Patents

Literature

237 results about "Solid carbon dioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

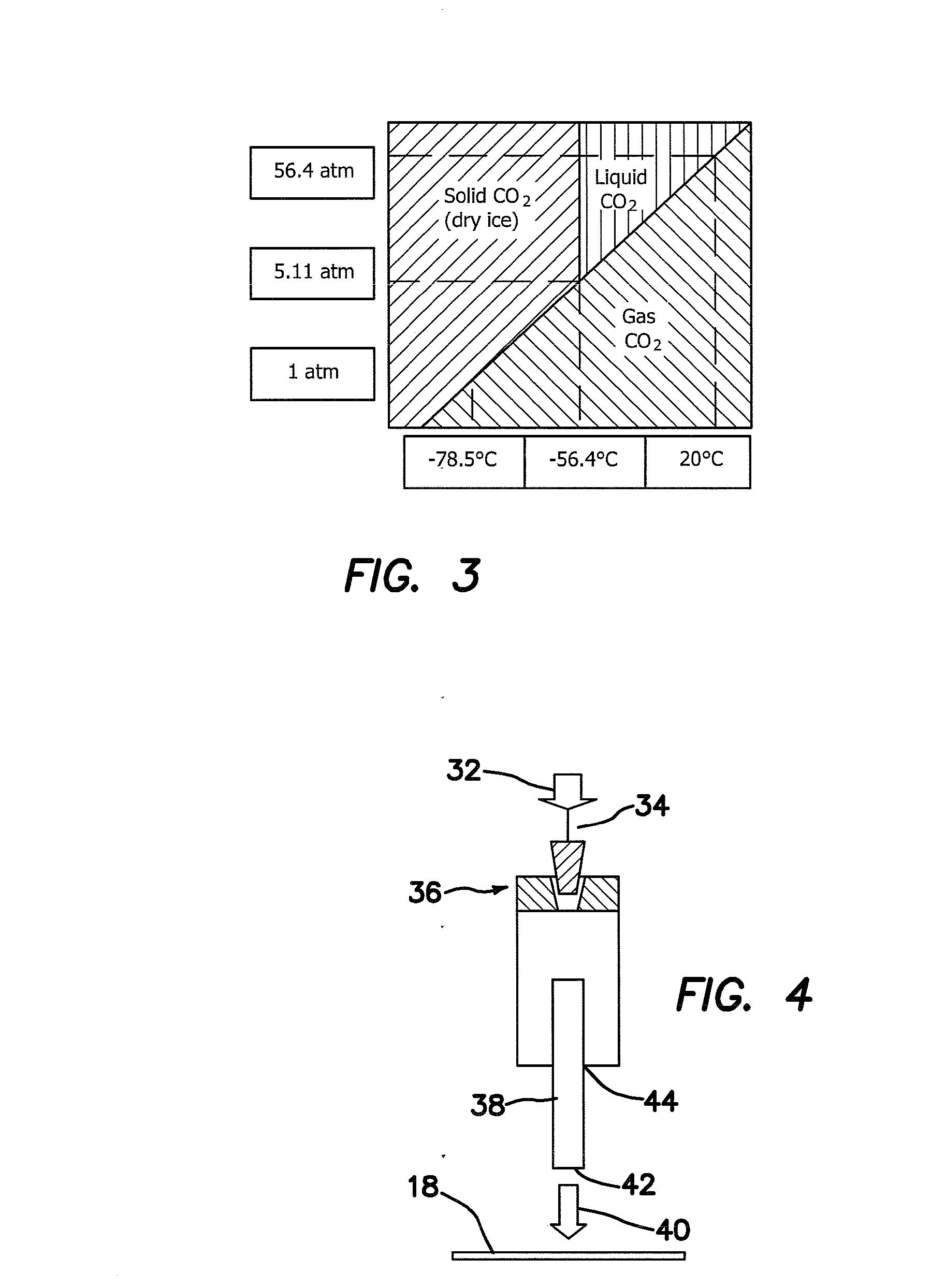

Solid CO2. Dry ice, sometimes referred to as "cardice" (chiefly by British chemists), is the solid form of carbon dioxide. It is used primarily as a cooling agent. Its advantages include lower temperature than that of water ice and not leaving any residue (other than incidental frost from moisture in the atmosphere).

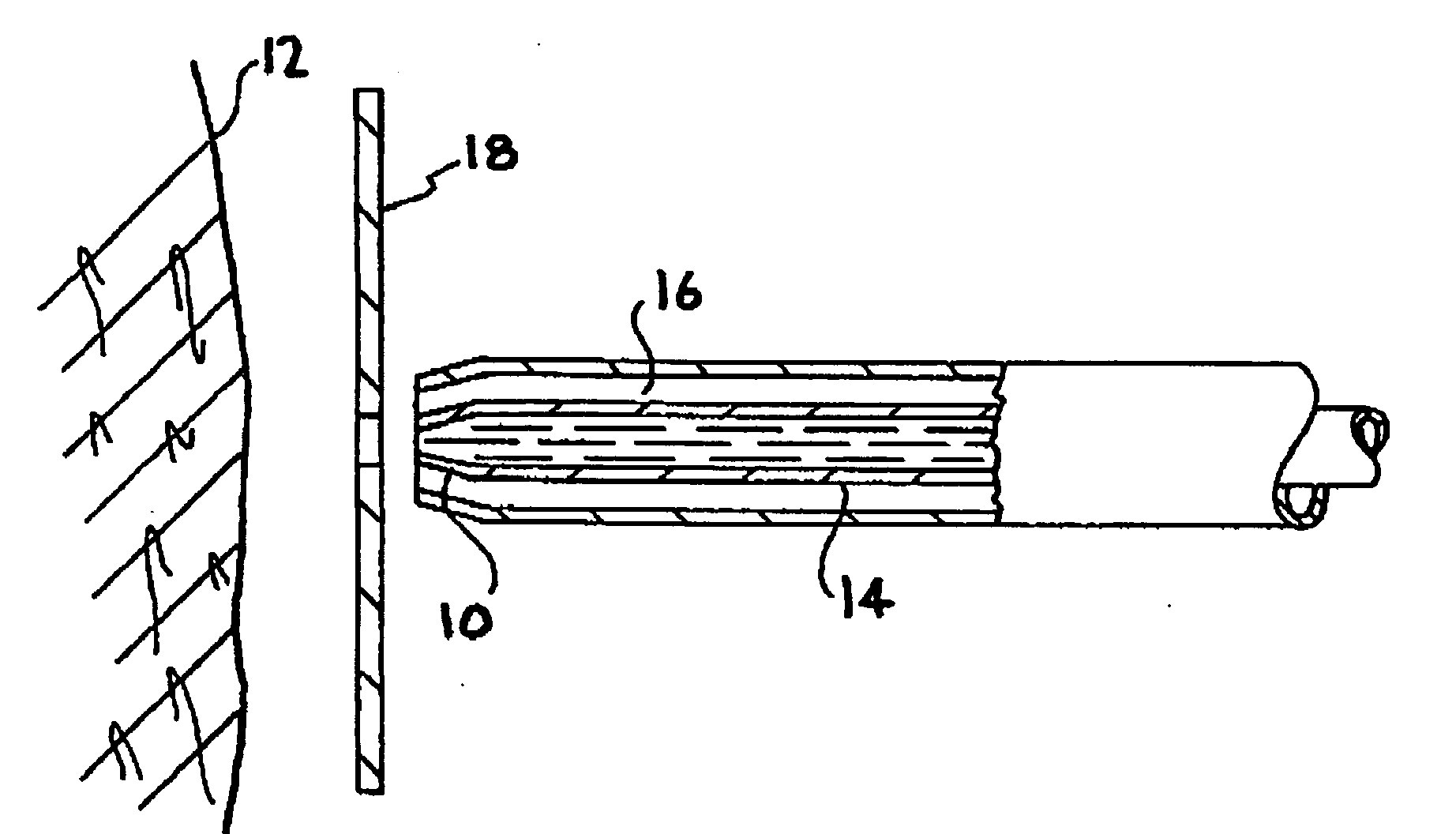

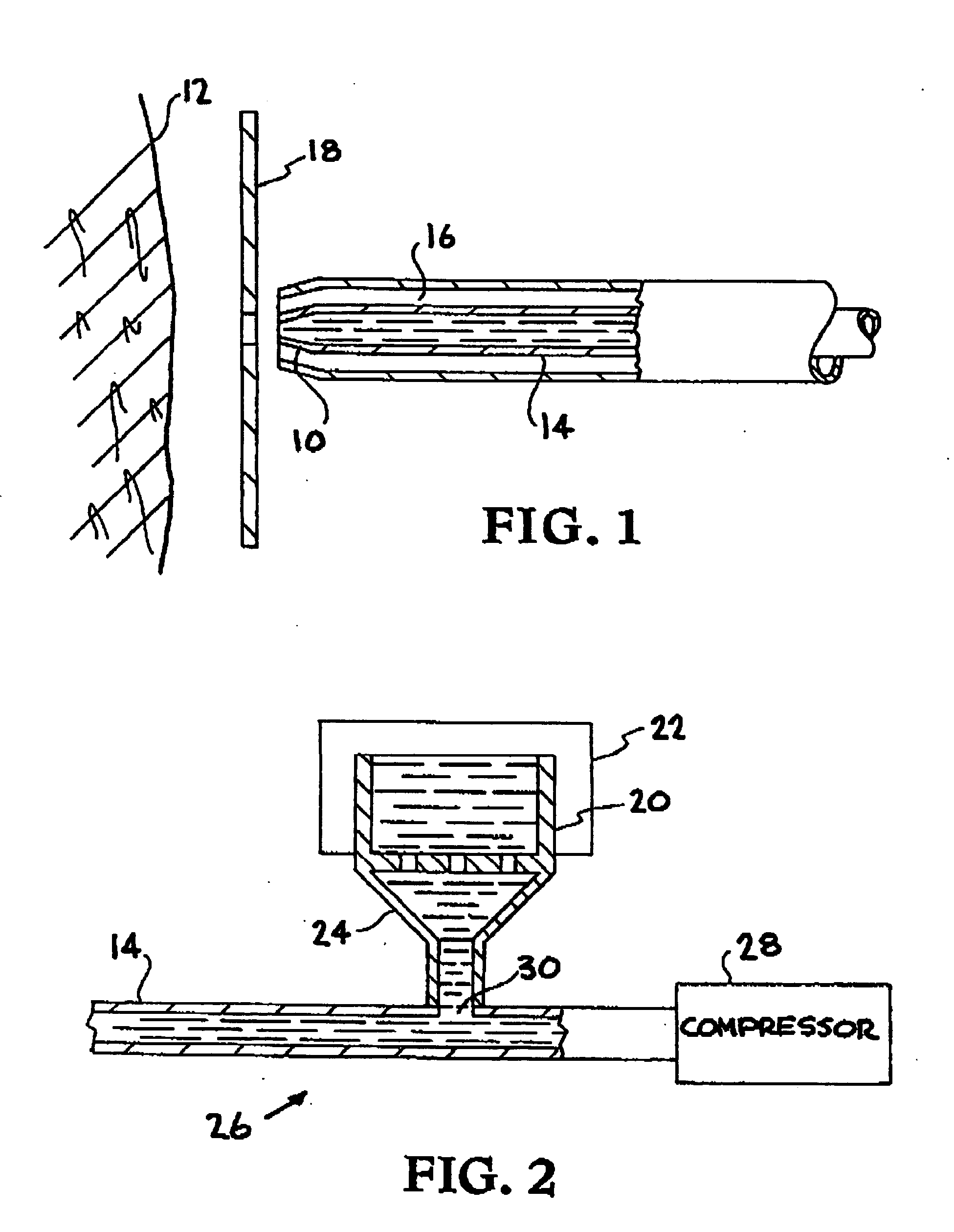

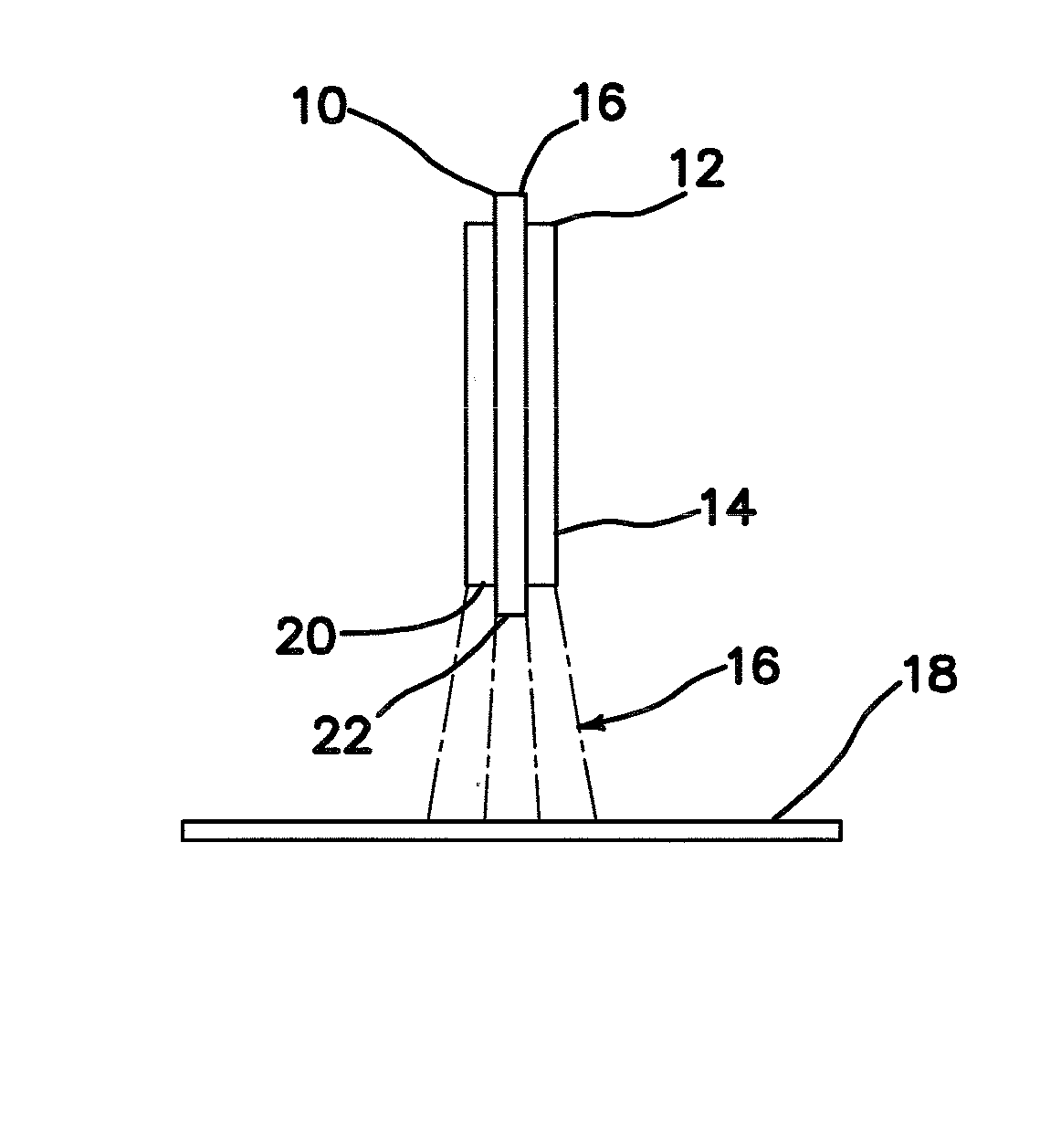

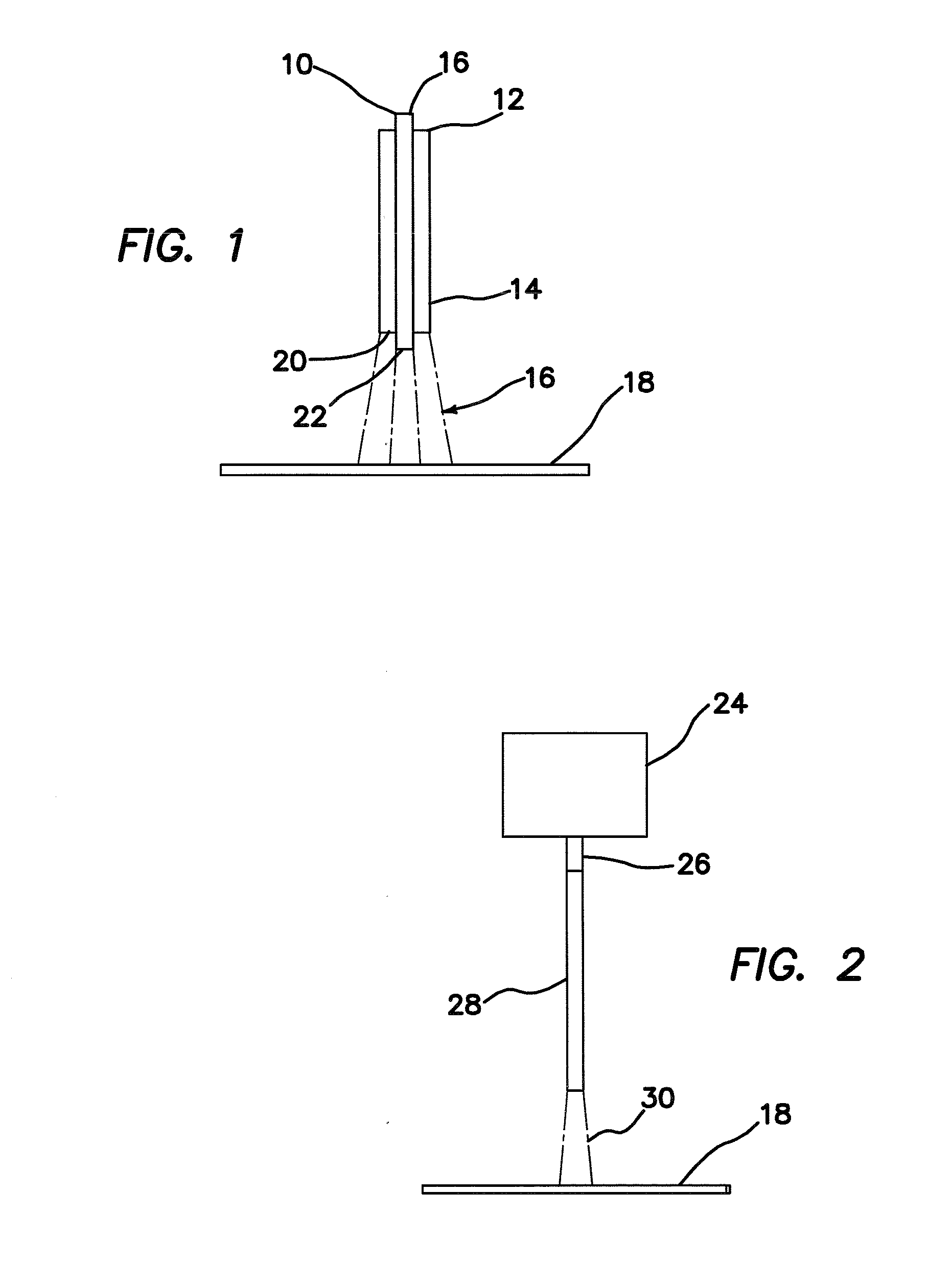

Skin resurfacing and treatment using biocompatible materials

InactiveUS20050059940A1Eliminate the problemAvoid infectionSurgeryMedical devicesHuman bodyCarrier fluid

Biocompatible materials are propelled at the skin with sufficient velocity to cause desired resurfacing of skin layers to the desired penetration depth. The materials, such as dry ice or water ice, are harmonious with the human body and thus eliminate foreign body reactions. Various materials may be used in combination, including local anesthetics and vasoconstrictors in solid or liquid form. The biocompatible solid or liquid particles are suspended in a cold carrier fluid and propelled through an insulated delivery system to the surface of the skin. The treatment of diseased skin lesions may be accomplished using the present invention as a drug delivery system.

