Dry ice drinking vessel

a drinking vessel and dry ice technology, applied in the field of dry ice drinking vessels, can solve the problems of only practicality, prior art devices do not serve to create visual effects, and dry ice can be dangerous to touch, so as to prolong the time between preparing and serving beverages, enhance visual effects, and improve the usefulness of drinking vessels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

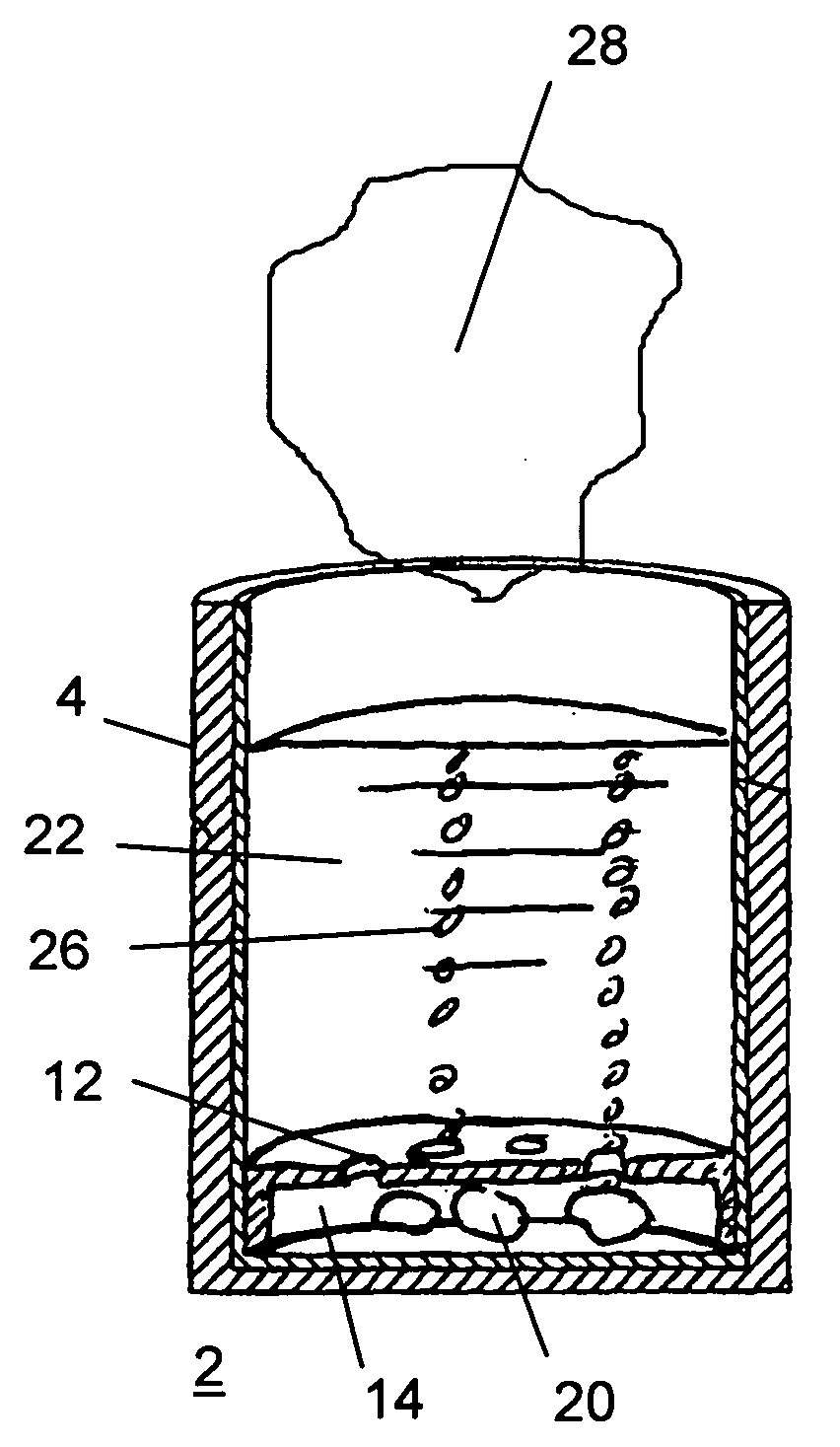

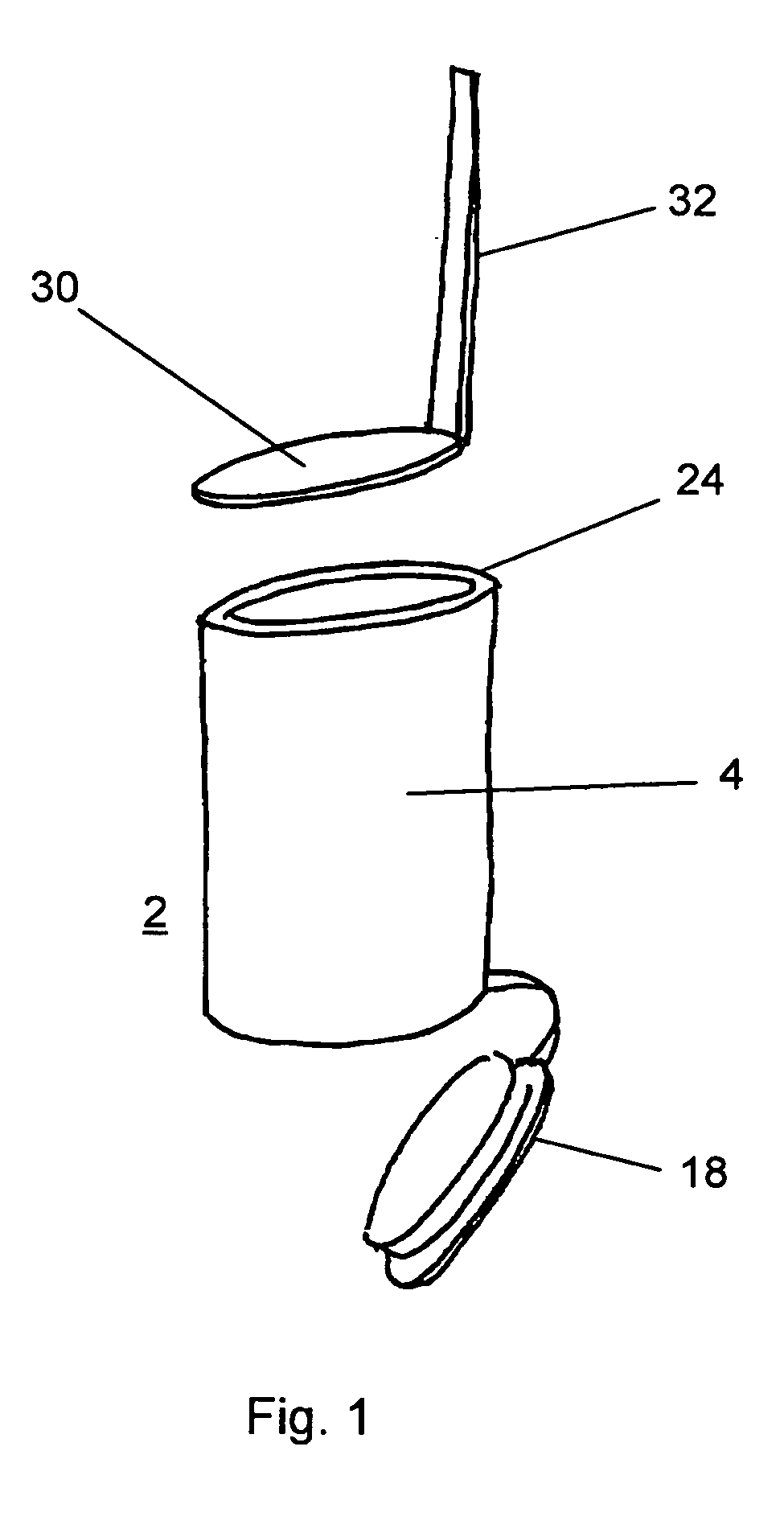

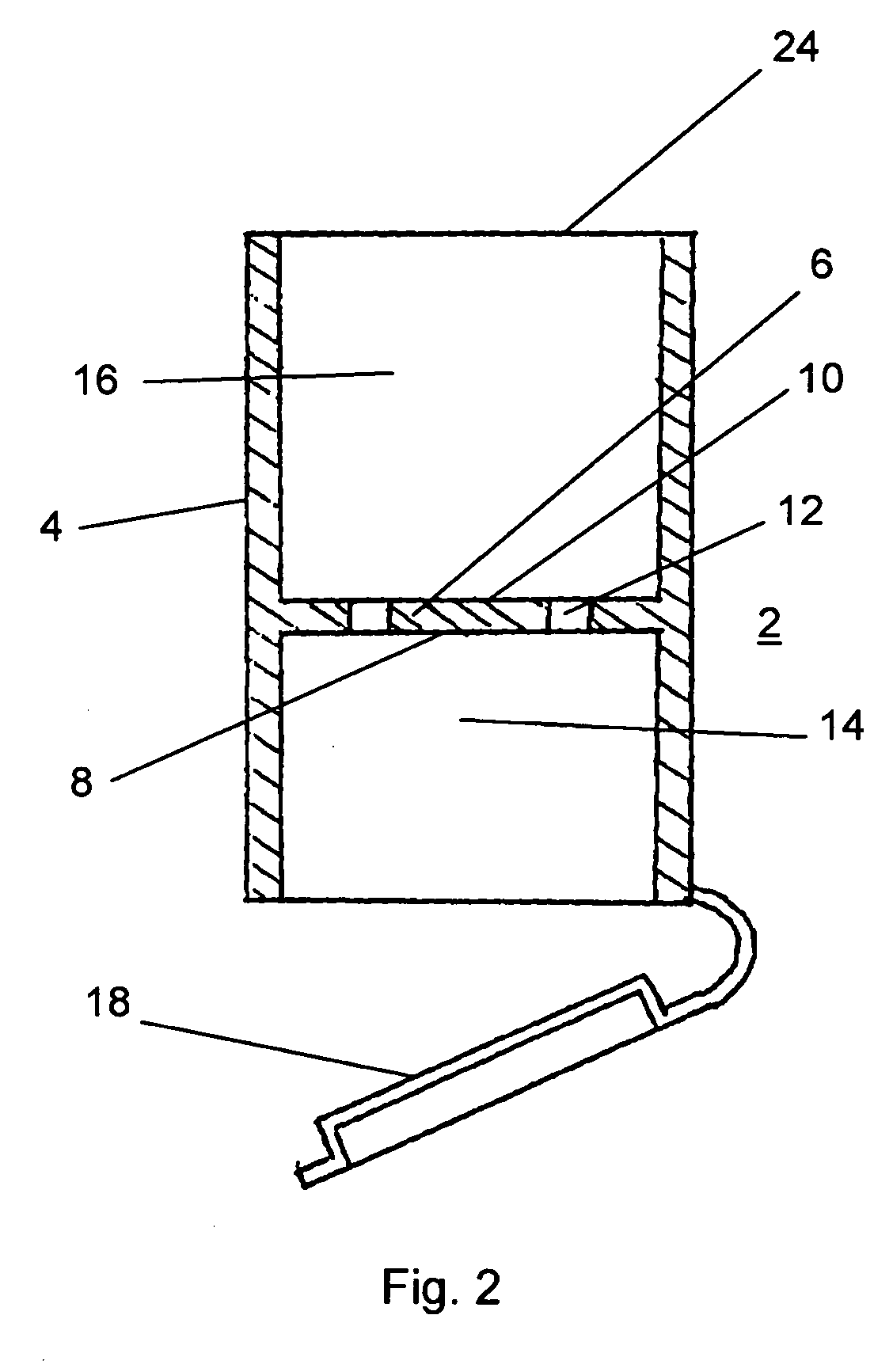

[0022] The Invention is in the form of a small drinking vessel such as might be used to consume alcoholic “shots.” the Invention is illustrated by FIGS. 1-4. A generally cylindrical drinking vessel 2 has a vessel wall 4. As shown by FIGS. 2-4, the drinking vessel 2 has a partition 6 in fixed engagement with the vessel wall 4. Partition 6 has a first side 8 and a second side 10. At least one perforation 12 through the partition 6 communicates between first side 8 and second side 10. Partition 6 and wall 4 together