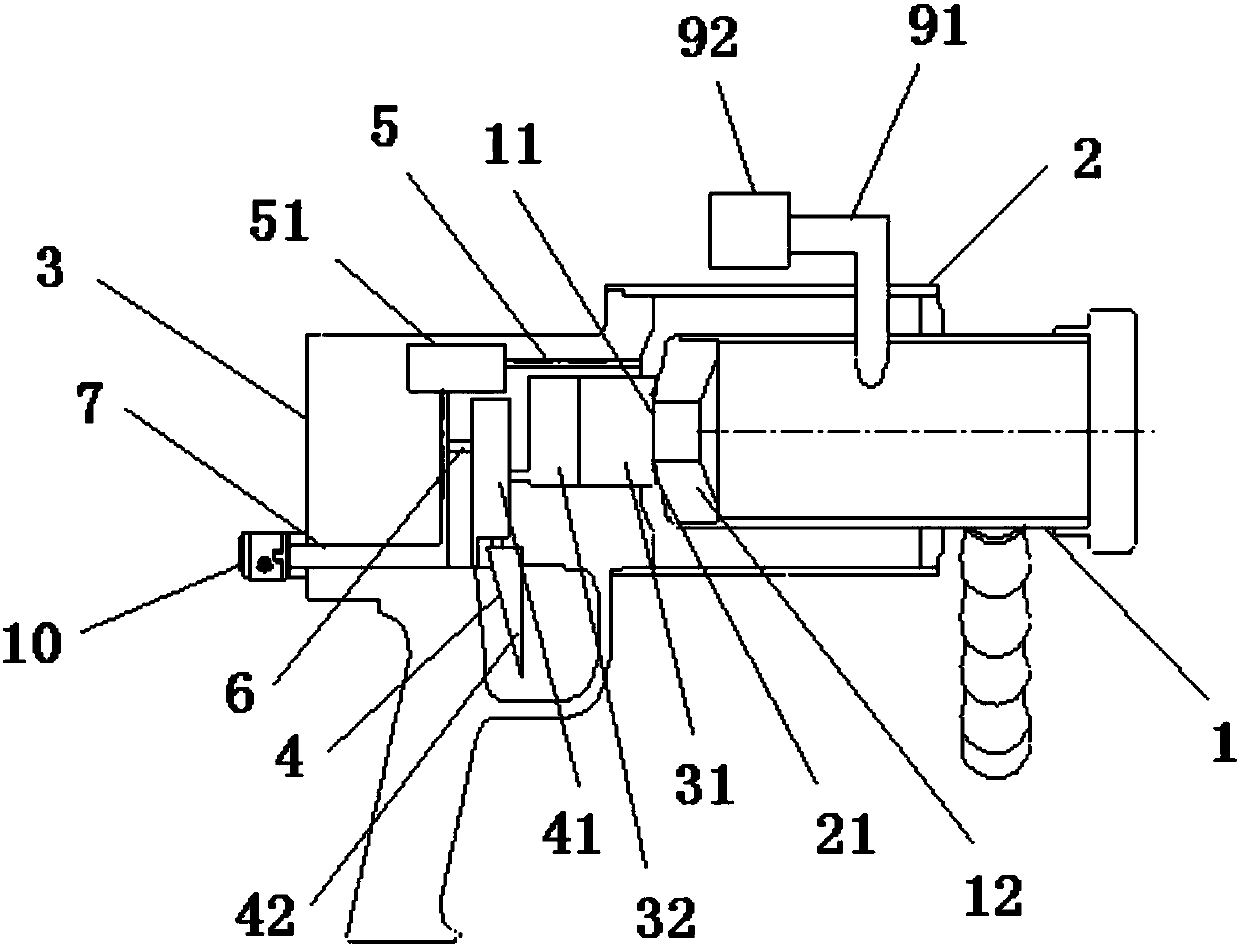

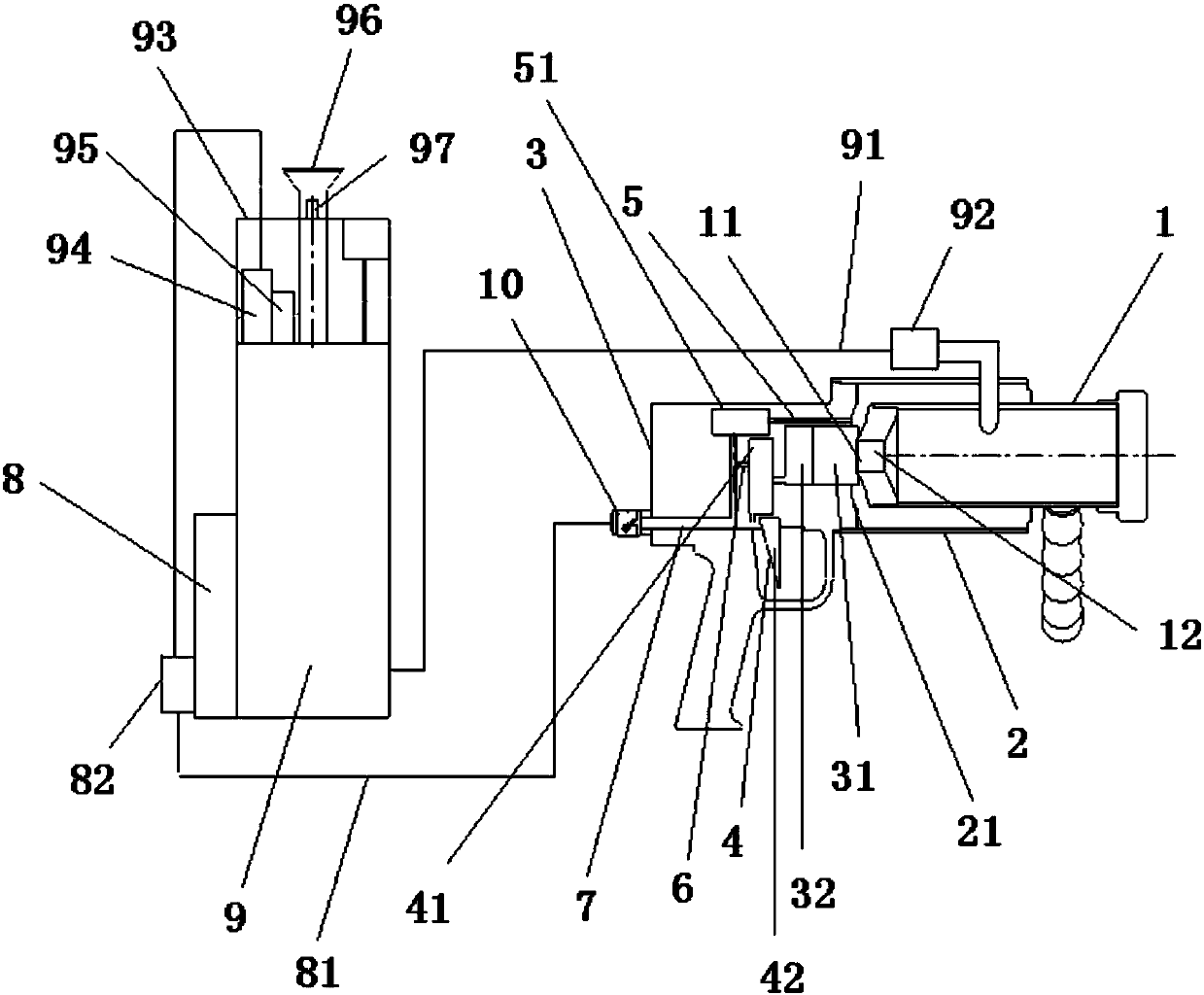

Intermittent atomization ejector and intermittent atomization ejecting system including same

The invention relates to the technical field of ejectors and particularly relates to an intermittent atomization ejector. The intermittent atomization ejector comprises a liquid storage cylinder (1),a gas storage cylinder (2), an integrated valve (3) and an operation mechanism (4), wherein the water is stored in the liquid storage cylinder (1); high-pressure gas is stored in the gas storage cylinder (2); the integrated valve (3) comprises a main valve element (31), and the main valve element (31) can move between closing positions and opening positions of a gas outlet (21) of the main valve element (31) and a gas inlet (11) of the liquid storage cylinder (1); the operation mechanism (4) is used for controlling the opening of the integrated valve (3); and the main valve element (31) is located outside an airflow channel between the gas outlet (21) of the main valve element (31) and the gas inlet (11) of the liquid storage cylinder (1) in an opening position. The invention further provides an intermittent atomization ejecting system including the intermittent atomization ejector. According to the intermittent atomization ejector and the intermittent atomization ejecting system including the intermittent atomization ejector, liquid drops ejected from liquid storage cylinder have certain kinetic energy.