Owner:PEARL TECHNOLOGY HOLDINGS LLC

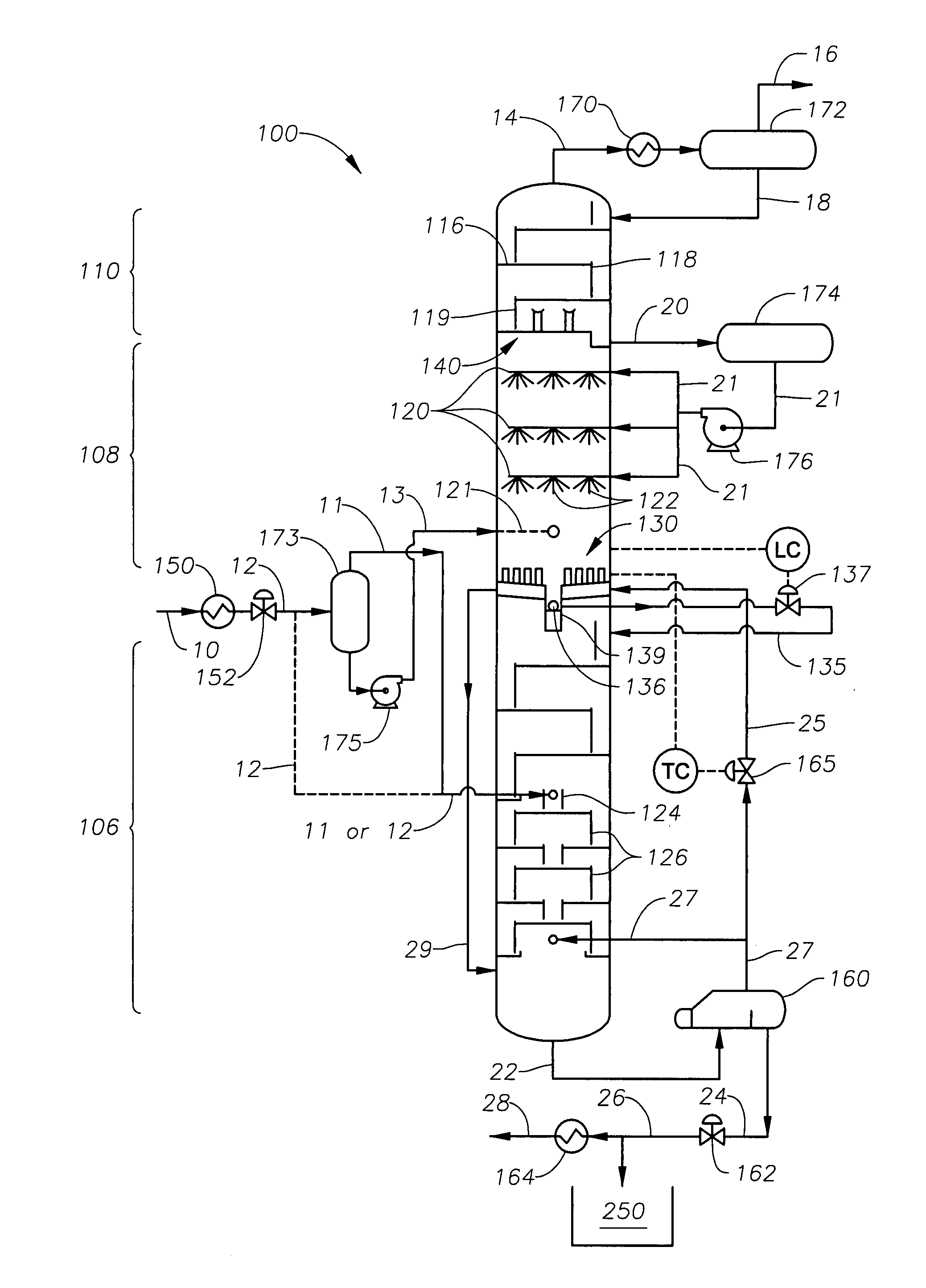

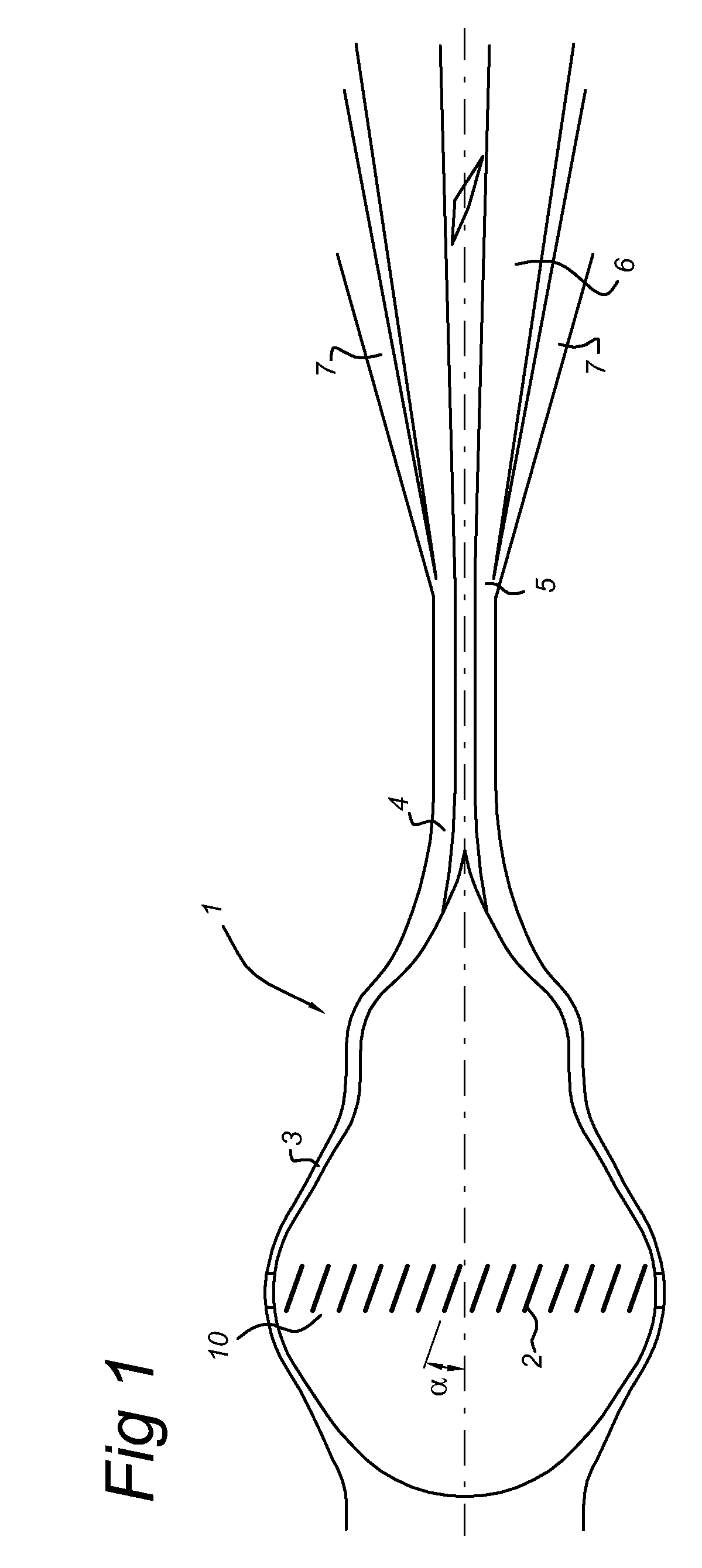

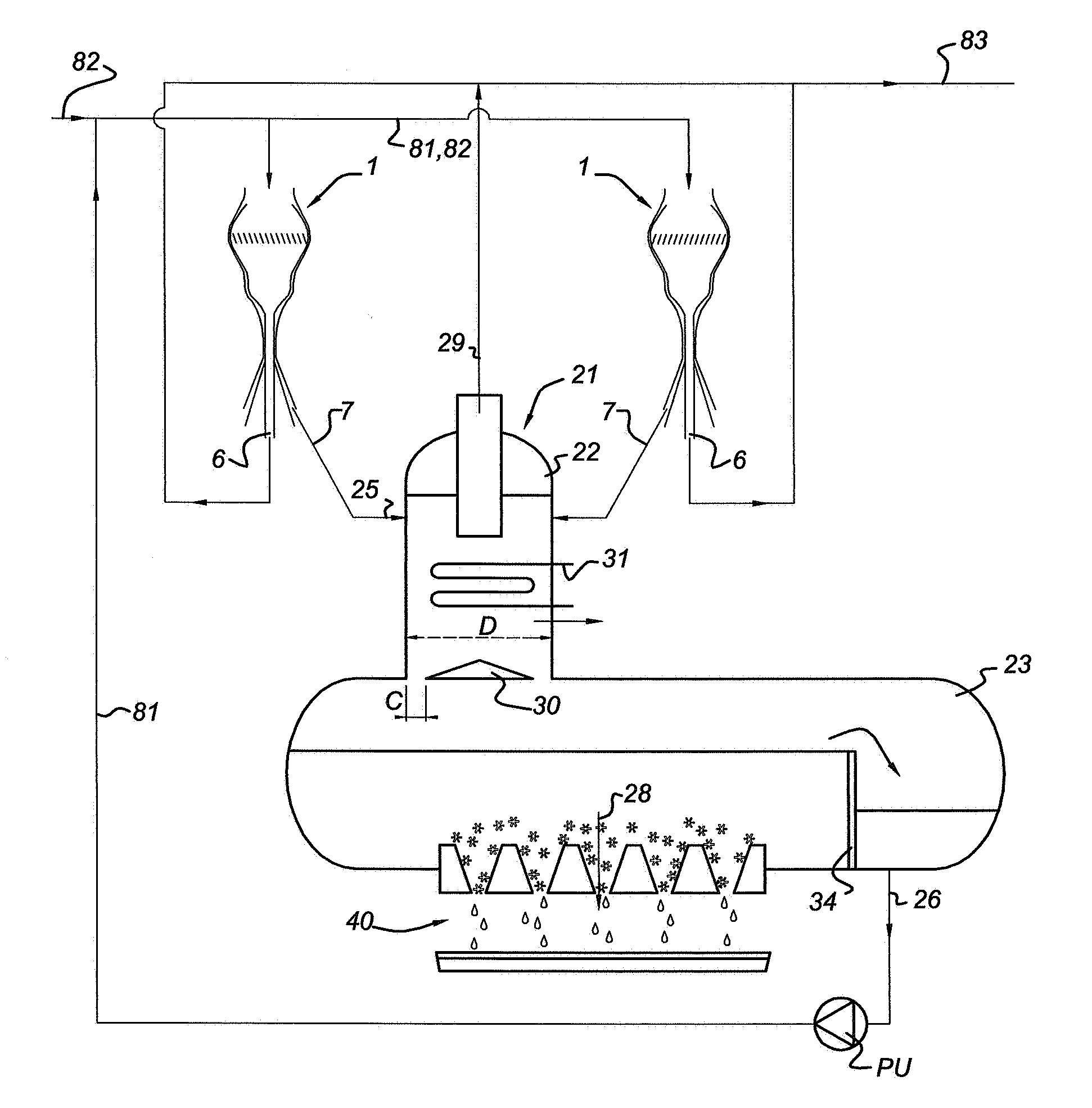

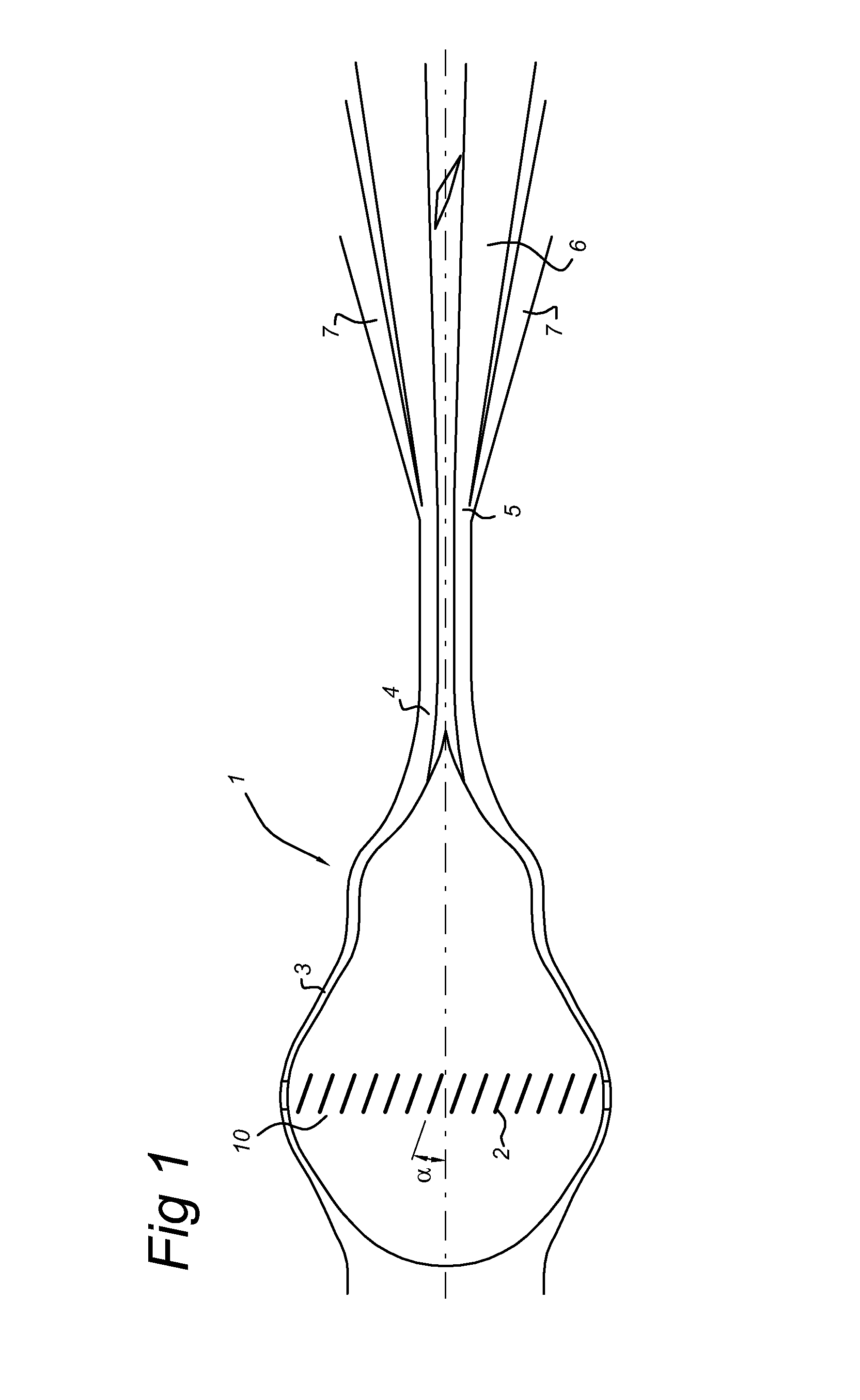

Controlled Freeze Zone Tower

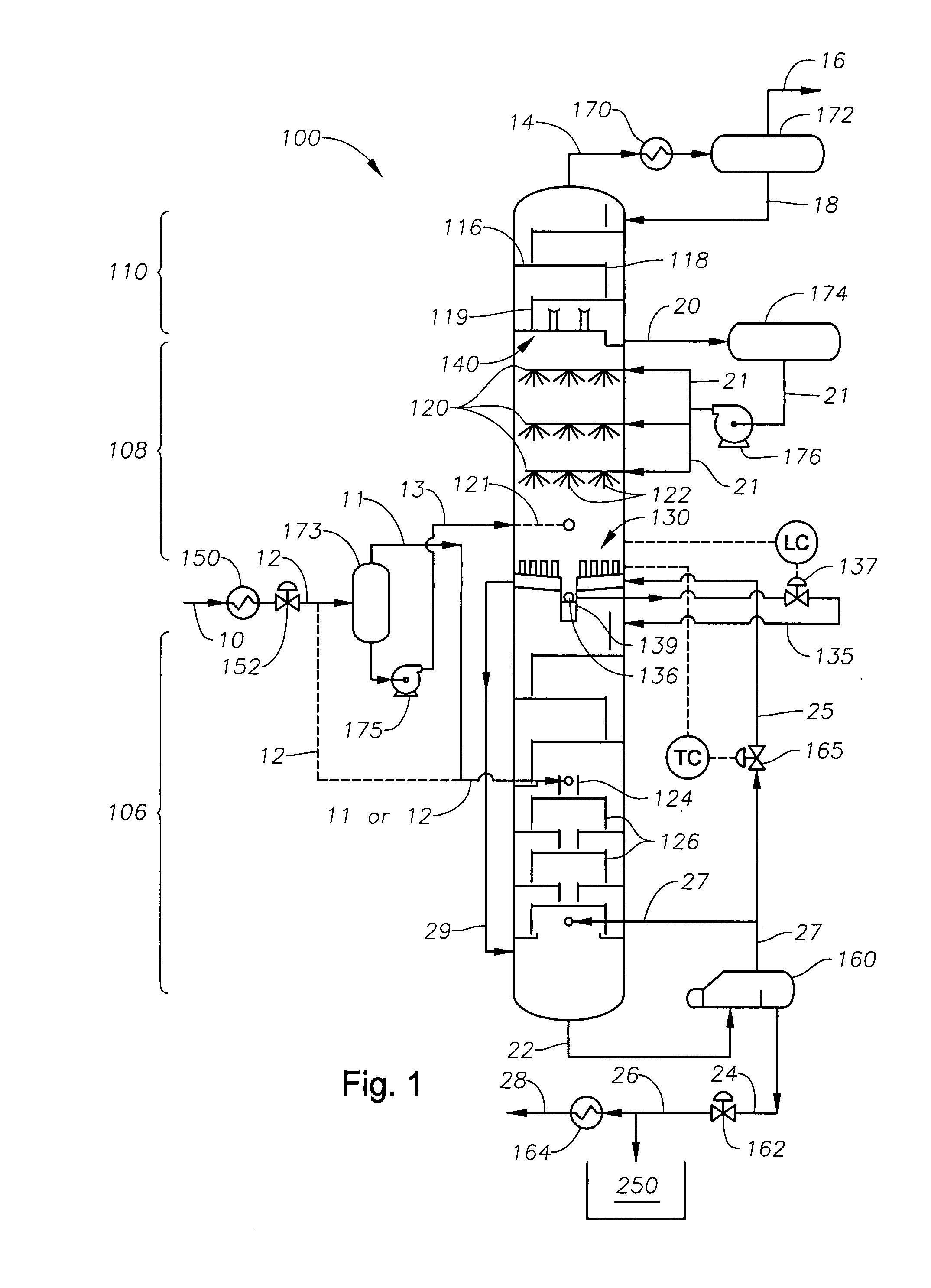

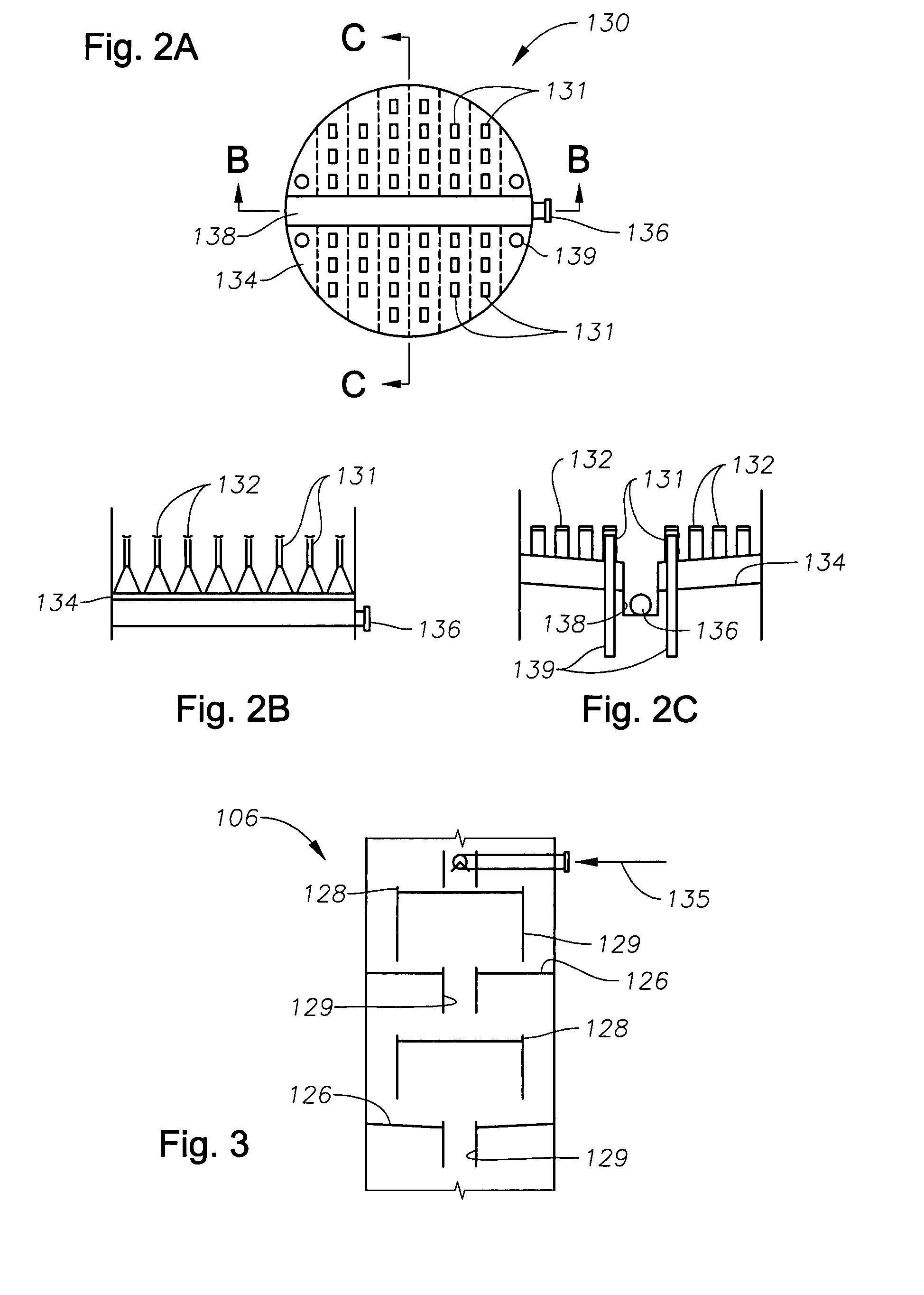

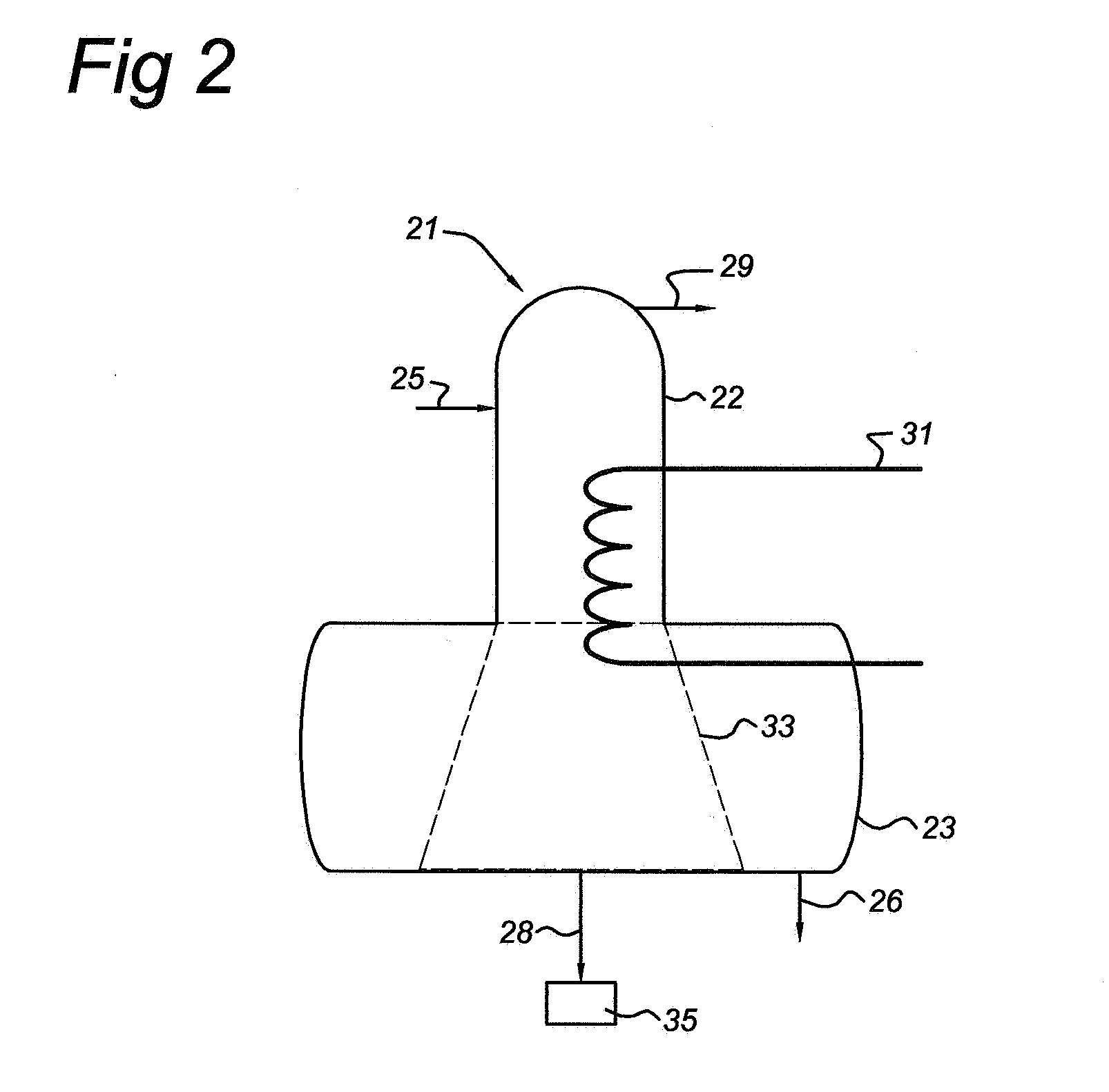

A cryogenic distillation tower is provided for the separation of a fluid stream containing at least methane and carbon dioxide. The cryogenic distillation tower has a lower stripping section, an upper rectification section, and an intermediate spray section. The intermediate spray section includes a plurality of spray nozzles that inject a liquid freeze zone stream. The nozzles are configured such that substantial liquid coverage is provided across the inner diameter of the intermediate spray section. The liquid freeze zone stream generally includes methane at a temperature and pressure whereby both solid carbon dioxide particles and a methane-enriched vapor stream are formed. The tower may further include one or more baffles below the nozzles to create frictional resistance to the gravitational flow of the liquid freeze zone stream. This aids in the breakout and recovery of methane gas. Additional internal components are provided to improve heat transfer and to facilitate the breakout of methane gas.

Owner:FIELER ELEANOR R +3

Method and system for treating food items with an additive and solid carbon dioxide

ActiveUS20100293969A1Reduce pressureMixing methodsStationary refrigeration devicesLiquid carbonSolid carbon dioxide

Embodiments of the invention generally provide methods and systems that distribute an additive in solid carbon dioxide in an interior of food processing equipment. The additive may be injected into a flow of liquid carbon dioxide upstream of an expander at or adjacent to the interior. Injection of the additive into the interior may be alternated with directing a flow of expanded carbon dioxide into the interior. In some embodiments, the freezing point of the additive with or without a diluent composition and / or additive(s) is lower than a temperature of the liquid carbon dioxide.

Owner:AIR LIQUIDE AMERICA INC +1

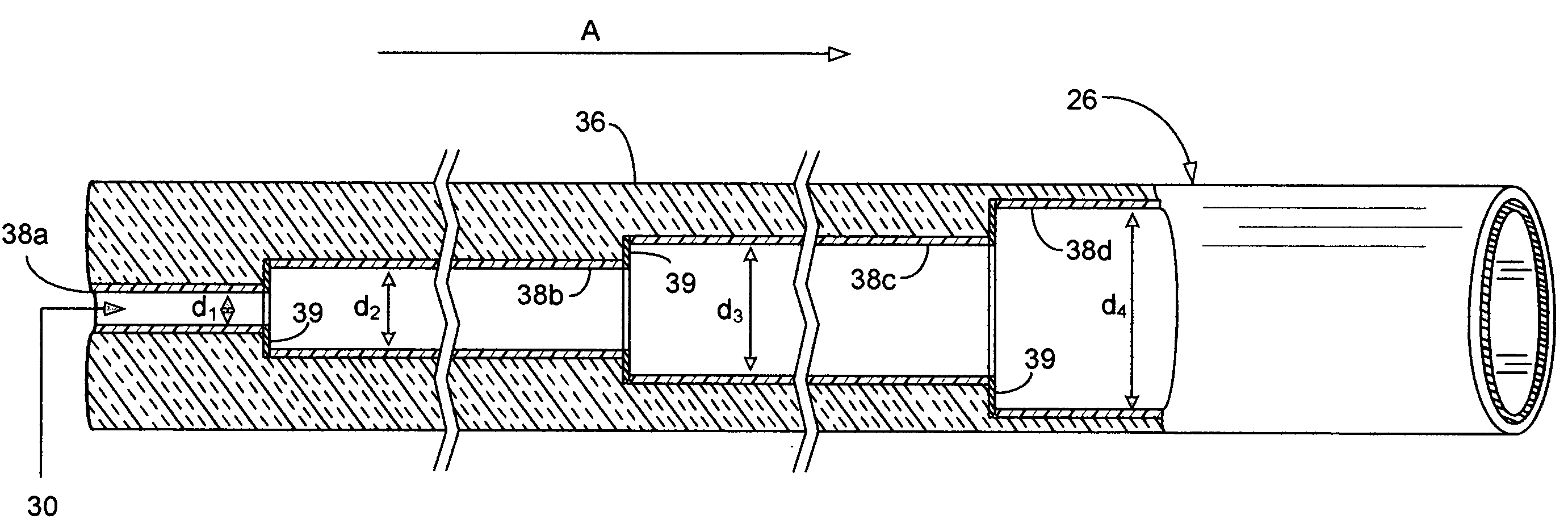

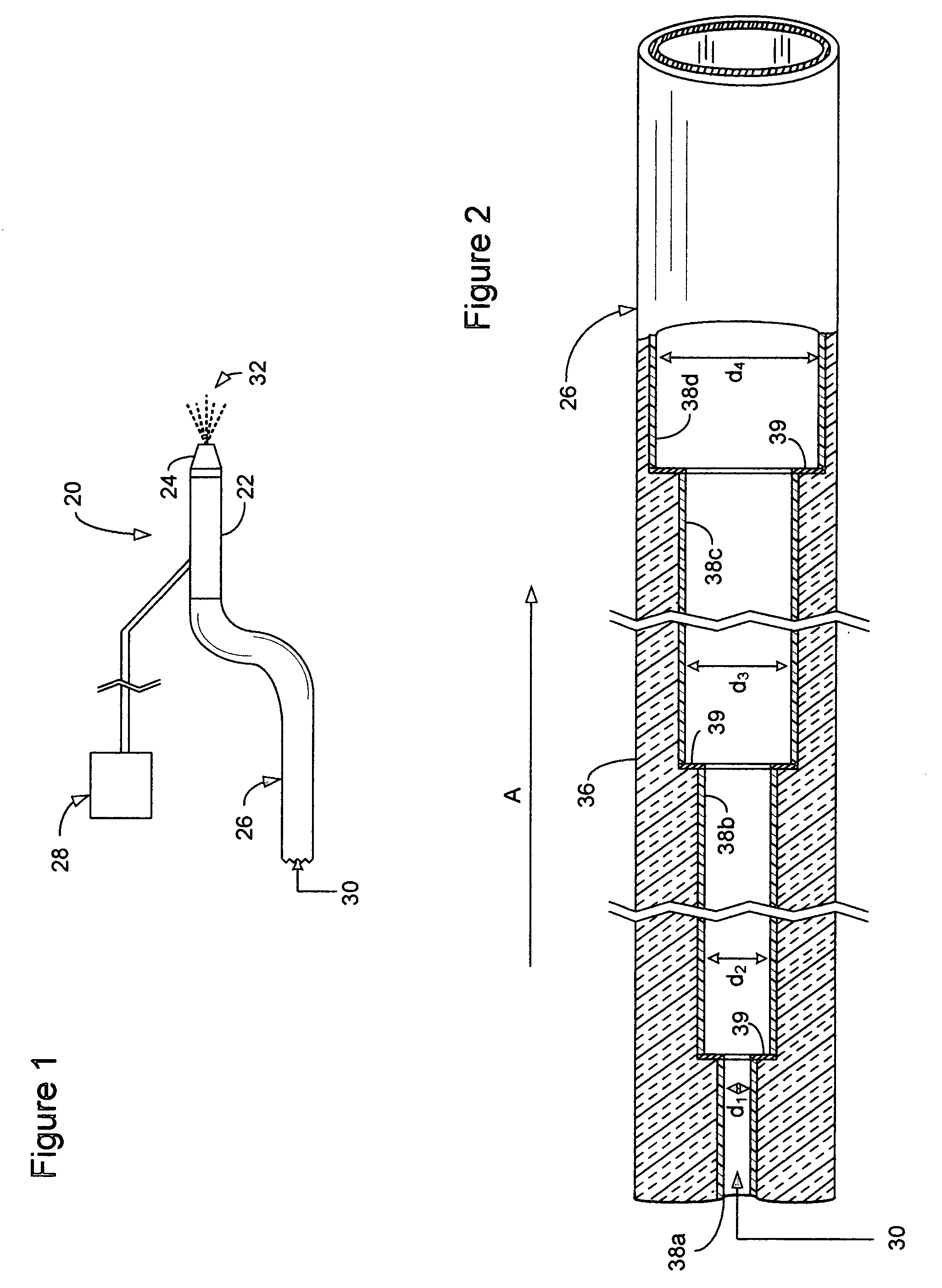

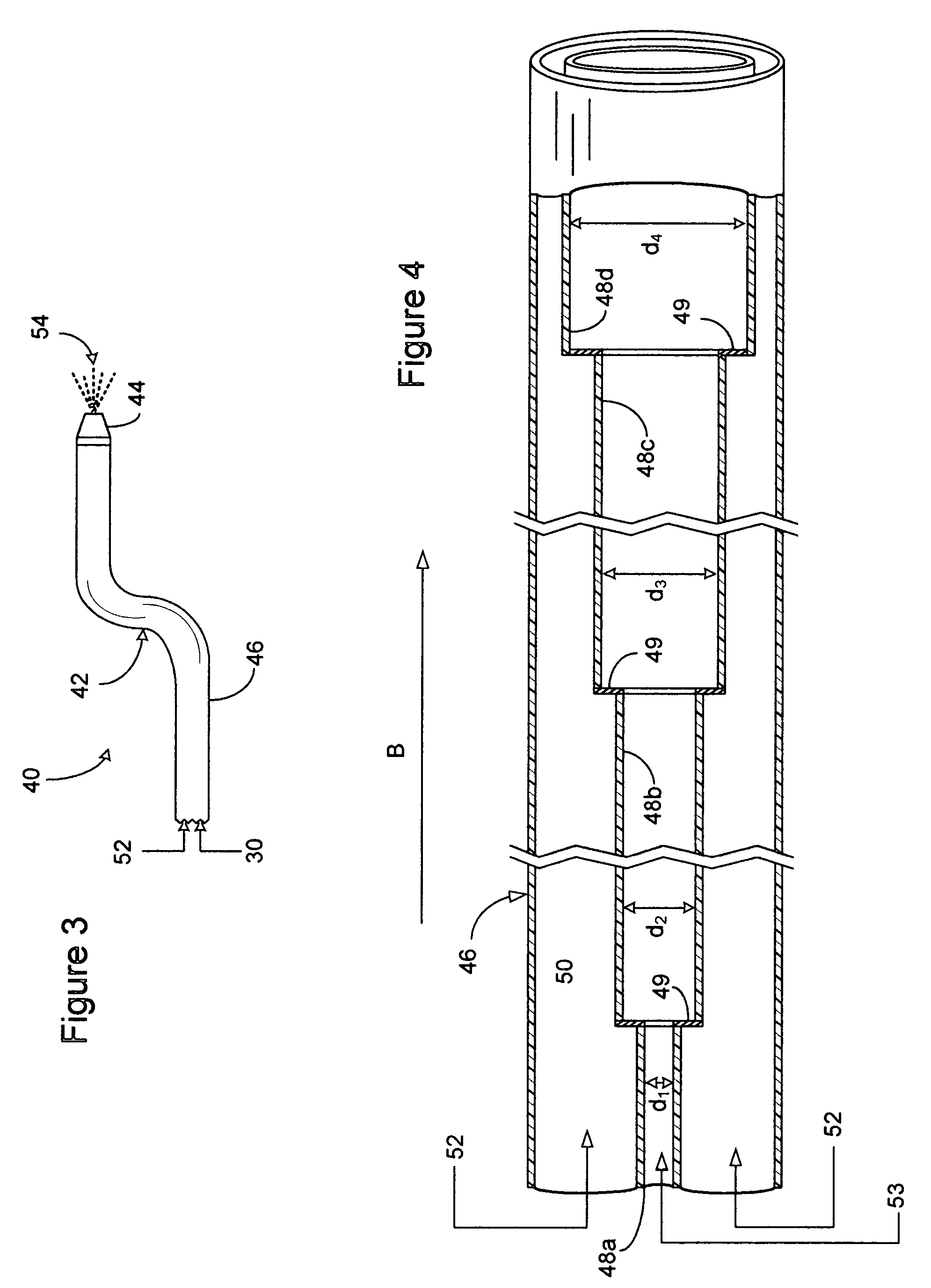

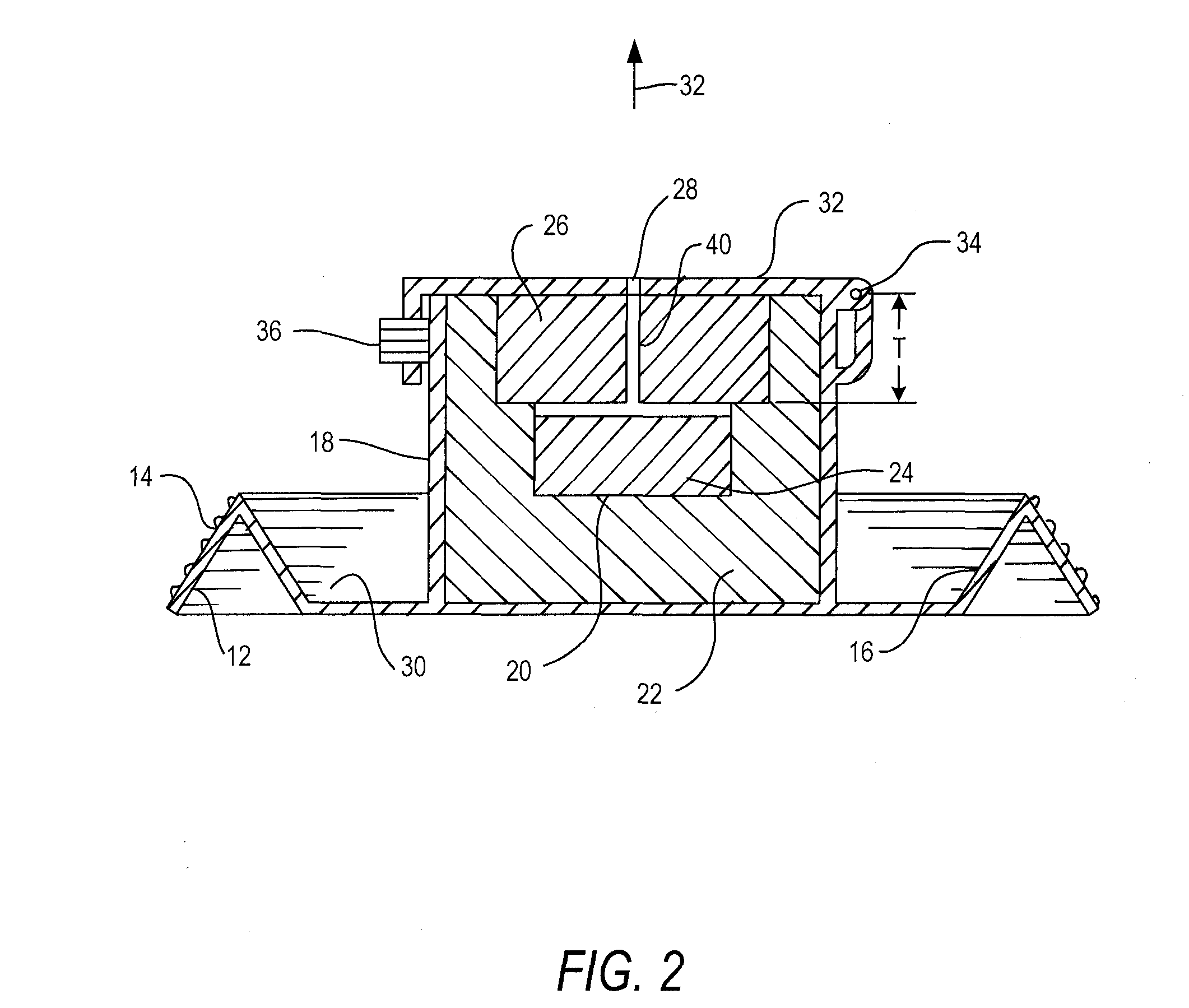

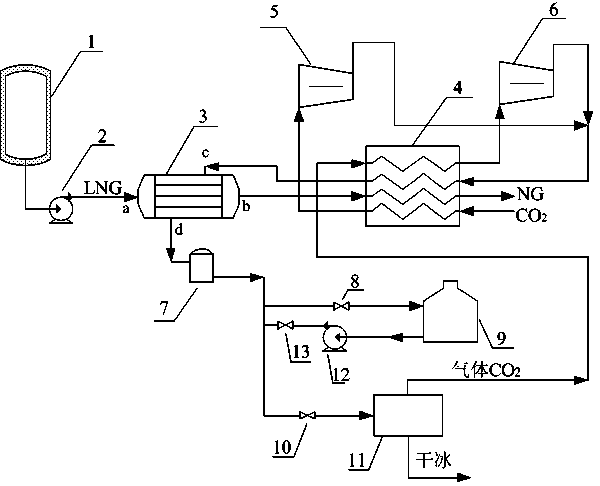

Carbon dioxide snow apparatus

ActiveUS7293570B2Increased Joule-Thompson coolingReduce cloggingBlast gunsSpray nozzlesLiquid carbonMachining process

A carbon dioxide snow apparatus of the present invention includes a carbon dioxide snow generation system and a propellant generation system connected to a common carbon dioxide gas source. The carbon dioxide snow generation system includes a condenser having a at least two connected segments, wherein a first segment has a lesser diameter than the a second segment to provide a stepped expansion cavity for cooling and condensing liquid carbon dioxide into solid carbon dioxide snow. Several snow generation systems, each separately controllable with separate condensers, may be integrated with the propellant generation system and common carbon dioxide source to provide for a multiplicity of carbon dioxide snow applicators for integration into both manual and automated machining processes.

Owner:COOL CLEAN TECH

Method of removing solid carbon dioxide

The invention provides a method of removing solid carbon dioxide from cryogenic equipment, including the steps of: (a) introducing a stream including ethane to the cryogenic equipment to convert solid carbon dioxide to liquid form whereby a mixture of liquid ethane and liquid carbon dioxide is formed; and (b) removing the mixture of liquid ethane and liquid carbon dioxide from the cryogenic equipment. In particular, the method can be used in a liquefied natural gas (LNG) plant wherein cryogenic equipment contains LNG, and the method includes the steps of: (a′) removing the LNG from the cryogenic equipment; (a) introducing a stream including ethane to convert solid carbon dioxide to liquid form whereby a mixture of liquid ethane and liquid carbon dioxide is formed; and (b) removing the mixture of liquid ethane and liquid carbon dioxide from the cryogenic equipment. The result is an effective cleaning method for fouled LNG equipment.

