Application of alpha-aminoisobutyric acid or beta-aminoisobutyric acid in preparation of fruit preservative as well as fruit preservative and using method

A technology of aminoisobutyric acid and antistaling agent, which is applied in the field of fruit antistaling agents, can solve the problems such as difficulty in controlling the treatment concentration and abnormal post-ripening of fruits, and achieve the effects of simple and convenient preservation methods, maintaining fruit quality, and improving commodity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1mM and 10mM α-aminoisobutyric acid solutions are respectively 1mmol and 10mmol α-aminoisobutyric acid dissolved in 1L of water, stirred evenly and completely dissolved to obtain 1mM and 10mM α-aminoisobutyric acid solutions.

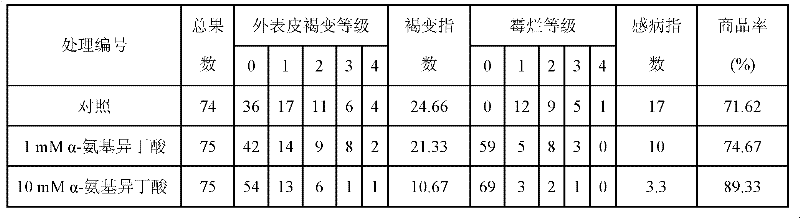

[0024] Freshly harvested "Guiwei" lychee fruits are sorted in order to remove diseased and pest fruits and defective fruits and obtain good quality fruits. Control and treatment fruits were soaked in clean water, 1.0 and 10mM α-aminoisobutyric acid for 5 minutes respectively, taken out and dried, packed in polyethylene bags with a thickness of 0.015mm, 20 fruits / bag, stored at 25°C, and observed the preservation effect after 6 days of storage , and the preservation effect is shown in Table 1.

[0025] As can be seen from Table 1, α-aminoisobutyric acid treatment obviously inhibited litchi fruit browning and rot, and the effect of high concentration (10mM) was better. Disease index decreased by 14% compared with the control.

[0026] Table 1: th...

Embodiment 2

[0029] 1.0, 100mM β-aminoisobutyric acid and 100mM α-aminoisobutyric acid are respectively 1.0, 100mmol β-aminoisobutyric acid and 100mmol α-aminoisobutyric acid dissolved in 1L of water, stirred evenly and completely dissolved to obtain 1.0 , 100mM β-aminoisobutyric acid and 100mM α-aminoisobutyric acid.

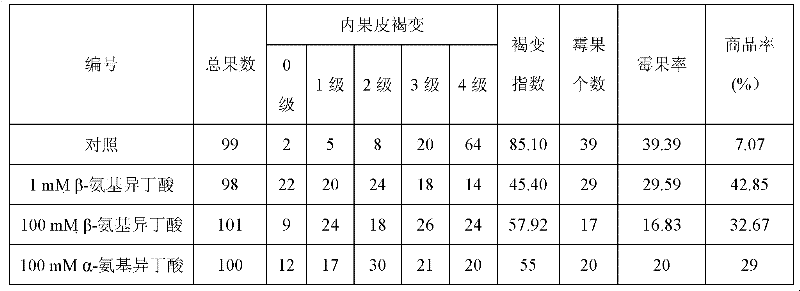

[0030] The freshly harvested "Shixia" longan fruits are sorted to remove diseased and insect fruits and defective fruits. The control and treatment fruits were soaked in 0.05% Sperke solution for 3 minutes respectively, after drying, soaked in water, 1.0, 100mM β-aminoisobutyric acid and 100mM α-aminoisobutyric acid for 3min, took out and dried , 0.015mm thick polyethylene bag packaging, 20 fruits / bag, stored at 25°C, and observed the fresh-keeping effect after 6 days.

[0031] Table 2: the fresh-keeping effect of fruit preservative of the present invention on longan

[0032]

[0033] The fresh-keeping effect is shown in Table 2. It can be seen from Table 2 that after ...

Embodiment 3

[0035] The mass fraction of 0.05% Teketol + 100mM α-aminoisobutyric acid is obtained by dissolving 0.5g Teketol and 100mmol α-aminoisobutyric acid in 1L of water, stirring and dissolving.

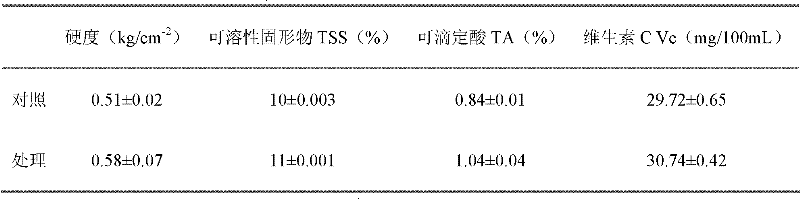

[0036] The freshly harvested Chinese kiwifruit fruits are sorted to remove diseased and pest fruits and defective fruits. Control and treatment fruits were soaked in 0.05% Teketol and 0.05% Teketol + 100mM α-aminoisobutyric acid for 0.5min respectively, taken out and dried, and packed in polyethylene bags with a thickness of 0.015mm , 15 fruits / bag, stored at 2°C. After 3 months of low temperature storage and 14 days of normal temperature shelf life, the fresh-keeping effect was observed, and its fresh-keeping effect is shown in Table 3. As can be seen from Table 3, the Chinese kiwi fruit after the fresh-keeping treatment by the fresh-keeping agent of the present invention has maintained a higher hardness, and the fruit TSS, TA, and Vc content are obviously higher than the contrast. The q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com