Owner:朱刚 +1

Tumor angiogenesis associated genes and a method for their identification

InactiveUS20110229483A1Reduce redundancyPrevent amplification of highly abundant moleculesPeptide/protein ingredientsMicrobiological testing/measurementAbnormal tissue growthMouse tumor

Crucial to designing anti-angiogenic and vascular targeting approaches is the identification of specific target molecules. We compared transcriptional profiles of tumor endothelial cells with that of normal resting endothelial cells, normal but angiogenically activated placental endothelial cells, and cultured endothelial cells. Although the majority of transcripts were classified as general angiogenesis markers, we identified 17 genes that show specific overexpression in tumor endothelium. Antibody targeting of four cell-surface expressed or secreted products (vimentin, CD59, HMGB1 and IGFBP7) inhibited angiogenesis in vitro and in vivo. Finally, targeting endothelial vimentin in a mouse tumor model significantly inhibited tumor growth and reduced microvessel density. Our results demonstrate the utility of the identification and subsequent targeting of specific tumor endothelial markers for anticancer therapy.

Owner:MAASTRICHT UNIVERSITY

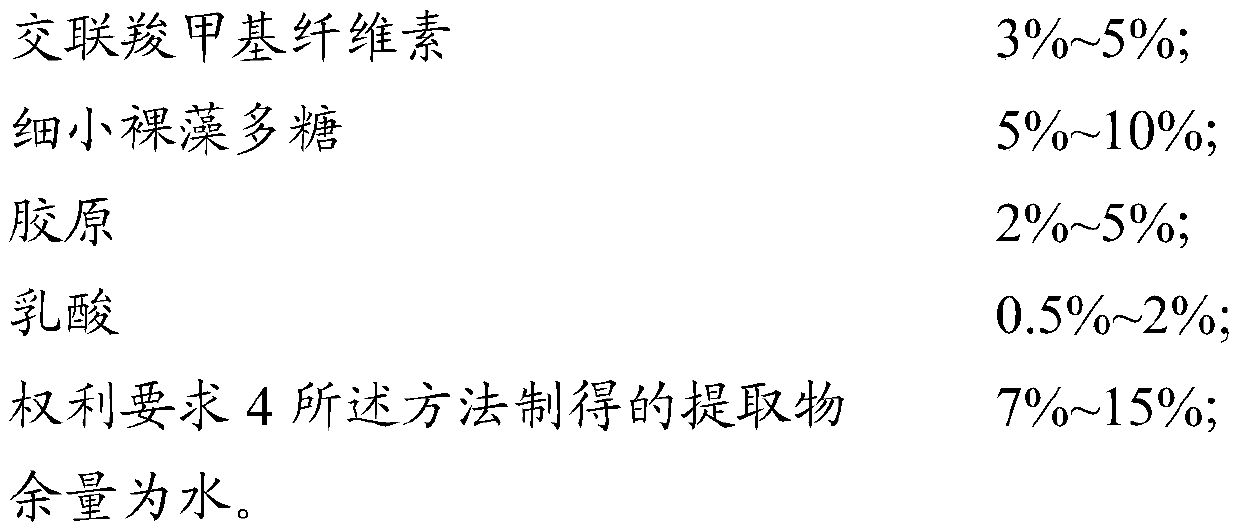

Antibacterial composition and preparation method and application thereof

InactiveCN110339121AGood antibacterial functionGood inhibitory effectCosmetic preparationsAntimycoticsIrritationAdditive ingredient

The invention relates to the technical field of daily chemical products, in particular to an antibacterial composition and a preparation method and application thereof. The adopted antibacterial composition is prepared from cortex erythrinae, herba taraxaci, rhizoma coptidis and pyrola rotundifolia, has no irritation to skin, can effectively inhibit and kill harmful bacteria and is prepared into adaily chemical product without addition of extra preservatives; a private product with the antibacterial composition for women does not contain medicine components, cannot generate medicine resistance and does not contain substances, such as nanometer silver, difficultly absorbed by the human body. The provided private product can restore the flora balance of the private part and keep a healthy bacterium environment for the vagina; the private product contains functional components such as euglena gracilis polysaccharide, a flos carthami extract and a motherwort herb extract, can effectivelyrestore elasticity of the inner wall of the vagina, enhance muscle control force and achieve an effect of tightening the vagina, and also achieves nursing, nourishing and repairing effects.

Owner:广州睿森生物科技有限公司

Micro-ecological preparation and preparation method thereof

InactiveCN108157595AGood effectEasy to solveAnimal feeding stuffAccessory food factorsDiseaseMedicine

The invention relates to the field of micro-ecological preparations, in particular to a micro-ecological preparation and a preparation method thereof. The preparation is prepared from inactivated bacteroides and fermented concentrate as main components, and the micro-ecological preparation containing the inactivated bacteroides has the efficacy of resisting bacteria, resisting inflammation, regulating gastrointestinal microbial flora and preventing human and animal gastrointestinal diseases, and has the characteristics of quick effect, high safety and convenient use. The preparation should beused for disease prevention and health care of human and animals, has good practical application value, and is especially outstanding when applied to animal feed. Therefore, the probiotic inactivatedmicro-ecological preparation is a technology which is worthy of popularization.

