Joint mercury removing method and device based on SNCR

A mercury removal and removal technology, applied in separation methods, chemical instruments and methods, mixers, etc., can solve the problems of difficulty in further improving denitration efficiency, high cost, and high operating costs, saving facility settings, improving efficiency, The effect of low initial investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with specific embodiments, which are for explanation rather than limitation of the present invention.

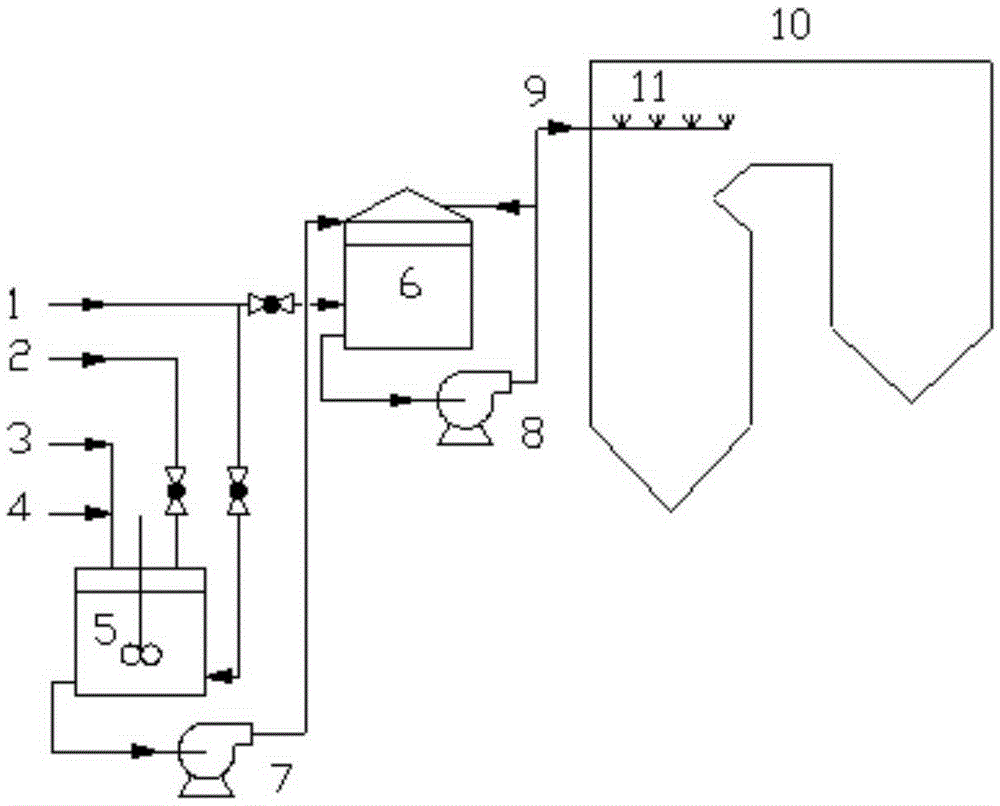

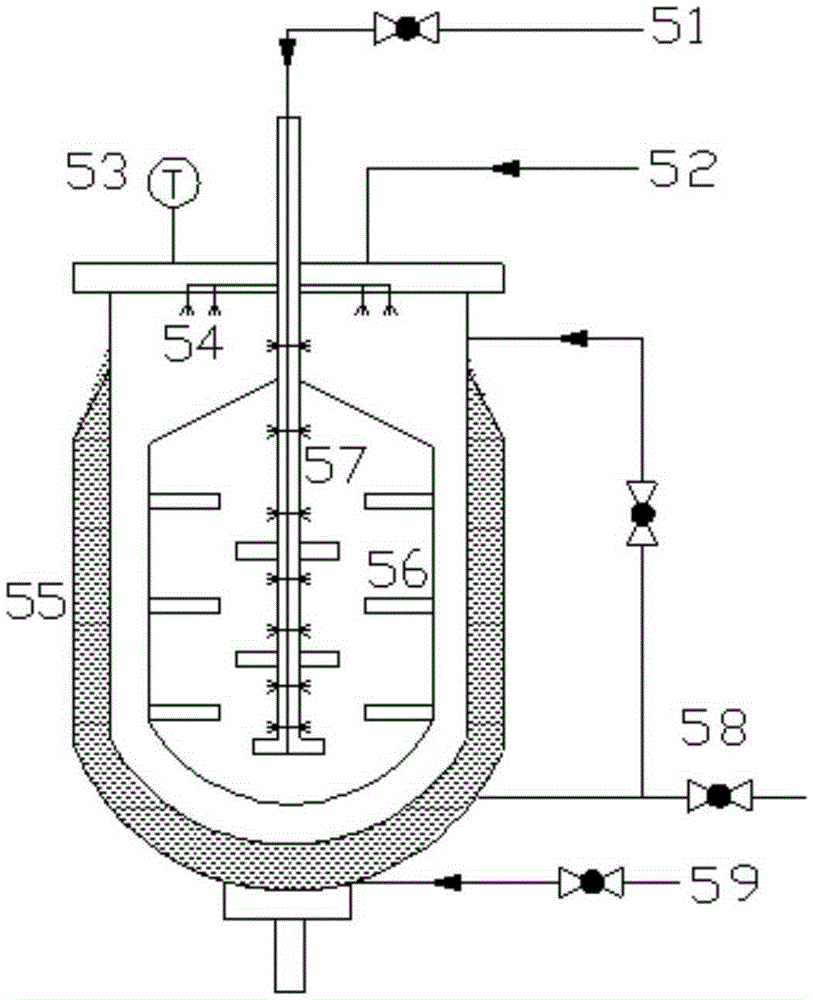

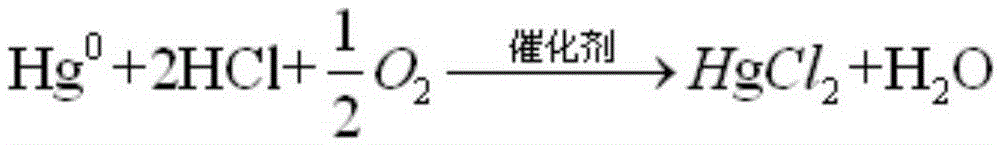

[0023] The present invention is a combined mercury removal method based on SNCR. Solid ammonium chloride and urea are added as raw materials to the SNCR system to form a mixed solution of urea and ammonium chloride, which is then injected into the corresponding flue through the SNCR system. NH obtained by thermal decomposition of urea and ammonium chloride 3 For NO in flue gas x Reductive removal is carried out, and zero-valent mercury in the flue gas is oxidized and removed by HCl obtained from the thermal decomposition of ammonium chloride. When solid ammonium chloride and urea are added as raw materials to the SNCR system, the solid ammonium chloride and urea are mixed according to the required ratio and then added or sequentially added according to the required ratio; the required ratio is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com