Owner:SHELL OIL CO

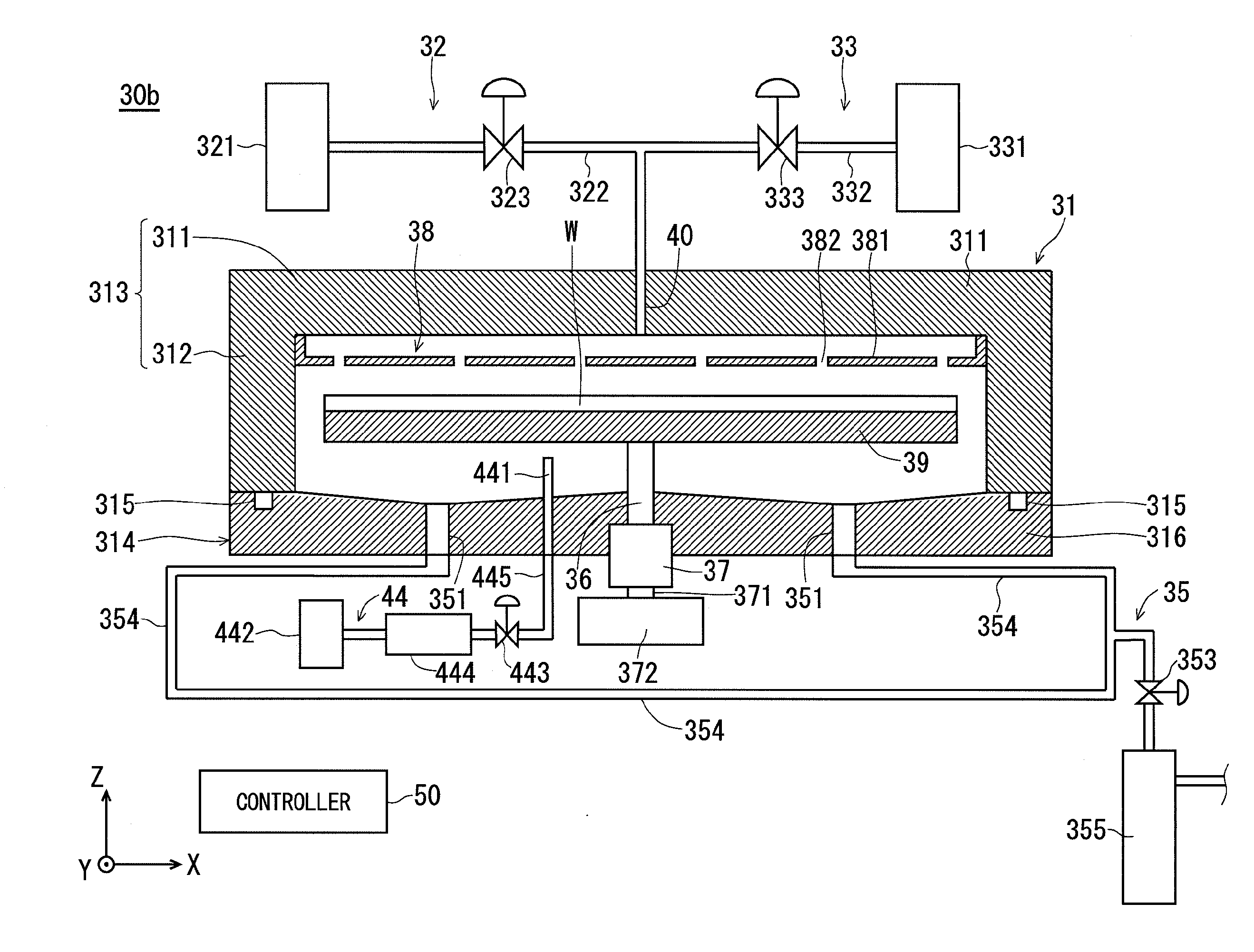

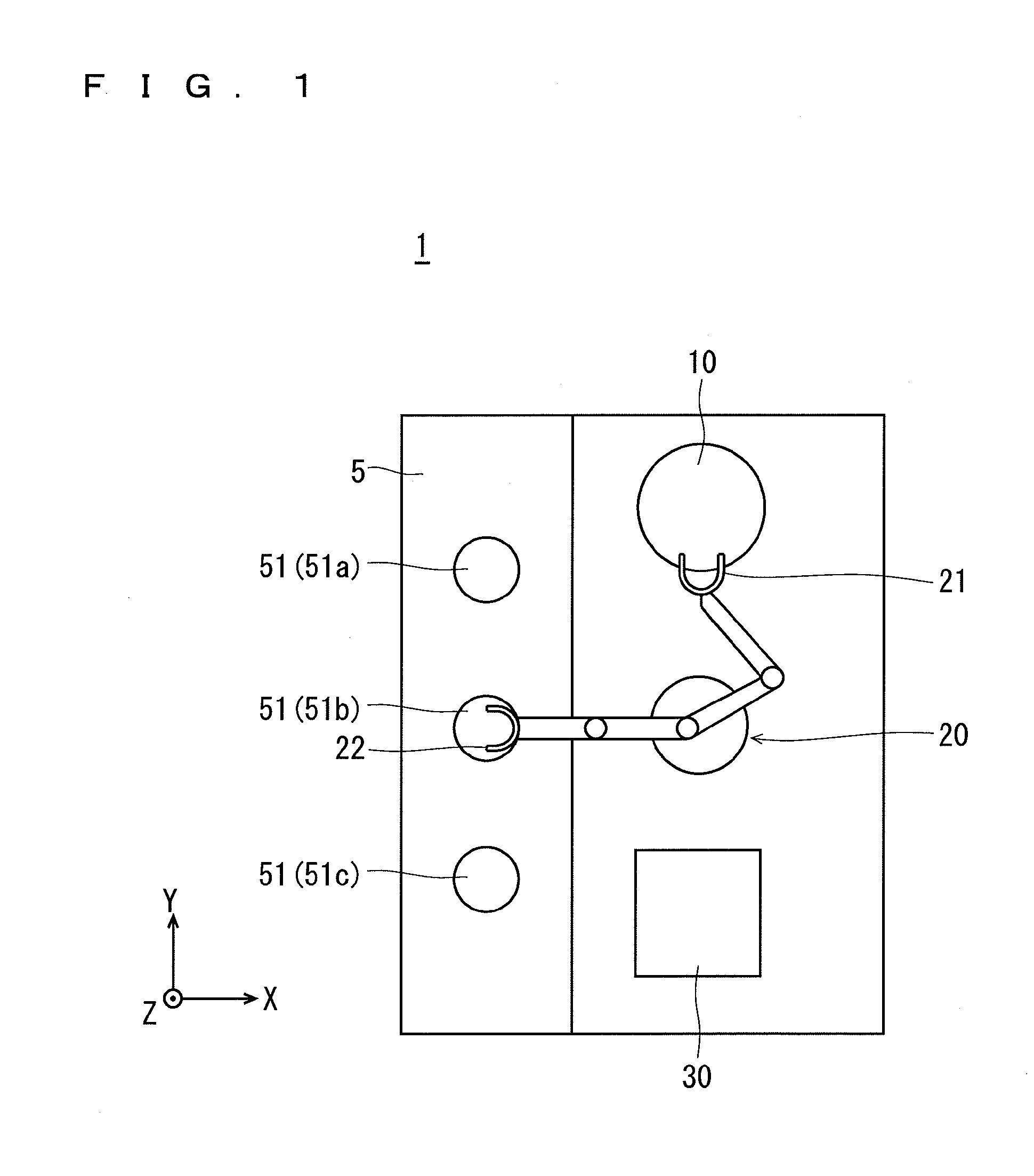

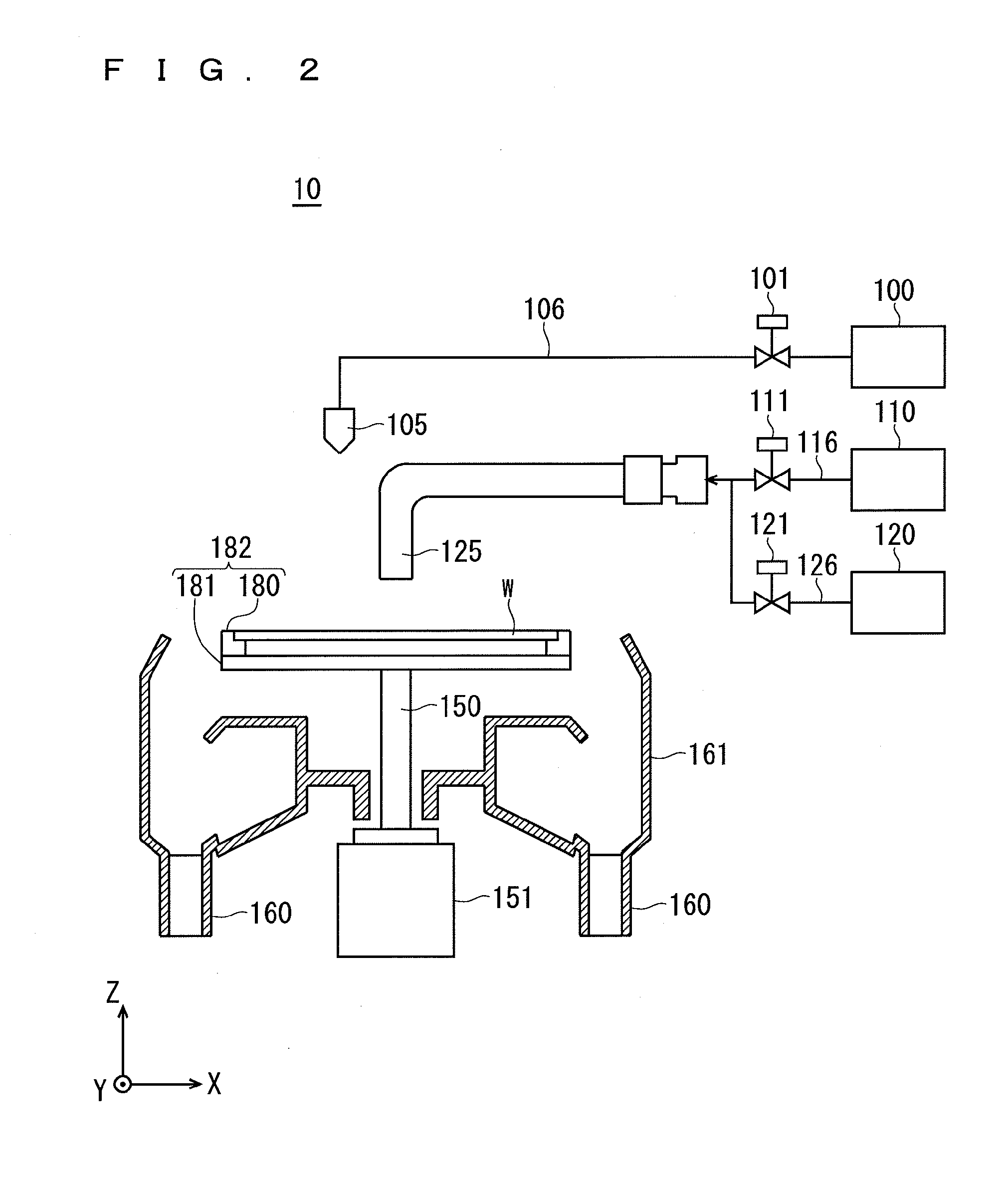

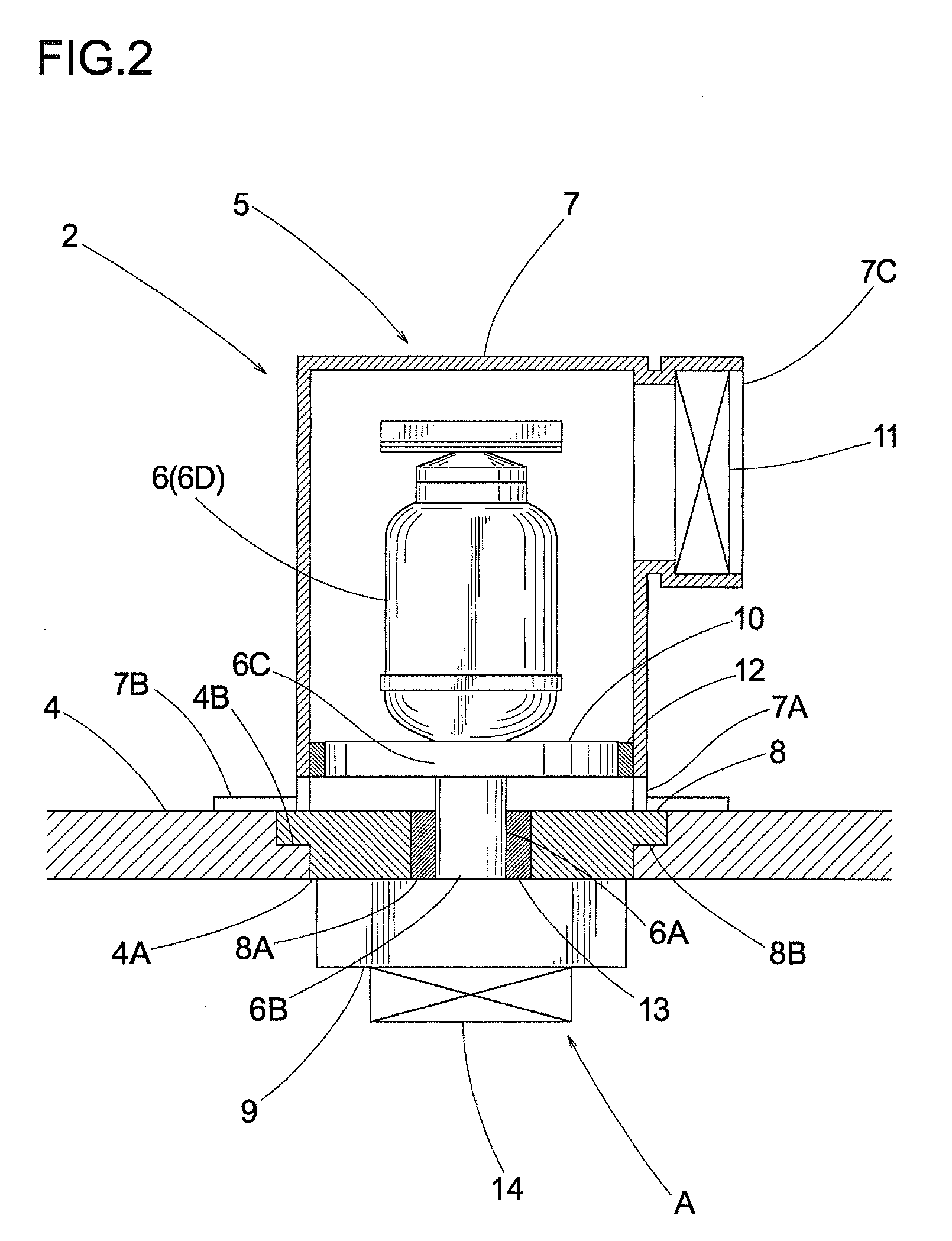

Apparatus for and method of processing substrate

InactiveUS20120073599A1Avoid damageLow costSemiconductor/solid-state device manufacturingCleaning using liquidsLiquid carbonAtmospheric pressure

A rinsing liquid adheres to a substrate subjected to a cleaning process. The rinsing liquid on the substrate is first replaced with IPA liquid. While the substrate covered with the IPA liquid is held in a dryer chamber, liquid carbon dioxide is supplied to the surface of the substrate. Liquid nitrogen is supplied to cool down the interior of the dryer chamber. This solidifies the liquid carbon dioxide on the substrate into solid carbon dioxide. Thereafter, the pressure in the dryer chamber is returned to atmospheric pressure, and gaseous nitrogen is supplied into the dryer chamber. Thus, the temperature in the dryer chamber increases. The solid carbon dioxide on the surface of the substrate is sublimated, and is hence removed from the substrate. All of the steps are performed while carbon dioxide is not in a supercritical state but in a non-supercritical state.