Owner:郑州神草生物技术有限公司

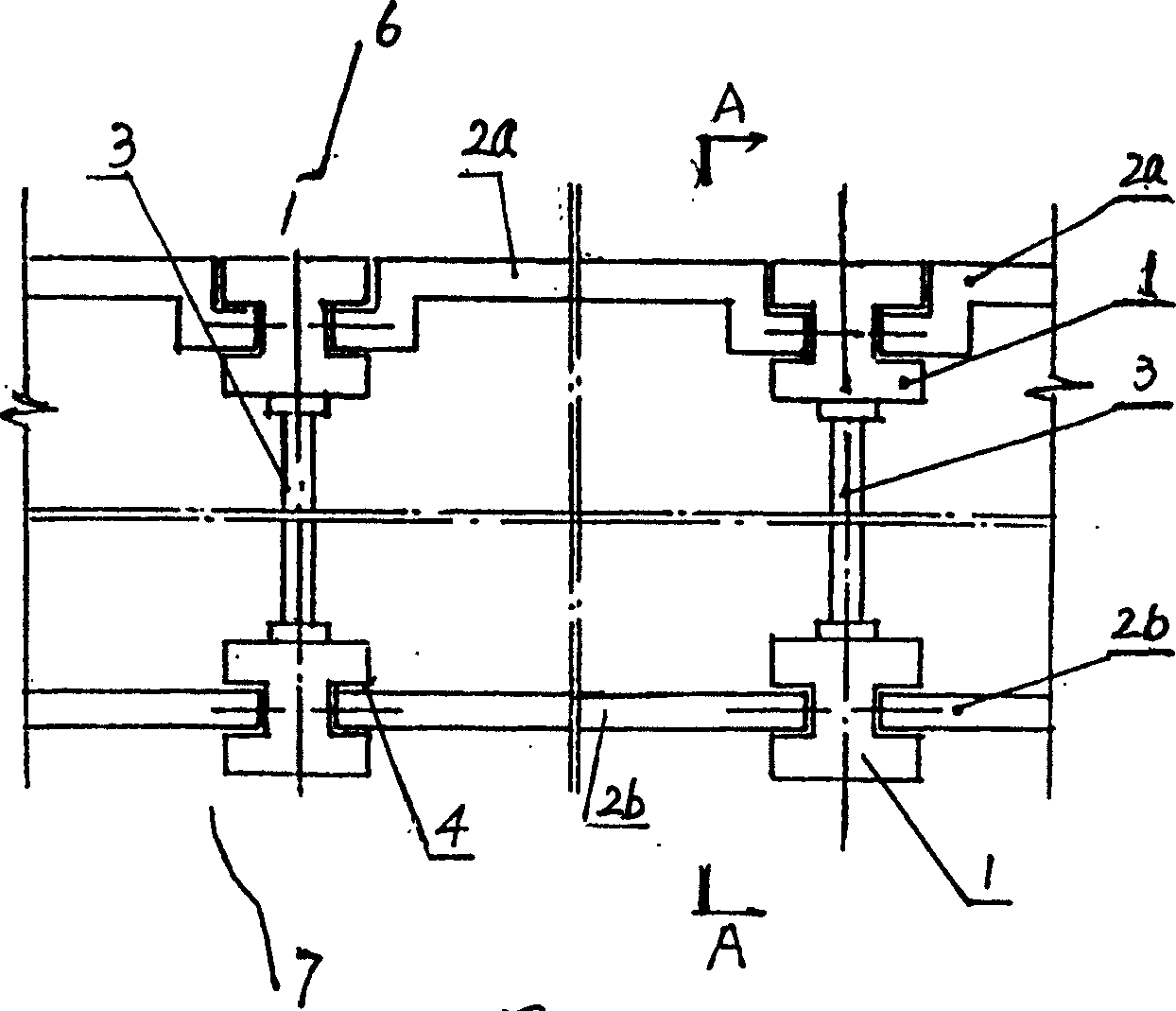

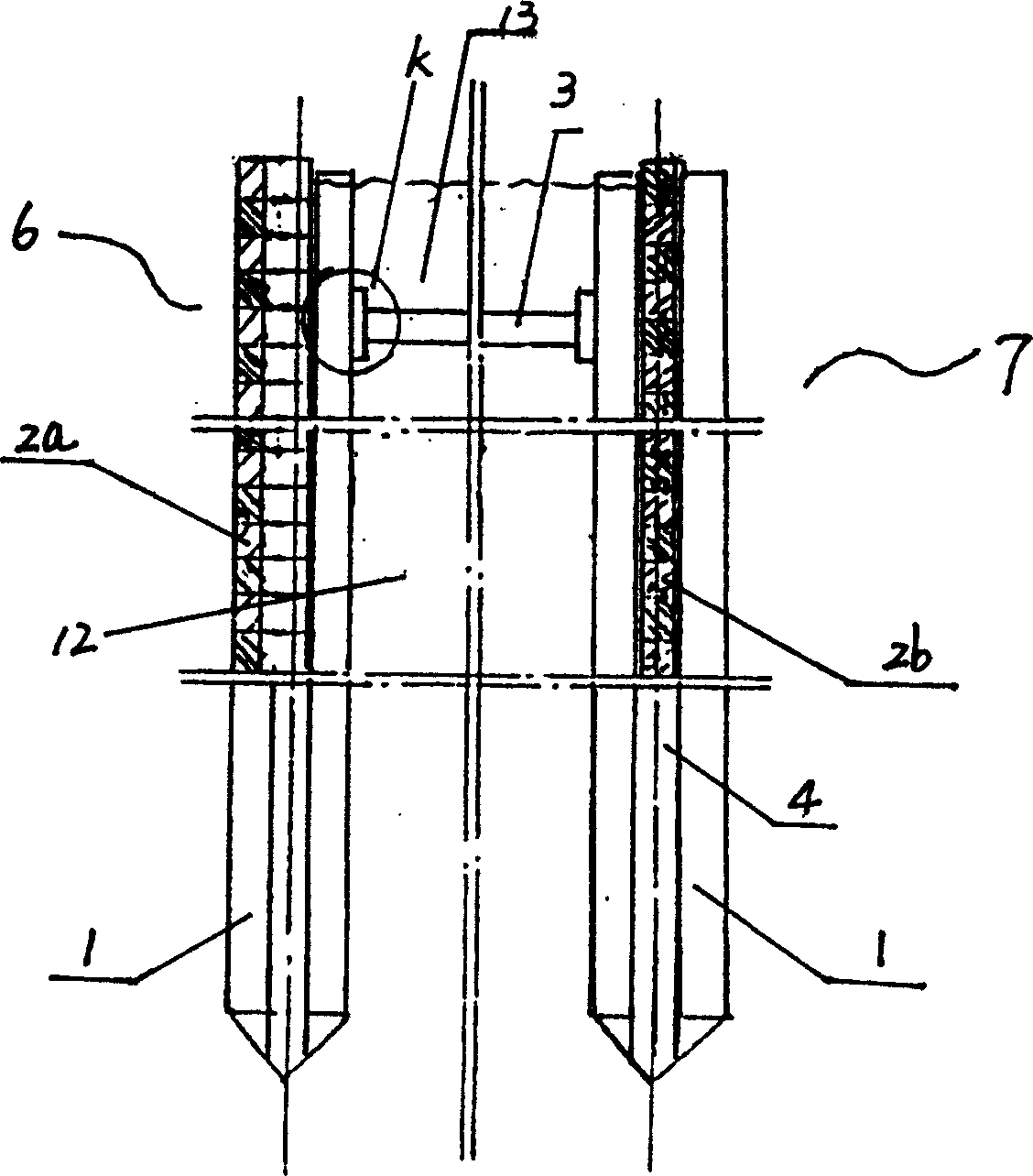

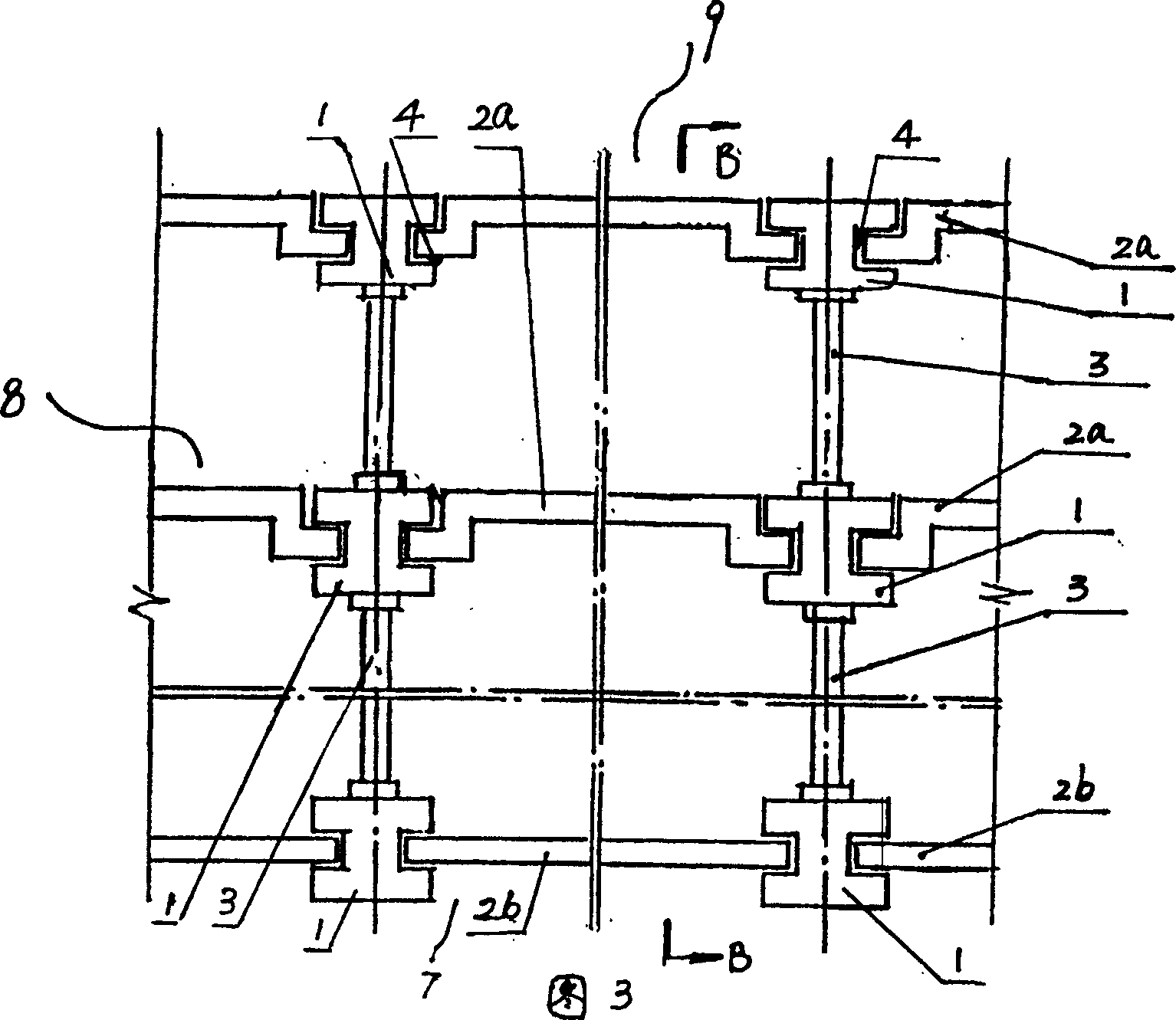

Frame type combined dam

This is a frame assembly of dikes and dams use to waterpower, navigation, and dredge the waterways in the river of seaport. It contains: The piles are not less than two arrangements of piles, on the pile's top install an interface for to connect with the prefabricated plates. The protective prefabricated plates inlay with successively pile's trough successively, two ends of the beams are connected with the neighboring different range of piles, the best form of the pile's bottom is wedge form, the best form of prefabricated plate on the lowest layer is wedge form too, and the section form of prefabricated plate may be square or T form.

