Backlight module

A backlight module and backplane technology, which is applied to electric light sources, light source fixing, lighting devices, etc., can solve problems such as cracks, lack of good fixing effect on light guide plates, and melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

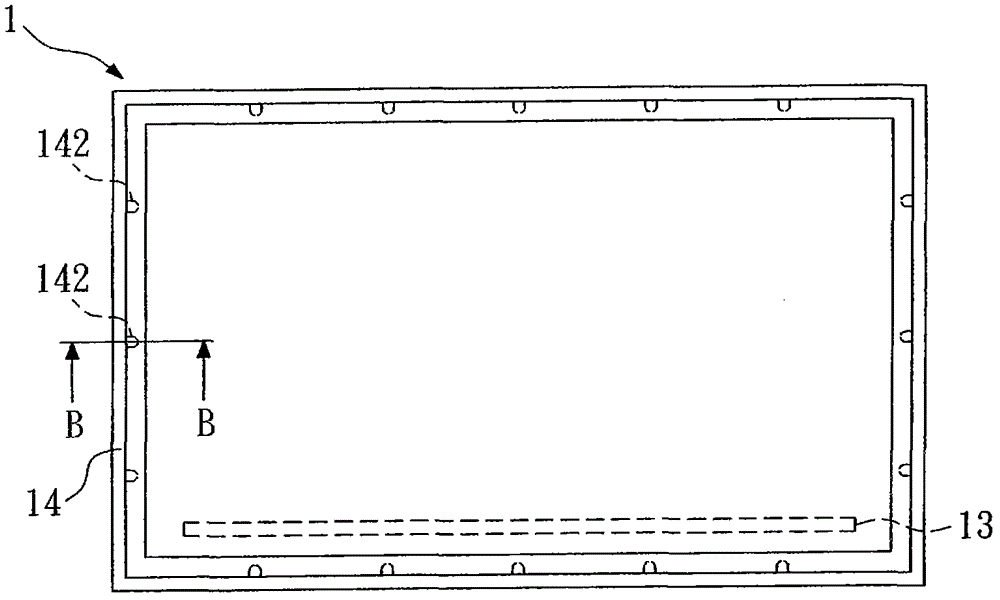

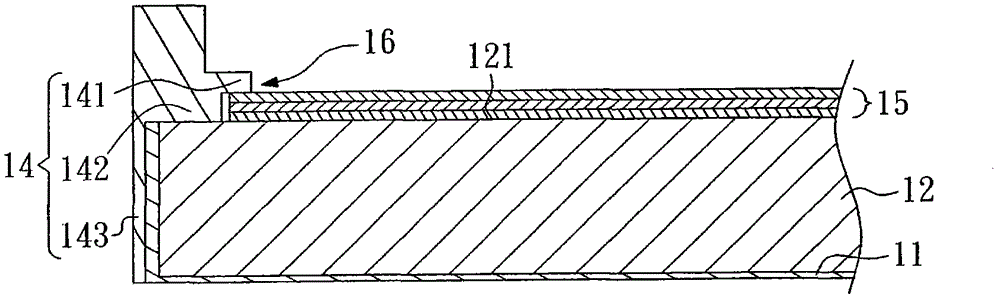

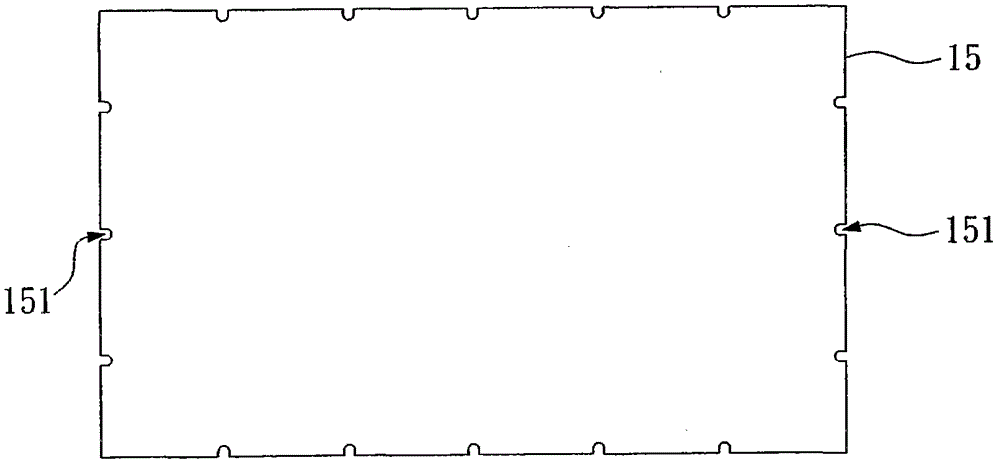

[0080] Figure 2A It shows a three-dimensional exploded view of the first embodiment of the backlight module of the present invention; Figure 2B It shows a combined rear top view of the first embodiment of the backlight module of the present invention; Figure 2C A rear sectional view showing the assembly of the first embodiment of the backlight module of the present invention is shown. with reference Figure 2A to Figure 2C , the backlight module 2 includes a backplane 21 , a light guide plate 22 , at least one light source 23 , an optical film 24 and a plastic frame 25 .

[0081] In this embodiment, the backboard 21 includes a bottom board 211 and four sidewalls 212 , and the sidewalls 212 are substantially vertically connected to the bottom board 211 so that the backboard 21 forms an accommodating space. The light guide plate 22 is disposed on the bottom plate 211 of the back plate 21 for guiding the light from the at least one light source 23 to the light emitting surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com