Owner:DAINIPPON SCREEN MTG CO LTD

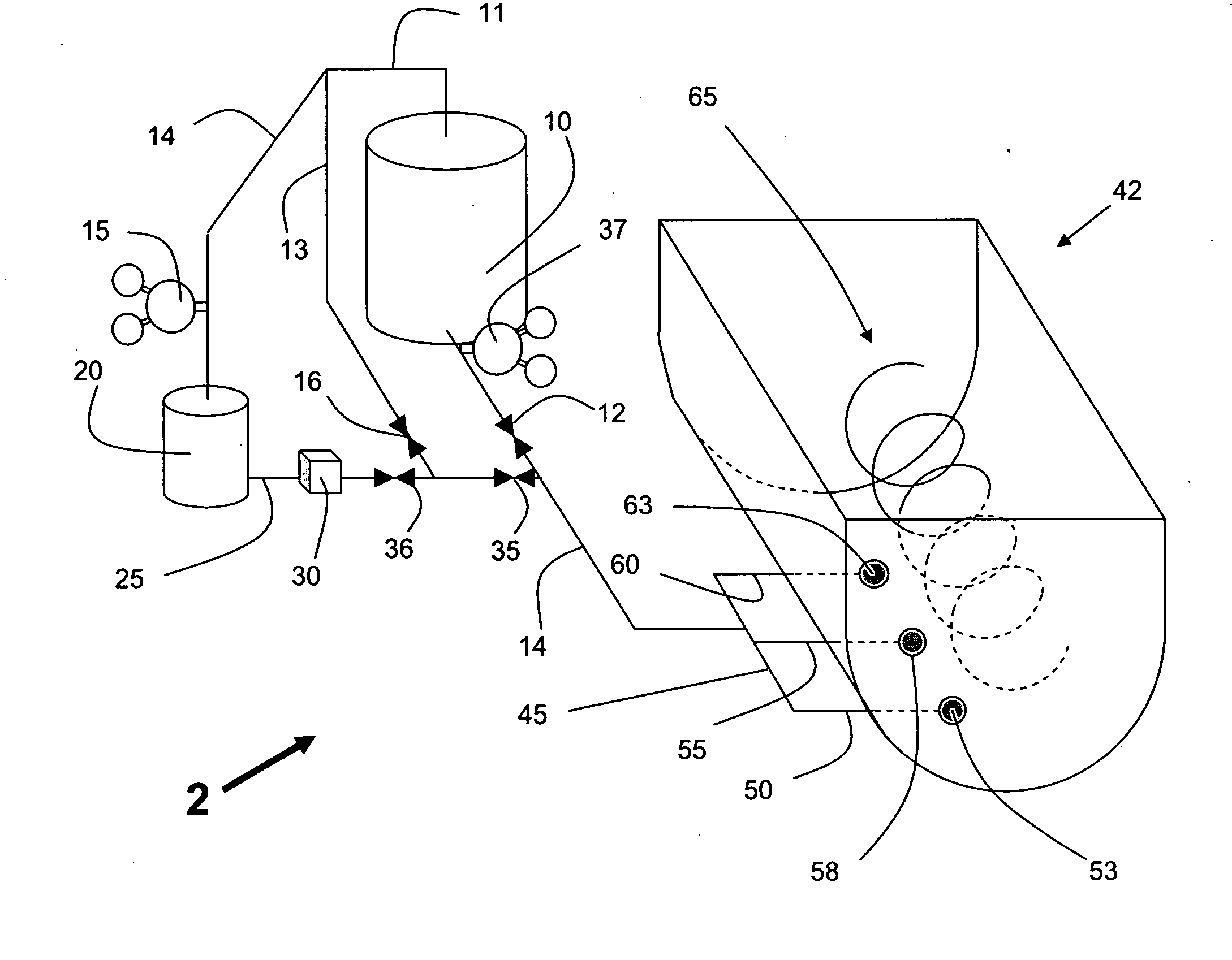

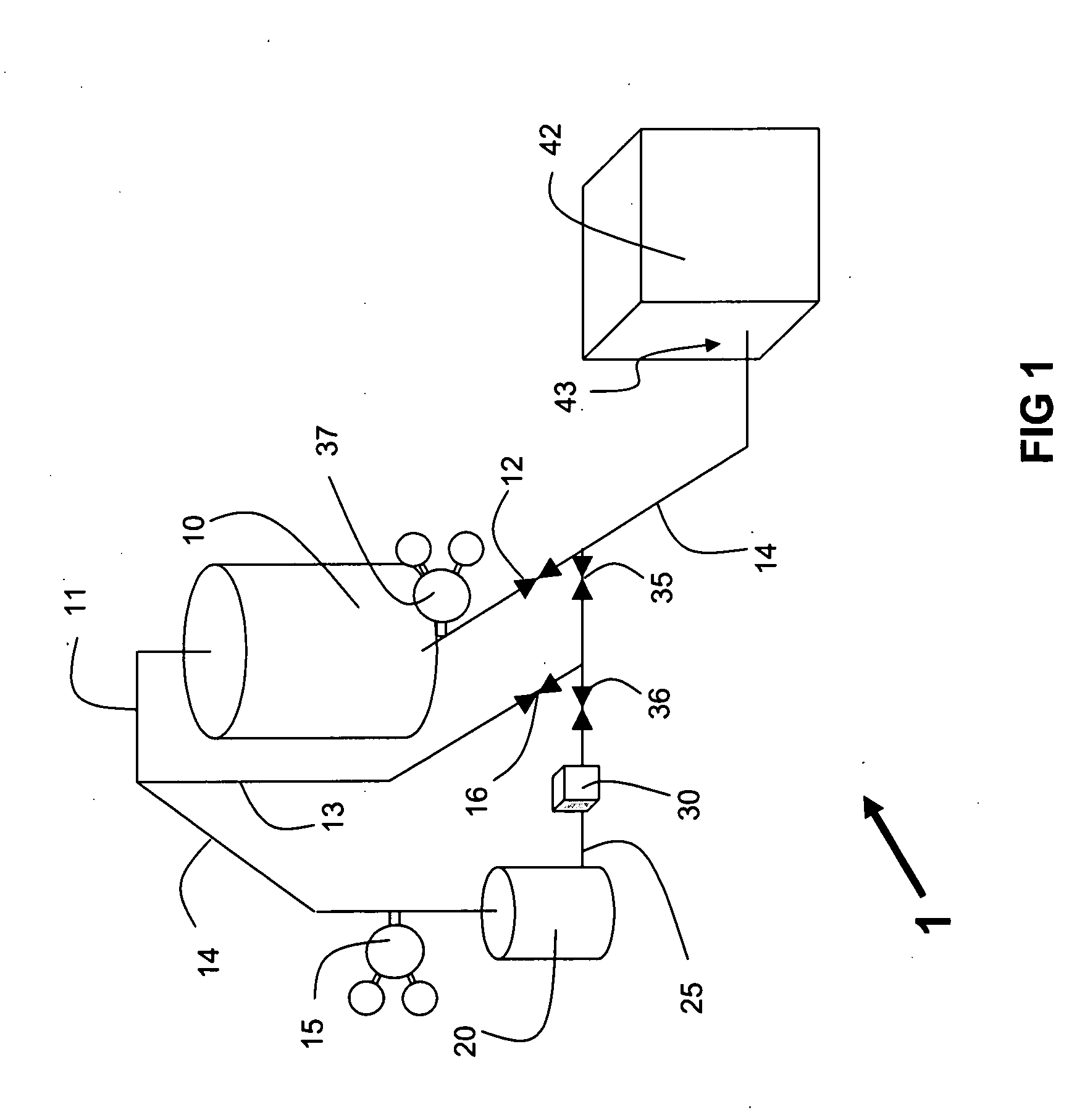

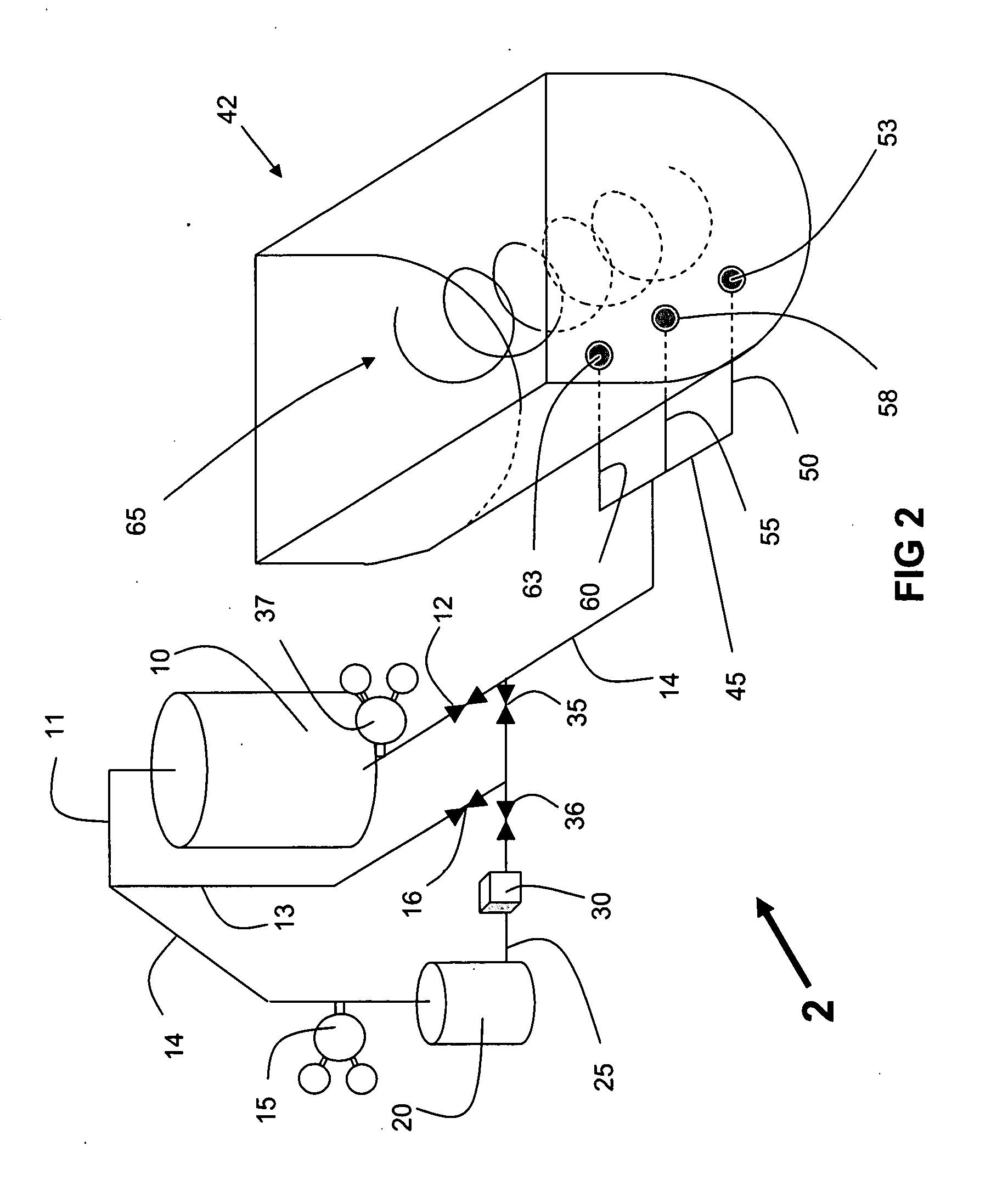

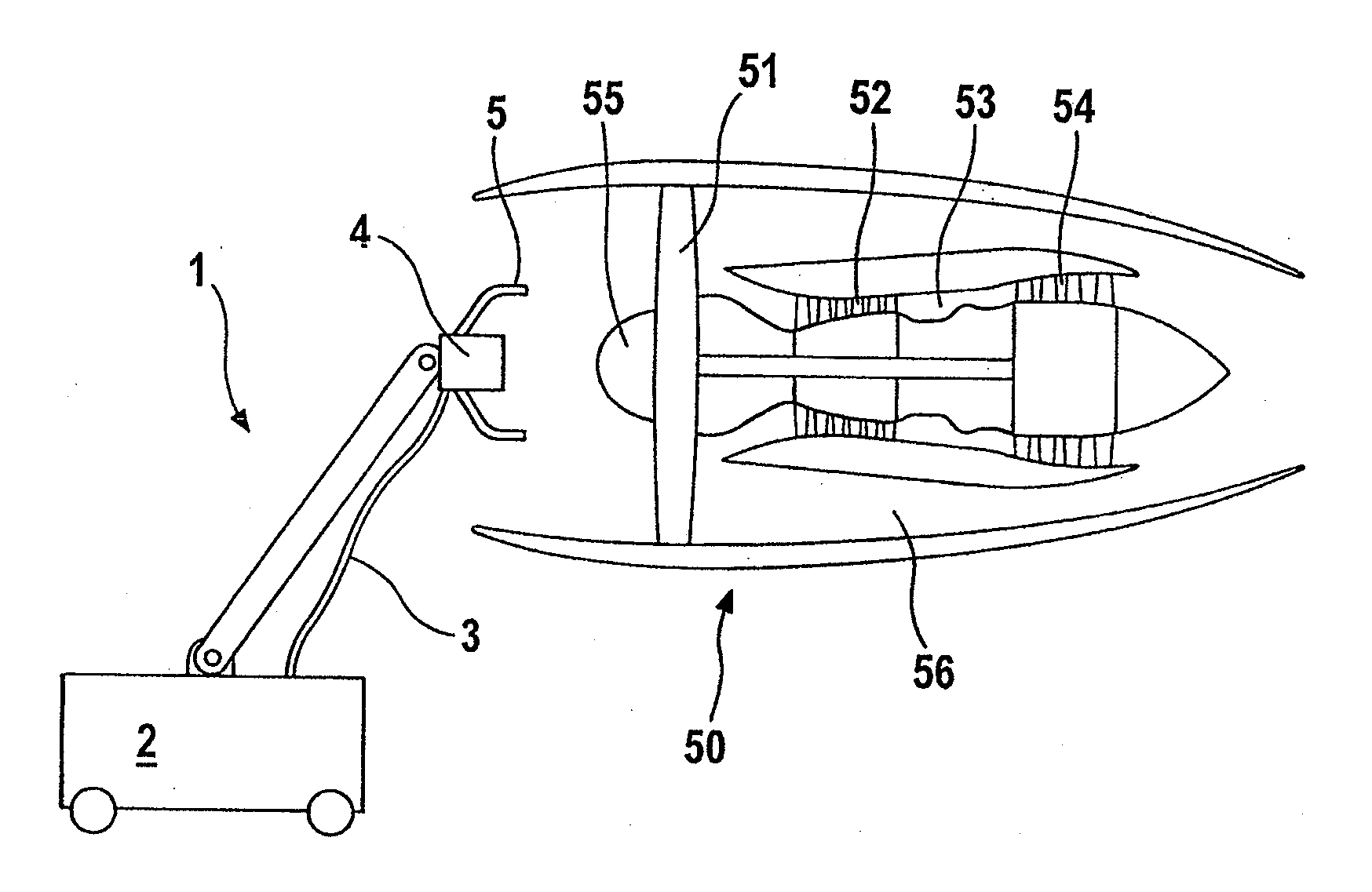

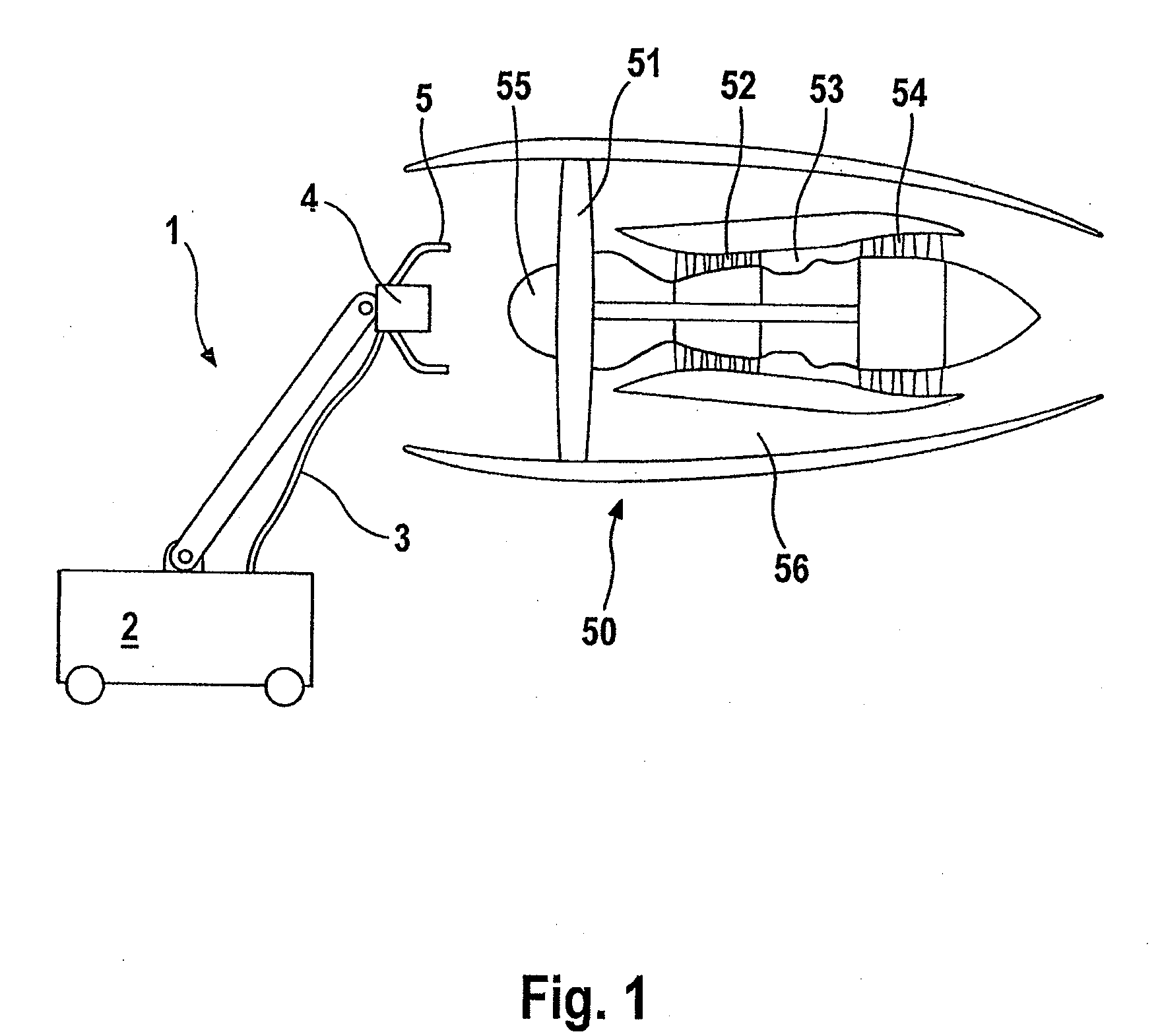

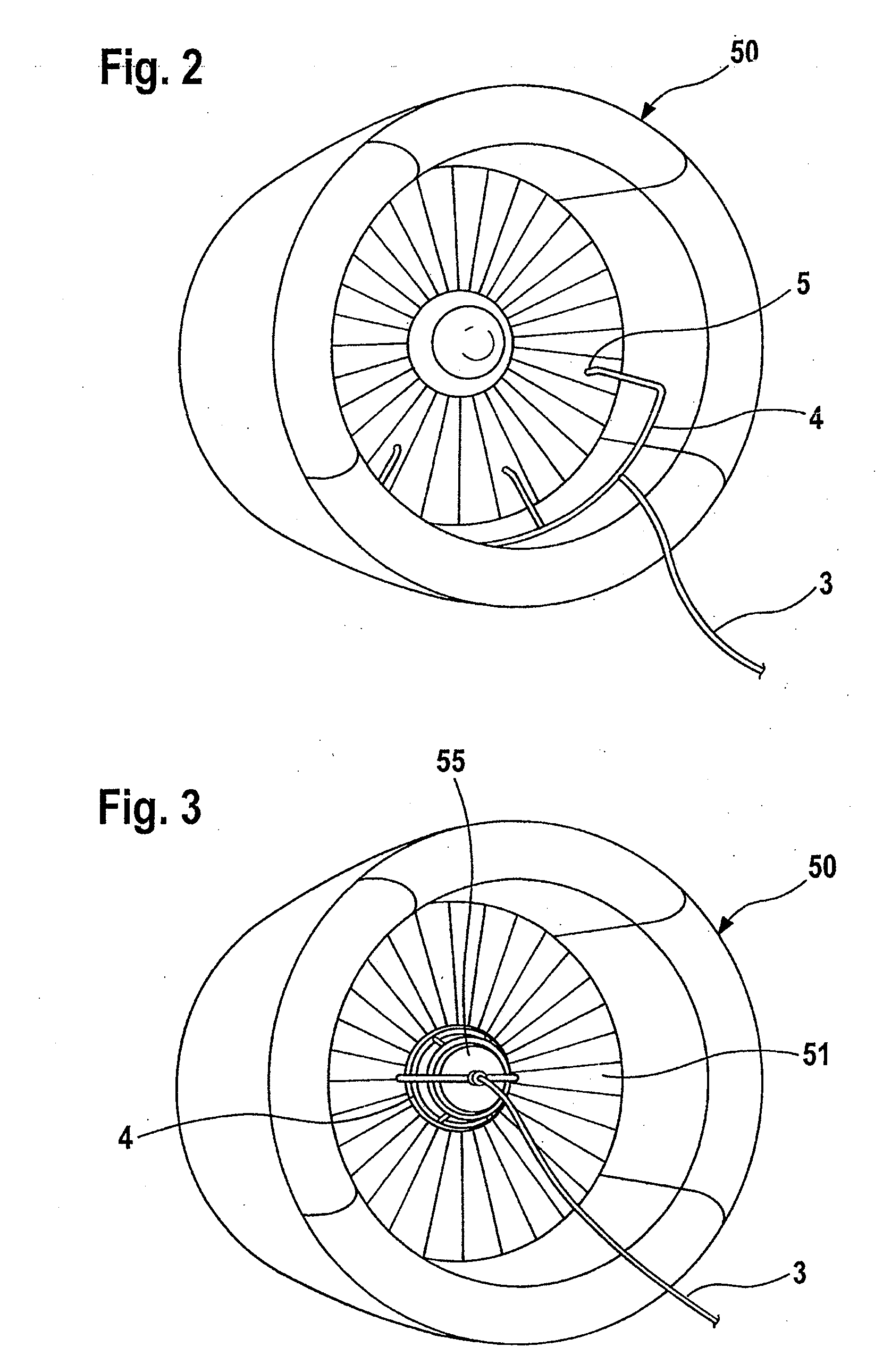

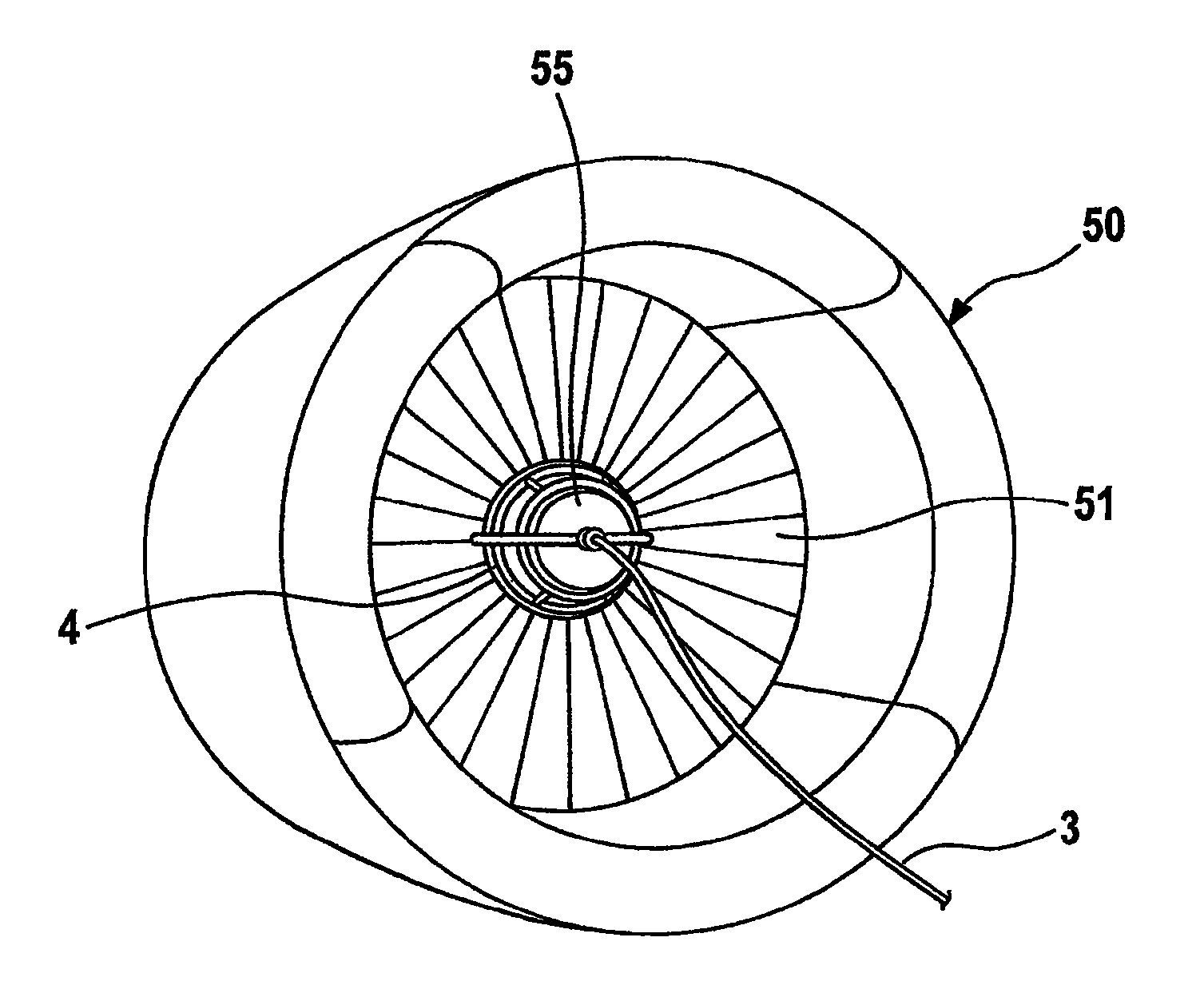

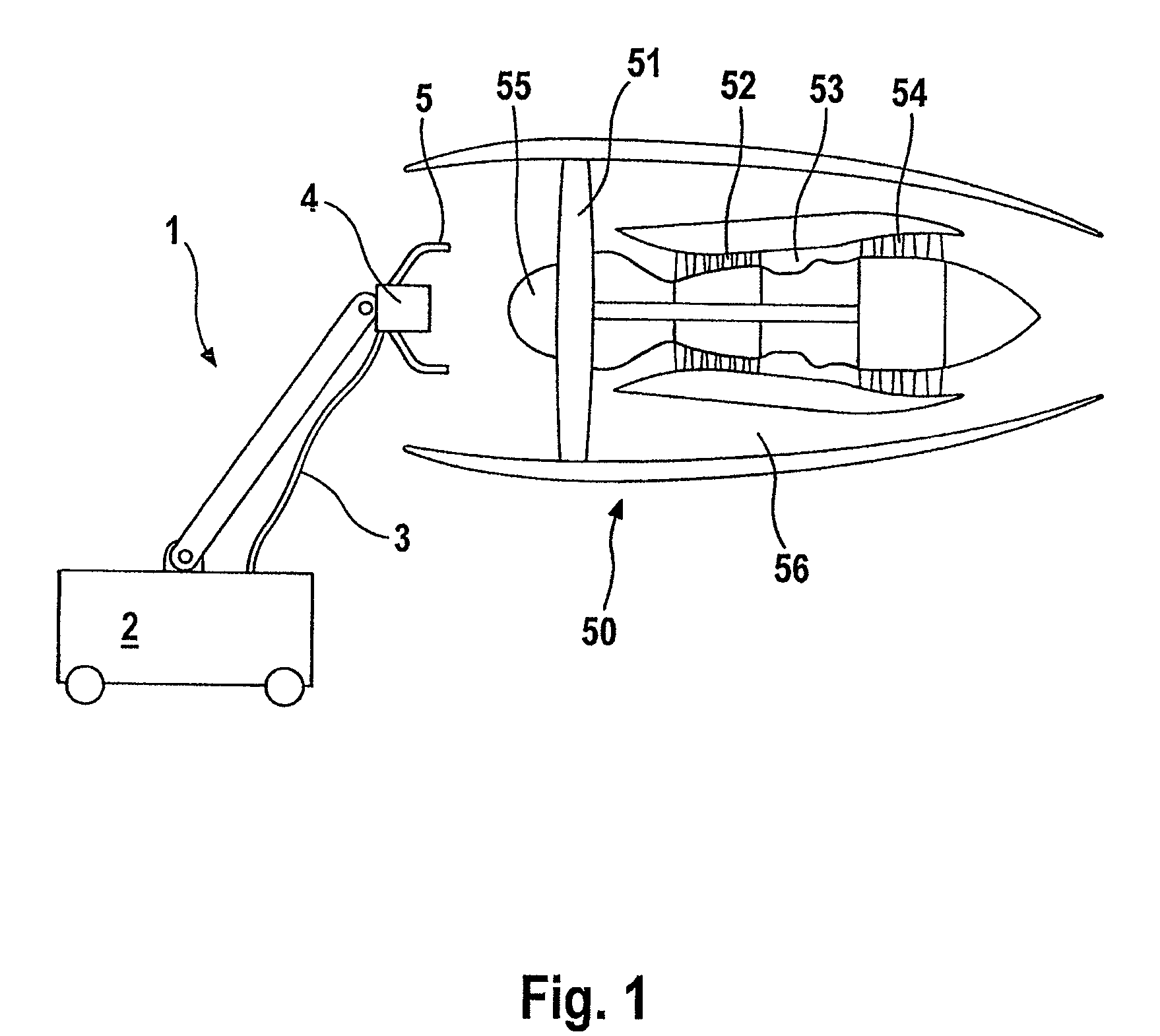

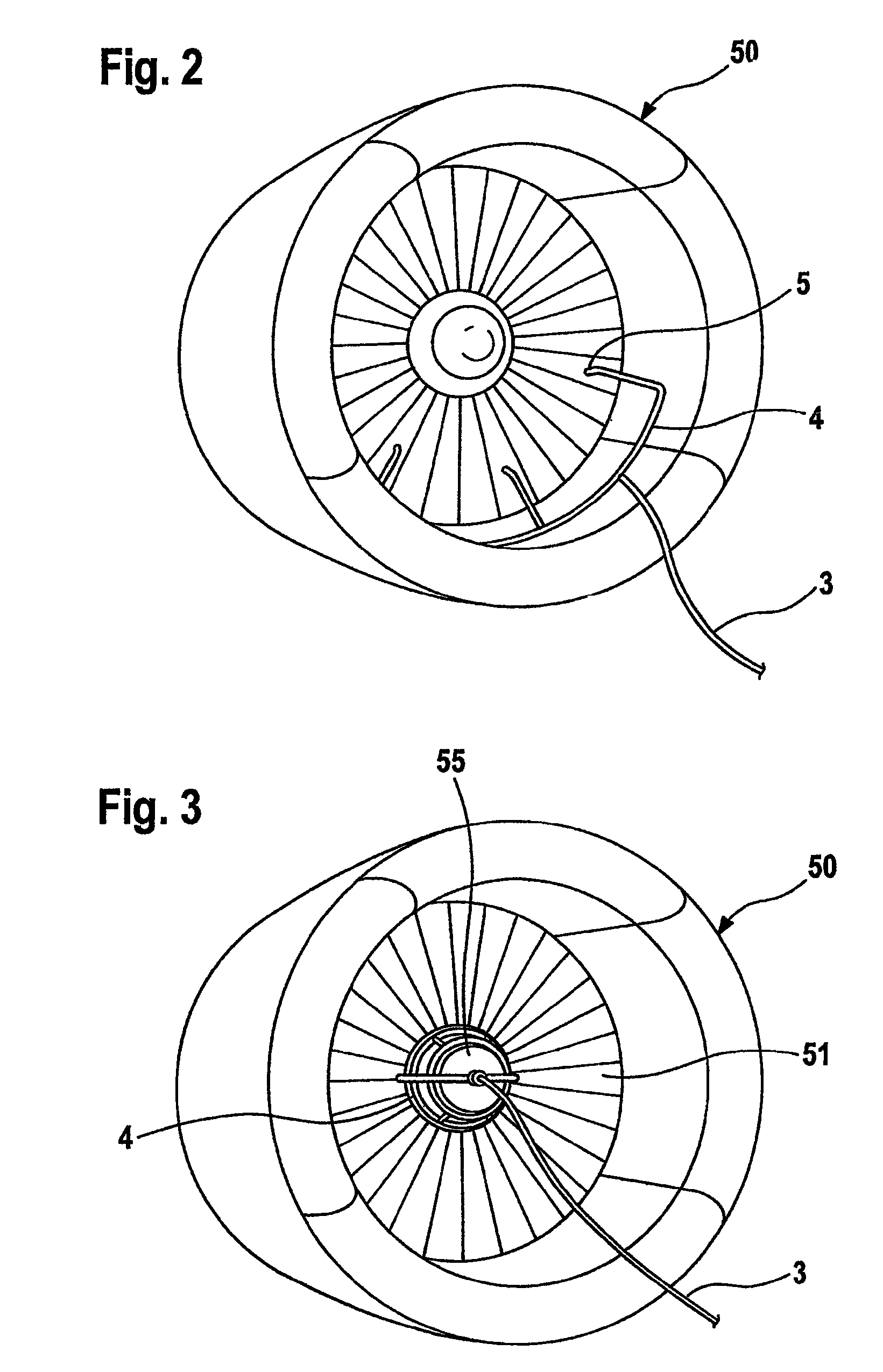

Method and apparatus for cleaning a jet engine

ActiveUS20100000572A1Easy to storeEasy to cleanHollow article cleaningElectrostatic cleaningJet engineSolid carbon dioxide

An apparatus for cleaning a jet engine includes a supply device configured to make cleaning medium available, a nozzle device configured to introduce the cleaning medium into the jet engine, and a line connection between the supply device and the nozzle device. The cleaning medium can be solid carbon dioxide. A system including a jet engine and the apparatus. A method for cleaning a jet engine using solid carbon dioxide.

Owner:LUFTHANSA TECH AG

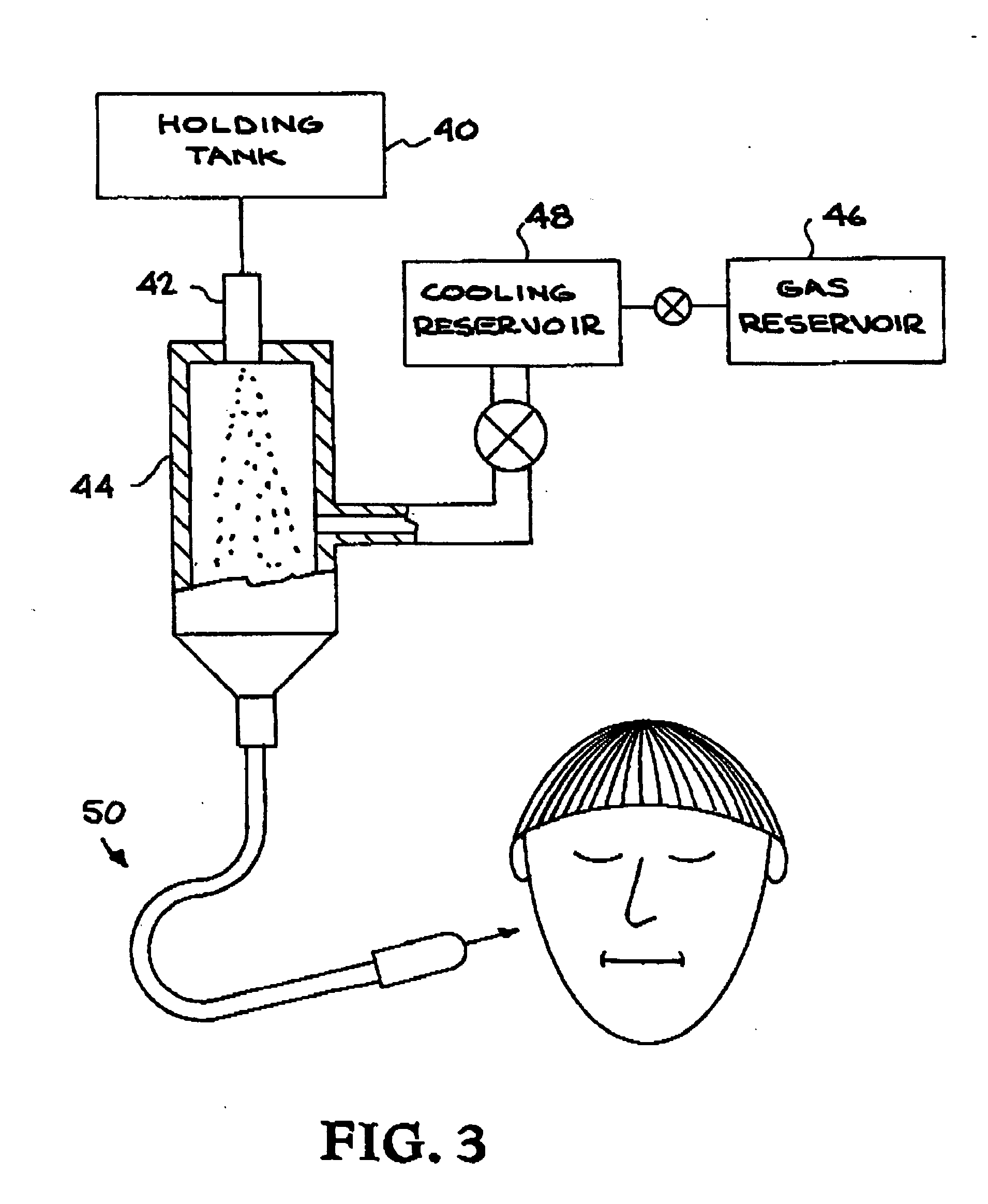

Dynamic cooling of human skin using a nontoxic cryogen with no ozone depletion and minimal global warming potential

ActiveUS20080071332A1Prevent heat transferAvoid ignitionHeat-exchange elementsLight therapyLiquid stateEngineering

An improvement in a method for providing localized cooling of tissue when thermally mediated by electromagnetic radiation comprises directing at least one spurt of a heat transferring substance onto a selected location on the tissue, and preventing ignition of the heat transferring substance by heating from the electromagnetic radiation. Preferably liquid carbon dioxide under pressure is supplied as the heat transferring substance, and adiabatically expanded to provide a solid carbon dioxide spray onto the selected location.

Owner:RGT UNIV OF CALIFORNIA

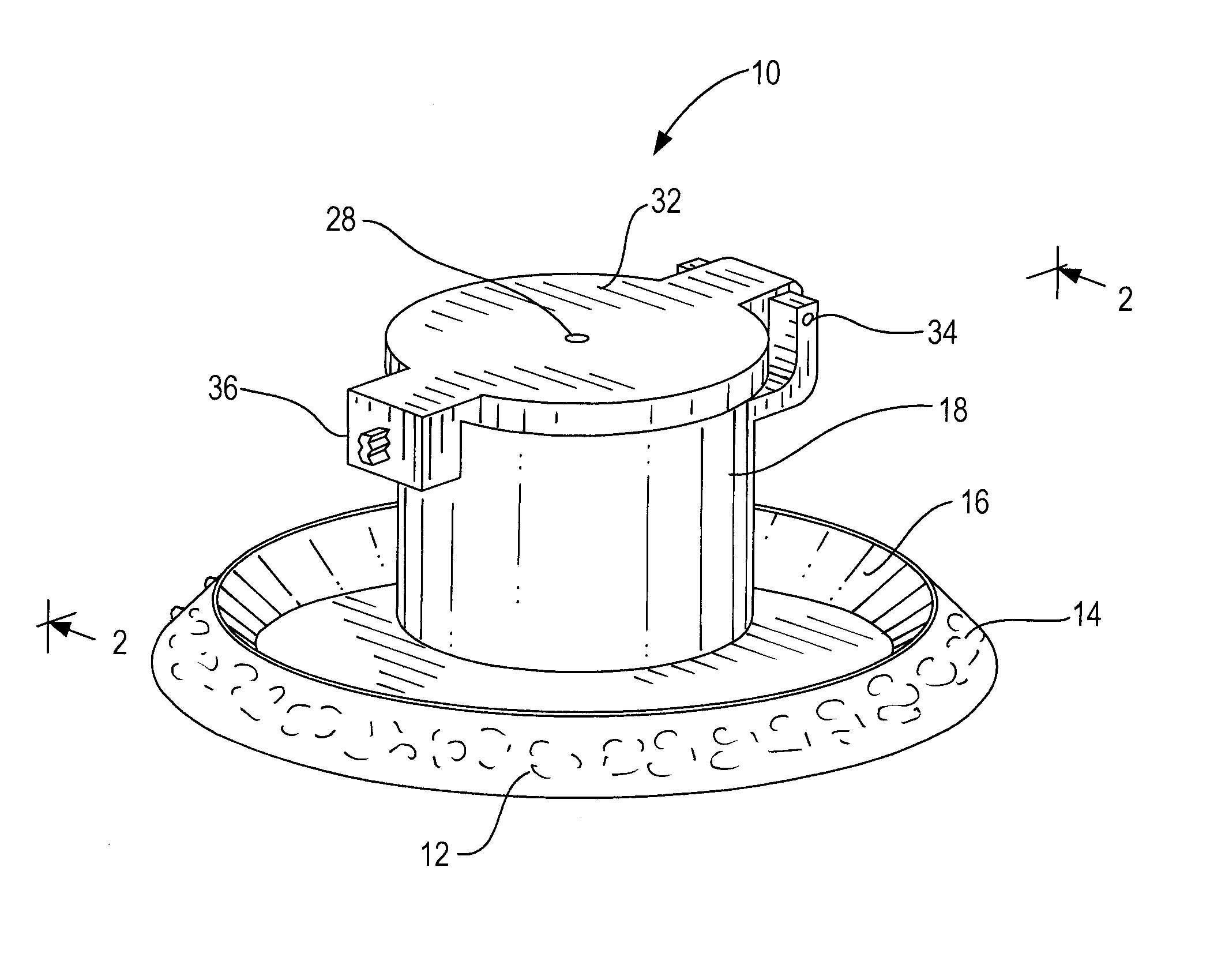

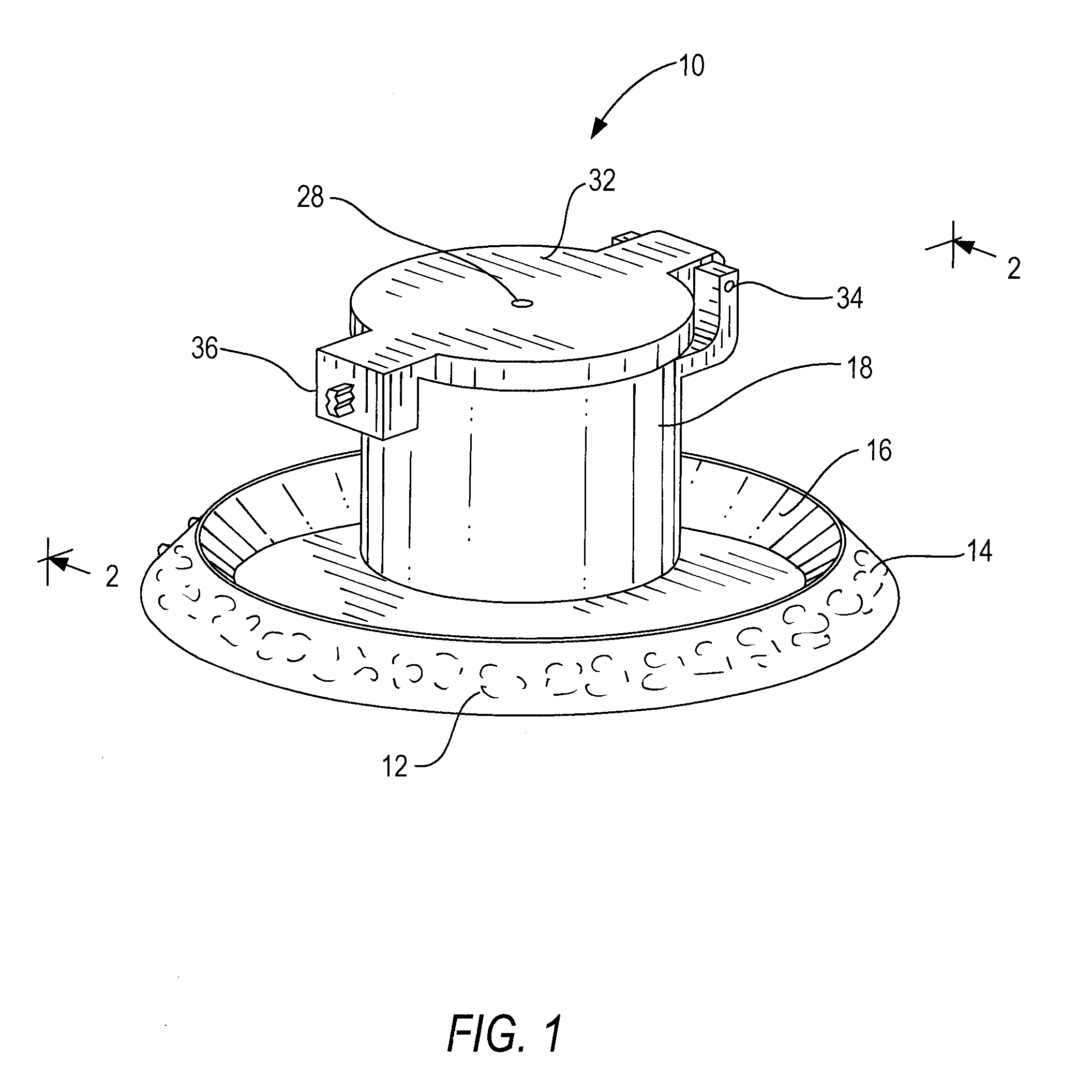

Bed bug monitor

A bed bug monitor includes a base and a central housing. The central housing is insulated and encloses a supply of solid carbon dioxide. During use an aperture in the housing releases a plume of carbon dioxide vapor which attracts bed bugs onto the base.

Owner:FRISCH JEFFREY +1

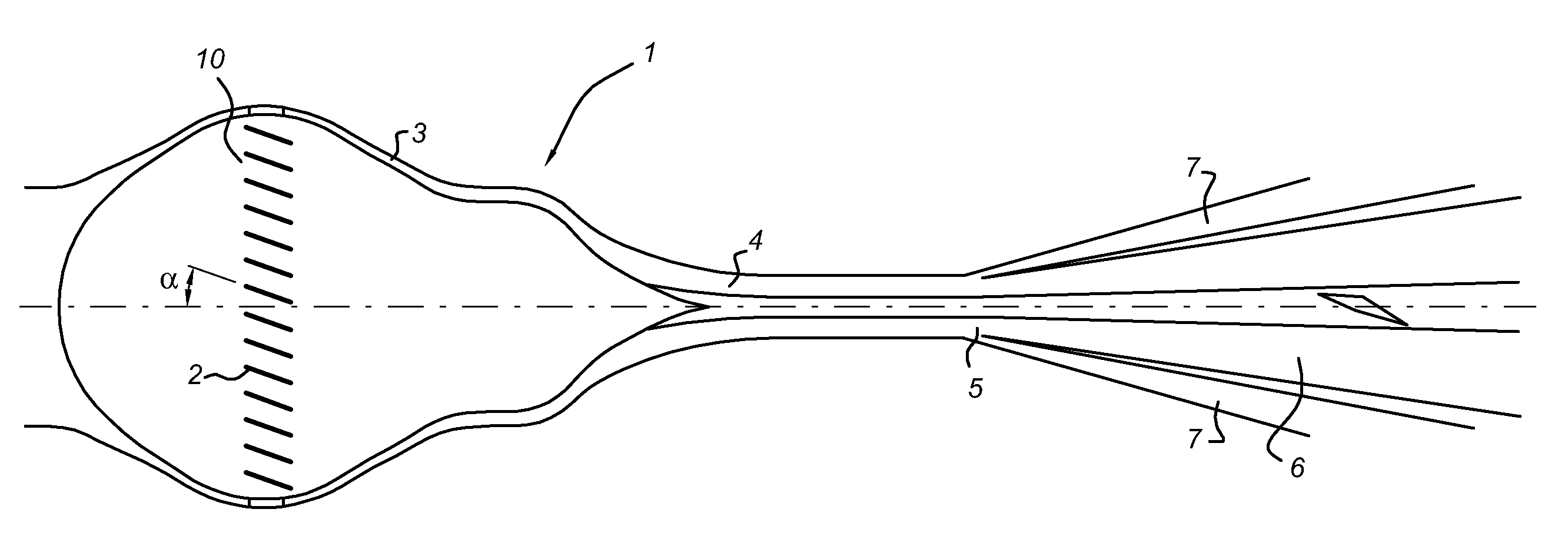

Method of removing and solidifying carbon dioxide from a fluid stream and fluid separation assembly

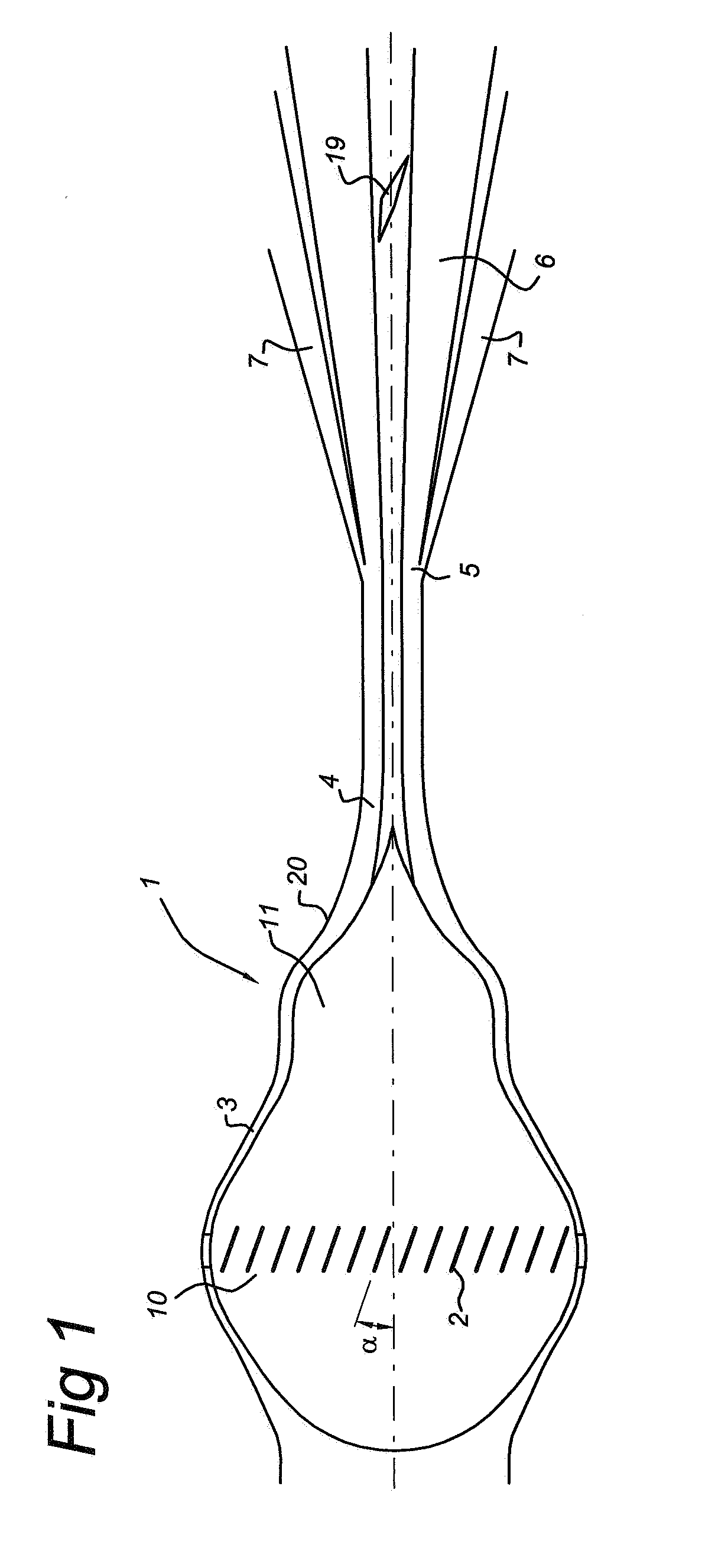

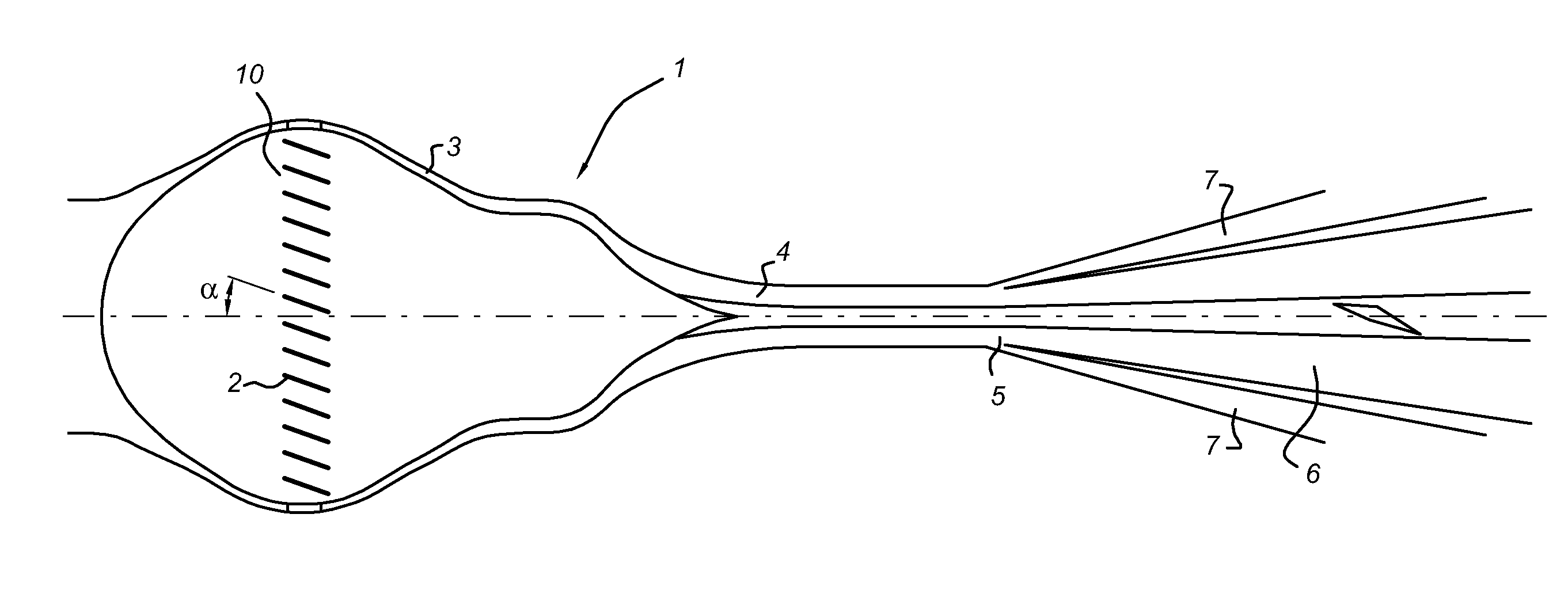

The invention relates to a method of removing carbon dioxide from a fluid stream by a fluid separation assembly. The fluid separation assembly has a cyclonic fluid separator with a tubular throat portion arranged between a converging fluid inlet section and a diverging fluid outlet section and a swirl creating device. The separation vessel has a tubular section positioned on and in connection with a collecting tank. In the method, a fluid stream with carbon dioxide is provided. Subsequently, a swirling motion is imparted to the fluid stream so as to induce outward movement. The swirling fluid stream is then expanded such that components of carbon dioxide in a meta-stable state within the fluid stream are formed. Subsequently, the outward fluid stream with the components of carbon dioxide is extracted from the cyclonic fluid separator and provided as a mixture to the separation vessel. The mixture is then guided through the tubular section towards the collecting tank while providing processing conditions such that solid carbon dioxide is formed. Finally, solidified carbon dioxide is extracted.

Owner:TWISTER BV

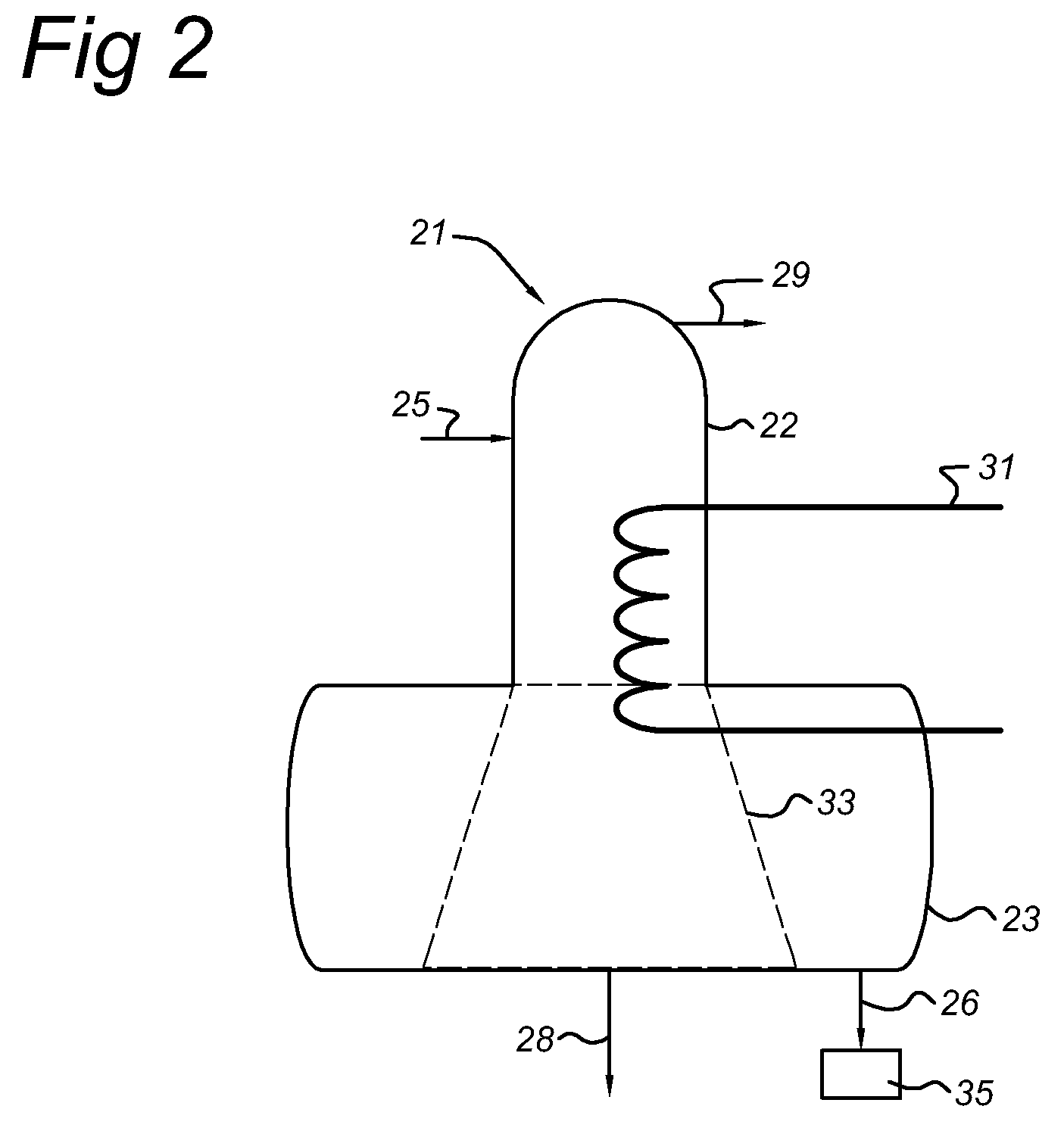

Method and device for preparing liquid CO2 (carbon diode) by cold energy of LNG (liquefied natural gas)

ActiveCN104236252AIncrease profitReduce energy consumptionSolidificationLiquefactionCo2 storageProcess engineering

The invention discloses a method and a device for preparing liquid CO2 (carbon diode) by cold energy of LNG (liquefied natural gas). The method comprises the following steps of pumping the LNG into a tube of a shell-and-tube heat exchanger, releasing the potential heat of the LNG in the tube of the shell-and-tube heat exchanger, cooling and liquefying the lower-temperature gaseous CO2, sending the gasifying byproduct of the LNG as a cold source into a multi-strand flow plate fin type heat exchanger, cooling the raw CO2, then sending into a CO2 compressor, cooling the outputted high-pressure and high-temperature CO2, raising the temperature of the LNG, and gasifying the LNG into the normal-temperature natural gas with the temperature of 10-20 DEG C; sending the cooled CO2 into a shell of the shell-and-tube heat exchanger, dividing the liquid CO2 flowing from an outlet of the shell of the shell-and-tube heat exchanger into two branches, sending one branch into a liquid CO2 storage tank, and sending the other branch into a dry ice machine to prepare carbon dioxide ice. The method has the advantages that the gradient utilization of the cold energy of the LNG is realized, and the utilization rate of the cold energy of the LNG is high; the preparation pressure of the liquid CO2 and the carbon dioxide ice is decreased to 0.6-1.0MPa by the cold energy of the LNG, the gaseous CO2 at the inlet of the compressor is cooled to the temperature of -40 to -30 DEG C, and finally the effect of saving the energy by more than 58% is realized in comparison with the effect of the common low pressure method.

