High-efficiency chemical fertilizer granulator

A granulator, high-efficiency technology, applied in the direction of raw material extrusion granulation, etc., can solve the problem of easy damage of the extrusion part of the fertilizer granulator, and achieve the effect of reducing maintenance time, prolonging the service life and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

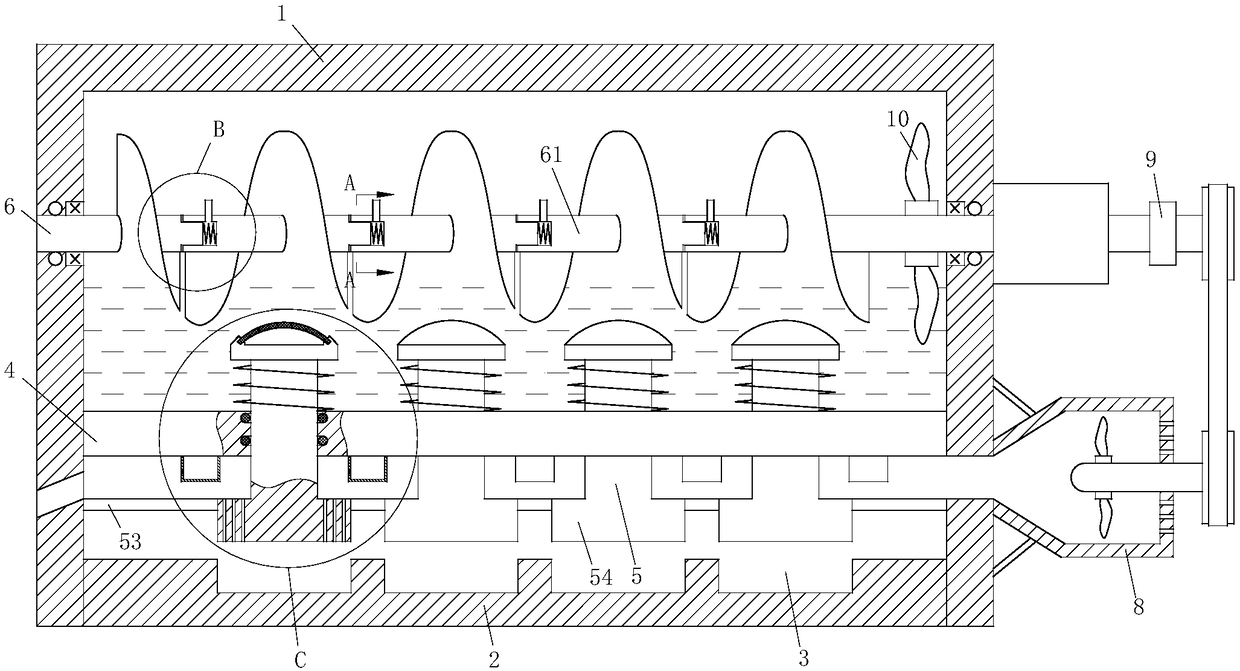

[0021] use Figure 1-Figure 5 A high-efficiency fertilizer granulator according to an embodiment of the present invention will be described as follows.

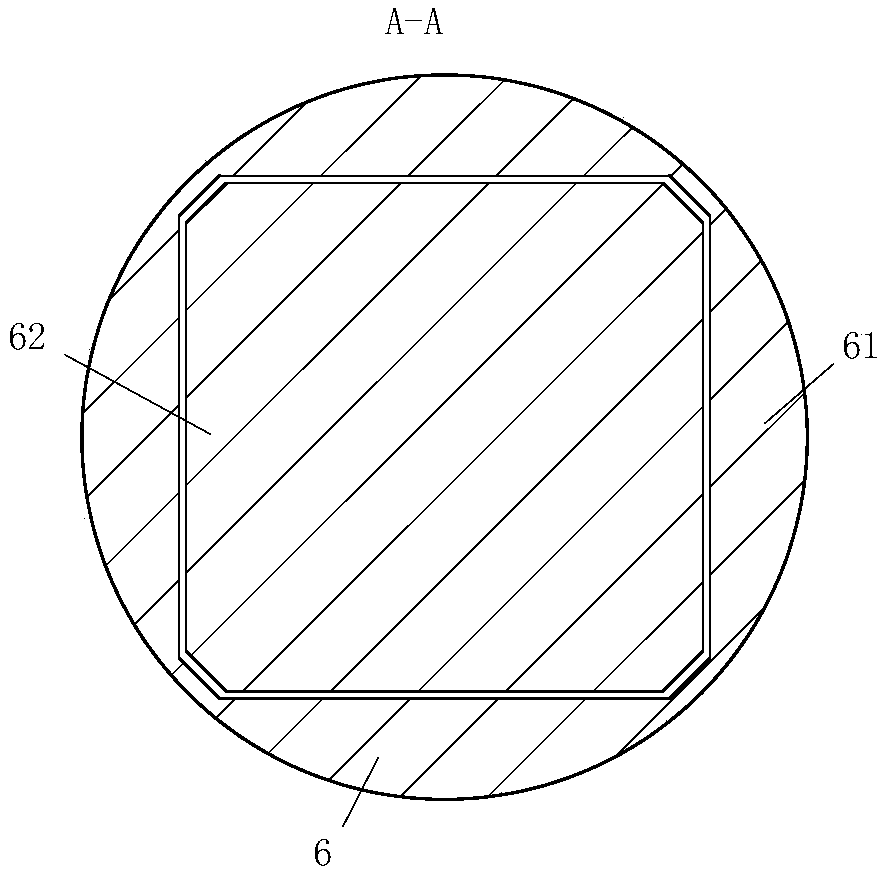

[0022] Such as Figure 1 to Figure 2 As shown, a high-efficiency fertilizer granulator according to the present invention includes a box body 1 and a discharge plate 2, the box body 1 is provided with a discharge port, and the discharge plate 2 is located at the bottom of the box body 1, The discharge plate 2 is evenly provided with several groups of discharge grooves 3, and the top of the discharge plate 2 is horizontally provided with a fixed plate 4; the fixed plate 4 is fixed in the box body 1, and the fixed plate 4 separates the box body 1 into two parts. Part, on the fixed plate 4, a through hole is provided at the position corresponding to the center of the discharge trough 3, and a pressure rod 5 is slidably connected in the through hole, and a sealing ring is provided between the through hole and the pressure rod 5;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com