Owner:GEOTECHN TECH

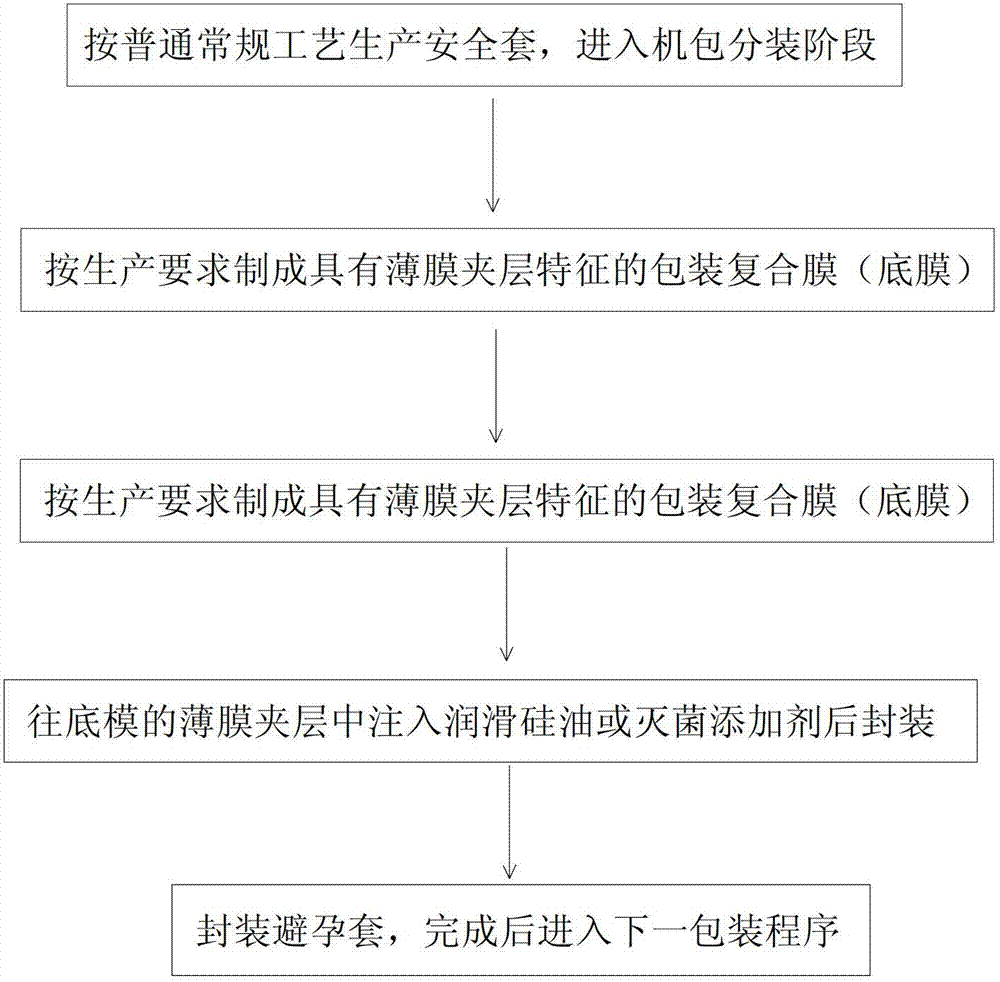

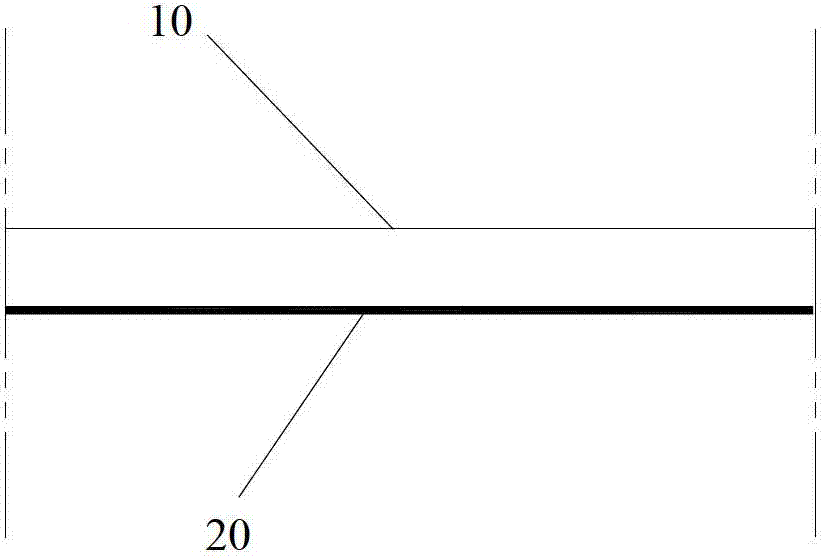

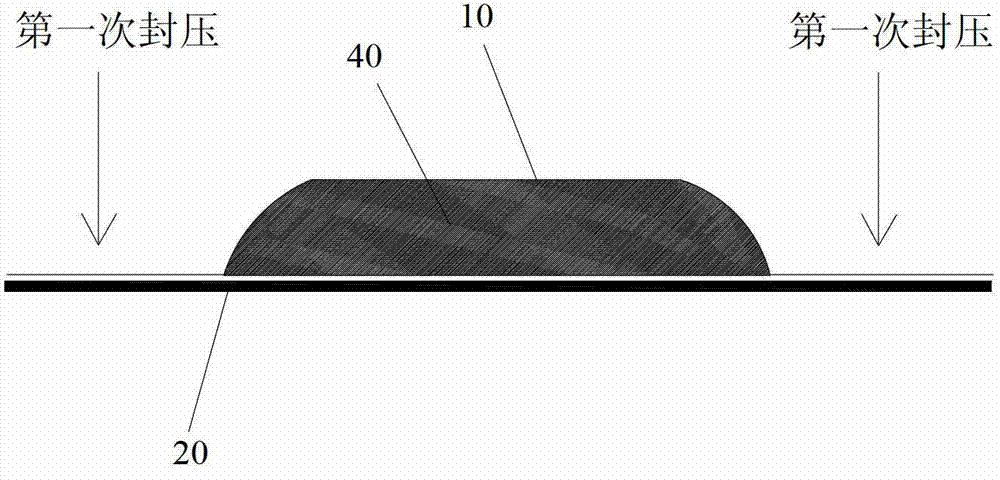

Condom with independently packaged additives and preparation method of same

The invention discloses a condom with independently packaged additives and a preparation method of the condom. After a lubricant, a bactericide and other additives are added into an independent package, the independent package packaged with a condom (anticonceptive condom) together, namely the condom is a pure condom without any additive before use and the independent package can be arranged on the inner side (for male use) or on the outer side (for female use) of the condom as required by a customer. The condom with the independently packaged additives is smeared with lubricating silicone oil (or sterilizing additive) rightly before use, so that the customer can choose the lubricant and the dosage thereof and the like independently.

Owner:陈汝霖 +1

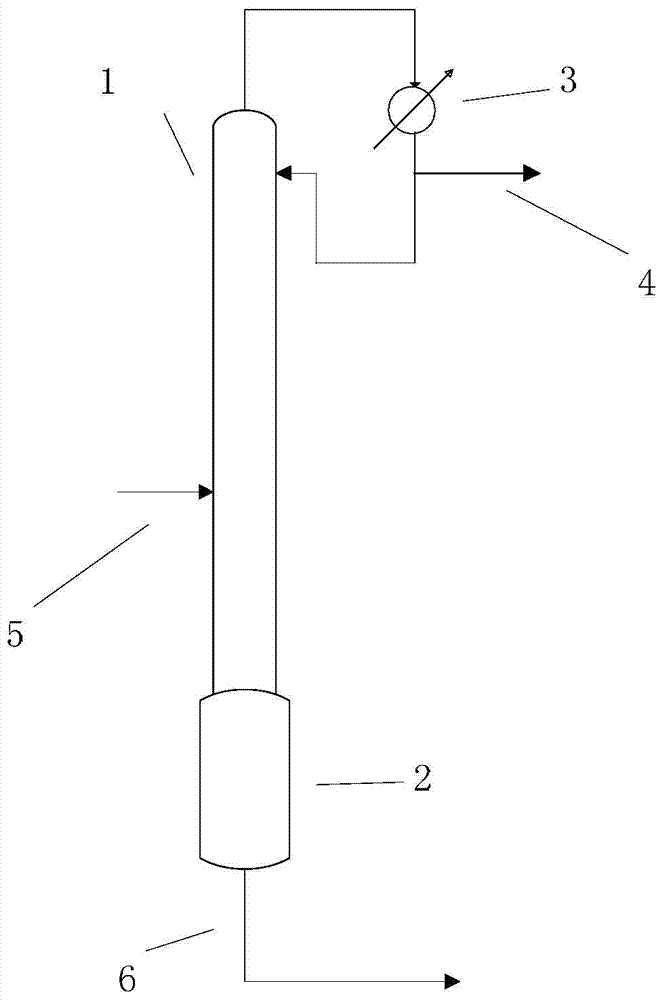

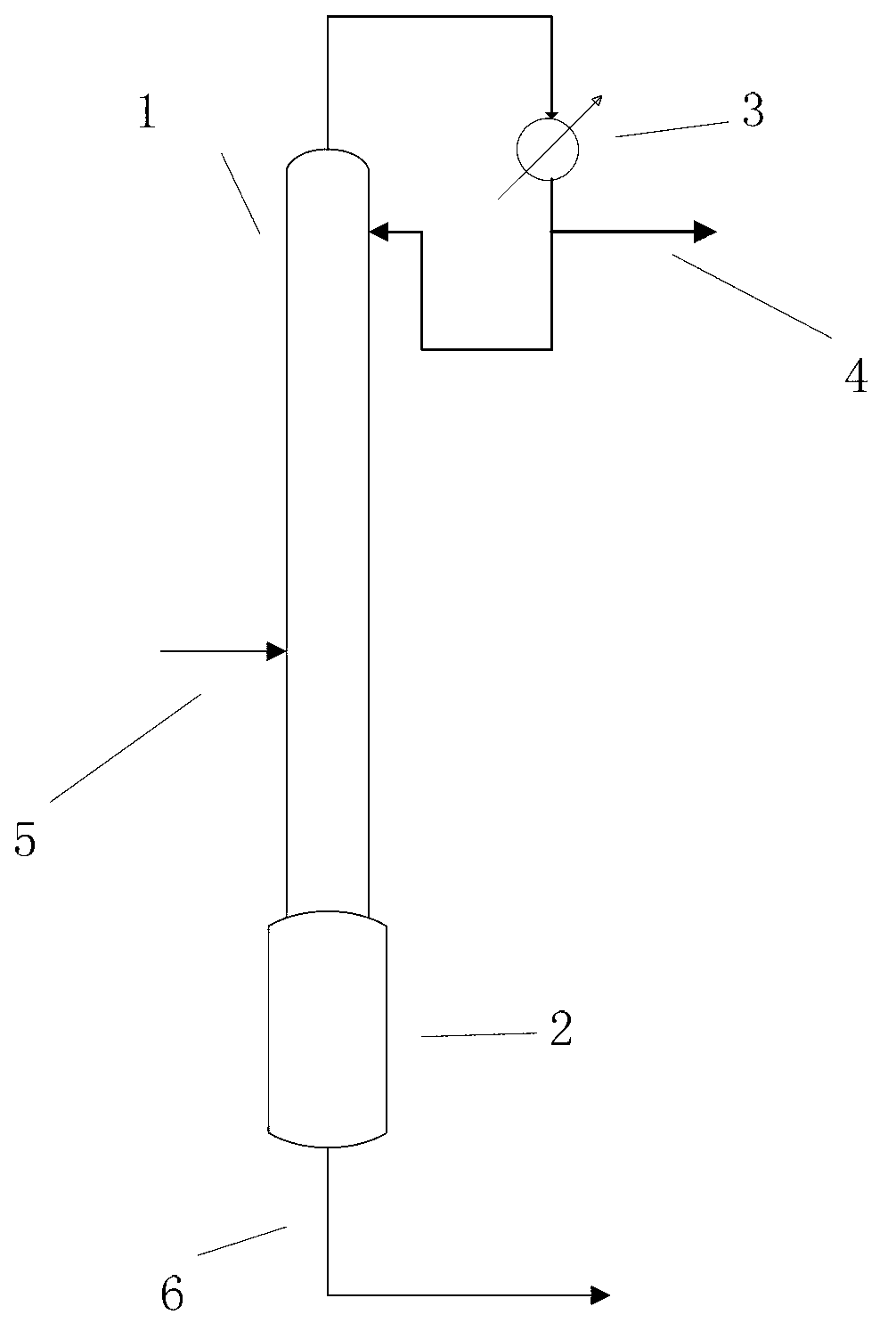

Method for rectifying iodine-containing hydriodic acid feed liquid

ActiveCN103212215BAvoid condensationPress down smoothlyFractional distillationHigh concentrationReflux

The invention provides a method for rectifying an iodine-containing hydriodic acid feed liquid. The method which is adopted for rectifying the iodine-containing hydriodic acid feed liquid comprises steps of: firstly, adding hydriodic acid with high concentration or iodine-containing hydriodic acid with low iodine content and high HI content into a rectifying still, then starting a heating device of the rectifying still and a condensation reflux device on a still top, and operating in a total reflux mode; and when the condensation reflux device on the still top can stably reflux the hydriodic acid, feeding the iodine-containing hydriodic acid feed liquid to be rectified into the rectifying still, and continuously feeding from the still top and a still bottom. When the rectifying method is adopted to rectifying the iodine-containing hydriodic acid feed liquid, I2 in the feed liquid can be effectively prevented from being condensed on a rectifying column top to cause rectifying operation failure.