Owner:佛山市寰晟通新能源科技有限公司

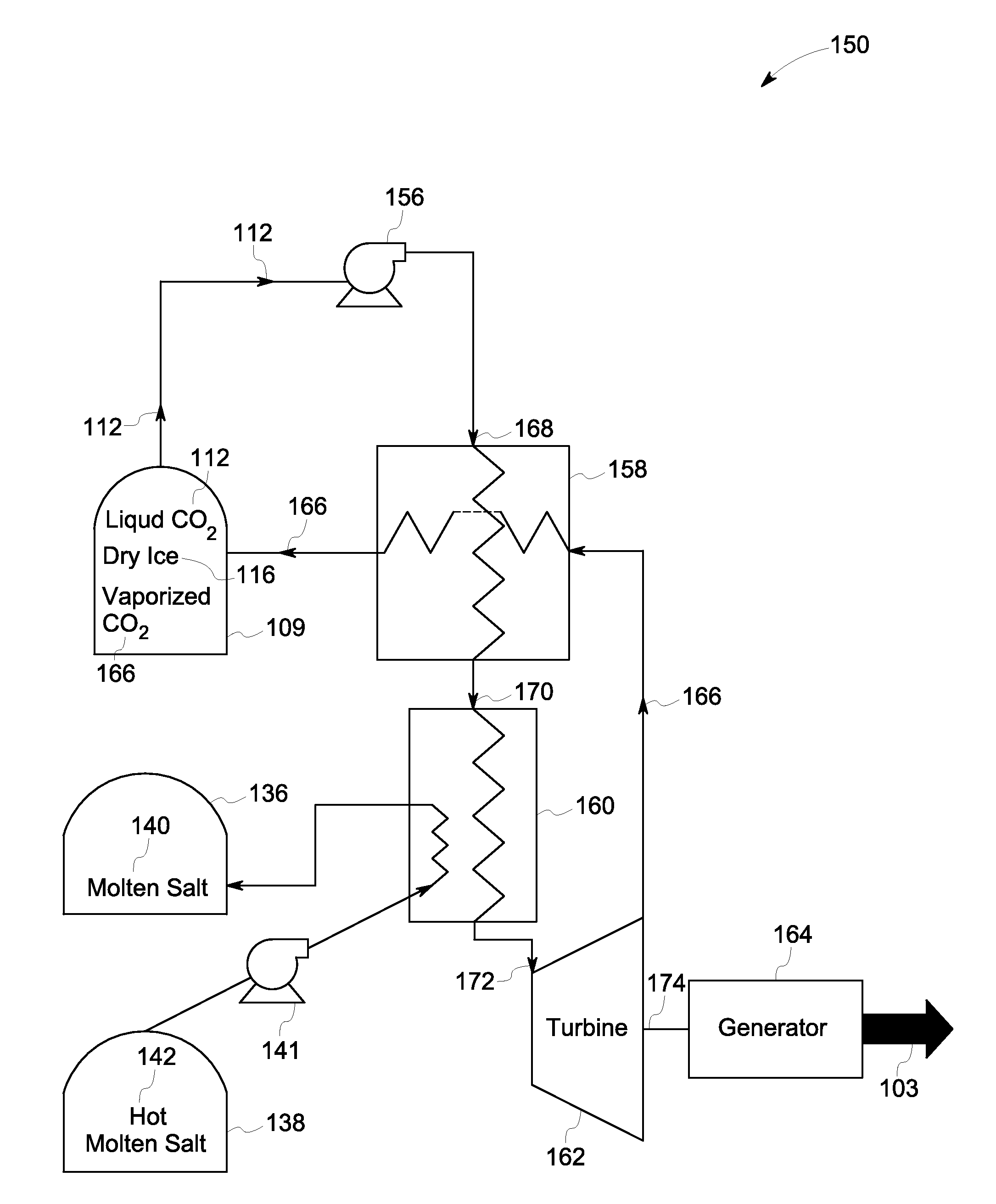

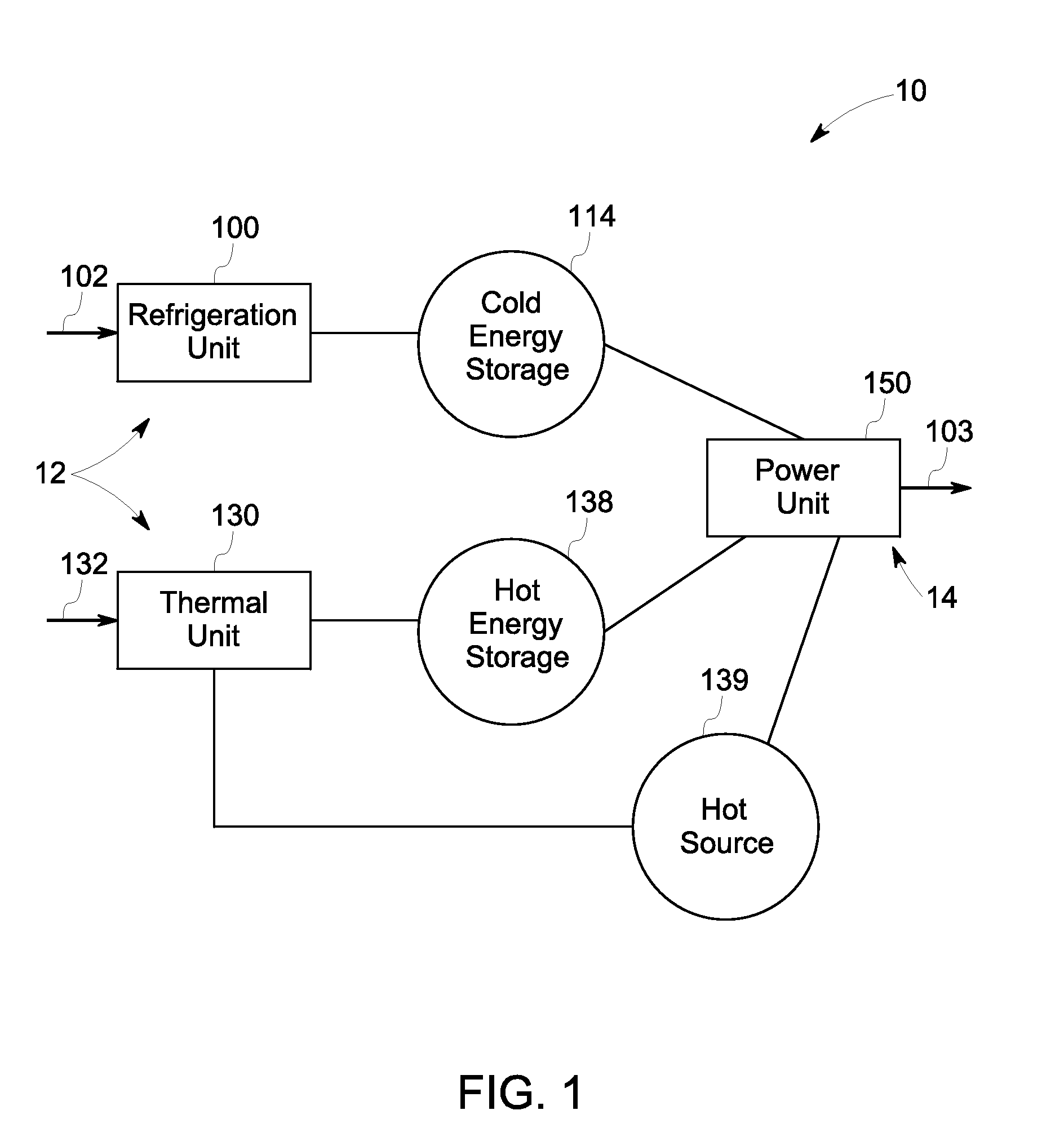

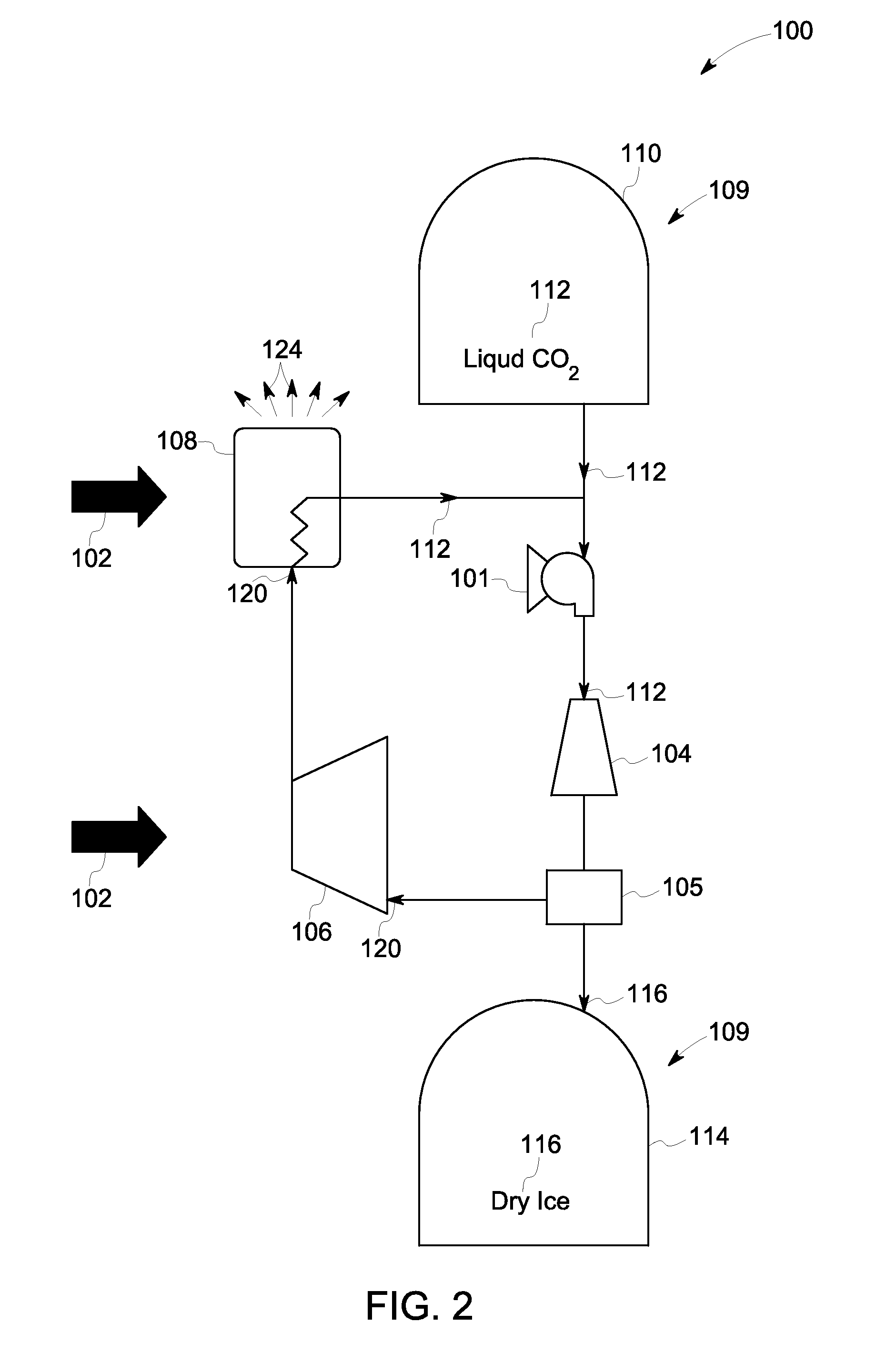

Electrothermal energy storage system and an associated method thereof

ActiveUS20160146061A1From solar energyHeat storage plantsSeasonal thermal energy storageHigh pressure

An electrothermal energy storage and discharge system is provided including a charging cycle and a discharging cycle. The charging cycle includes a refrigeration unit and a thermal unit, and the discharging cycle includes a power unit. The refrigeration unit is driven by an excess electric power and is configured to generate a cold energy storage having a solid carbon dioxide. The thermal unit is driven by a thermal energy and is configured to generate a hot energy storage and / or provide a hot source. The power unit operates between the cold energy storage and at least one of the hot energy storage and hot source so as to retrieve the energy by producing a high pressure carbon dioxide and a hot supercritical carbon dioxide, and generating an electric energy using the hot supercritical carbon dioxide.

Owner:NUOVO PIGNONE TECH SRL

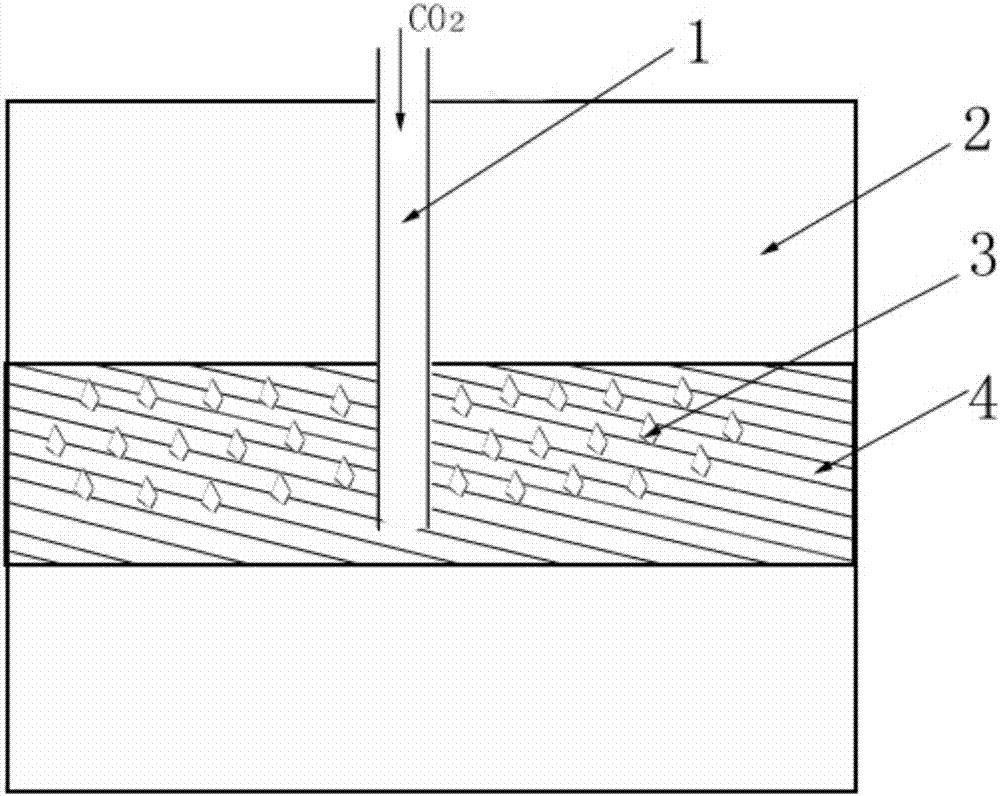

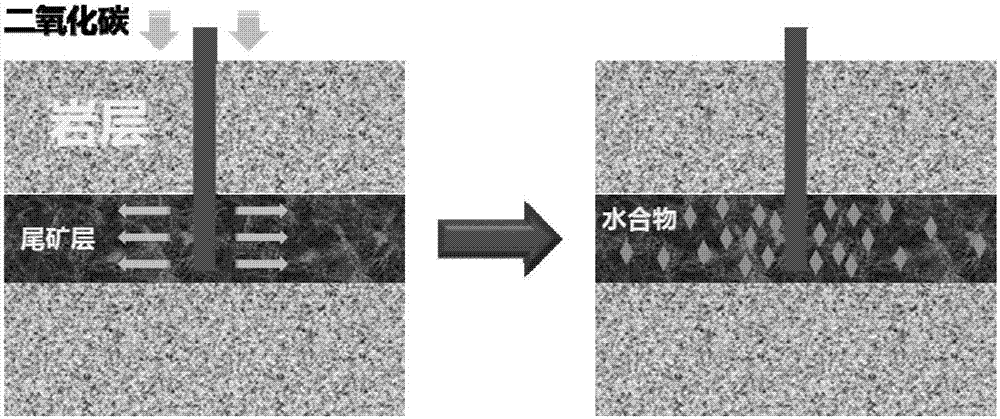

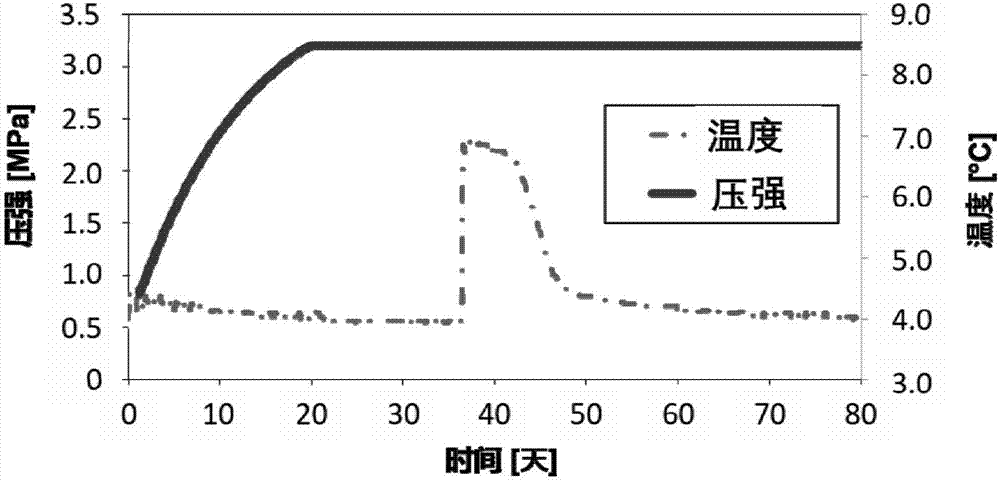

Geological carbon dioxide sequestration structure and sequestration method

PendingCN106904616AReduce liquidityEasy to moveMining devicesCarbon compoundsEnvironmental resistanceCarbon sequestration

The invention discloses a geological carbon dioxide sequestration structure and sequestration method and belongs to the technical field of carbon dioxide sequestration and environmental protection. The carbon dioxide produced in industrial production is recovered in a centralized mode and injected into abandoned oil fields and gas fields to make carbon dioxide and underground water generate a solid carbon dioxide hydrate, and the sequestration and emission reduction purposes are achieved. The carbon dioxide hydrate related in the invention has the characteristic of containing ultra-volume gas and can be safety saved under the stable geological conditions verified over thousands of years, and the leakage risk is greatly reduced. In addition, a well area device for oil and gas extraction injects carbon dioxide to the position 300-500 meters away from the ground, and the sequestration cost is greatly reduced. In consideration of policy making and implementation for carbon dioxide emission reduction in our country or even throughout the word, the geological carbon dioxide sequestration structure and sequestration method has a very wide market space.

Owner:孙铎

Method of removing carbon dioxide from a fluid stream and fluid separation assembly

The invention relates to a method of removing carbon dioxide from a fluid stream by a fluid separation assembly. The fluid separation assembly has a cyclonic fluid separator with a tubular throat portion arranged between a converging fluid inlet section and a diverging fluid outlet section and a swirl creating device. The separation vessel has a tubular section positioned on and in connection with a collecting tank. In the method, a fluid stream with carbon dioxide is provided. Subsequently, a swirling motion is imparted to the fluid stream so as to induce outward movement. The swirling fluid stream is then expanded such that components of carbon dioxide in a meta-stable state within the fluid stream are formed. Subsequently, the outward fluid stream with the components of carbon dioxide is extracted from the cyclonic fluid separator and provided as a mixture to the separation vessel. The mixture is then guided through the tubular section towards the collecting tank while providing processing conditions such that solid carbon dioxide is formed. Finally, solidified carbon dioxide is extracted.

Owner:TWISTER BV

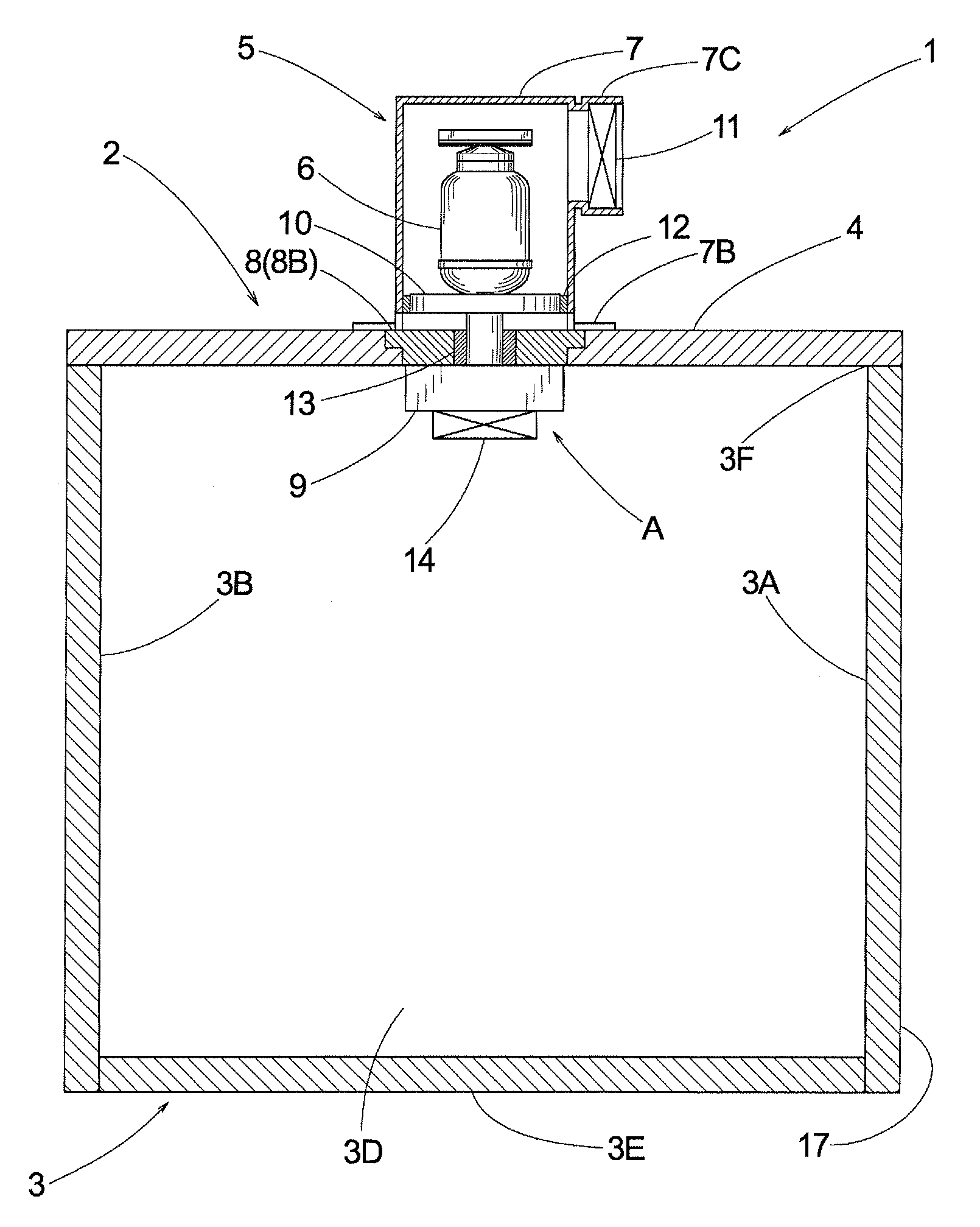

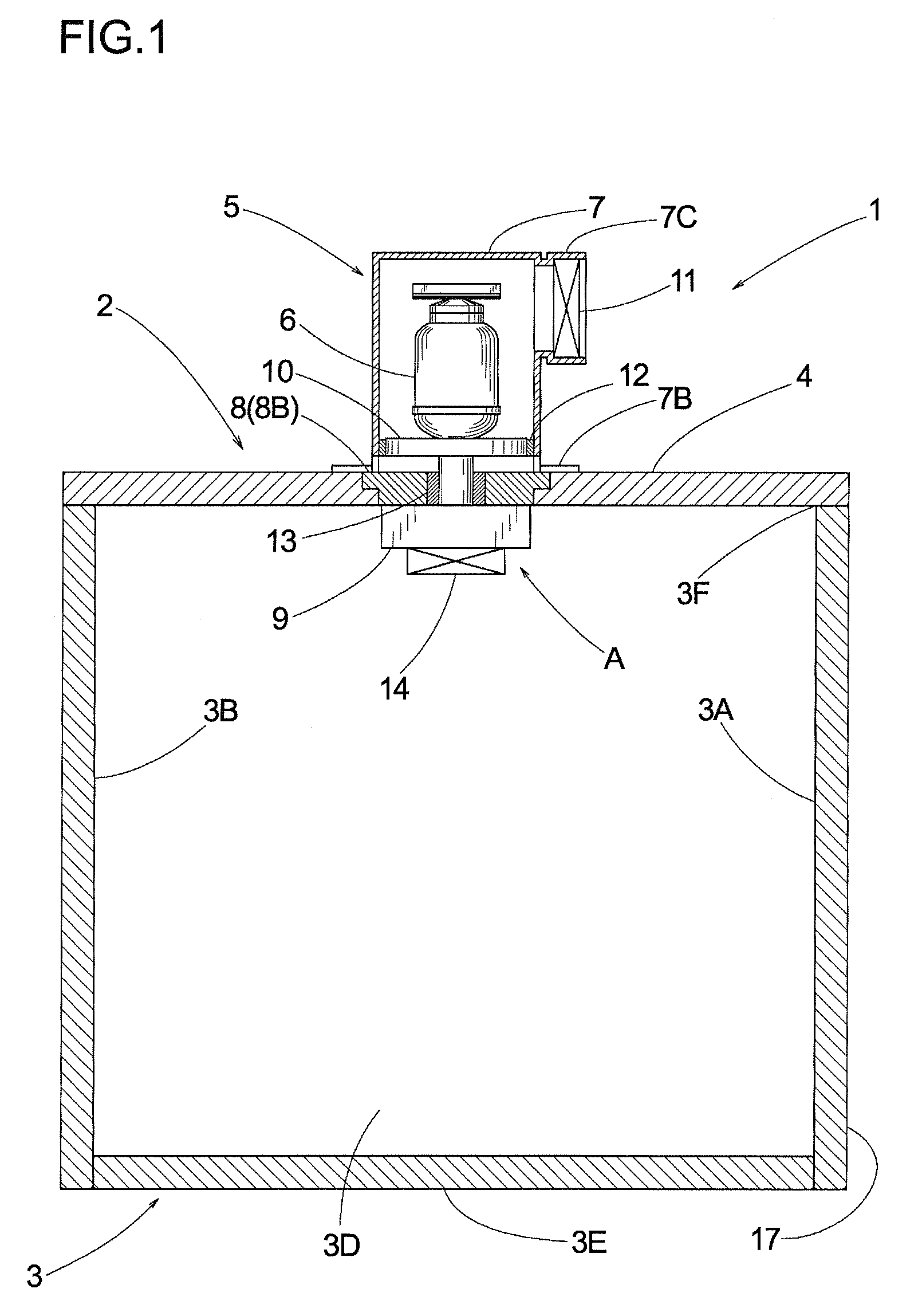

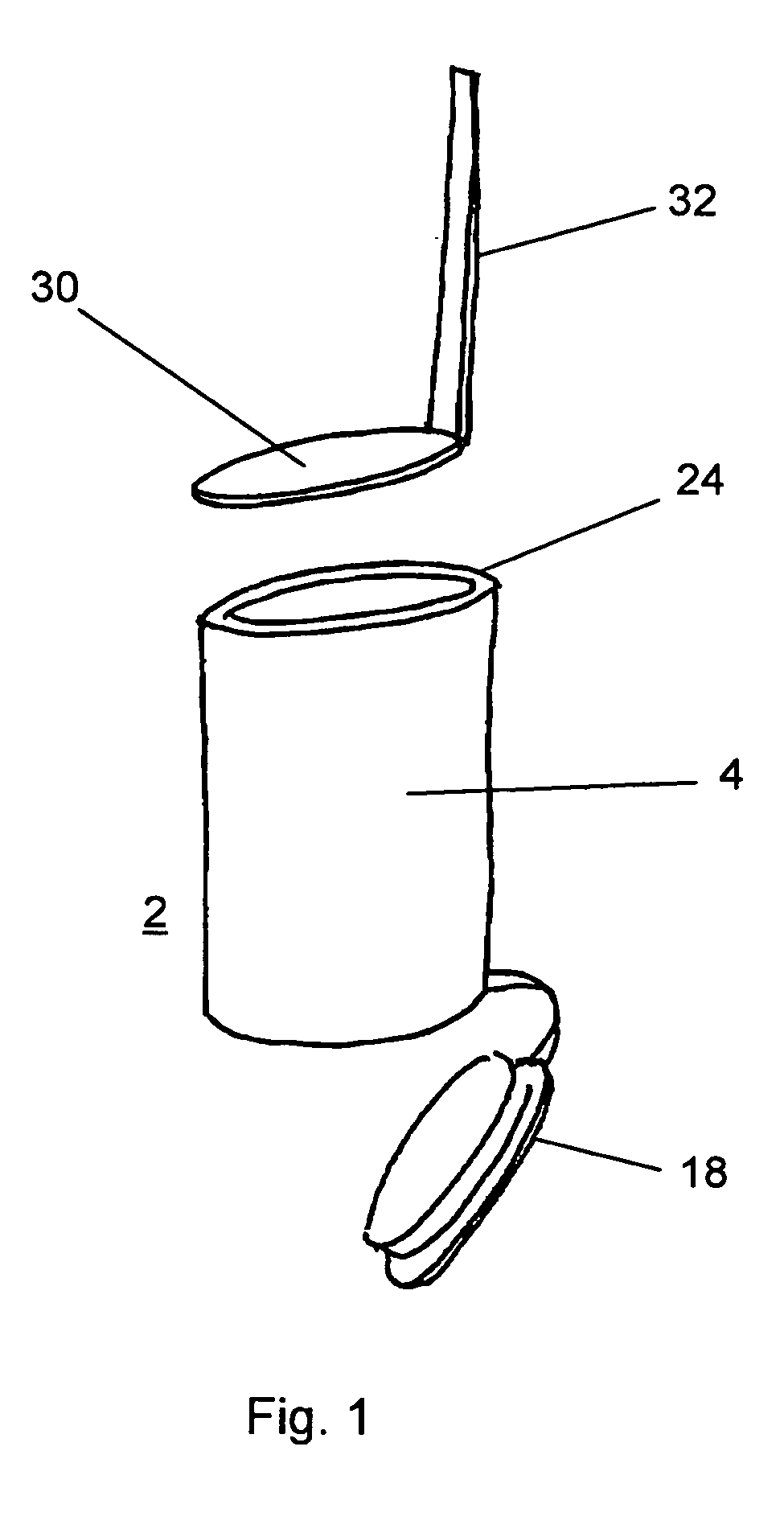

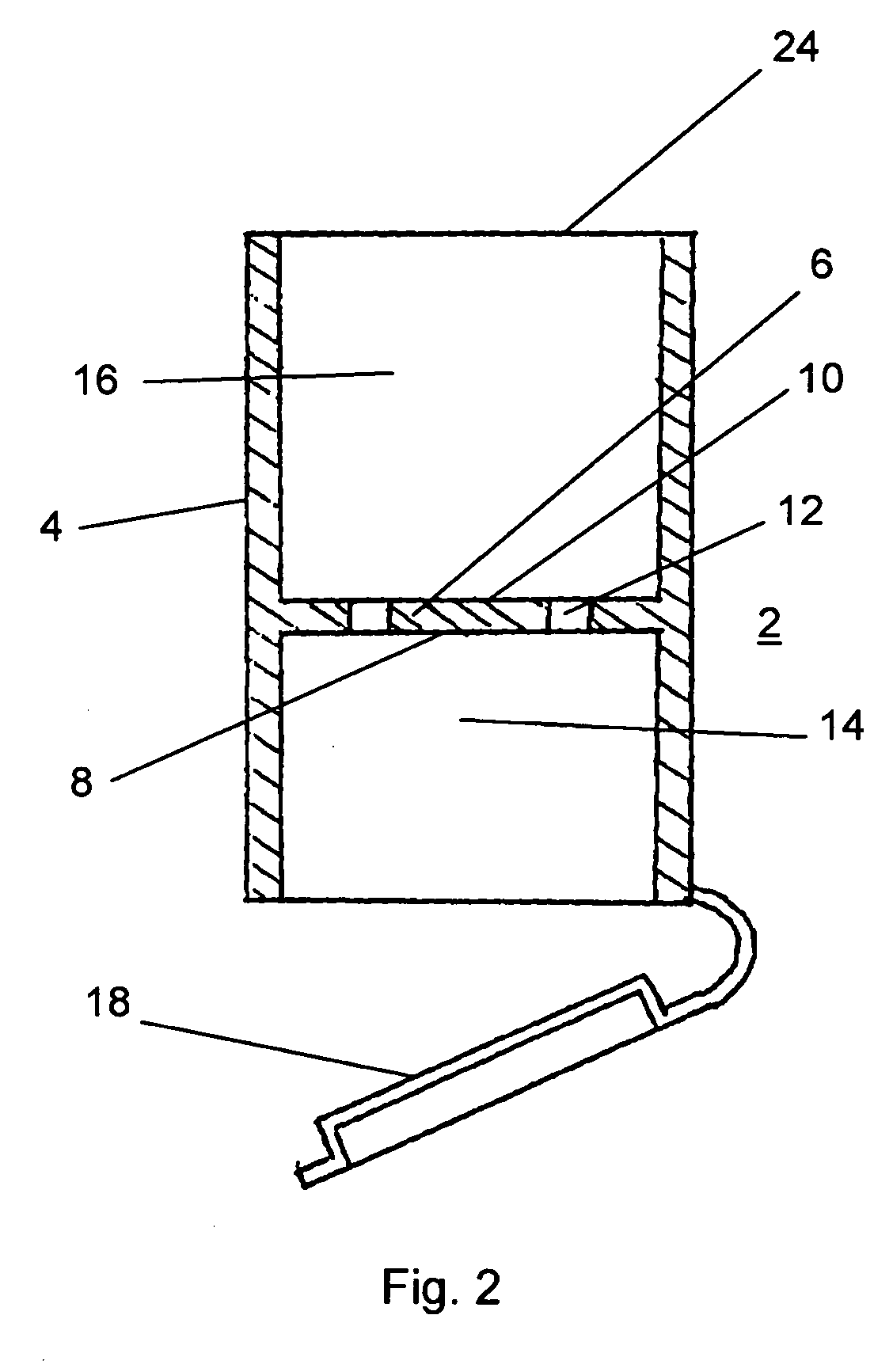

Storage container

InactiveUS20090200320A1Light structureSet a volume of the storage container relatively freelyCapsContainer filling methodsTemperature controlEngineering

A storage container includes an insulating container having an opening; a temperature controlling unit that is independent of the insulating container and detachably attached to the opening of the insulating container in a manner closing and sealing a portion of the opening; and a main lid attached to the opening of the insulating container in a manner closing and sealing an other portion of the opening. The temperature controlling unit is composed of an insulative sub-lid; and a temperature controlling subunit provided on the sub-lid. The temperature controlling subunit is composed of a base fitted into a through-hole formed on the sub-lid; and a Stirling refrigerator including a temperature control effect member thermally exposed inside the insulating container. Accordingly, the interior of the insulating container of an arbitrary size can be cooled, and items can be continuously stored longer than when using conventional solid carbon dioxide or cold reserving agent.

