Soft-seal valve element of valve

A soft sealing and valve core technology, applied in the field of valve soft sealing valve core, can solve the problems of too fast pressing, poor water locking, damaged valve core, etc., to achieve easy maintenance, simple and practical processing technology, and saving The effect of pressing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

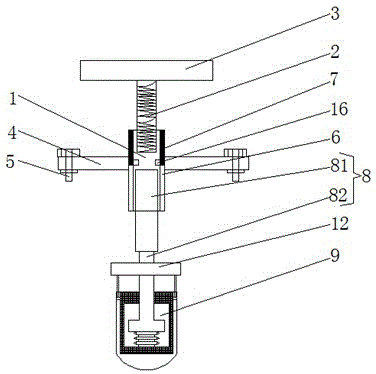

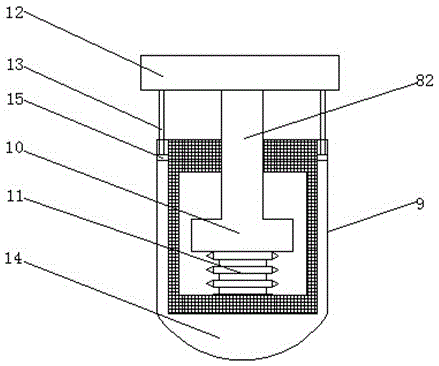

[0012] See Figure 1-2 , A technical solution proposed by the present invention: a soft sealing valve core of a valve, comprising a connecting pipe 1, a limit block 16 is fixedly installed on the inner wall of the connecting pipe 1, and the limit block 16 is located between the telescopic rod 8 and the threaded column 2. , The top of the connecting pipe 1 is sleeved with a threaded column 2, and the threaded column 2 is provided to achieve a more stable downward pressure on the valve core 9. The threaded column 2 is not only stable and not easy to slip through the threaded connection, but also the processing technology is simple and practical, and the cost is low , Suitable for a wide range of applications, the top of the threaded column 2 is integrally formed with a handle 3, both sides of the connecting tube 1 are provided with brackets 4, one end of the bracket 4 is provided with a bolt 5, the inside of the connecting tube 1 is a hollow structure, and the inner wall of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com