Novel coke stove based on wet-method quenching

A dry coke quenching and coke oven technology, which is applied in coke ovens, coke cooling, petroleum industry, etc., can solve problems affecting the uniformity of coke blocks, destroying the quality and mechanical stability of coke products, and improving mechanical stability , Improve thermal insulation coefficient, improve quality and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

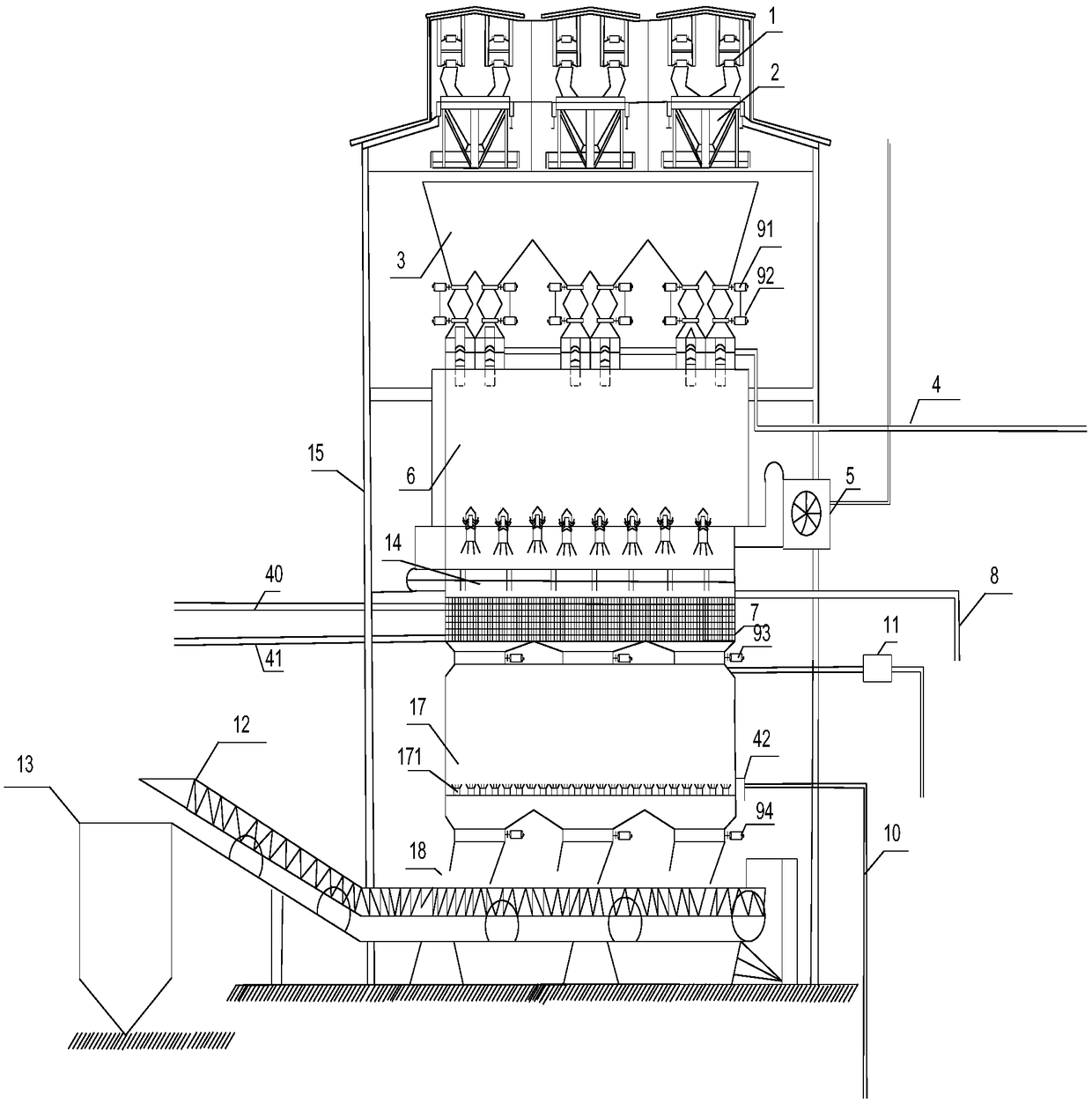

[0026] Such as figure 1 As shown, the present invention includes a square-shaped sealed furnace body, which includes a steel support frame 15, and the square-shaped sealed furnace body is sequentially provided with a drying section 3, a dry distillation section 6, and a coke quenching section 17 from top to bottom. There are gates for isolation, respectively the first gate 91 and the second gate 92 between the drying section 3 and the retort section 6, and the third gate 93 between the retort section 6 and the coke quenching section 17. The fourth gate 94 at the position of the coke outlet 18 at the bottom of the quenching section 17;

[0027] The top of the drying section 3 is provided with incoming coal 1 and the coal loading car 2; the bottom of the quenching section 17 is provided with a number of nozzles 171, and the nozzles are divided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com