define a first interior volume 14 and a second interior volume 16. Partition 6 segregates first interior volume 14 from second interior volume 16, while allowing fluid and pneumatic communication between first interior volume 14 and second interior volume 16.

[0023] Drinking vessel 2 has a bottom 18 selectable engaging the wall 4. Bottom 18 has an open position illustrated by FIGS. 1 and 2, and a closed position illustrated by FIGS. 3 and 4. In the open position, dry ice pel...

second embodiment

[0027]FIGS. 5 and 6 illustrate the drinking vessel 2. Partition 6 is in fixed engagement with wall 4. Bottom 18 and partition 6 cooperate to define first interior volume 14. Bottom 18 selectably engages wall 4 in a fluid-tight connection using any suitable engagement means, such as a snap connection or threads 34. Dry ice 20 is placed within first interior volume 14 and beverage 22 is poured through open rim 24. Beverage flows through perforations 12 but does not leak from the vessel 2 because of the fluid tight connection between wall 4 and bottom 18. Dry ice 20 sublimates, causing the boiling, smoking effect and chilling beverage 22.

third embodiment

[0028]FIGS. 7-10 illustrate a In the embodiment of FIGS. 7-10, bottom 18 is in fixed engagement with wall 4 and partition 6 selectably engages wall 4. Partition 6 is inserted into the drinking vessel 2 through open rim 24. Partition 6 slidably engages wall 4, securing partition 6 in place within drinking vessel 2 and confining dry ice 20 within the first interior volume 14.

[0029] In the third embodiment illustrated by FIGS. 7-9, the partition 6 has perforations 12. In the variation on the third embodiment illustrated by FIG. 10, partition has no perforations 12 and instead the diameter of partition 6 is less than the inside diameter of wall 4 of drinking vessel 2. The resulting space between the wall 4 and the partition 6 allows the beverage 22 to flow around partition 6 to reach dry ice and allows bubbles 26 of carbon dioxide to flow from dry ice 20. Spring members 36 resiliently engage wall 4, holding partition 6 in place within the drinking vessel 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com