Owner:TSINGHUA UNIV

Method for rectifying iodine-containing hydriodic acid feed liquid

ActiveCN103212215APreventing failed distillation operationsAvoid condensationFractional distillationChemistryHydroiodic acid

The invention provides a method for rectifying an iodine-containing hydriodic acid feed liquid. The method which is adopted for rectifying the iodine-containing hydriodic acid feed liquid comprises steps of: firstly, adding hydriodic acid with high concentration or iodine-containing hydriodic acid with low iodine content and high HI content into a rectifying still, then starting a heating device of the rectifying still and a condensation reflux device on a still top, and operating in a total reflux mode; and when the condensation reflux device on the still top can stably reflux the hydriodic acid, feeding the iodine-containing hydriodic acid feed liquid to be rectified into the rectifying still, and continuously feeding from the still top and a still bottom. When the rectifying method is adopted to rectifying the iodine-containing hydriodic acid feed liquid, I2 in the feed liquid can be effectively prevented from being condensed on a rectifying column top to cause rectifying operation failure.

Owner:TSINGHUA UNIV

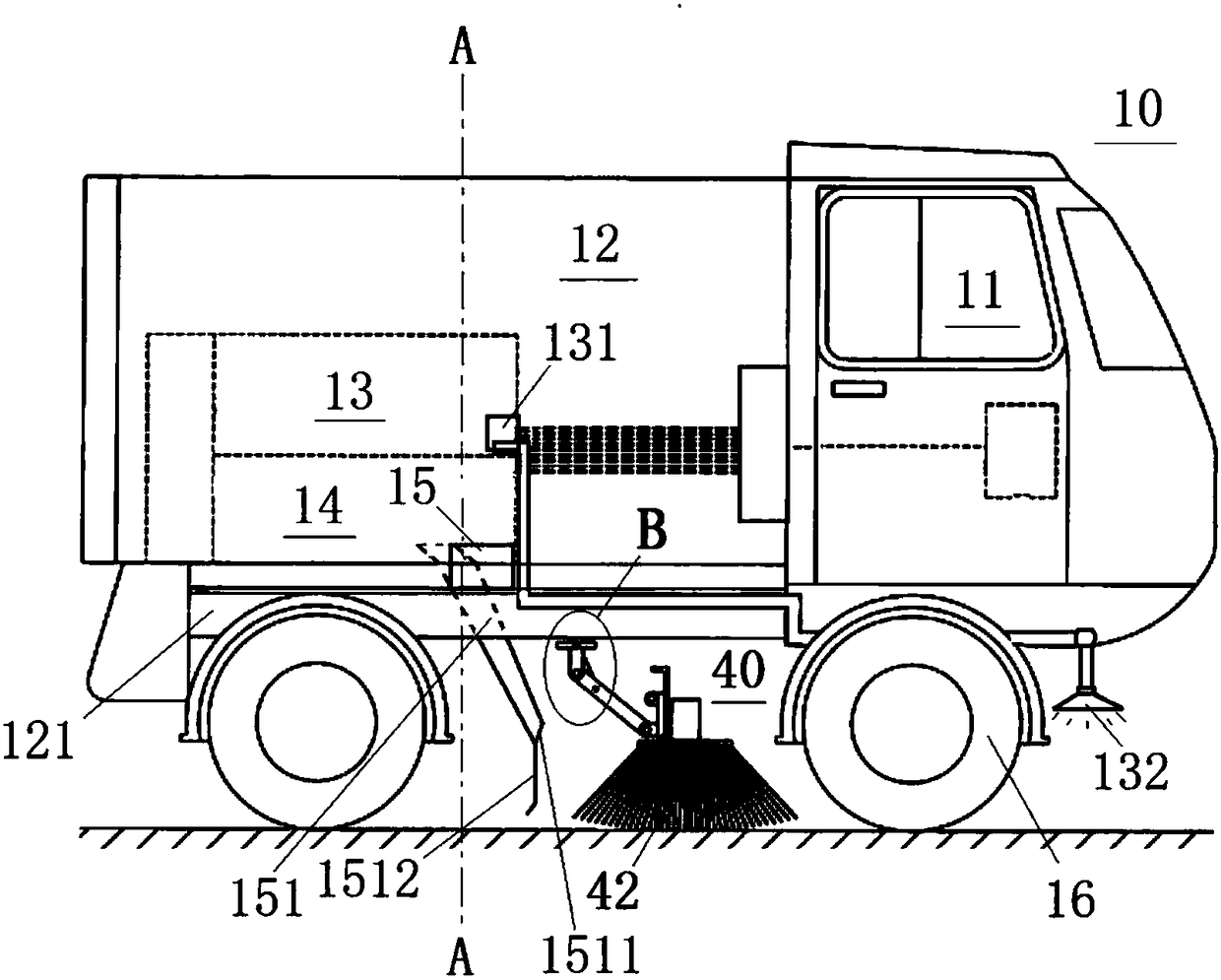

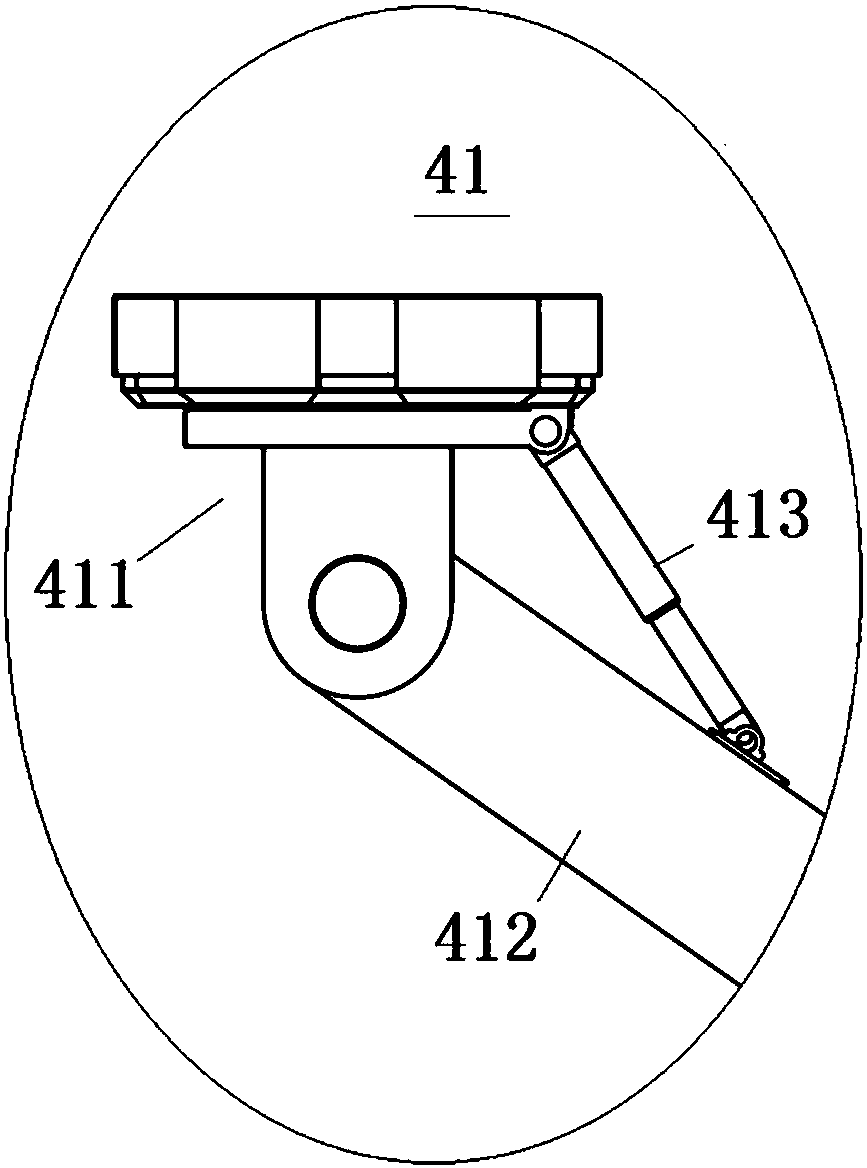

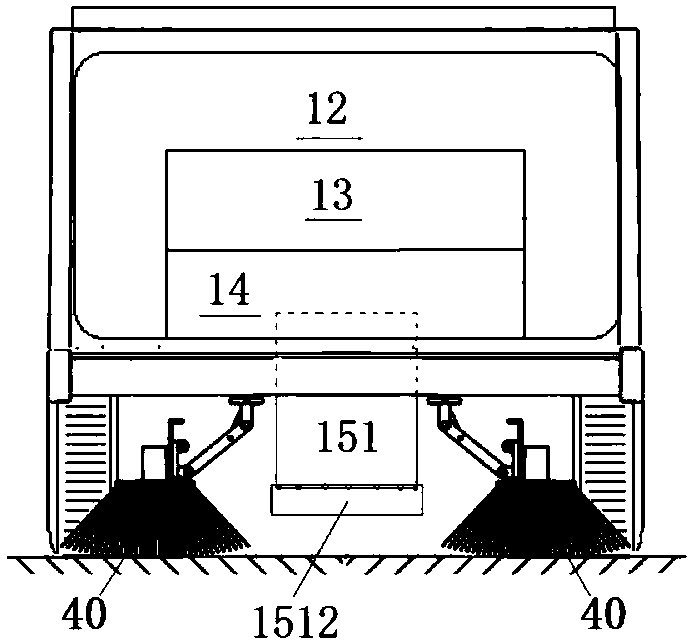

Environmental sanitation sweeper

The invention relates to the technical field of machinery, and provides an environmental sanitation sweeper which comprises a body, a control panel, a control device and a sweeping device. The body isprovided with a cab and a box seat connected to the rear of the cab, a sprinkling water tank system and a garbage container are arranged in the box seat, the watering water tank system comprises a water tank, a sprinkler and a sprinkler head, the sprinkler head is arranged on the lower surface of a bottom plate of the cab, the box seat is provided with a frame bottom plate, a dust collector and an absorption channel are lifted on the frame bottom plate and communicated with the garbage container, and the absorption channel penetrates the frame bottom plate and extends downwards to form an absorption opening. The control panel is arranged in the cab, and the control device is arranged at the back of the control panel and communicated with the control panel through a cable. The sweeping device is lifted on the lower surface of the frame bottom plate between the dust collector and the cab, the technical problems of sanitation vehicle structure simplification and sweeping angle adjustmentare solved by the structure, and the environmental sanitation sweeper has the advantages of easiness in manufacture, reduction of manufacturing cost and improvement of use functions.

Owner:XINGTAI POLYTECHNIC COLLEGE

Novel coke stove based on wet-method quenching

PendingCN108611106AQuality improvementImprove qualityCoke quenchingEnergy inputNitrogenMechanical stability

The invention discloses a novel coke stove based on wet-method quenching. The novel coke stove comprises a quenching section as well as a dry distillation section, wherein a plurality of nozzles are arranged at the bottom of the quenching section; the nozzles are divided into two parts; one part of the nozzles are communicated with a nitrogen inlet tube; the other part of the nozzles are communicated with an ammonia water inlet tube; the dry distillation section is arranged above the quenching section; the quenching section comprises an upper section and a lower section which are connected together; the upper section is directly connected with the dry distillation section, is provided with a water cooling wall and is used for carrying out radiation heat exchange with red hot semi-coke at the dry distillation section; a steam outlet tube of the water cooling wall is fed into a power plant through a waste heat boiler; the lower section is an inert gas quenching section. Quenching of cokeis carried out with nitrogen and ammonia water in a spraying manner, so that the quality of the coke is greatly improved, the red coke can be slowly cooled by using a circulated inert gas in a quenching process, cracks caused by water spraying in wet-method quenching can be avoided, the coke is subjected to mechanical pellet shaping in a dry quenching furnace, the uniformity of coke blocks is improved, and the mechanical stability of the coke is improved.