Owner:TWINBIRD CORP

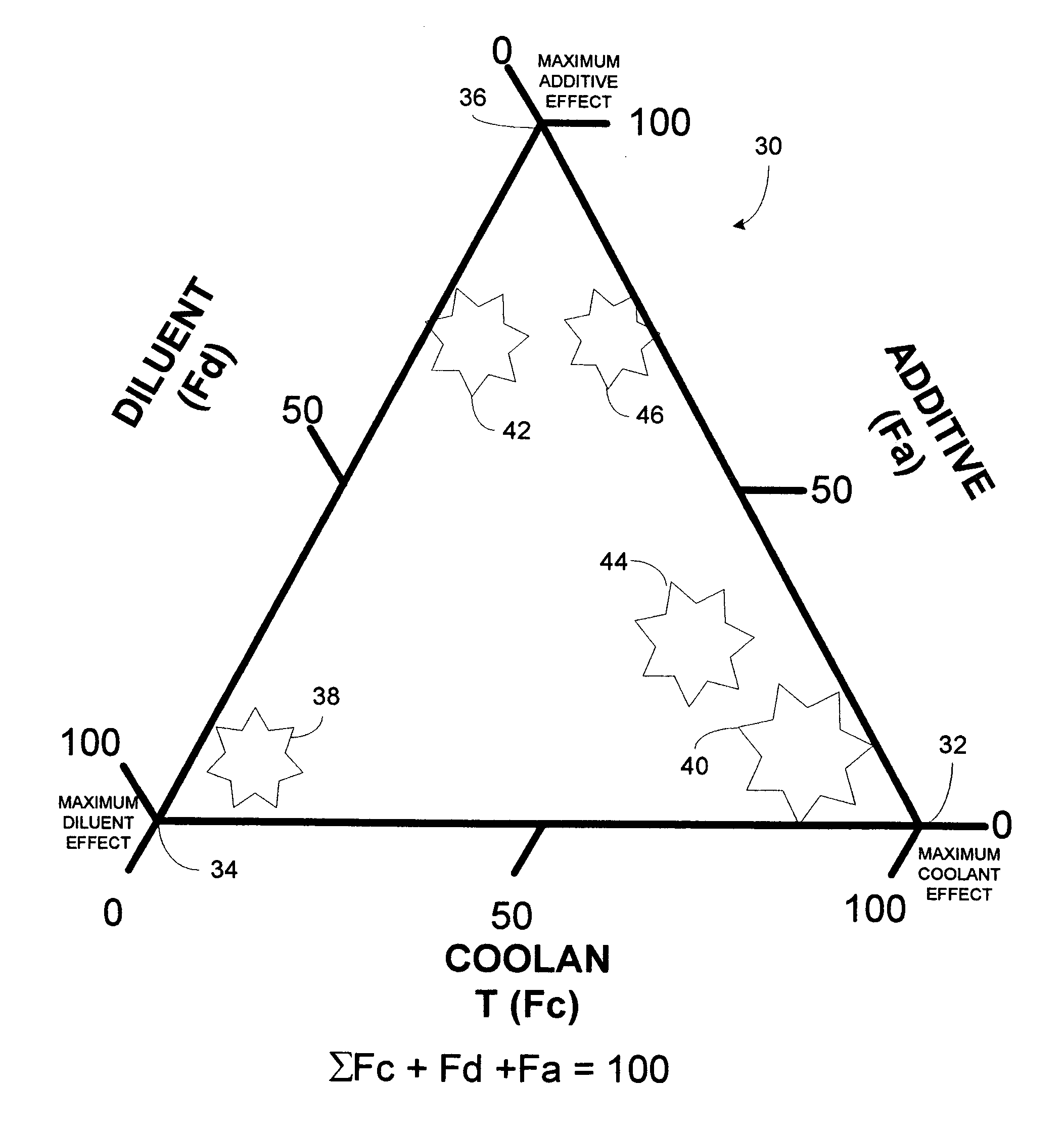

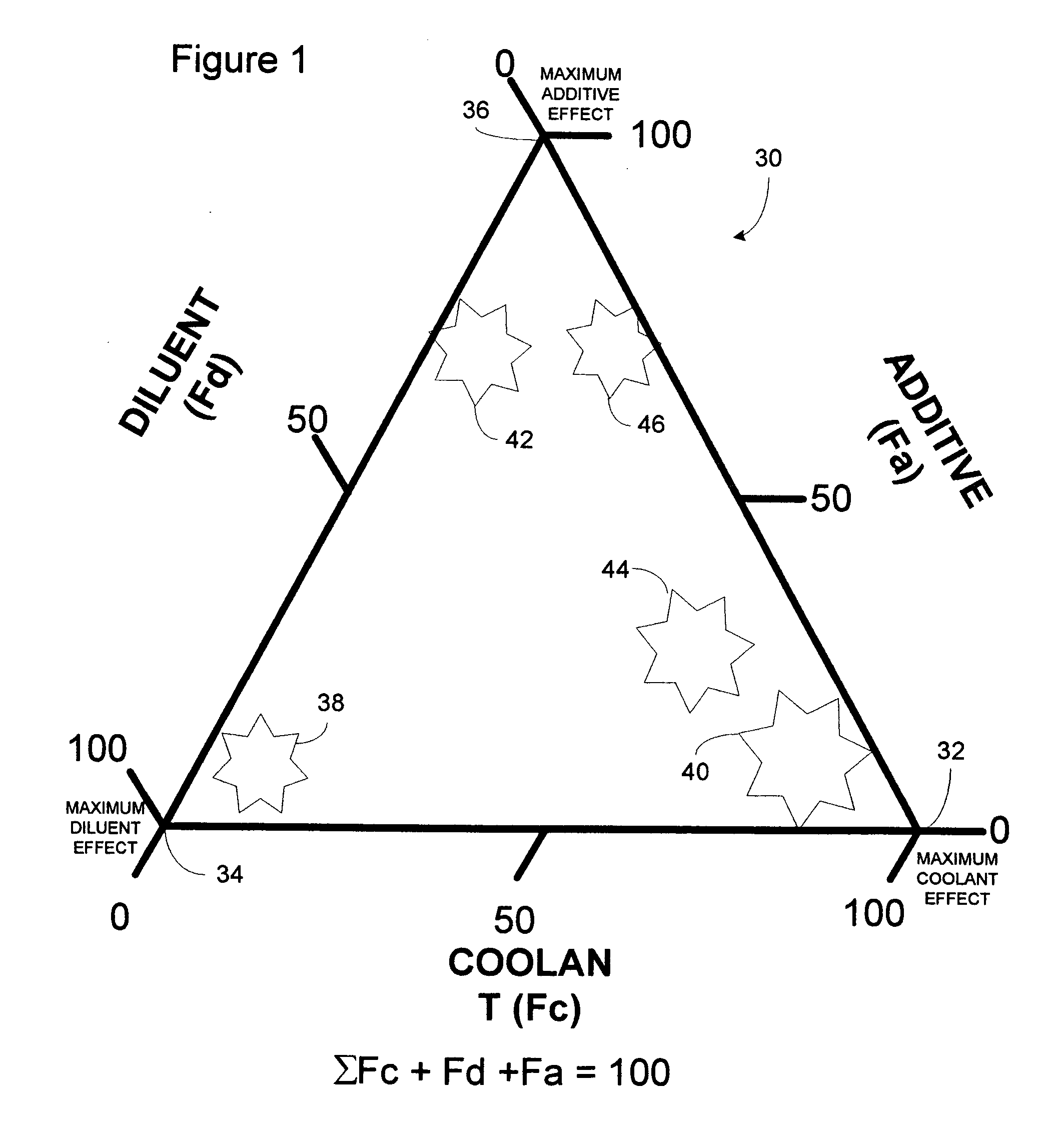

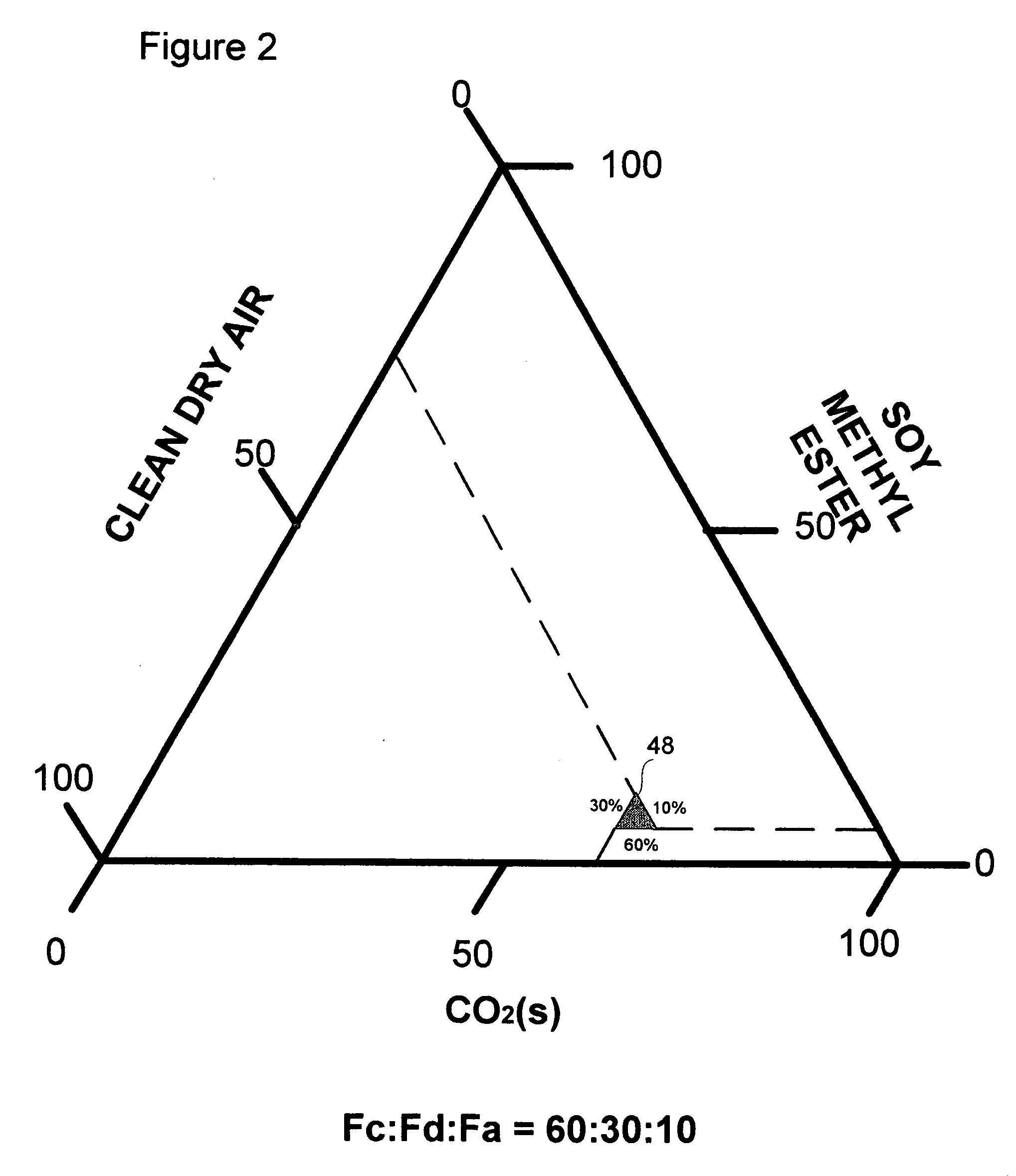

Cryogenic fluid composition

InactiveUS20070114488A1Heat-exchange elementsMaintainance and safety accessoriesGas phaseHigh pressure

A cryogenic fluid composition, and method of forming same, having hyperbaric, lubricating and cooling properties includes selectivity combining a solid phase carbon dioxide, an inert diluent gas and additives in various proportions. The cryogenic machining fluid can be derived by combining a solid carbon dioxide coolant, which may contain or entrain one or more machining lubricant additives, and a diluent phase which is an inert and relatively non-condensing gas phase in various concentrations. The cryogenic fluid composition can be used in cleaning, machining or manufacturing processes to cool, lubricate or ablate a substrate. The cryogenic fluid composition can also be used in conjunction with laser treatment or machining processes without adversely affecting lasing qualities of the laser.

Owner:COOL CLEAN TECH

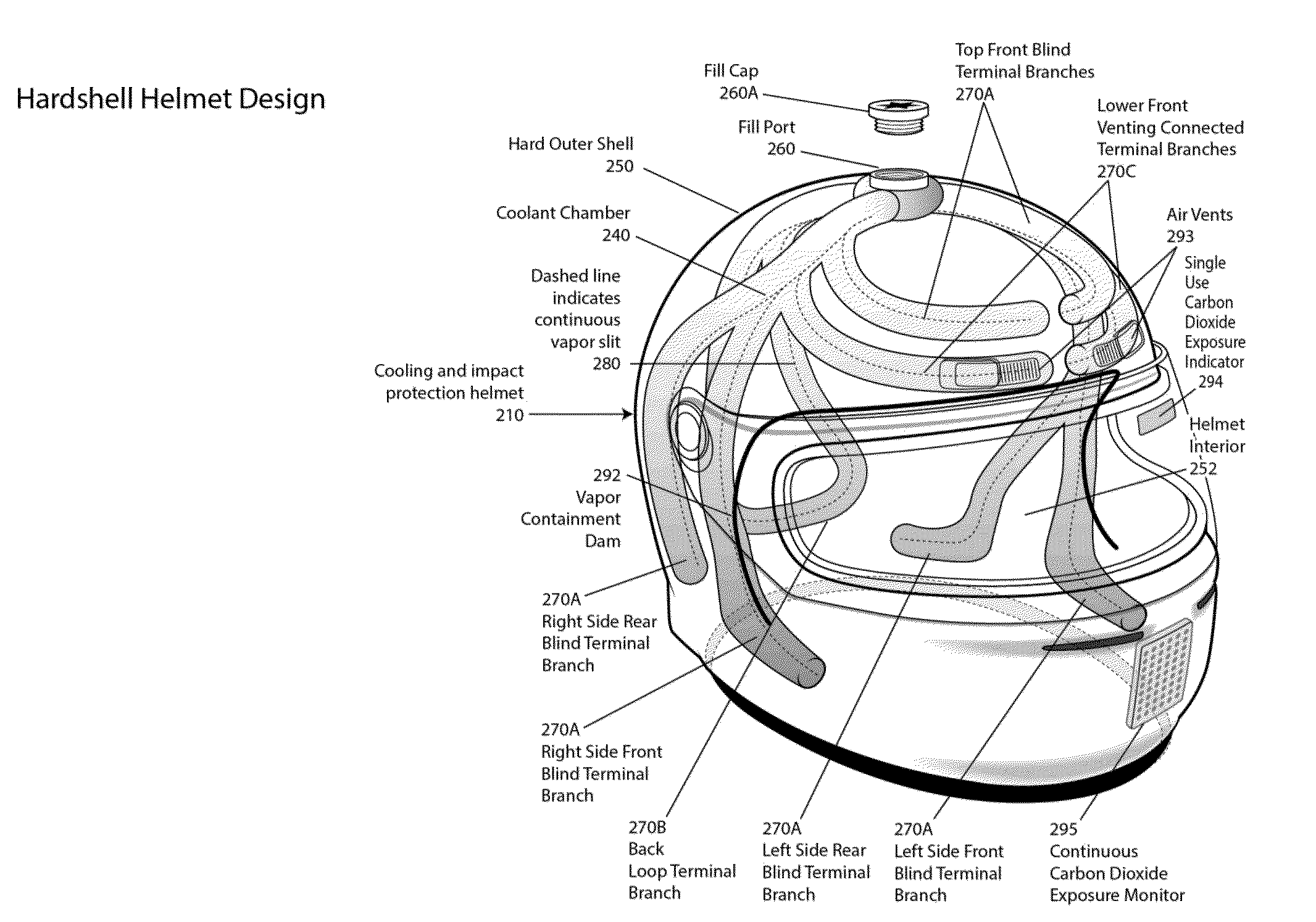

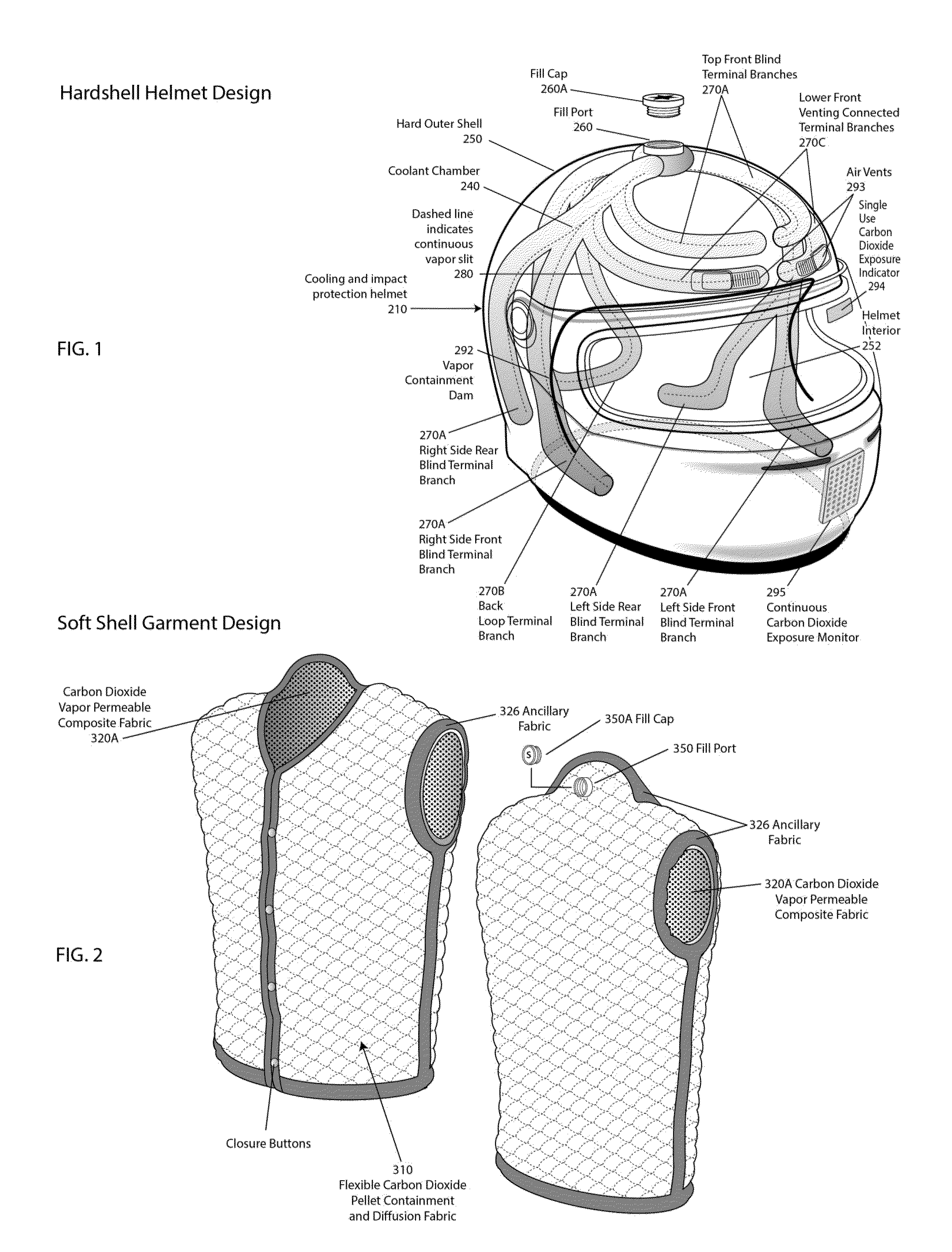

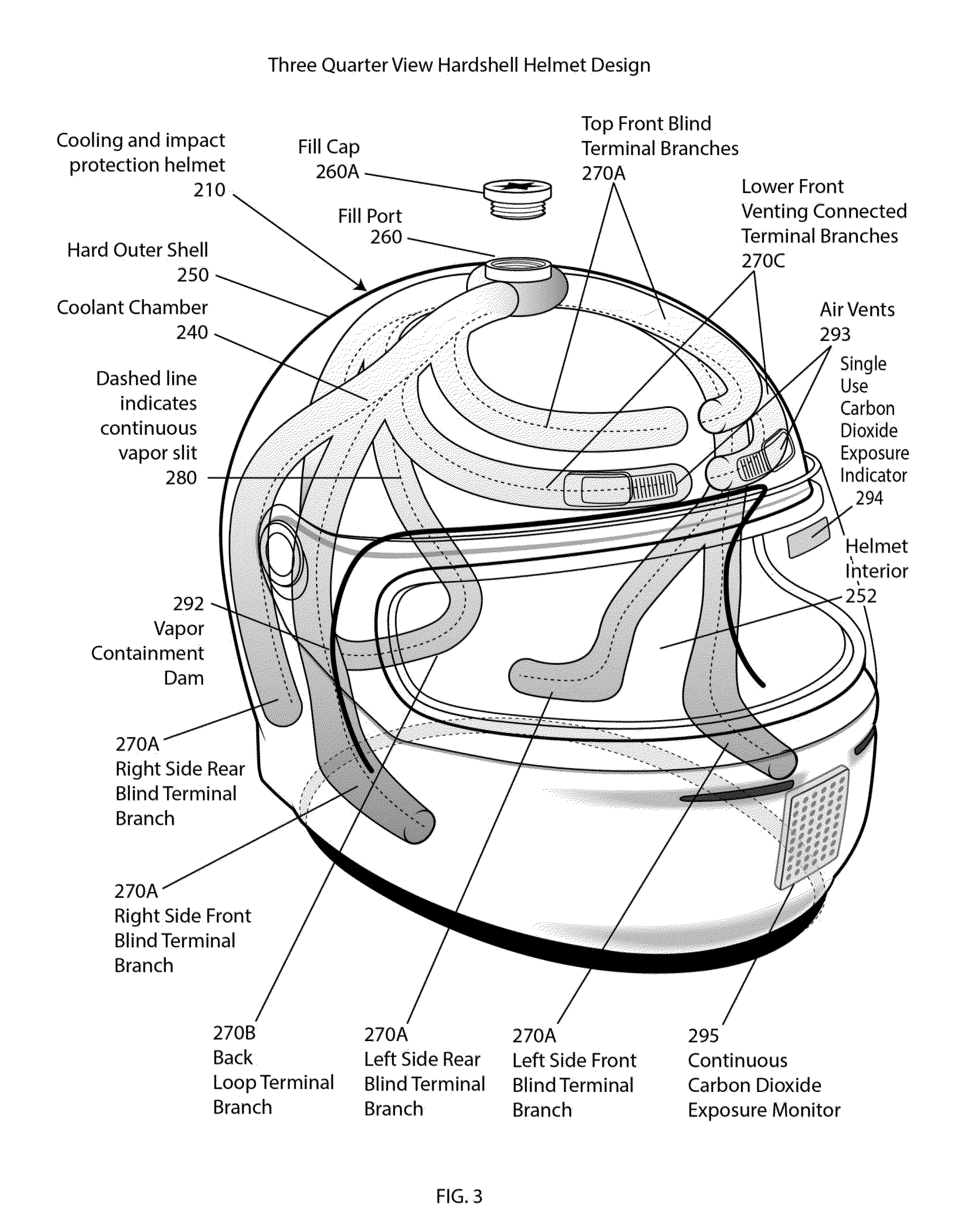

Carbon Dioxide Pellet Cooling Safety Helmet and a Flexible Carbon Dioxide Pellet Containment and Vapor Diffusion Fabric Segment

InactiveUS20160037833A1Increase heightImprove consistencyDomestic cooling apparatusLighting and heating apparatusPhase transitionSolid carbon dioxide

The invention is a reusable personal cooling apparatus that utilizes exclusively pourable pellet forms of Carbon-Dioxide Pellets as an expendable coolant. This coolant is placed in one or more compatibly designed, refillable Coolant Chambers that are integrated into a wearable garment that can be either a Hard-Shell Design (by example, an impact-protection helmet) or a Soft-Shell Design (by example, a vest), or a combination thereof. The Carbon-Dioxide Pellets are of machine manufacture and high density. They enhance the conformability of the Soft-Shell Design garment, promote ease of filling both garment designs and make possible the application of the pellet form of coolant to rigid, thin, curved structures like a helmet.The application of vibration expedites the speed of filling the apparatus and maximizes the fill volume by minimizing void formation within the Coolant Chamber. The cooling effect is achieved through the process of phase transition wherein solid carbon dioxide subliminates to Carbon-Dioxide Vapor which in turn is vented toward the skin of the individual wearing the garment. The ramifications are a versatile, reusable, convenient and diversely configurable personal cooling apparatus and a complementary coolant that function together to enhance personal comfort.

Owner:KRIESEL ROGER M

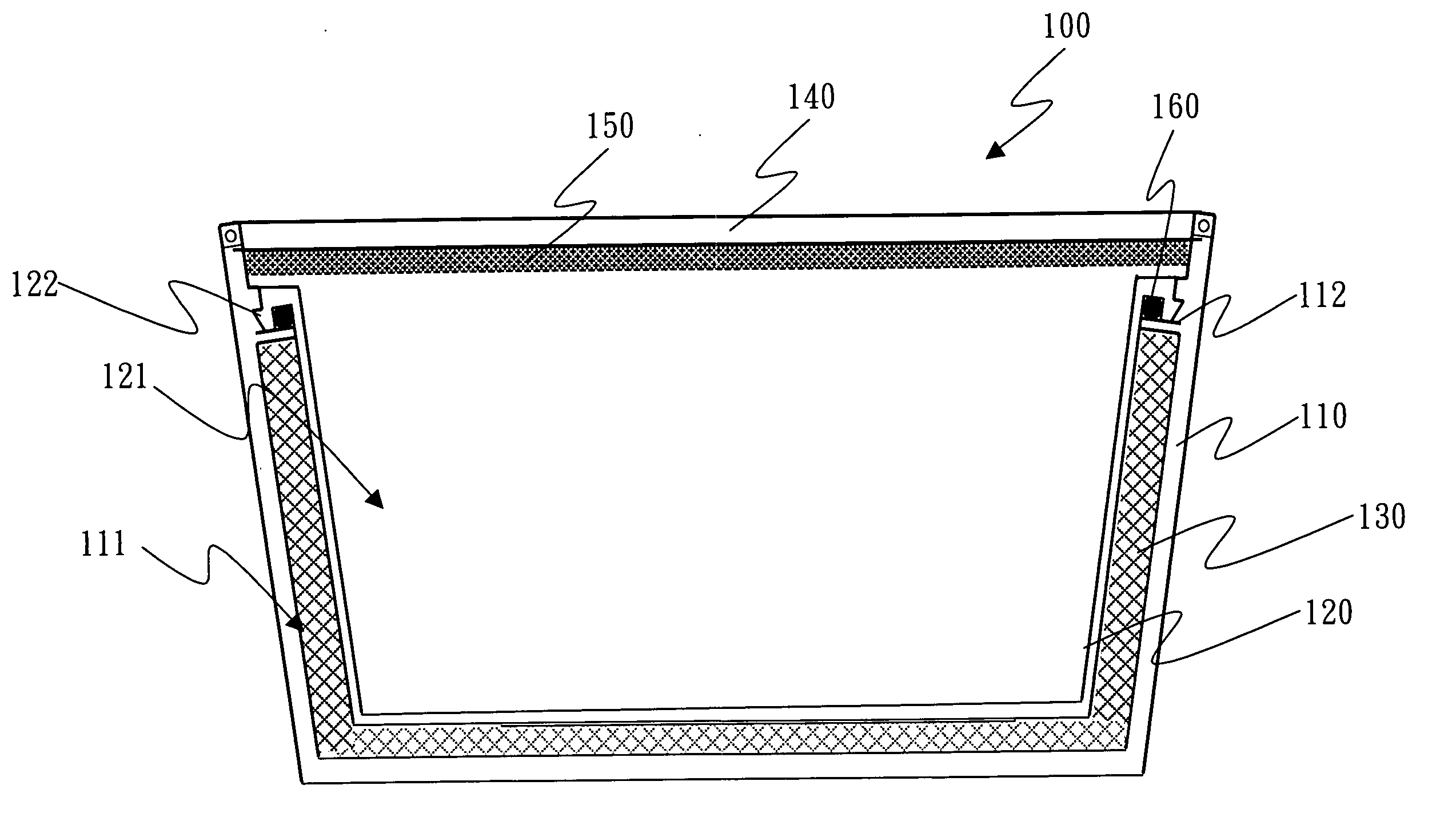

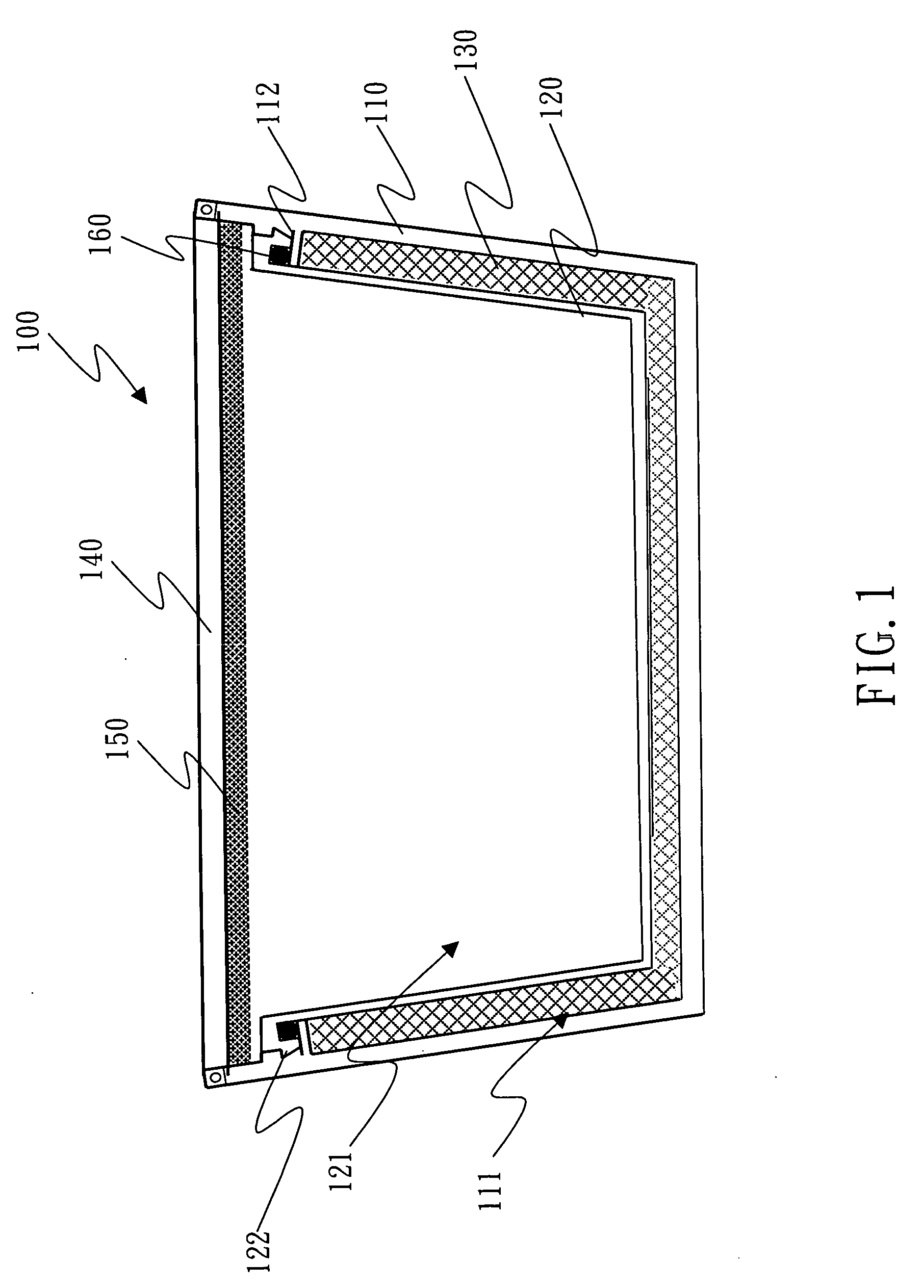

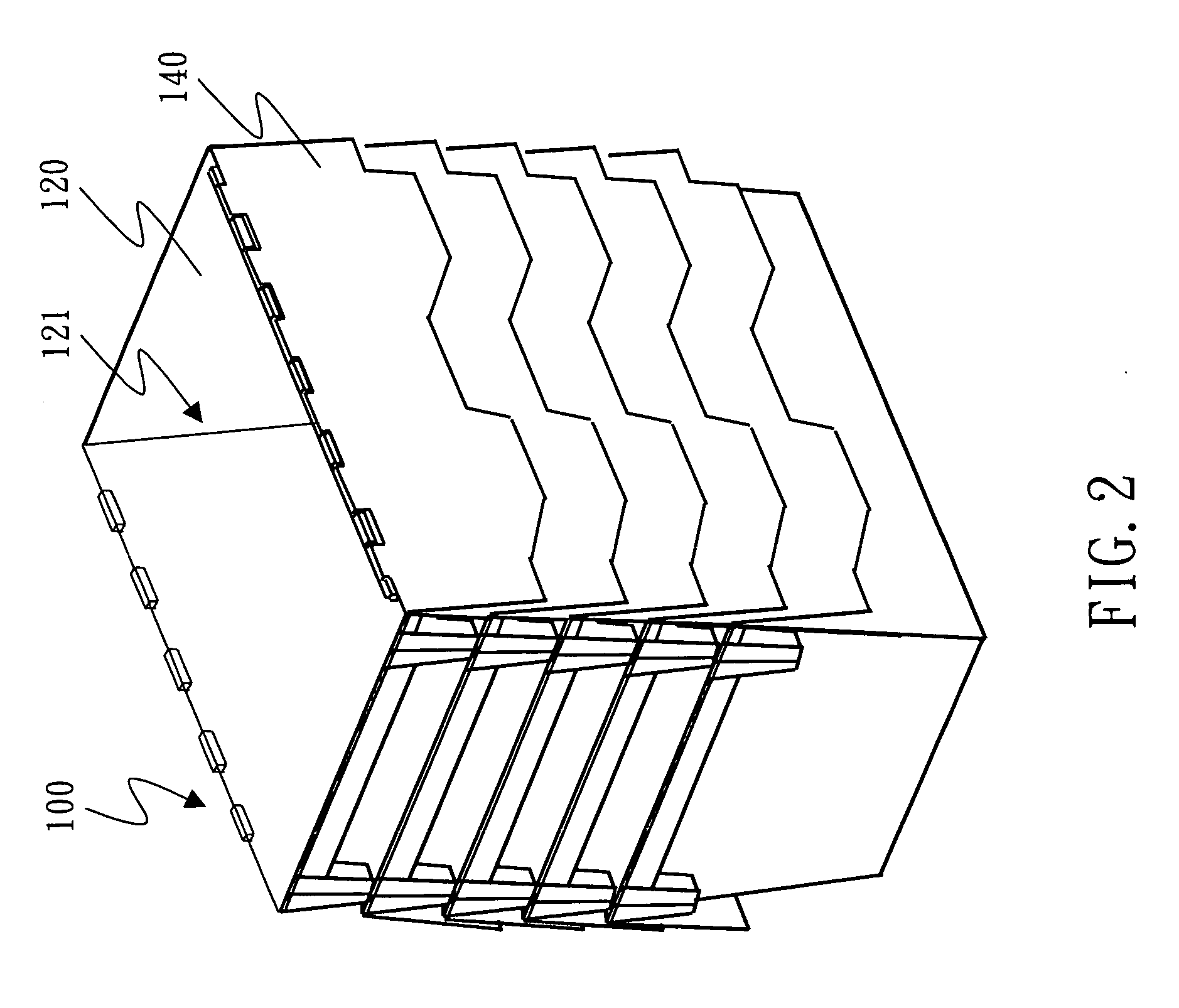

Insulated logistic container and delivery system using such insulated container

InactiveUS20070087087A1Easy temperature controlConstant internal temperatureFruit and vegetables preservationShock-sensitive articlesTemperature controlLogistics management

An insulated logistic container includes an outer case, an inner case defining a receiving space for holding articles and being located in the outer case, an insulating material disposed in an insulation space formed between the outer and the inner case, and a top cover pivotally connected to a top of the outer case to openably close the receiving space. In a delivery system using such insulated logistic containers to deliver articles to clients, articles having similar product temperatures are positioned in the same insulated container. Eutectic plates or consumptive refrigerant, such as dry ice, is used together with the insulated logistic container to achieve good product temperature control, making the delivery system more efficient and cost-effective, and the insulating effect and the delivery efficiency thereof are improved.

