Optical camera

A camera and camera lens technology, applied in the field of optical cameras, can solve problems such as high molding requirements, unfavorable large-scale mass production, and inability to meet the needs of miniaturization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

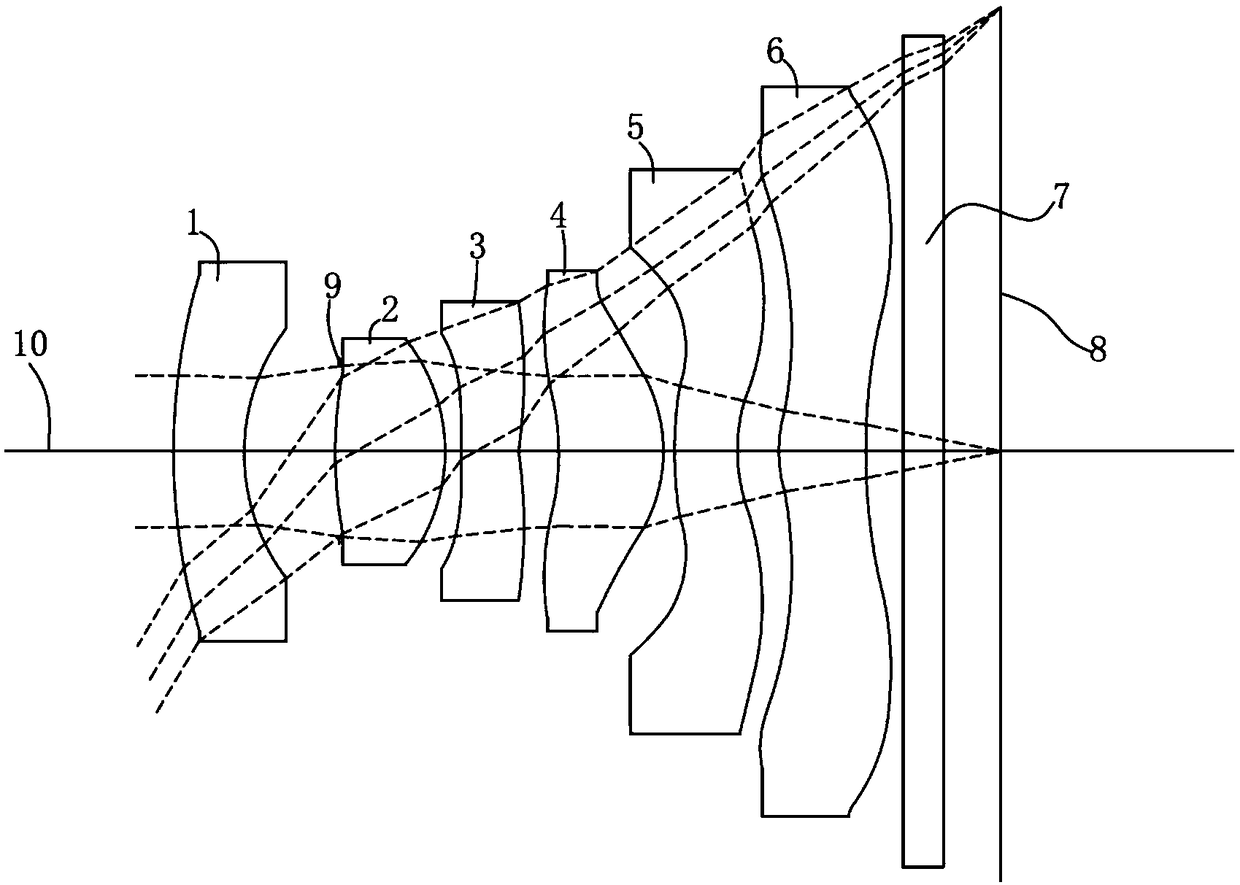

[0045] The invention is a camera used in electronic products. See figure 1 As shown, this is a schematic structural diagram of Embodiment 1 of the present invention. The camera lens is along its optical axis 10 from the object side to the image side direction (i.e. figure 1 shown in the left-to-right direction) include, in order:

[0046] A first lens 1 with negative refractive power, its image side is concave; this helps light from a larger viewing angle to enter the imaging lens system to provide a wider viewing angle

[0047] A second lens 2 with positive refractive power, the object side is convex, and the image side is convex; it can provide positive refractive power of the camera lens and correct the aberration of some systems

[0048] A third lens 3 with refractive power, the object side is concave near the optical axis, and the image side is also concave near the optical axis, which can correct the astigmatism of some systems and improve the imaging quality

[0049] ...

Embodiment 2

[0103] See Figure 5-Figure 8 As shown, this is the second embodiment of the present invention.

[0104] The structure of the second embodiment is the same as that of the first embodiment above. Specifically, as shown in the following table 2-1, the specification parameters of the components of the second embodiment are as follows:

[0105]

[0106] Similarly, in the second embodiment, the object-side surfaces and image-side surfaces of all lenses are aspherical, and the aspheric coefficients of each lens are shown in Table 2-2.

[0107]

[0108]

[0109] Combined with the following table 2-3, this is the condition that the lens assembly in the second embodiment needs to meet:

[0110]

[0111] As shown in Table 2-3, compared with the first embodiment above, the specific parameters of the conditions to be met in the second embodiment are adjusted within the conditional range.

[0112] After the above-mentioned technical conditions are adopted in the second embod...

Embodiment 3

[0114] See Figure 9-Figure 12 As shown, this is the third embodiment of the present invention, and the third embodiment has the same structure as the above-mentioned embodiment. As shown in the following table 3-1, the specification parameters of the parts of the present embodiment three are as follows:

[0115]

[0116]

[0117] Similarly, in the third embodiment, the object-side surface and the image-side surface of all lenses are aspheric, and the specific aspheric coefficients of each lens are shown in Table 3-2.

[0118]

[0119]

[0120] Combined with the following table 3-3, this is the condition that the lens assembly in the third embodiment needs to meet:

[0121]

[0122] As shown in Table 4-3, compared with the above-mentioned embodiments, the specific parameters of the conditions to be met in the third embodiment are adjusted within the condition range.

[0123] After the above-mentioned technical conditions are adopted in the third embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com