Owner:YULIN UNIV

Chinese medicine and western medicine preparation for treating pig yellow and white diarrhea

InactiveCN106860857AEffective suppressionEliminate heat and humidityAntibacterial agentsOrganic active ingredientsSolventSwine dysentery

The invention relates to a medicament for treating pig diarrhea, in particular to a Chinese medicine and western medicine preparation for treating pig yellow and white diarrhea. The preparation has the advantages that pig serum is used as a solvent; 0.15 to 1.2g of ceftiofur sodium is dissolved into per 10 ml of purpose-made pig serum to obtain the Chinese medicine and western medicine preparation. The purpose-made pig serum is obtained through the following steps that 3-month-old pigs are continuously fed with silage abrus precatorius leaves and stems for 4 to 5 days; then, the food stop is performed for 7 days; in the food stop period, only isatis root water boiling preparations are fed every day; after the food stop period is ended, the pigs are killed; the blood is collected; the obtained serum is separated; the effective ingredients in the purpose-made pig serum are matched with the ceftiofur sodium; the problem of drug resistance of bacteria on the ceftiofur sodium can be effectively solved; the effect and the medicine effect of the ceftiofur sodium are simultaneously improved.

Owner:安徽天安生物科技股份有限公司

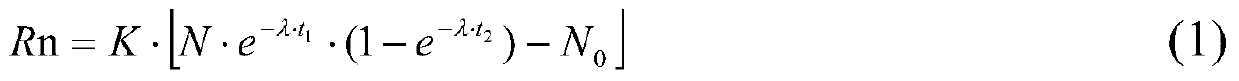

A radioactive prospecting method for characterizing deep sandstone-type uranium mineralization information

ActiveCN106840778BEasy to identifyEffective suppressionMaterial analysis using wave/particle radiationWithdrawing sample devicesActivated carbonConcentration ratio

The invention belongs to the field of radioactive geophysical exploration in uranium exploration and particularly discloses a radioactive exploration method for characterizing deep sandstone type uranium mineralization information. The radioactive exploration method comprises the following steps: selecting an exploration work area and designing a work area measuring grid; calibrating a gamma energy spectrum measuring system and an activated carbon radon measuring instrument; determining the position of a measuring point on site; measuring the measuring point to obtain the content of uranium U in surface shallow soil; measuring the measuring point to obtain a concentration value of radon Rn; respectively interpolating the U and the Rn into U-0 and Rn-0, sliding the U-0 to averagely generate U-1, sliding the Rn-0 to averagely generate Rn-1, dividing the Rn-1 by the U-1 to generate K-0 and then multiplying the K-0 by the U-0 to generate Rn', wherein the Rn' is calculated radon concentration; dividing the Rn-0 by the Rn' to generate radon concentration and calculated radon concentration ratio raster data R; delineating a deep uranium mineralization information favorable area according to the R. According to the method, the surface information interference can be effectively pressed, and a deep sandstone type uranium mine can be rapidly and directly explored.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

Microlithography projection objective

ActiveUS20140333913A1Effective lightingEffective suppressionPhotomechanical exposure apparatusMicrolithography exposure apparatusComputer scienceImage plane

Microlithography projection objectives for imaging into an image plane a pattern arranged in an object plane are described with respect to suppressing false light in such projection objectives.