Owner:IND TECH RES INST

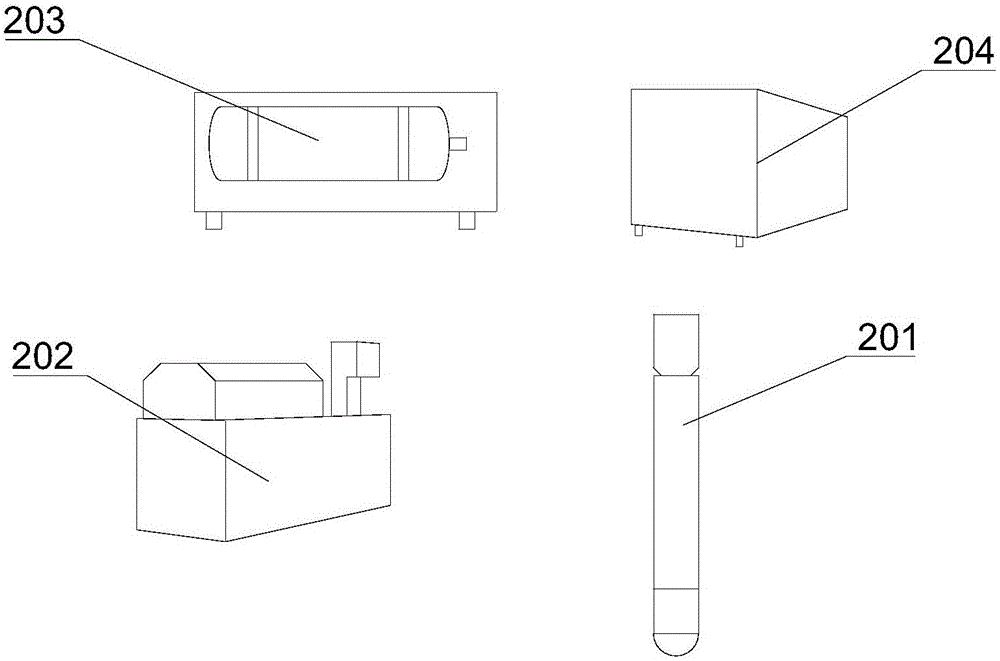

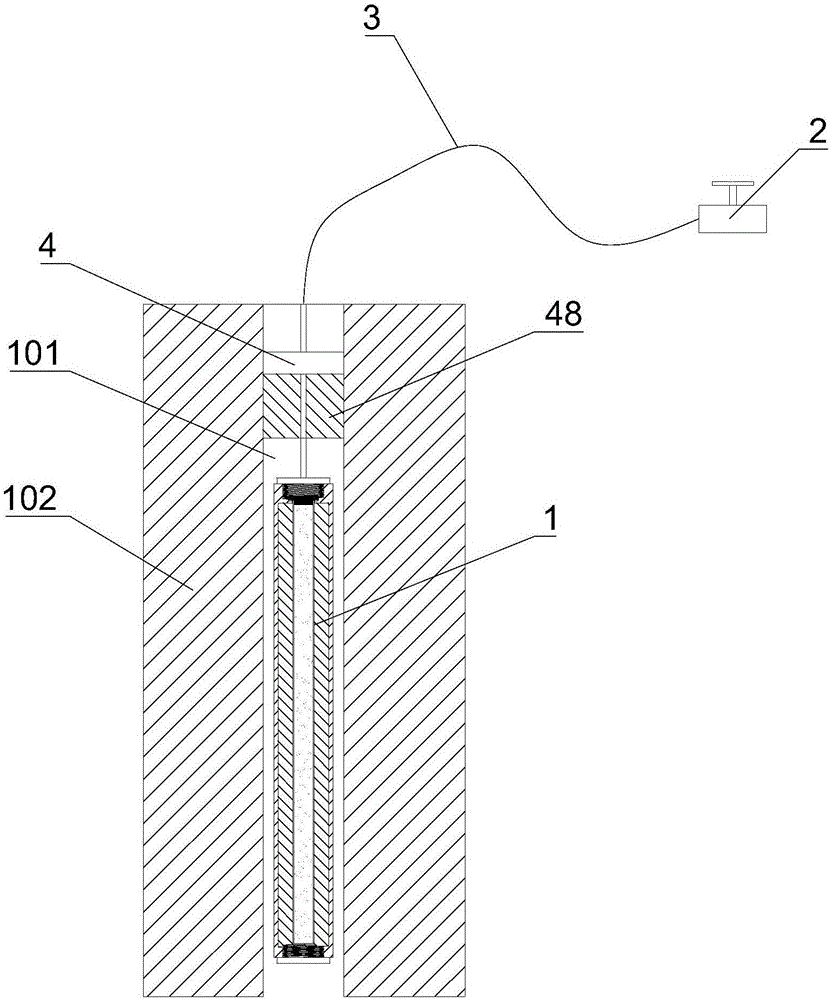

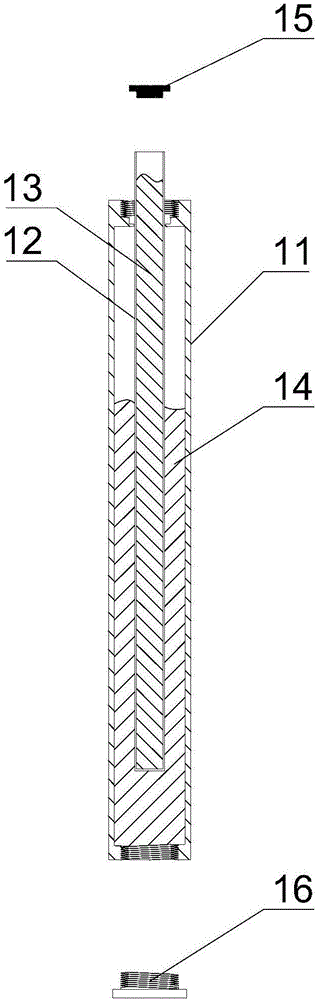

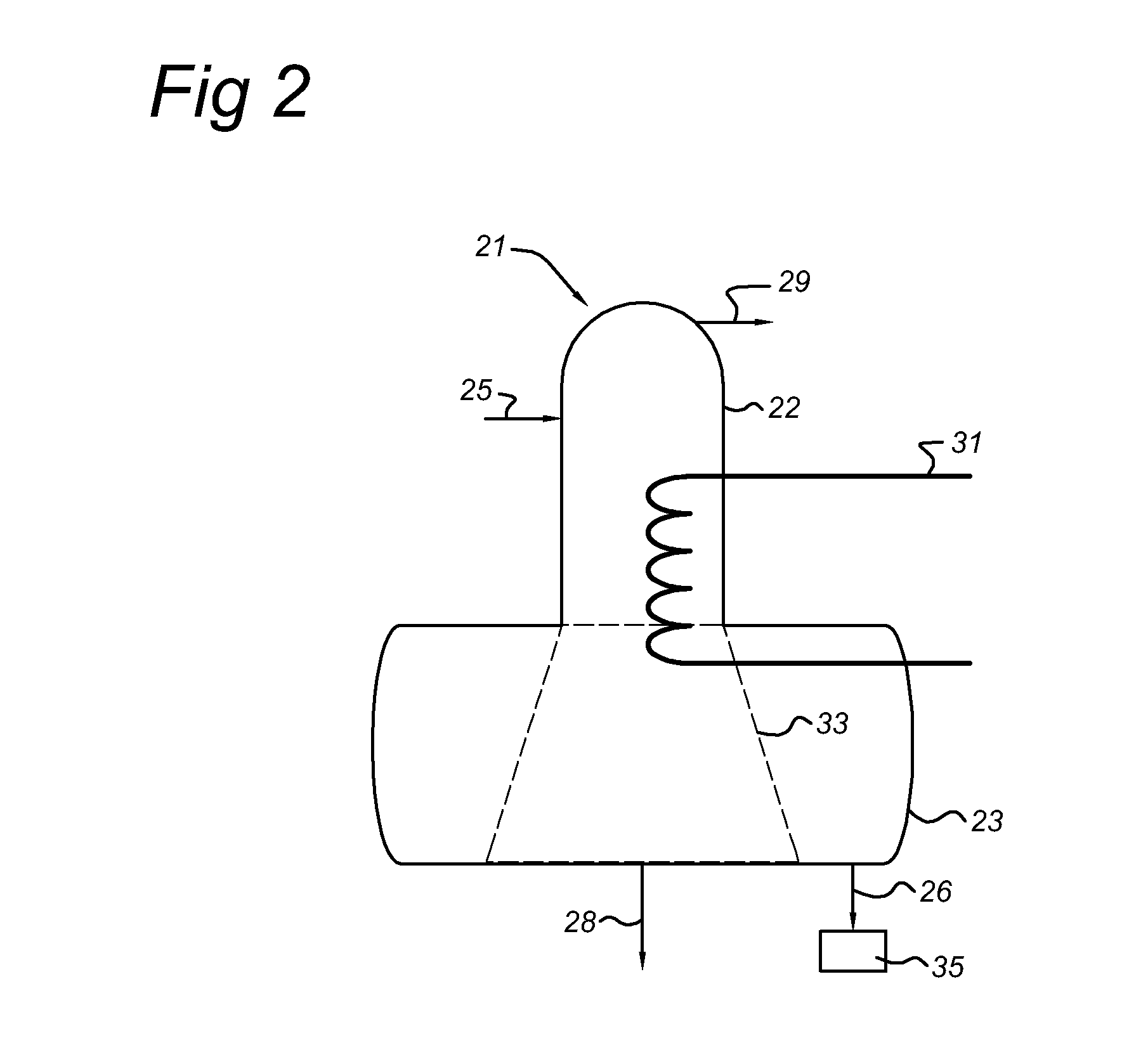

Solid carbon dioxide fracturing device and method

InactiveCN106437709AHeating fastSolve the problem of investment thresholdDisloding machinesPaperboardHigh pressure

The invention discloses a solid carbon dioxide fracturing device and method; the device is used for being mounted in a blast hole to blast a substratum to be blasted; the device comprises a solid carbon dioxide storage tube, two ends of the solid carbon dioxide storage tube are sealed, a heating tube is passed through the solid carbon dioxide storage tube and is filled with a heating agent, a cavity between the heating tube and the solid carbon dioxide storage tube is used for filling with solid carbon dioxide, the heating tube is also connected to a detonating device through a detonating circuit, and allowable pressure of material for the solid carbon dioxide storage tube is less than 10 Mpa. Small tensile strength of the solid carbon dioxide storage tube can be provided, most low-price materials in the market, such as plastic or paperboard, can be adapted to, and the fracturing device is greatly lower in device cost and usage cost than a fracturing device prepared with high-pressure-tolerant metal material; since these low-price materials are light in weight, it is convenient for workers to move or assemble the fracturing device and labor generation efficiency is improved accordingly.

Owner:曾庆平

Method and System for Continuously Pumping a Solid Material and Method and System for Hydrogen Formation

A method of continuously providing a pressurized slurry of a solid material and liquid carbon dioxide is disclosed. The method comprises mixing particles of the solid material and particles of solid carbon dioxide in a mixing container and feeding the mixture of the solid material and the solid carbon dioxide to a pump to form a slurry of the solid material and liquified carbon dioxide. Within the pump, the solid carbon dioxide sublimates, forming a gaseous carbon dioxide which subsequently liquefies due to an increase in pressure. The liquid carbon dioxide and the solid material then mix to form the slurry of the solid material and the liquid carbon dioxide. In some embodiments, the pressurized slurry may be used for pipeline transportation of the solid material. A system of producing a continuous pressurized slurry of solid material and liquid carbon dioxide is also disclosed. A method of producing hydrogen is also disclosed.

Owner:JOHN P DOOHER TRUST +1

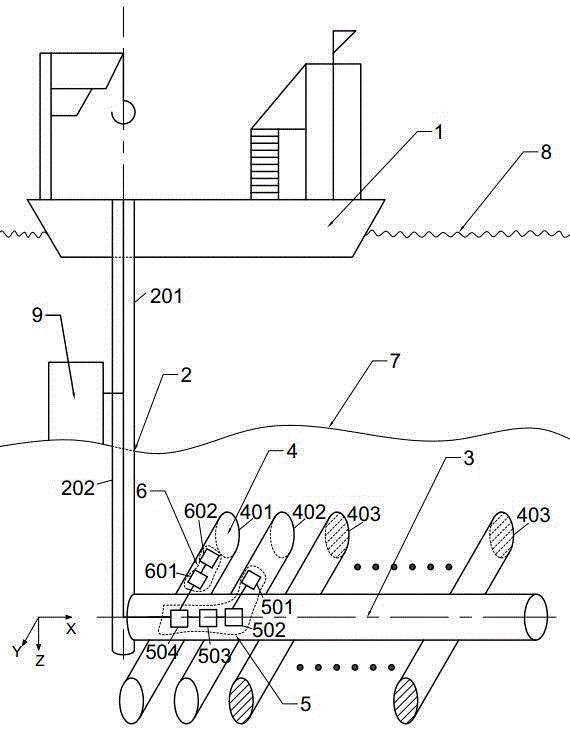

Ocean non-diagenetic gas hydrate reservoir mining system and mining process thereof

Owner:SOUTHWEST PETROLEUM UNIV

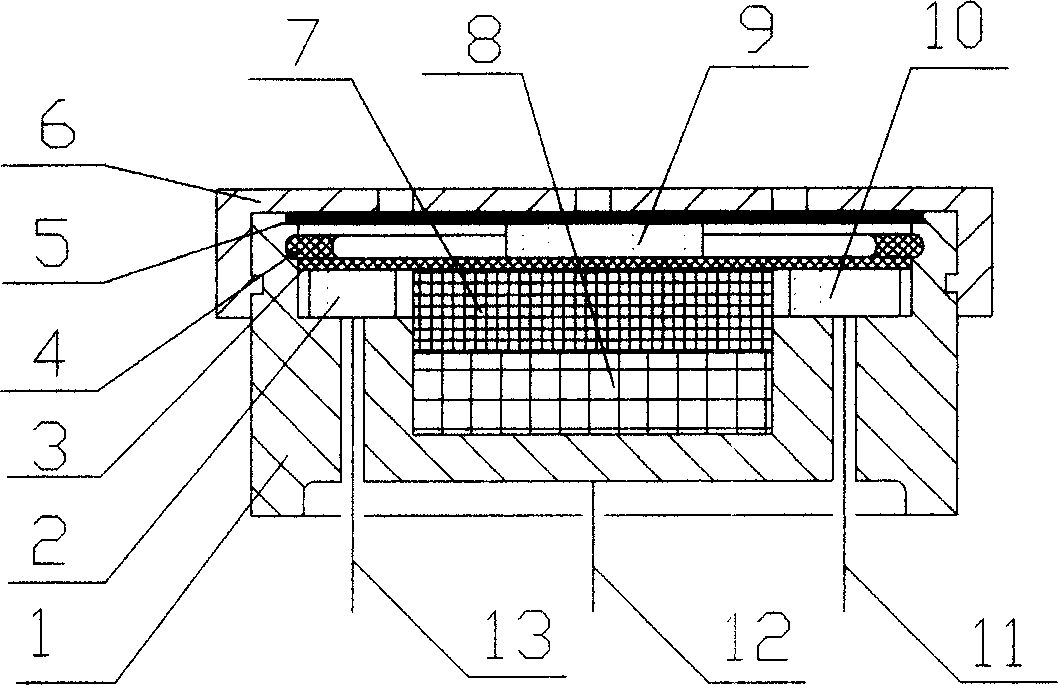

Complete solid carbon dioxide electrochemical sensor

InactiveCN1667407AConcentration direct determinationMaterial analysis by electric/magnetic meansDesorptionGas phase

The invention relates to a method, which adopts solid polymer electrode instead of traditional liquid electrolyte solution and uses SPE gas electrode as CO2 sensitive electrode.The method comprises following steps: SPE-CO2 electrode absorbing gas phase CO2; conducting CO2 oxidization desorption; controlling some conditions to make CO2 oxidization desorption rate and CO2 density in the sample gas in linear relationship; then directly detecting CO2 density in the sample gas.

Owner:GUANGZHOU SENSCN INSTR

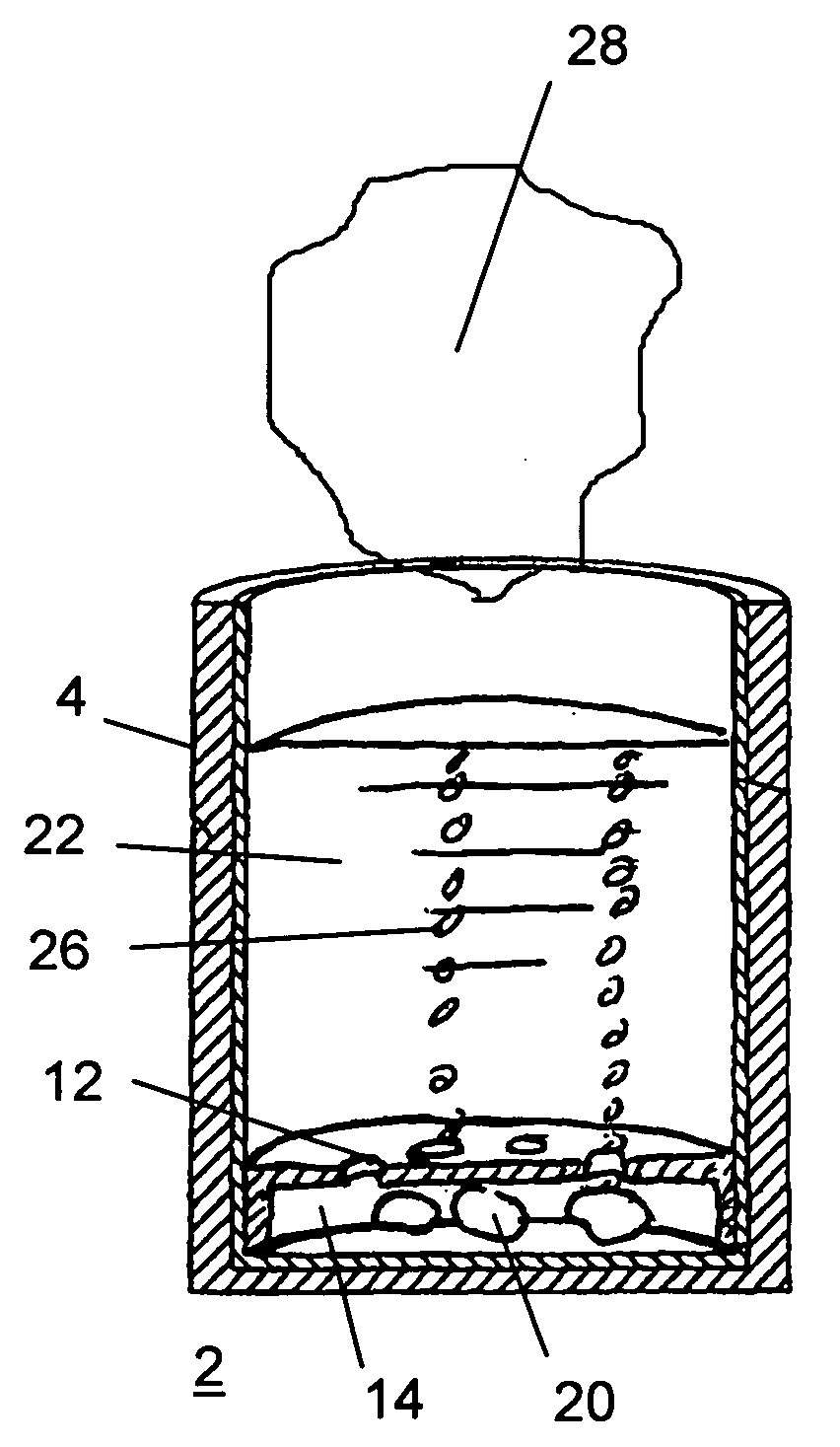

Dry ice drinking vessel

InactiveUS20050039484A1Improve visual effectsEnhancing its appealLighting and heating apparatusCooling fluid circulationEngineeringSolid carbon dioxide

The Invention is an apparatus which may be a drinking vessel to contain dry ice submerged within a beverage to create a visual effect. A partition has a first side and a second side and is adapted to contain dry ice on the first side. The partition is adapted to allow the beverage to flow from the second side of said partition to said first side of said partition when said partition is immersed in the beverage, exposing the beverage to the dry ice, creating a visual effect and chilling the beverage.

Owner:NIELSEN PETER

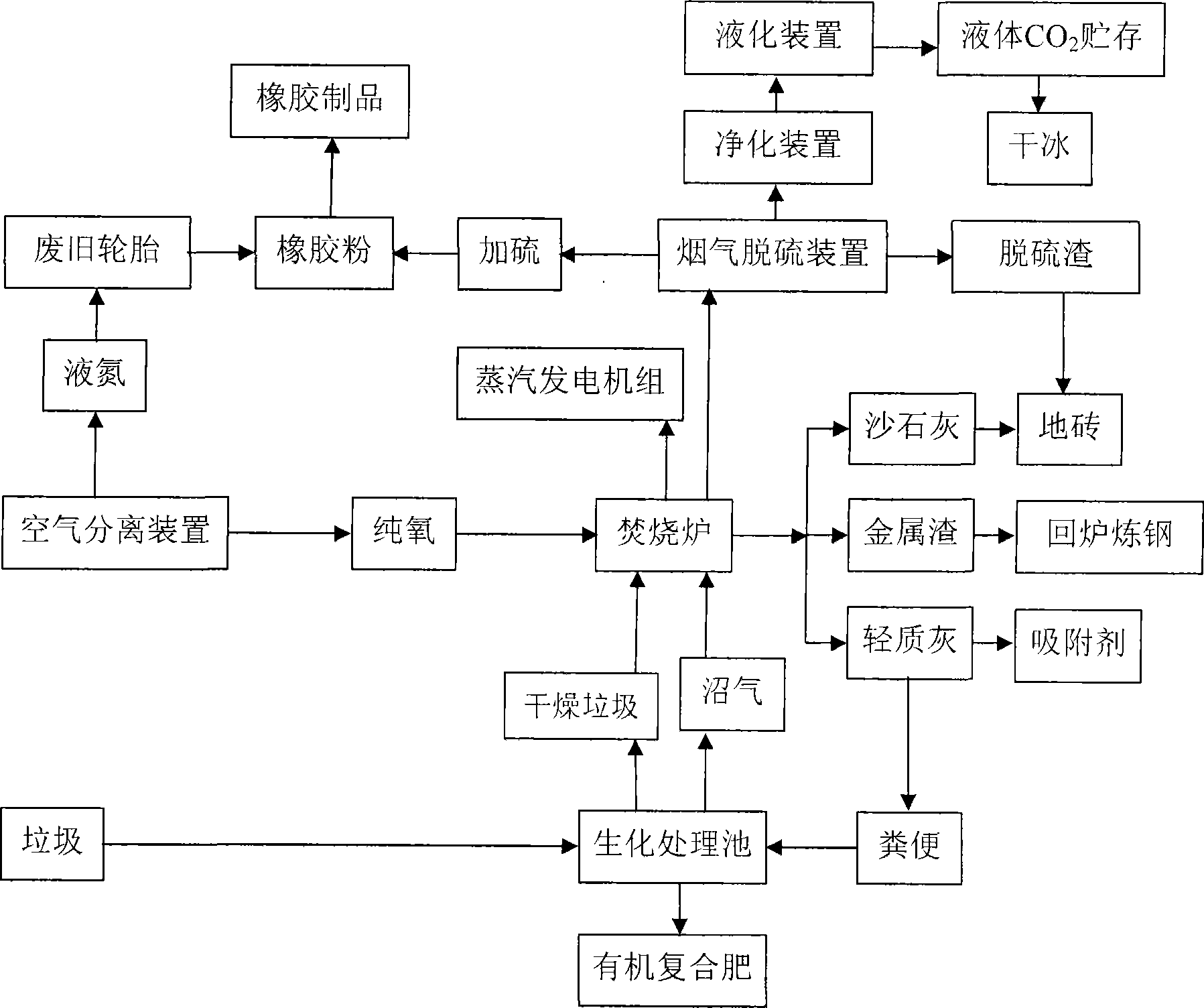

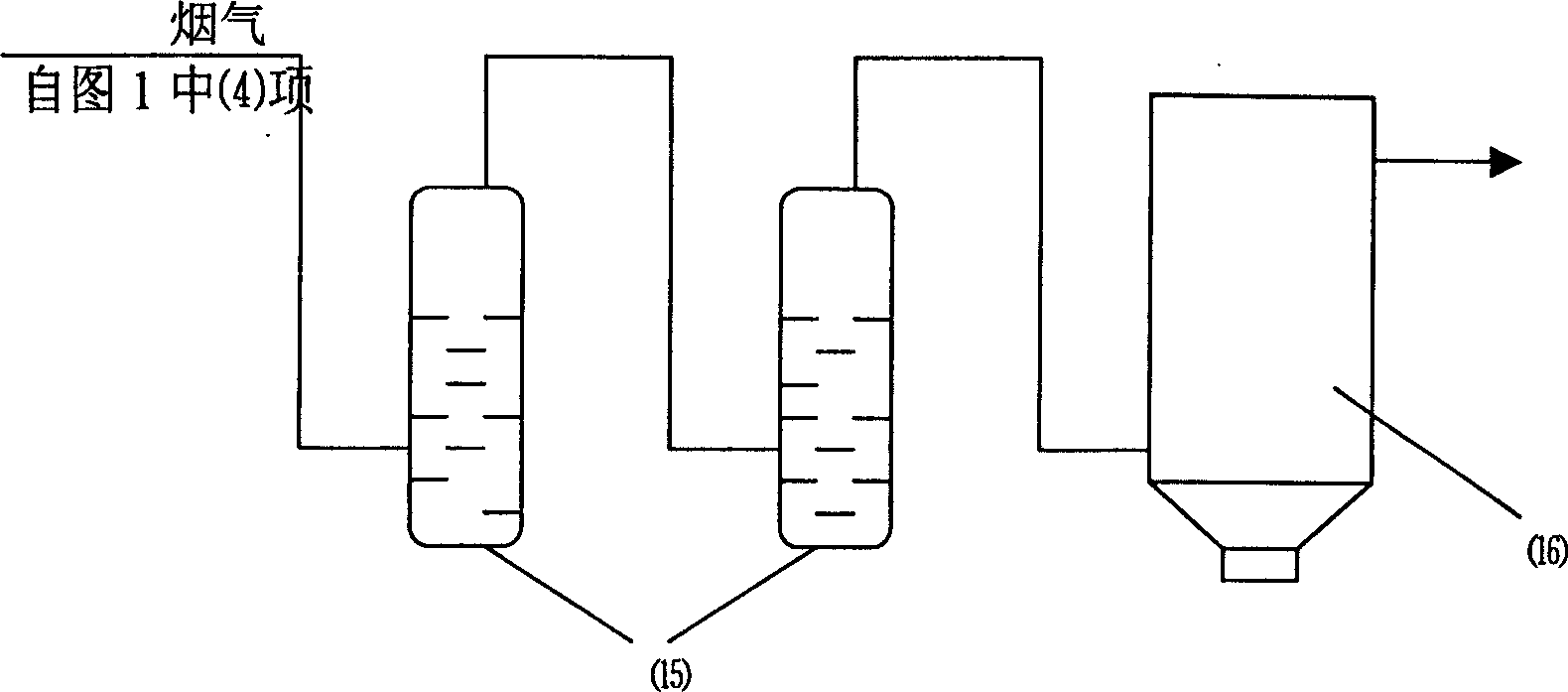

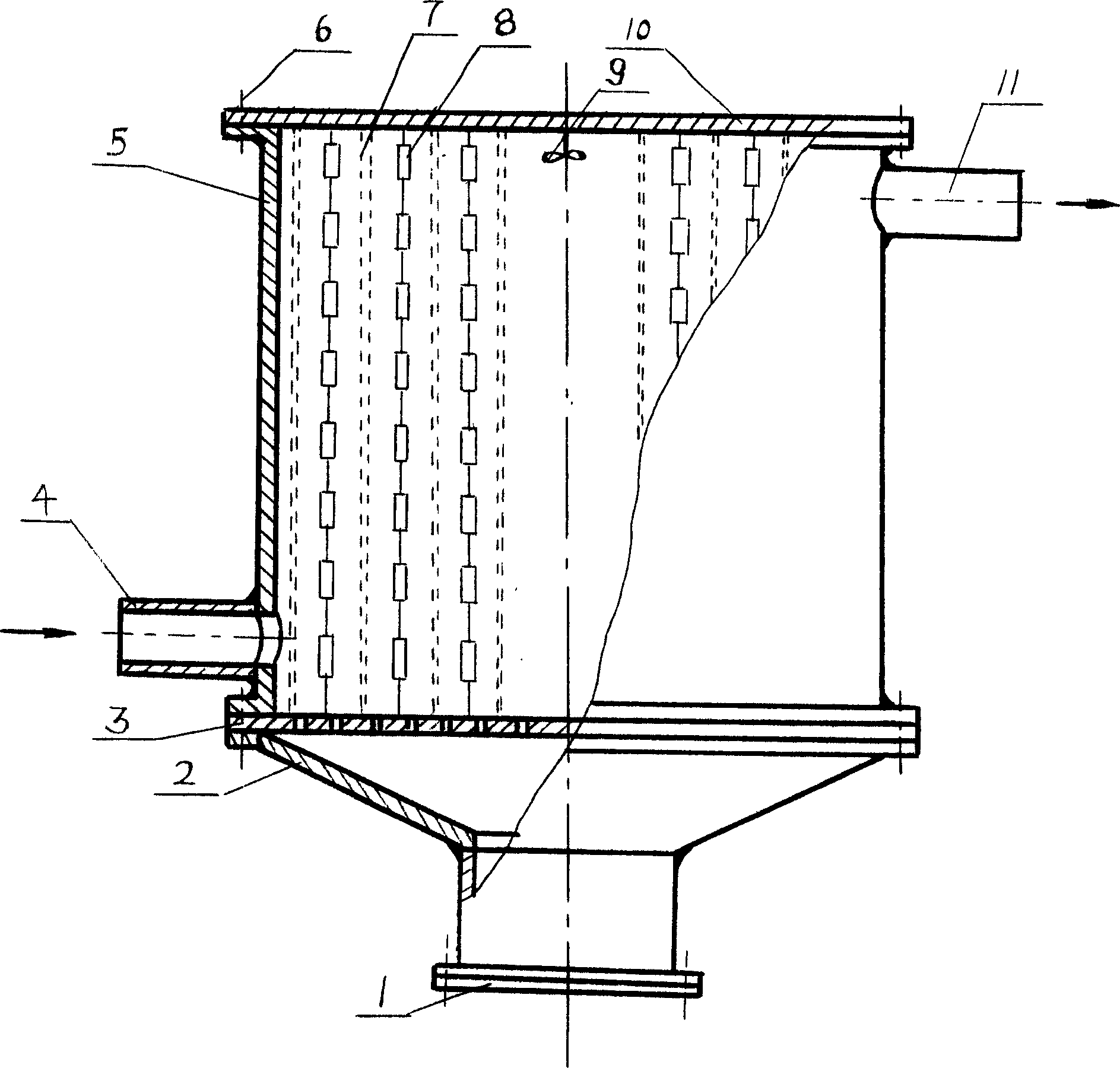

Garbage treatment method and comprehensive utilization

InactiveCN101367088AIncrease concentrationReduce generationBio-organic fraction processingCarbon compoundsHigh concentrationThermal energy

The invention discloses a method for treating waste and comprehensive utilization thereof. The method adopts a high-temperature incineration technology to greatly reduce a virulent gas in smoke gas dioxin and greatly increase the concentration of a CO2 gas; heat energy, the smoke gas and clinker produced in the incineration process can generate power and produce dry ice, rubber powder, floor tiles, organic compound fertilizer and the like after treatment, thereby realizing no emission, no pollution and no waste in the waste incineration treatment. The waste treatment method comprises the following steps: methane produced in a biochemical treatment pool is conducted to an incinerator and ignites the dry waste in the incinerator; pure oxygen produced in an air separation device is conducted to the incinerator and supports the combustion of the waste to produce the smoke gas containing high-concentration CO2; the temperature in the incinerator is up to over 1,200 DEG C; and the smoke gas is desulphurized and purified to obtain purified CO2. In the method, the smoke gas, the heat energy and the clinker produced by incinerating the waste are matched with liquid nitrogen produced by a liquefier and the air separation device to prepare CO2 liquid, the floor tiles, the rubber powder, the organic compound fertilizer and other useful resources.

Owner:袁永扬

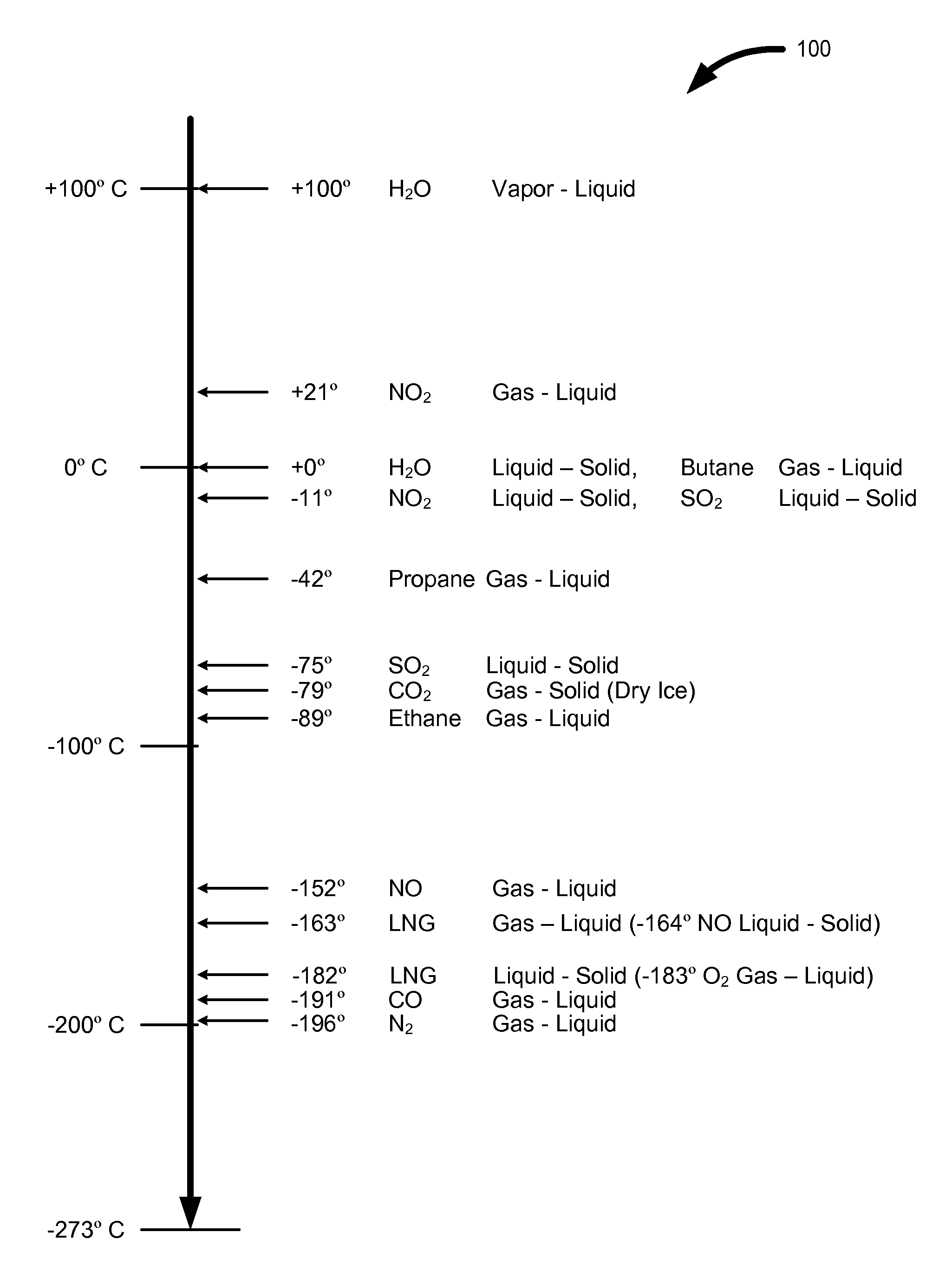

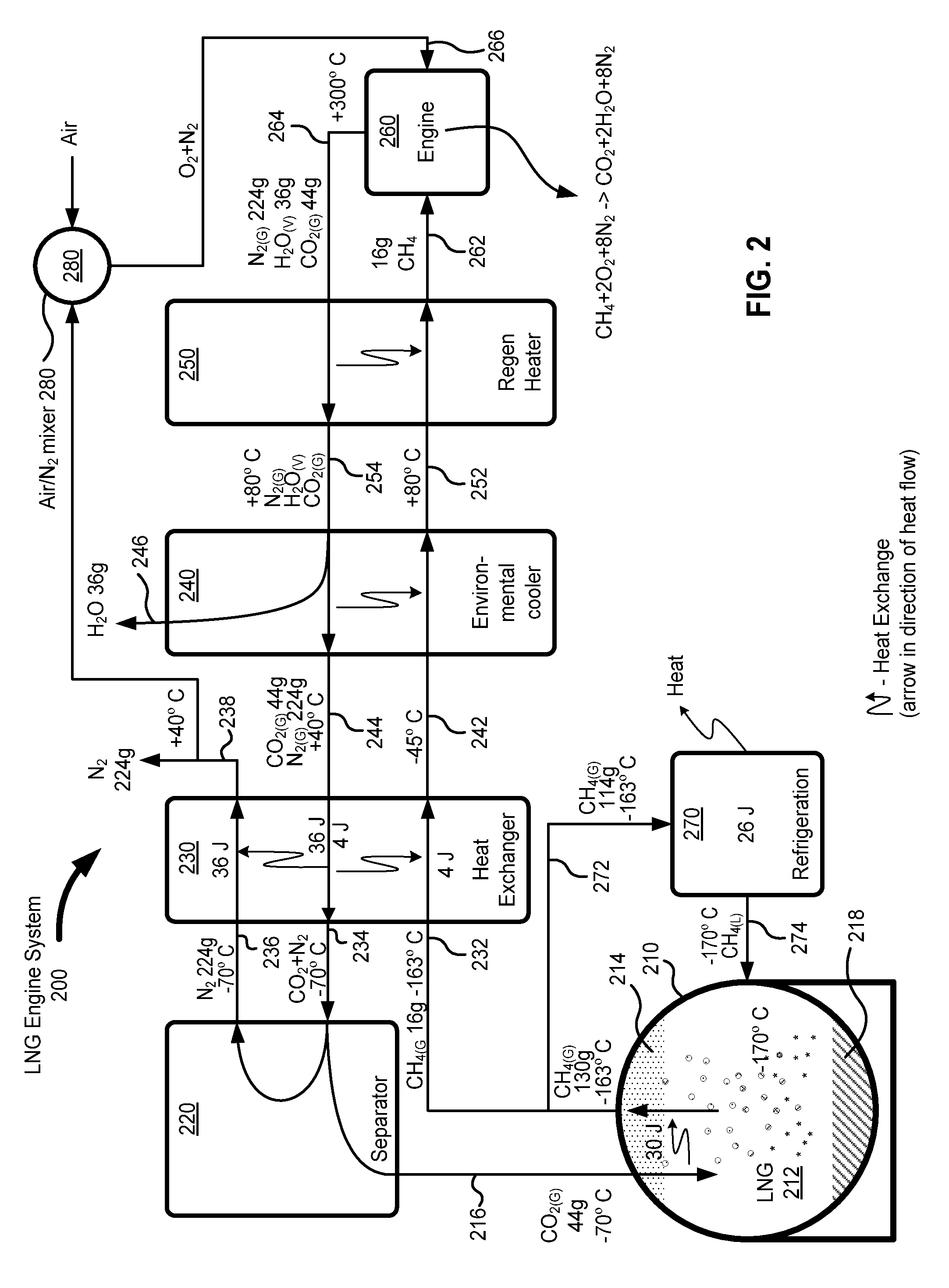

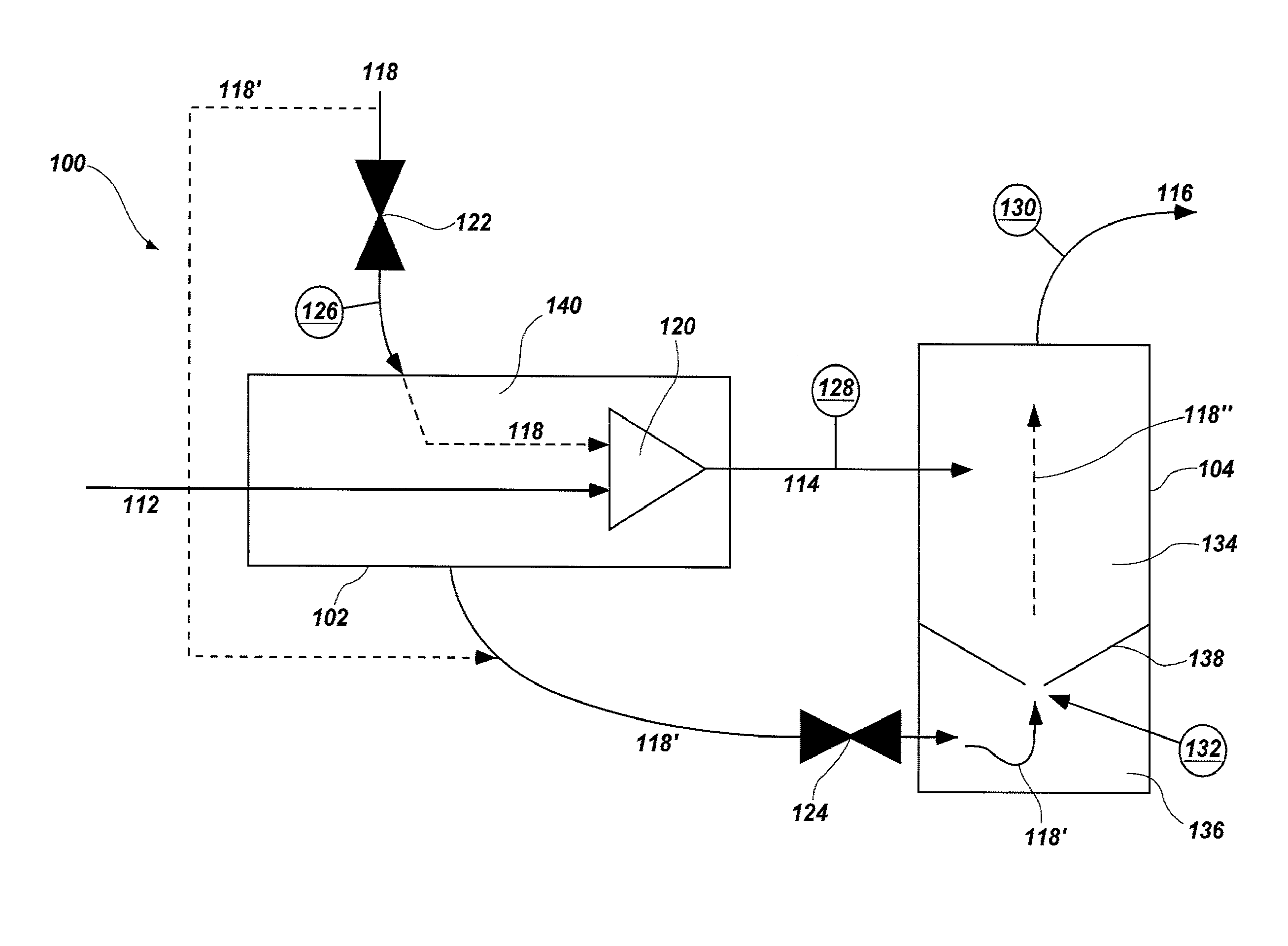

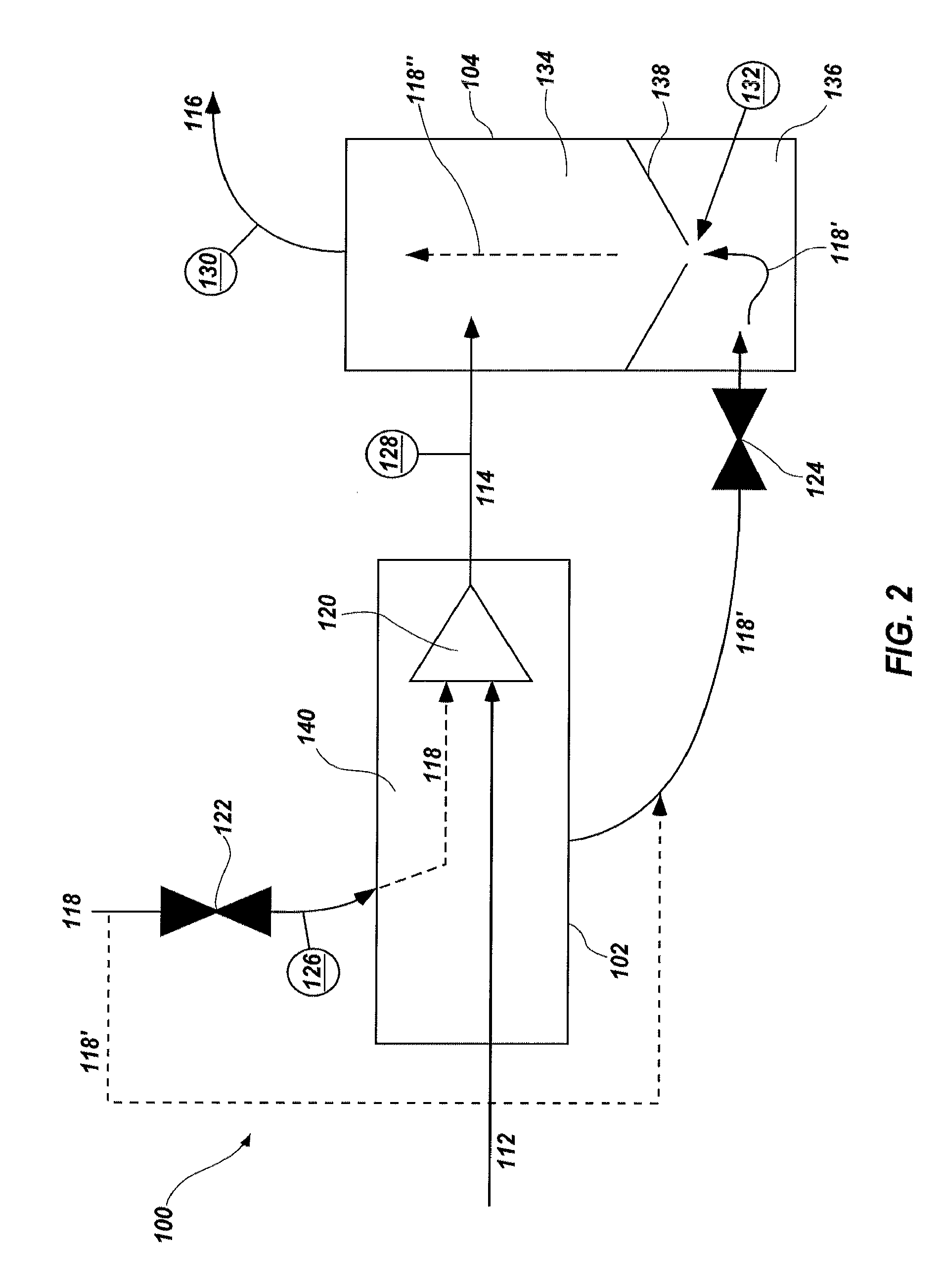

System and method for sequestering emissions from engines

InactiveUS20110167798A1Gas treatmentInternal combustion piston enginesExhaust fumesFractional distillation

A system is provided for sequestering carbon dioxide emitted in exhaust gas from an engine. The exhaust gas may be cooled using heat exchange techniques, for example reverse flow heat exchangers. Carbon dioxide may be separated from the exhaust gases, for example using fractional distillation, heat exchangers, and turbo chargers. The separated carbon dioxide may be stored, for example using injection deep into the earth for enhancing natural gas and oil extraction. Alternatively, the separated carbon dioxide may be cooled to solid carbon dioxide and stored, for example, in an LNG tank for use as ballast onboard a ship or for use in industry.

Owner:PURIFY SOLUTIONS INC

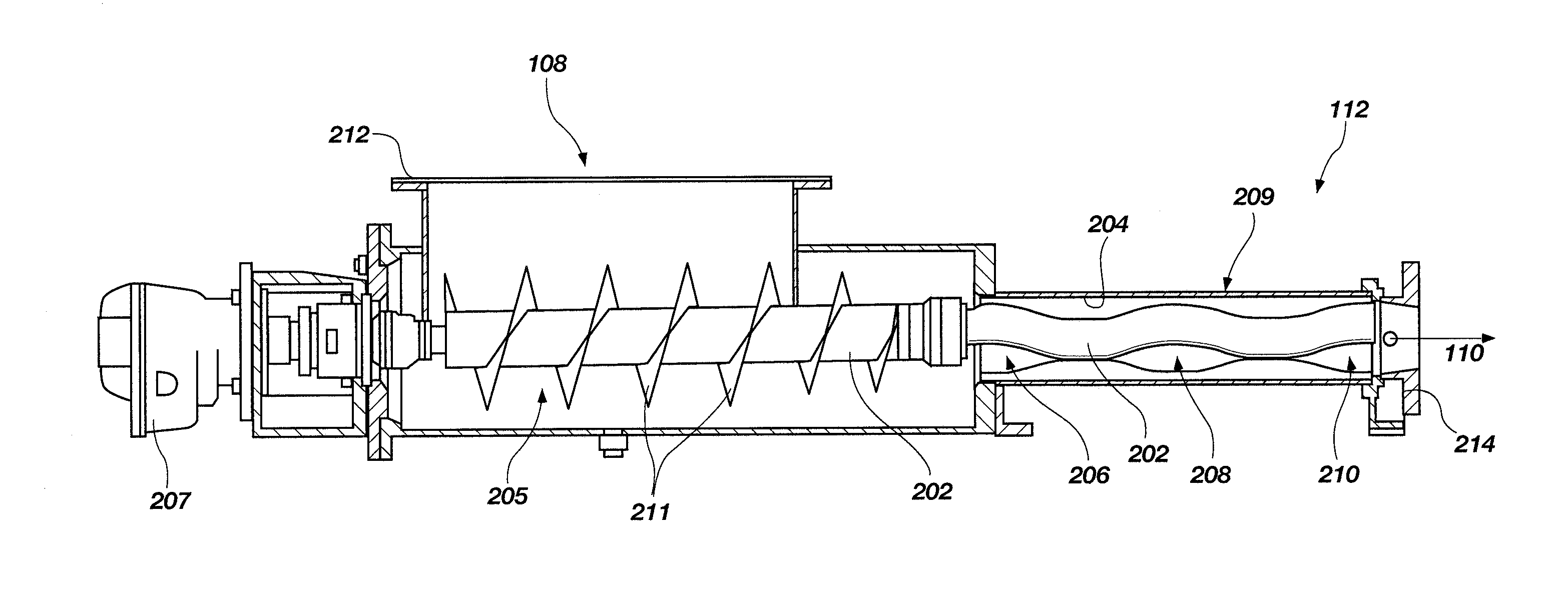

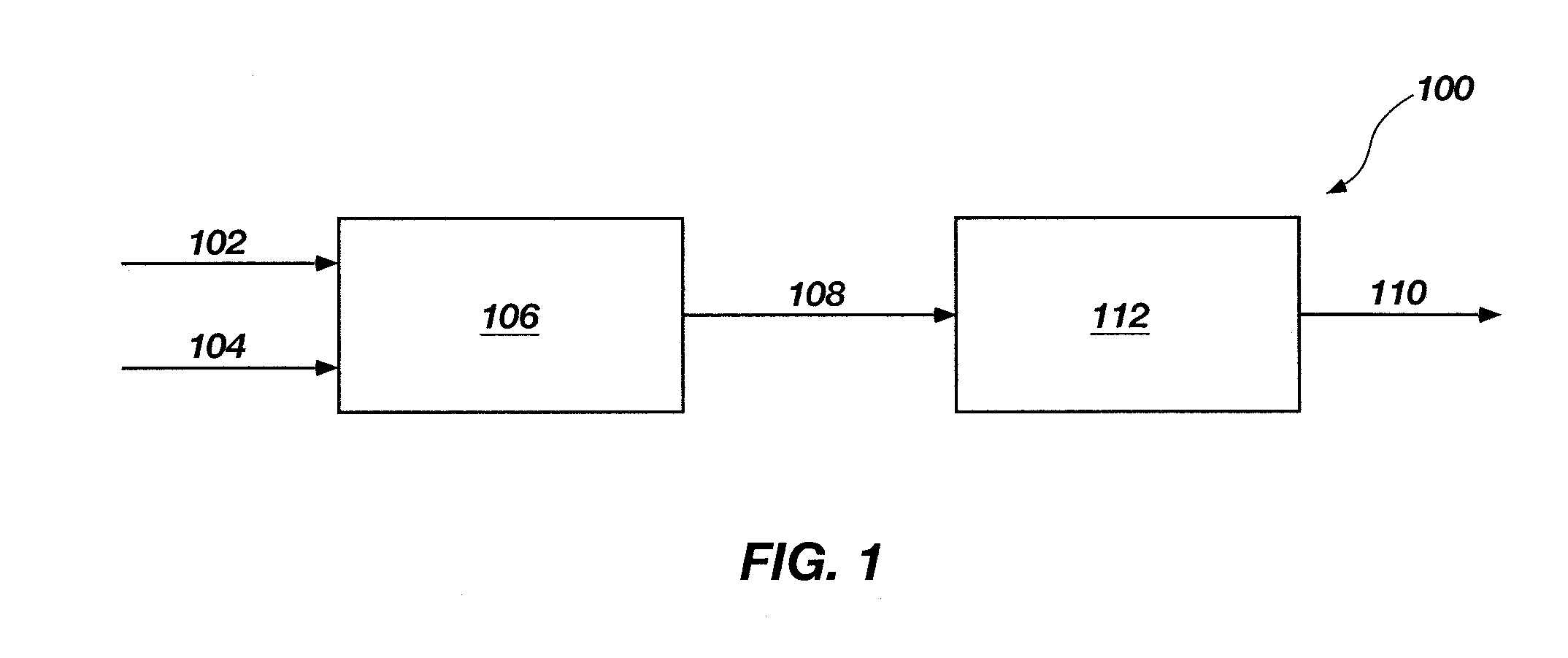

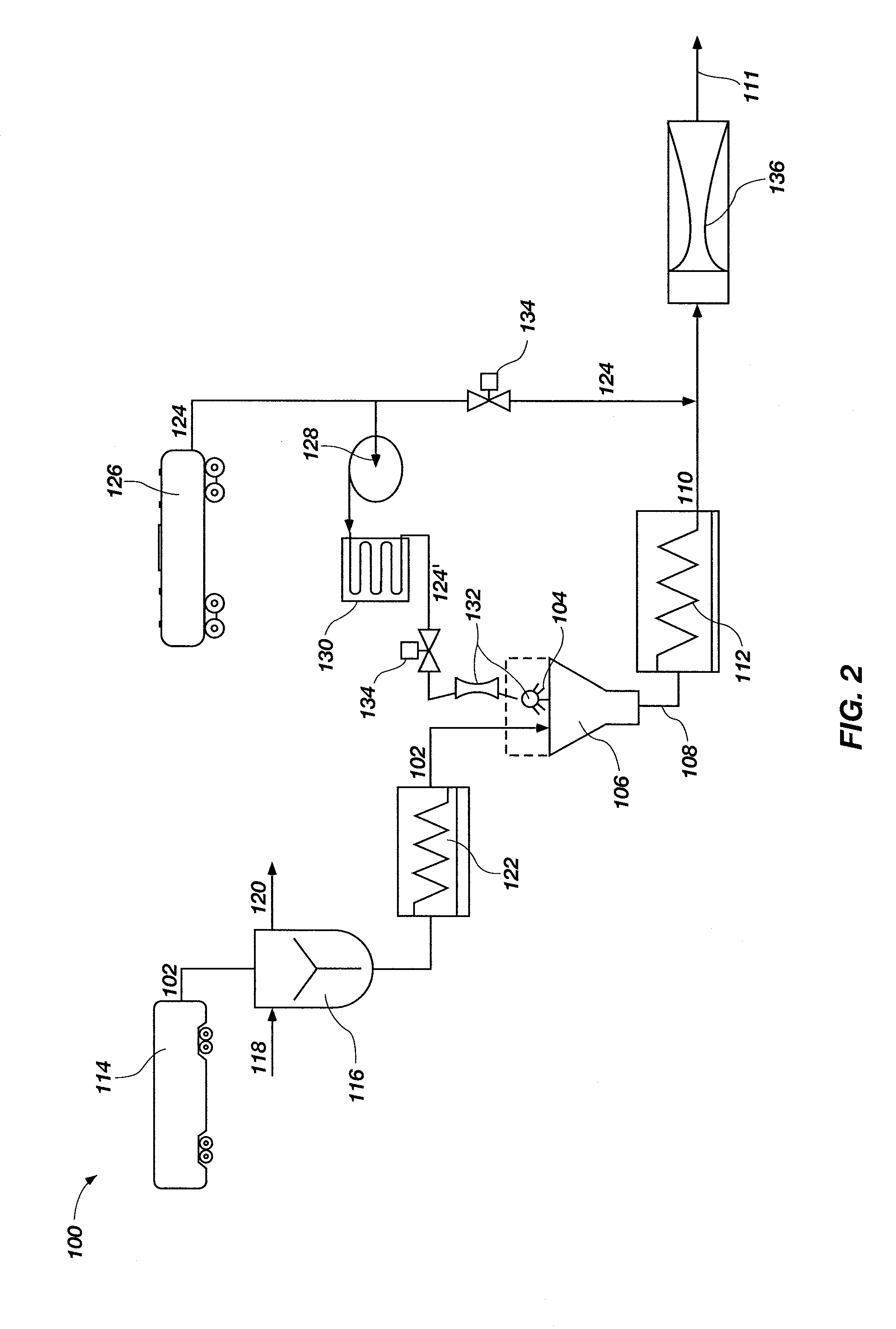

Sublimation systems and associated methods

A system for vaporizing and sublimating a slurry comprising a fluid including solid particles therein. The system includes a first heat exchanger configured to receive the fluid including solid particles and vaporize the fluid and a second heat exchanger configured to receive the vaporized fluid and solid particles and sublimate the solid particles. A method for vaporizing and sublimating a fluid including solid particles therein is also disclosed. The method includes feeding the fluid including solid particles to a first heat exchanger, vaporizing the fluid, feeding the vaporized fluid and solid particles to a second heat exchanger and sublimating the solid particles. In some embodiments the fluid including solid particles is liquid natural gas or methane including solid carbon dioxide particles.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Method of removing and solidifying carbon dioxide from a fluid stream and fluid separation assembly

The invention relates to a method of removing carbon dioxide from a fluid stream by a fluid separation assembly. The fluid separation assembly has a cyclonic fluid separator with a tubular throat portion arranged between a converging fluid inlet section and a diverging fluid outlet section and a swirl creating device. The separation vessel has a tubular section positioned on and in connection with a collecting tank. In the method, a fluid stream with carbon dioxide is provided. Subsequently, a swirling motion is imparted to the fluid stream so as to induce outward movement. The swirling fluid stream is then expanded such that components of carbon dioxide in a meta-stable state within the fluid stream are formed. Subsequently, the outward fluid stream with the components of carbon dioxide is extracted from the cyclonic fluid separator and provided as a mixture to the separation vessel. The mixture is then guided through the tubular section towards the collecting tank while providing processing conditions such that solid carbon dioxide is formed. Finally, solidified carbon dioxide is extracted.

Owner:TWISTER BV

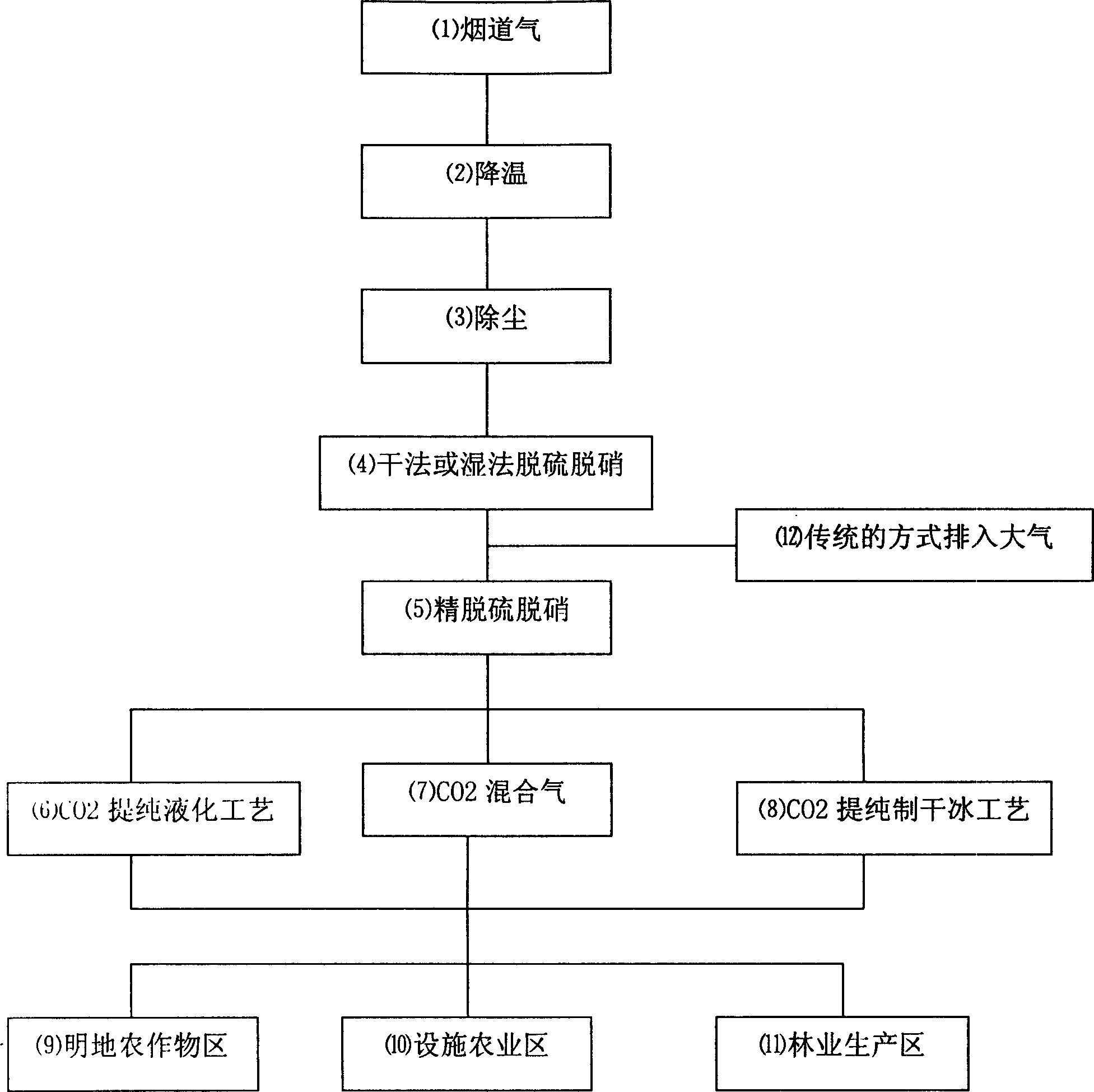

Comprehensive recovery and utilization method for exhaust gas

InactiveCN1800715AReduce pollutionEmission reductionCarbon dioxide producing fertilisersCarbon compoundsProcess engineeringSolid carbon dioxide

The invention relates to a tail gas recycle and integrated utilization method, which prepares the smoke of coal boiler via temperature decreasing, de-rusting, dry method or wetting desulfuration denitration method, and finished desulfuration denitration into gas, liquid and solid carbon dioxide product to apply agriculture and forest.

Owner:李志恒

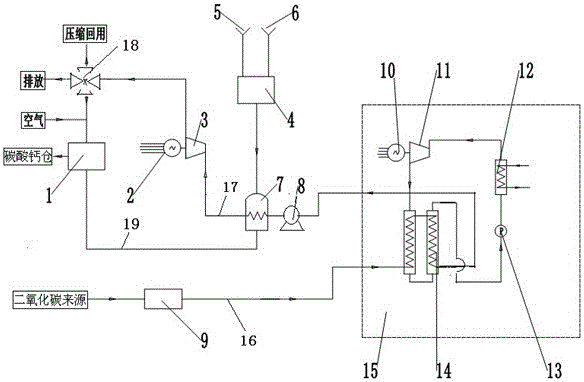

Carbon dioxide energy storage and supply system

ActiveCN105927299AHigh densityFlexible adjustment and utilizationSteam engine plantsStored energyCo2 storage

The invention relates to a carbon dioxide energy storage and supply system, which comprises an organic working medium power generation unit, a carbon dioxide energy storage unit, a heat exchanger, a carbon dioxide fan, a carbon dioxide expander, a first generator, a calcium carbonate preparation unit and a calcium oxide water absorption unit. The carbon dioxide energy storage unit is connected to the organic working medium power generation unit by means of a liquid / solid carbon dioxide pipe; the organic working medium power generation unit is connected to the carbon dioxide fan; an outlet of the carbon dioxide fan is connected to the head exchanger by means of a high-pressure carbon dioxide pipe; an outlet of the heat exchanger is connected to the carbon dioxide expander; an outlet of the carbon dioxide expander is connected to an exhaust emission unit, a carbon dioxide compression and recycling unit, and the calcium carbonate preparation unit. The carbon dioxide energy storage and supply system enables low-temperature utilization with carbon dioxide stored energy, thus effectively storing and utilizing surplus energy and achieving flexible regulation and utilization of energy.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Method and apparatus for cleaning a jet engine

ActiveUS8109807B2Easy to storeEasy to cleanHollow article cleaningElectrostatic cleaningJet engineEngineering

An apparatus for cleaning a jet engine includes a supply device configured to make cleaning medium available, a nozzle device configured to introduce the cleaning medium into the jet engine, and a line connection between the supply device and the nozzle device. The cleaning medium can be solid carbon dioxide. A system including a jet engine and the apparatus. A method for cleaning a jet engine using solid carbon dioxide.

Owner:LUFTHANSA TECH AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com