Owner:CARL ZEISS SMT GMBH

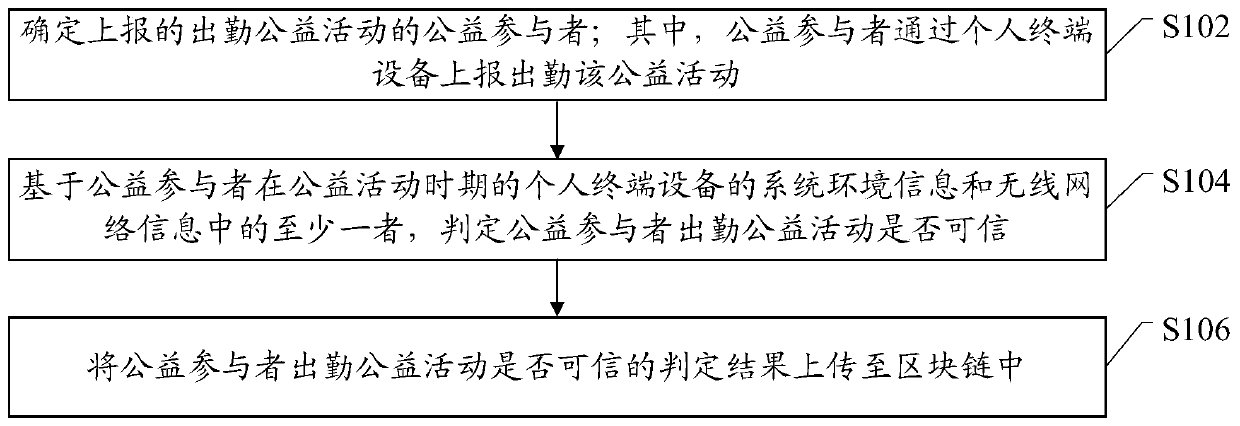

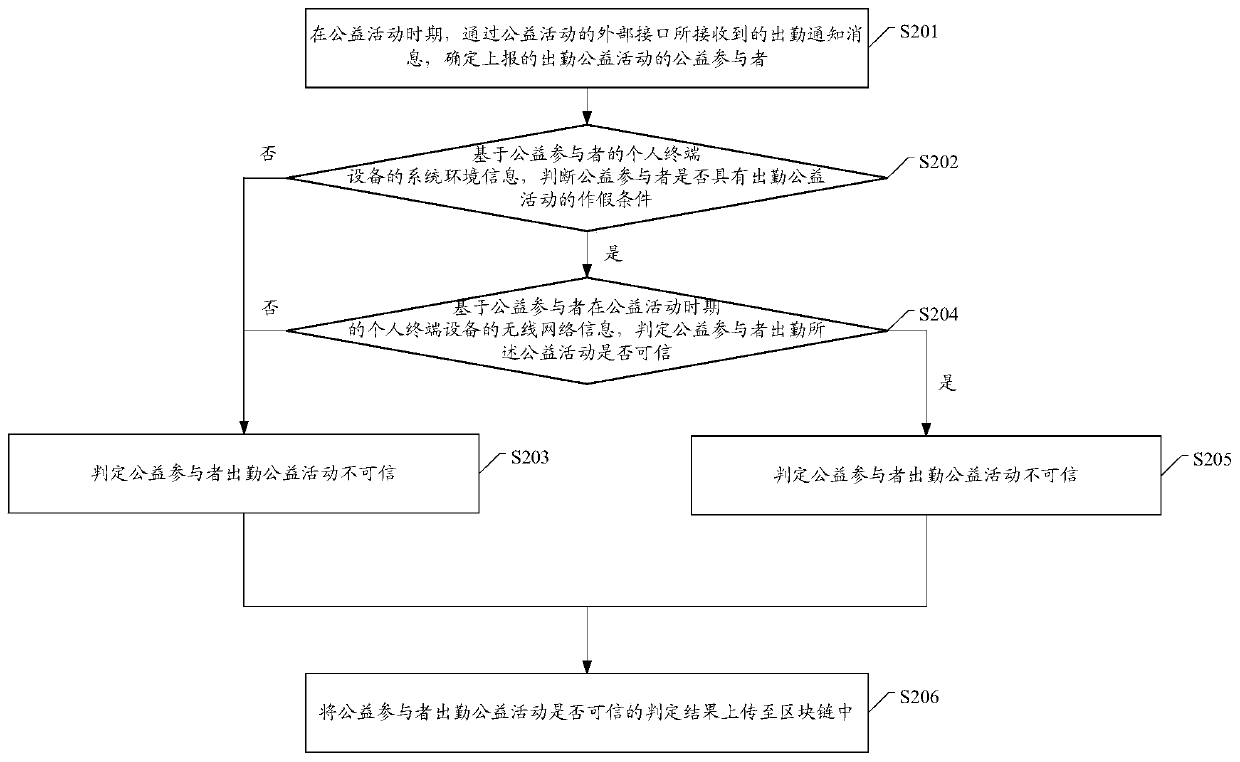

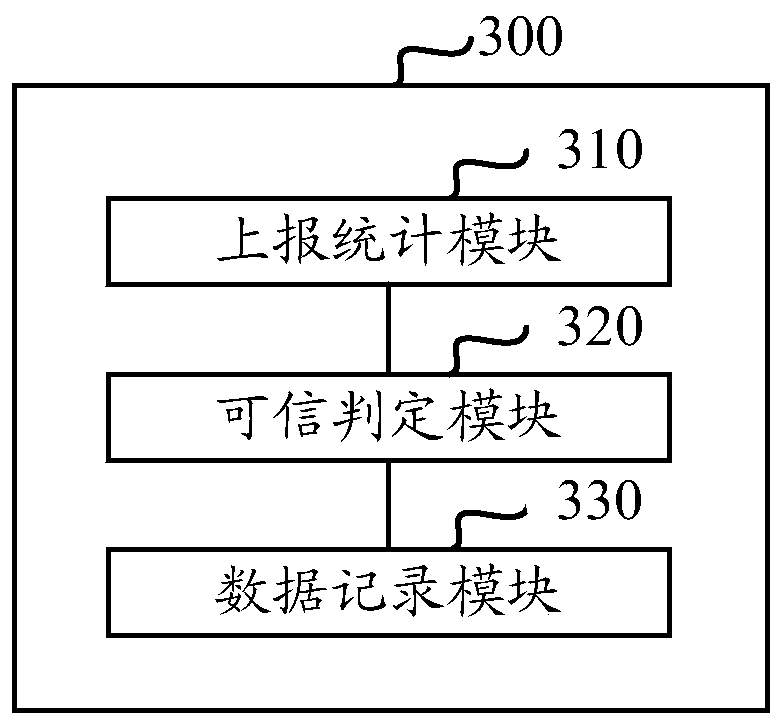

Public welfare recording method based on block chain and related device

The embodiment of the invention provides a public welfare recording method based on a block chain and a related device. The method comprises the following steps: determining public benefit participants of a reported attendance public benefit activity, wherein the public welfare participants report the public welfare activities through personal terminal equipment; based on at least one of the system environment information and the wireless network information of the personal terminal equipment of the public welfare participant in the public welfare activity period, judging whether the public welfare participant attendance of the public welfare activity is credible or not; and uploading a judgment result about whether the public welfare activity is credible or not when the public welfare participants attendance the public welfare activity to the block chain.

Owner:ADVANCED NEW TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com